Abstract

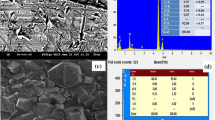

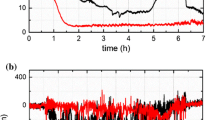

The formation of nanoscopic ripple patterns on top of material surfaces has been reported for different materials and processes, such as sliding against polymers, high-force scanning in atomic force microscopy (AFM), and surface treatment by ion beam sputtering. In this work, we show that such periodic ripples can also be obtained in prolonged reciprocating sliding against nanocrystalline diamond (NCD) films. NCD films with a thickness of 0.8 µm were grown on top of silicon wafer substrates by hot-filament chemical vapor deposition using a mixture of methane and hydrogen. The chemical structure, surface morphology, and surface wear were characterized by Raman spectroscopy, scanning electron microscopy (SEM), and AFM. The tribological properties of the NCD films were evaluated by reciprocating sliding tests against Al2O3, Si3N4, and ZrO2 counter balls. Independent of the counter body material, clear ripple patterns with typical heights of about 30 nm induced during the sliding test are observed by means of AFM and SEM on the NCD wear scar surfaces. Although the underlying mechanisms of ripple formation are not yet fully understood, these surface corrugations could be attributed to the different wear phenomena, including a stress-induced micro-fracture and plastic deformation, a surface smoothening, and a surface rehybridization from diamond bonding to an sp 2 configuration. The similarity between ripples observed in the present study and ripples reported after repeated AFM tip scanning indicates that ripple formation is a rather universal phenomenon occurring in moving tribological contacts of different materials.

Similar content being viewed by others

References

Haubner, R., Kalss, W.: Diamond deposition on hardmetal substrates—comparison of substrate pre-treatments and industrial applications. Int. J. Refract. Met. Hard Mater. 28, 475–483 (2010)

Auciello, O., Birrell, J., Carlisle, J.A., Gerbi, J.E., Xiao, X., Peng, B., Espinosa, H.D.: Materials science and fabrication processes for a new MEMS technology based on ultrananocrystalline diamond thin films. J. Phys. Condens. Matter 16, R539–R552 (2004)

Hantschel, T., Niedermann, P., Trenkler, T., Vandervorst, W.: Highly conductive diamond probes for scanning spreading resistance microscopy. Appl. Phys. Lett. 76(12), 1603–1605 (2000)

Butler, J.E., Sumant, A.V.: The CVD of nanodiamond materials. Chem. Vap. Depos. 14, 145–160 (2008)

Pastewka, L., Moser, S., Gumbsch, P., Moseler, M.: Anisotropic mechanical amorphization drives wear in diamond. Nat. Mater. 10, 34–38 (2011)

Bhushan, B., Subramaniam, V.V., Malshe, A., Gupta, B.K., Ruan, J.: Tribological properties of polished diamond films. J. Appl. Phys. 74(6), 4174–4180 (1993)

Erdemir, A., Halter, M., Fenske, G.R., Zuiker, C., Csencsits, R., Krauss, A.R., Gruen, D.M.: Friction and wear mechanisms of smooth diamond films during sliding in air and dry nitrogen. Tribol. Trans. 40, 667–675 (1997)

Erdemir, A., Fenske, G.R., Krauss, A.R., Gruen, D.M., McCauley, T., Csencsits, R.T.: Tribological properties of nanocrystalline diamond films. Surf. Coat. Technol. 120–121, 565–572 (1999)

Chromik, R.R., Winfrey, A.L., Lüning, J., Nemanich, R.J., Wahl, K.J.: Run-in behavior of nanocrystalline diamond coatings studied by in situ tribometry. Wear 265, 477–489 (2008)

Kumar, N., Panda, K., Dash, S., Popov, C., Reithmaier, J.P., Panigrahi, B.K., Tyagi, A.K., Raj, B.: Tribological properties of nanocrystalline diamond films deposited by hot filament chemical vapor deposition. AIP Adv. 2, 032164-1–032164-14 (2012)

