Abstract

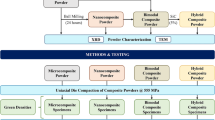

We describe herein the use of octadecyltrimethylammonium-templated aluminosilicate (designated as LS) as a thickener to induce gelation. LS samples with different aluminum/silicon molar ratios (Al/Si = 0, 0.05, 0.10, 0.15, 0.20) were synthesized hydrothermally and characterized by X-ray diffraction analysis, 27Al MAS NMR spectra, elemental analysis, and scanning electron microscopy. The aluminum/silicon molar ratio was shown to be an important factor affecting the rheological properties of LS gels. With an increasing Al/Si molar ratio, the viscoelasticity and structural strength of the LS gel were enhanced, the dropping point increased, and the amount of oil separation decreased. LS(0.20) gel exhibited superior relative elastic properties. The strength of the LS(0.20) gel was also enhanced with increasing LS(0.20) content. In SRV tests, LS(0.20) gel with different content showed good performance in terms of load-bearing and anti-wear properties, indicating that LS was strongly adhered on the friction surface, and thereby promoted lubrication. A fair comparison was made between organic montmorillonite gel and LS gel under the same test conditions. Owing to simple preparation and the promising rheological and tribological properties, LS gels hold great potential for application in lubricating grease.

Graphical Abstract

Similar content being viewed by others

References

Lugt, P.: A review on grease lubrication in rolling bearings. Tribol. Trans. 52, 470–480 (2009)

Lugt, P.: Modern advancements in lubricating grease technology. Tribol. Int. 97, 467–477 (2016)

Boner, C.J.: Manufacture and application of lubricating greases. Reinhold Publishing (1954)

Donahue, C.: Lubricating grease: a chemical primer. J. Chem. Educ. 83, 862 (2006)

Muller, D., Matta, C., Thijssen, R., Bin Yusof, M., Van Eijk, M., Chatra, S.: Novel polymer grease microstructure and its proposed lubrication mechanism in rolling/sliding contacts. Tribol. Int. 110, 278–290 (2017)

Martín-Alfonso, J., Núñez, N., Valencia, C., Franco, J., Diaz, M.: Formulation of new biodegradable lubricating greases using ethylated cellulose pulp as thickener agent. J. Ind. Eng. Chem. 17, 818–823 (2011)

Sánchez, R., Franco, J., Delgado, M., Valencia, C., Gallegos, C.: Thermal and mechanical characterization of cellulosic derivatives-based oleogels potentially applicable as bio-lubricating greases: influence of ethyl cellulose molecular weight. Carbohydr. Polym. 83, 151–158 (2011)

Murray, H.: Traditional and new applications for kaolin, smectite, and palygorskite: a general overview. Appl. Clay Sci. 17, 207–221 (2000)

Martín-Alfonso, J., Martín-Alfonso, M., Franco, J.: Tunable rheological-tribological performance of “green” gel-like dispersions based on sepiolite and castor oil for lubricant applications. Appl. Clay Sci. 192, 105632 (2020)

Cai, M., Yu, Q., Liu, W., Zhou, F.: Ionic liquid lubricants: when chemistry meets tribology. Chem. Soc. Rev. (2020). https://doi.org/10.1039/D0CS00126K

Christian, J.B.: Grease composition containing poly (alpha-olefin). US Patent 4,406,800 (1983)

Magauran, E.D., Cody, C.A., Reichert, W.W., Kieke, M.D., Kemnetz, S.J., Chiavoni, A.: Preactivated organophilic clay gellant lubricating grease thickened with preactivated organophilic clay gellant and process for preparing preactivated organophilic clay gellants. US Patent 4,664,820 (1987)

Morita, M., Otake, S., Mukasa, E., Hosaki, K.: Grease composition. US Patent 4,990,272 (1991)

Dennis, H.R.: Organoclay products containing a branched chain alkyl quaternary ammonium ion. US Patent 5,739,087 (1998)

Chtourou, M., Frikha, M.H., Trabelsi, M.: Modified smectitic Tunisian clays used in the formulation of high performance lubricating greases. Appl. Clay Sci. 32, 210–216 (2006)

Beck, J.S., Vartuli, J., Roth, W.J., Leonowicz, M., Kresge, C., Schmitt, K., Chu, C., Olson, D.H., Sheppard, E., McCullen, S.: A new family of mesoporous molecular sieves prepared with liquid crystal templates. J. Am. Chem. Soc. 114, 10834–10843 (1992)

Hedin, N., Graf, R., Christiansen, S.C., Gervais, C., Hayward, R.C., Eckert, J., Chmelka, B.F.: Structure of a surfactant-templated silicate framework in the absence of 3D crystallinity. J. Am. Chem. Soc. 126, 9425–9432 (2004)

Luo C.: Synthesis, characterization, structural analysis and catalytic properties of IEZ-MCM-50. Master Dissertation, East China Normal University (2013)

