Abstract

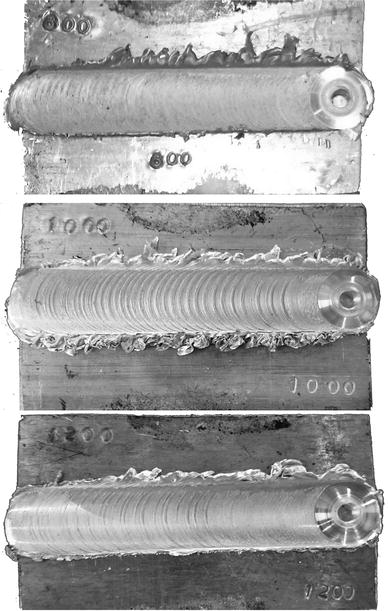

Aluminum foams with varying densities of 1.21-0.62 g/cm3 and pore sizes of 0.3-5.8 mm were successfully fabricated by friction stir processing (FSP) by varying the foaming temperature and fixing FSP parameters. Further, the combined effect of density and pore distribution on quasi-static compression deformation was investigated with a fixed strain rate of 0.001 s−1. Experiments have been done to establish a relationship between the stress–strain curve and the cell deformation mechanism. A separate compressive stress–strain curve is drawn to a minimum density of 0.62 g/cm3, while corresponding deformation points on the curve are analyzed by the SEM micrograph and related to identifying the cell failure mechanism. The EDS mapping was also done to illustrate the elemental Ti, O and Al distributions before and after compression. The compression testing identified four types of cell failure, including hinge formation, shearing, bending and crack initiation with tearing. Furthermore, the combined effect of density and pore size on different mechanical properties has been studied. Quasi-static compression studies confirm that with an increase in density and pore size, plateau stress and energy absorption also increased in the studied region. Energy absorption per unit volume was reported highest at a density of 1.21 g/cm3.

Similar content being viewed by others

References

I.N. Orbulov, A. Kemény, Á. Filep, and Z. Gácsi, Compressive Characteristics of Bimodal Aluminium Matrix Syntactic Foams, Compos. Part A Elsevier, 2019, 124, p 105479. https://doi.org/10.1016/j.compositesa.2019.105479

I. Norbert, Materials Science & Engineering A Metal Matrix Syntactic Foams Produced by Pressure in Fi Ltration—The Effect of in Fi Ltration, Parameters, 2013, 583, p 11–19.

I. Norbert and K. Májlinger, Materia Ls and Design Description of the Compressive Response of Metal Matrix Syntactic Foams, Mater. Des Elsevier Ltd, 2013, 49, p 1–9. https://doi.org/10.1016/j.matdes.2013.02.007

M.I. Idris, T. Vodenitcharova, and M. Hoffman, Mechanical Behaviour and Energy Absorption of Closed-Cell Aluminium Foam Panels in Uniaxial Compression, Mater. Sci. Eng. A, 2009, 517(1–2), p 37–45.

T. Mukai, T. Miyoshi, S. Nakano, H. Somekawa, and K. Higashi, Compressive Response of a Closed-Cell Aluminum Foam at High Strain Rate, Scr. Mater., 2006, 54(4), p 533–537.

I.W. Hall, M. Guden, and C.J. Yu, Crushing of Aluminum Closed Cell Foams: Density and Strain Rate Effects, Scr. Mater., 2000, 43(6), p 515–521.

J. Banhart, Manufacture, Characterisation and Application of Cellular Metals and Metal Foams, Prog. Mater. Sci., 2001, 46(6), p 559–632.

M.A. Kader, M.A. Islam, P.J. Hazell, J.P. Escobedo, M. Saadatfar, A.D. Brown, and G.J. Appleby-Thomas, Modelling and Characterization of Cell Collapse in Aluminium Foams during Dynamic Loading, Int. J. Impact Eng, 2016, 1(96), p 78–88. https://doi.org/10.1016/j.ijimpeng.2016.05.020

L. Salvo, P. Cloetens, E. Maire, S. Zabler, J.J. Blandin, J.Y. Buffiere, W. Ludwig, E. Boller, D. Bellet, and C. Josserond, X-ray Micro-Tomography an Attractive Characterisation Technique in Materials Science, Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms., 2003, 1(200), p 273–286.

H. Yu, Z. Guo, B. Li, G. Yao, H. Luo, and Y. Liu, Research into the Effect of Cell Diameter of Aluminum Foam on Its Compressive and Energy Absorption Properties, Mater. Sci. Eng. A, 2007, 454–455, p 542–546.