Holmberg, K., Ronkainen, H., Laukkanen, A., Wallin, K.: Friction and wear of coated surfaces—scales, modeling and simulation of tribomechanisms. Surf. Coat. Technol. 202, 1034–1049 (2007)

Grillo, S.E., Field, J.E., van Bouwelen, F.M.: Diamond polishing: the dependency of friction and wear on load and crystal orientation. J. Phys. D Appl. Phys. 33, 985–990 (2000)

El-Dasher, B.S., Gray, J.J., Tringe, J.W., Biener, J., Hamza, A.V.: Crystallographic anisotropy of wear on a polycrystalline diamond surface. Appl. Phys. Lett. 88, 241915-1–241915-3 (2006)

Hird, J.R., Field, J.E.: Diamond polishing. Proc. R. Soc. Lond. A 460, 3547–3568 (2004)

Van Bouwelen, F.M., Enckevort, W.J.P.: A simple model to explain the anisotropy of diamond polishing. Diam. Relat. Mater. 8, 840–844 (1999)

Van Bouwelen, F.M., Field, J.E., Brown, L.M.: Electron microscopy analysis of debris produced during diamond polishing. Philos. Mag. 83, 839–856 (2003)

Couto, M.S., van Enckvort, W.J.P., Seal, M.: On the mechanism of diamond polishing in the soft directions. J. Hard Mater. 5, 31–47 (1994)

Couto, M.S., van Enckevort, W.J.P., Seal, M.: Diamond polishing mechanisms: an investigation by scanning tunnelling microscopy. Philos. Mag. B 69, 621–641 (1994)

Abreu, C.S., Amaral, M., Fernandes, A.J.S., Oliveira, F.J., Silva, R.F., Gomes, J.R.: Friction and wear performance of HFCVD nanocrystalline diamond coated silicon nitride ceramics. Diam. Relat. Mater. 15, 739–744 (2006)

Casari, C.S., Li Bassi, A., Ravagnan, L., Siviero, F., Lenardi, C., Piseri, P., Bongiorno, G., Bottani, C.E., Milani, P.: Chemical and thermal stability of carbyne-like structures in cluster-assembled carbon films. Phys. Rev. B 69, 075422-1–075422-7 (2004)

Gardos, M.N., Soriano, B.L.: The effect of environment on the tribological properties of polycrystalline diamond films. J. Mater. Res. 5, 2599–2609 (1990)

Gardos, M.N., Gabelich, S.A.: Atmospheric effects of friction, friction noise and wear with silicon and diamond. Part III. SEM tribometry of polycrystalline diamond in vacuum and hydrogen. Tribol. Lett. 6, 103–112 (1999)

Konicek, A.R., Grierson, D.S., Sumant, A.V., Friedmann, T.A., Sullivan, J.P., Gilbert, P.U.P.A., Sawyer, W.G., Carpick, R.W.: Influence of surface passivation on the friction and wear behavior of ultrananocrystalline diamond and tetrahedral amorphous carbon thin films. Phys. Rev. B 85, 155448-1–155448-13 (2012)

Shi, W., Dong, H., Bell, T.: Tribological behaviour and microscopic wear mechanisms of UHMWPE sliding against thermal oxidation-treated Ti6Al4V. Mater. Sci. Eng. A 291, 27–36 (2000)

Leung, O.M., Goh, M.C.: Orientational ordering of polymers by atomic force microscope tip-surface interaction. Science 255, 64–66 (1992)

Socoliuc, A., Gnecco, E., Bennewitz, R., Meyer, E.: Ripple formation induced in localized abrasion. Phys. Rev. B 68, 115416-1–115416-4 (2003)

Such, B., Krok, F., Szymonski, M.: AFM tip-induced ripple pattern on AIII-BV semiconductor surfaces. Appl. Surf. Sci. 254, 5431–5434 (2008)

Filippov, A.E., Popov, V.L., Urbakh, M.: Mechanism of wear and ripple formation induced by mechanical action of an atomic force microscope tip. Phys. Rev. Lett. 106, 025502-1–025502-4 (2011)