Na, K., Jo, C., Kim, J., Cho, K., Jung, J., Seo, Y., Messinger, R.J., Chmelka, B.F., Ryoo, R.: Directing zeolite structures into hierarchically nanoporous architectures. Science 333, 328–332 (2011)

Čejka, J., Mintova, S.: Perspectives of micro/mesoporous composites in catalysis. Catal. Rev. 49, 457–509 (2007)

Auroux, A.: Acidity and Basicity: Determination by Adsorption Microcalorimetry, pp. 45–152. Springer, Berlin (2006)

Seliem, M.K., Komarneni, S., Parette, R., Katsuki, H., Cannon, F., Shahien, M., Khalil, A., Abd El-Gaid, I.: Perchlorate uptake by organosilicas, organo-clay minerals and composites of rice husk with MCM-48. Appl. Clay Sci. 53, 621–626 (2011)

Wang, Y.J.: The synthesis and characterization of modified layered sodium silicates. Master Dissertation, Taiyuan University of Techknowledge (2009)

Luan, Z., Cheng, C.F., Zhou, W., Klinowski, J.: Mesopore molecular sieve MCM-41 containing framework aluminum. J. Phys. Chem. 99, 1018–1024 (1995)

Maksimova, Y.M., Shakhmatova, A., Ilyin, S., Pakhmanova, O., Lyadov, A., Antonov, S., Parenago, O.: Rheological and tribological properties of lubricating greases based on esters and polyurea thickeners. Pet. Chem. 58, 1064–1069 (2018)

Zakani, B., Ansari, M., Grecov, D.: Dynamic rheological properties of a fumed silica grease. Rheol. Acta 57, 83–94 (2018)

Shen, T., Wang, D., Yun, J., Liu, Q., Liu, X., Peng, Z.: Mechanical stability and rheology of lithium–calcium-based grease containing ZDDP. RSC Adv. 6, 11637–11647 (2016)

Martín-Alfonso, J.E., Martin-Alfonso, M.J., Valencia, C., Cuberes, M.T.: Rheological and tribological approaches as a tool for the development of sustainable lubricating greases based on nano-montmorillonite and castor oil. Friction 9, 415–428 (2021)

Martín-Alfonso, J., Romero, A., Valencia, C., Franco, J.: Formulation and processing of virgin and recycled polyolefin/oil blends for the development of lubricating greases. J. Ind. Eng. Chem. 19, 580–588 (2013)

Núñez, N., Martín-Alfonso, J., Eugenio, M., Valencia, C., Díaz, M., Franco, J.: Influence of eucalyptus globulus Kraft pulping severity on the rheological properties of gel-like cellulose pulp dispersions in castor oil. Ind. Eng. Chem. Res. 51, 9777–9782 (2012)

Wang, Z., Xia, Y., Liu, Z.: The rheological and tribological properties of calcium sulfonate complex greases. Friction 3, 28–35 (2015)

Xi, Y., Ding, Z., He, H., Frost, R.L.: Structure of organoclays—an X-ray diffraction and thermogravimetric analysis study. J. Colloid Interface Sci. 277, 116–120 (2004)

Delgado, M., Sánchez, M., Valencia, C., Franco, J., Gallegos, C.: Relationship among microstructure, rheology and processing of a lithium lubricating grease. Chem. Eng. Res. Des. 83, 1085–1092 (2005)

Delgado, M., Valencia, C., Sánchez, M., Franco, J., Gallegos, C.: Influence of soap concentration and oil viscosity on the rheology and microstructure of lubricating greases. Ind. Eng. Chem. Res. 45, 1902–1910 (2006)

Martín-Alfonso, J., Valencia, C., Sánchez, M., Franco, J., Gallegos, C.: Development of new lubricating grease formulations using recycled LDPE as rheology modifier additive. Eur. Polym. J. 43, 139–149 (2007)

Moreno, G., Valencia, C., Franco, J., Gallegos, C., Diogo, A., Bordado, J.: Influence of molecular weight and free NCO content on the rheological properties of lithium lubricating greases modified with NCO-terminated prepolymers. Eur. Polym. J. 44, 2262–2274 (2008)

Cai, M., Liang, Y., Zhou, F., Liu, W.: Functional ionic gels formed by supramolecular assembly of a novel low molecular weight anticorrosive/antioxidative gelator. J. Mater. Chem. 21, 13399–13405 (2011)

Acknowledgements

This work was financially supported by the Key Program of National Natural Science Foundation of China (Grant Number 21436008) and the General Program of National Natural Science Foundation of China (Grant Number 21978186).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

We declare that we have no known competing financial interests or personal relationships that could have appeared to influence inappropriately our work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Han, L., Niu, W., Zhao, X. et al. Synthesis of Layered Octadecyltrimethylammonium-Templated Aluminosilicate and Its Use as a Thickening Agent for Lubricating Grease. Tribol Lett 70, 17 (2022). https://doi.org/10.1007/s11249-021-01548-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-021-01548-1