R.E. Raj and B.S.S. Daniel, Structural and Compressive Property Correlation of Closed-Cell Aluminum Foam, J. Alloys Compd., 2009, 467(1–2), p 550–556.

B. Zhang, S. Hu, and Z. Fan, Anisotropic Compressive Behavior of Functionally Density Graded Aluminum Foam Prepared by Controlled Melt Foaming Process, Materials., 2018, 11(12), p 2470.

D. Yang, H. Wang, S. Guo, J. Chen, Y. Xu, D. Lei, J. Sun, L. Wang, J. Jiang, and A. Ma, Coupling Effect of Porosity and Cell Size on the Deformation Behavior of Al Alloy Foam under Quasi-Static Compression, Materials., 2019, 12(6), p 951.

A.D. Resnyansky and D.S. and T. Organisation, The Impact Response of Composite Materials Involved in Helicopter Vulnerability Assessment Literature Review-Part 2, Science (80)., (AR-013-615), p 98 (2006)

E. Amsterdam, J.H.B. de Vries, J.T.M. De Hosson, and P.R. Onck, The Influence of Strain-Induced Damage on the Mechanical Response of Open-Cell Aluminum Foam, Acta Mater., 2008, 56(3), p 609–618.

E. Amsterdam, J.T.M. De Hosson, and P.R. Onck, Failure Mechanisms of Closed-Cell Aluminum Foam under Monotonic and Cyclic Loading, Acta Mater., 2006, 54(17), p 4465–4472.

Z. Zheng, J. Yu, C. Wang, S. Liao, and Y. Liu, Dynamic Crushing of Cellular Materials: A Unified Framework of Plastic Shock Wave Models, Int. J. Impact Eng, 2013, 1(53), p 29–43. https://doi.org/10.1016/j.ijimpeng.2012.06.012

R.E. Raj, V. Parameswaran, and B.S. Daniel, Comparison of Quasi-Static and Dynamic Compression Behavior of Closed-Cell Aluminum Foam, Mater. Sci. Eng. A, 2009, 526(1–2), p 11–15.

K.A. Dannemann and J. Lankford, High Strain Rate Compression of Closed-Cell Aluminum Foams, Mater. Sci. Eng. A, 2000, 293(1), p 157–164.

C.M. Cady, G.T. Gray, C. Liu, M.L. Lovato, and T. Mukai, Compressive Properties of a Closed-Cell Aluminum Foam as a Function of Strain Rate and Temperature, Mater. Sci. Eng. A, 2009, 525(1–2), p 1–6.

Y. Hangai and T. Utsunomiya, Fabrication of Porous Aluminum by Friction Stir Processing, Metall. Mater. Trans. A, 2009, 40, p 275–277.

Y. Hangai, K. Takada, R. Endoh, S. Koyama, and T. Utsunomiya, Foaming Behavior of Aluminum Foam Precursor Induced by Friction Heat Generated by Rotating Tool Used for Spot Friction Stir Welding, J. Manuf. Process., 2017, 1(25), p 426–431. https://doi.org/10.1016/j.jmapro.2017.01.002

J.Q. Su, T.W. Nelson, and C.J. Sterling, Friction Stir Processing of Large-Area Bulk UFG Aluminum Alloys, Scr. Mater., 2005, 52(2), p 135–140.

Y.S. Sato, S.H.C. Park, A. Matsunaga, A. Honda, and H. Kokawa, Novel Production for Highly Formable Mg Alloy Plate, J. Mater. Sci., 2005, 40(3), p 637–642.

Y. Hangai and T. Utsunomiya, Manufacture of Porous Aluminum by Utilizing Friction Stir Processing, Nippon Kinzoku Gakkaishi/J. Jpn. Inst. Metals., 2009, 73(2), p 131–133.

Y. Hangai, Y. Ozeki, S. Kawano, T. Utsunomiya, O. Kuwazuru, M. Hasegawa, S. Koyama, and N. Yoshikawa, Nondestructive Observation of Pore Structures of A1050 Porous Aluminum Fabricated by Friction Stir Processing, Mater. Trans., 2010, 51(3), p 548–552.

T. Utsunomiya, K.I. Tamura, Y. Hangai, O. Kuwazuru, and N. Yoshikawa, Effects of Tool Rotating Rate and Pass Number on Pore Structure of A6061 Porous Aluminum Fabricated by Using Friction Stir Processing, Mater. Trans., 2010, 51(3), p 542–547.

S. Rathore, R.K. Singh, and K.L. Khan, Effect of Process Parameters on Mechanical Properties of Aluminum Composite Foam Developed by Friction Stir Processing, Proceed. Inst. Mech. Eng. Part B J. Eng. Manuf., 2021, 235(12), p 1892–1903.