Datta, D., Bhattacharyya, S.R., Chini, T.K., Sanyal, M.K.: Evolution of surface morphology of ion sputtered GaAs(100). Nucl. Instr. Methods Phys. Res. B 193, 596–602 (2002)

Cuerno, R., Castro, M., Muńoz-Garcķa, J., Gago, R., Vázquez, L.: Nanoscale pattern formation at surfaces under ion-beam sputtering: a perspective from continuum models. Nucl. Instr. Methods Phys. Res. B 269, 894–900 (2011)

Datta, A., Wu, Y.-R., Wang, Y.L.: Real-time observation of ripple structure formation on a diamond surface under focused ion-beam bombardment. Phys. Rev. B 63, 125407-1–125407-6 (2001)

Adams, D.P., Vasile, M.J., Mayer, T.M., Hodges, V.C.: Focused ion beam milling of diamond: effects of H2O on yield, surface morphology and microstructure. J. Vac. Sci. Technol. B 21(6), 2334–2343 (2003)

Brookes, E.J., Greenwood, P., Xing, G.: Friction and wear of synthetic diamond. Int. J. Refract. Metal Hard Mater. 17, 69–77 (1999)

Vandenbulcke, L., De Barros, M.I.: Deposition, structure, mechanical properties and tribological behavior of polycrystalline to smooth fine-grained diamond coatings. Surf. Coat. Technol. 146–147, 417–424 (2001)

Castro, M., Cuerno, R., Nicoli, M., Vázquez, L., Buijnsters, J.G.: Universality of cauliflower-like fronts: from nanoscale thin films to macroscopic plants. N. J. Phys. 14, 103039-1–103039-15 (2012)

Buijnsters, J.G., Vázquez, L.: Growth dynamics of nanocrystalline diamond thin films deposited by hot filament chemical vapor deposition: influence of low sticking and renucleation processes. J. Phys. Chem. C 115, 9681–9691 (2011)

May, P.W., Ludlow, W.J., Hannaway, M., Heard, P.J., Smith, J.A., Rosser, K.N.: Raman and conductivity studies of boron-doped microcrystalline diamond, facetted nanocrystalline diamond and cauliflower diamond films. Diam. Relat. Mater. 17, 105–117 (2008)

Ferrari, A.C., Robertson, J.: Raman spectroscopy of amorphous, nanostructured, diamond-like carbon, and nanodiamond. Philos. Trans. R. Soc. Lond. A 362, 2477–2512 (2004)

Ferrari, A.C.: Robertson J Resonant Raman spectroscopy of disordered, amorphous, and diamondlike carbon. Phys. Rev. B 64, 075414-1–075414-13 (2001)

Bowden, F.P., Freitag, E.H.: The friction of solids at very high speeds. Proc. R. Soc. Lond. A 248, 350–367 (1958)

Rigney, D.A., Karthikeyan, S.: The evolution of tribomaterial during sliding: a brief introduction. Tribol. Lett. 39, 3–7 (2010)

Heslot, F., Baumberger, T., Perrin, B.: Creep, stick-slip, and dry-friction dynamics: experiments and a heuristic model. Phys. Rev. E 49, 4973–4988 (1994)

Mohrbacher, H., Celis, J.-P., Roos, J.R.: Laboratory testing of displacement and load induced fretting. Tribol. Int. 28(5), 269–278 (1995)

Acknowledgments

The work was supported by the Estonian Science Foundation Grant Number 8696. J.G.B. would like to thank the Executive Research Agency of the European Union for funding under the Marie Curie IEF Grant Number 272448.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Podgursky, V., Hantschel, T., Bogatov, A. et al. Rippling on Wear Scar Surfaces of Nanocrystalline Diamond Films After Reciprocating Sliding Against Ceramic Balls. Tribol Lett 55, 493–501 (2014). https://doi.org/10.1007/s11249-014-0379-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-014-0379-z