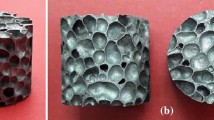

This work investigates the effect of two different foaming materials on the energy absorption of closed-cell aluminum structures. For this purpose, two different cellular aluminum samples were prepared by incorporating TiH2 and CaCO3 as foaming agents into molten A356 aluminum alloy at 700°C. The SEM observation of the foam samples revealed that the cell structure of the foam produced with CaCO3 is comprised of a smaller and more uniform structure than the sample produced with TiH2. Uniaxial compressive tests were performed on the foam samples to evaluate the mechanical properties of closed-cell aluminum foams. The results indicated that in a 50% strain, the energy absorption of aluminum foam with calcium carbonate is about 100% more than a closed-cell structure, which has been foamed with titanium hydride.

Similar content being viewed by others

References

D. Wang, W. Xue, and Z. Shi, “Cell size prediction of a closed aluminum foam,” Mater. Sci. Eng. A, 431, No. 1-2, 298–305 (2006).

L. E. G. Cambronero, J. M. Ruiz-Roman, F. A. Corpas, and J. M. Ruiz Prieto, “Manufacturing of Al–Mg–Si alloy foam using calcium carbonate as foaming agent,” J. Mater. Process. Technol., 209, No. 4, 1803–1809 (2009).

O. Prakash, H. Sang, and J. D. Embury, “Structure and properties of Al–SiC foam,” Mater. Sci. Eng. A, 199, No. 2, 195–203 (1995).

M. Alizadeh and M. Mirzaei-Aliabadi, “Compressive properties and energy absorption behavior of Al–Al2O3 composite foam synthesized by space-holder technique,” Mater. Des., 35, 419–424 (2012).

N. Movahedi, S. M. H. Mirbagheri, and S. R. Hosseini, “Effect of foaming temperature on the mechanical properties of produced closed-cell A356 aluminum foams with melting method,” Met. Mater. Int., 20, No. 4, 757–763 (2014).

B. Matijasevic and J. Banhart, “Improvement of aluminium foam technology by tailoring of blowing agent,” Scripta Mater., 54, 503–508 (2006).

J. Lázaro, E. Solórzano, and M. A. Rodriguez-Pérez, “Alternative carbonates to produce aluminium foams via melt route,” Proc. Mater. Sci., 4, 275–280 (2014).

H. P. Degischer and B. Kriszt, Handbook of Cellular Metals Production, Processing, Applications, Wiley-VCH Verlag GmbH, Weinheim (2002).

C. Koerner, Integral Foam Molding of Light Metals, Springer-Verlag, Berlin–Heidelberg (2008).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 3, pp. 128 – 134, May – June, 2016.

Rights and permissions

About this article

Cite this article

Movahedi, N., Mirbagheri, S.M.H. Comparison of the Energy Absorption of Closed-Cell Aluminum Foam Produced by Various Foaming Agents. Strength Mater 48, 444–449 (2016). https://doi.org/10.1007/s11223-016-9783-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-016-9783-y