Y. Hangai, H. Kato, T. Utsunomiyav, S. Kitahara, O. Kuwazuru, and N. Yoshikawa, Effects of Porosity and Pore Structure on Compression Properties of Blowing-Agent-Free Aluminum Foams Fabricated from Aluminum Alloy Die Castings, Mater. Trans., 2012, 53(8), p 1515–1520.

S.U. Nisa, S. Pandey, and P.M. Pandey, Significance of Al2O3 Addition in the Aluminum 6063 Metal Foam Formation Through Friction Stir Processing Route-A Comprehensive Study, Proceed. Inst. Mech. Eng. Part L J. Mater. Des. Appl., 2021, 235(12), p 2737–2745.

Y. Hangai, K. Takahashi, R. Yamaguchi, T. Utsunomiya, S. Kitahara, O. Kuwazuru, and N. Yoshikawa, Nondestructive Observation of Pore Structure Deformation Behavior of Functionally Graded Aluminum Foam by x-ray Computed Tomography, Mater. Sci. Eng. A, 2012, 556, p 678–684.

Y. Hangai, R. Yamaguchi, S. Takahashi, T. Utsunomiya, O. Kuwazuru, and N. Yoshikawa, Deformation Behavior Estimation of Aluminum Foam by x-ray CT Image-Based Finite Element Analysis, Metall. Mater. Trans. A, 2013, 44, p 1880–1886.

T. Utsunomiya, K. Takahashi, Y. Hangai, and S. Kitahara, Effects of Amounts of Blowing Agent and Contained Gases on Porosity and Pore Structure of Porous Aluminum Fabricated from Aluminum Alloy Die Casting by Friction Stir Processing Route, Mater. Trans., 2011, 52(6), p 1263–1268.

N. Mahmutyazicioglu, O. Albayrak, M. Ipekoglu, and S. Altintas, Effects of Alumina (Al2O3) Addition on the Cell Structure and Mechanical Properties of 6061 Foams, J. Mater. Res., 2013, 28(17), p 2509–2519.

F. García-Moreno and J. Banhart, Influence of Gas Pressure and Blowing Agent Content on the Formation of Aluminum Alloy Foam, Adv. Eng. Mater., 2021, 23(10), p 2–9.

Y. Hangai, T. Utsunomiya, and M. Hasegawa, Effect of Tool Rotating Rate on Foaming Properties of Porous Aluminum Fabricated by Using Friction Stir Processing, J. Mater. Process. Technol., 2010, 210(2), p 288–292.

H.T. Ccy, Aluminum Foams by Designing Pore-Density, (2021).

C. Wang, L. Pan, Y. Zhang, S. Xiao, and Y. Chen, Deoxidization Mechanism of Hydrogen in TiH2 Dehydrogenation Process, Int. J. Hydrog. Energy, 2016, 41(33), p 14836–14841. https://doi.org/10.1016/j.ijhydene.2016.05.155

I. Paulin, Č Donik, D. Mandrino, M. Vončina, and M. Jenko, Surface Characterization of Titanium Hydride Powder, Vacuum, 2012, 86(6), p 608–613.

M.A. Kader, M.A. Islam, M. Saadatfar, P.J. Hazell, A.D. Brown, S. Ahmed, and J.P. Escobedo, Macro and Micro Collapse Mechanisms of Closed-Cell Aluminium Foams during Quasi-Static Compression, Mater. Des., 2017, 15(118), p 11–21.

Y. Mu, G. Yao, L. Liang, H. Luo, and G. Zu, Deformation Mechanisms of Closed-Cell Aluminum Foam in Compression, Scr. Mater., 2010, 63(6), p 629–632. https://doi.org/10.1016/j.scriptamat.2010.05.041

H. Song, Q. He, J. Xie, and A. Tobota, Composites Science and Technology Fracture Mechanisms and Size Effects of Brittle Metallic Foams, In Situ Compress. Tests Inside SEM, 2008, 68, p 2441–2450.

Y. Cheng, Y. Li, X. Chen, X. Zhou, and N. Wang, Compressive Properties and Energy Absorption of Aluminum Foams with a Wide Range of Relative Densities, J. Mater. Eng. Perform., 2018, 27, p 4016–4024. https://doi.org/10.1007/s11665-018-3514-4

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lohani, D., Daniel, B.S.S. Quasi-static Deformation Mechanism and Compressive Properties of Aluminum Foams Fabricated by Friction Stir Processing. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09508-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09508-1