Abstract

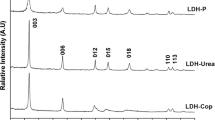

Porous zirconia particles were synthesized through a low-temperature hydrothermal synthesis process. Under hydrothermal conditions, water can control the direction of crystal growth, morphology, particle size, and size distribution because thermodynamics and transport properties can be controlled by pressure and temperature. In a batch process, the hydrothermal synthesis was conducted at 200–300 °C and 30 MPa with an SUS-304 tube as the reactor. At the same reaction pressure, experiments were also performed for a flow process with temperatures of 180–200 °C. The synthesized products were calcined and characterized by scanning electron microscopy (SEM), transmission electron microscopy (TEM), and X-ray diffraction (XRD). The results showed that the macroporous zirconia particles that were formed had pore diameters around 419 nm. The XRD pattern indicated that the products were composed of zirconium oxide particles with monoclinic, tetragonal, and cubic structures.

Similar content being viewed by others

References

M. Fernandez-Garcia, A. Martinez-Arias, J.C. Hanson, J.A. Rodriguez, Chem. Rev. 104, 4063 (2004)

G. Dercz, K. Prusik, L. Pajak, J. Achiev. Mater. Manuf. Eng. 18, 259 (2006)

K. Vernieuwe, P. Lommens, J.C. Martins, F. Van Den Broeck, I. Van Driessche, K. De Buysser, Materials 6, 4082 (2013)

B. Tyagi, K. Sidhpuria, B. Shaik, R.V. Jasra, Ind. Eng. Chem. Res. 45, 8643 (2006)

G. Herrera, N. Montoya, A. Domenech-Carbo, J. Alarcon, Phys. Chem. Chem. Phys. 15, 9312 (2013)

A.K. Singh, U.T. Nakate, Sci. World J. (2014). doi:10.1155/2014/349457

T. Boningari, R. Koirala, P.G. Smirniotis, Appl. Catal. B: Environ. 127, 255 (2012)

J.H. Ryu, H.S. Kil, J.H. Song, D.Y. Lim, S.B. Cho, Powder Technol. 221, 228 (2012)

A.C. Pierre, Introduction to sol–gel processing (Springer, USA, 2002), pp. 6–8

V. Bounor-Legare, P. Cassagnau, Prog. Polym. Sci. 39, 1473 (2014)

S. Kalia, Y. Haldorai, Organic–inorganic hybrid nanomaterials (Springer, Switzerland, 2015), p. 7

C. Kaya, J.Y. He, X. Gu, E.G. Butler, J. Microporous Mesoporous Mat. 54, 37 (2002)

H. Hayashi, Y. Hakuta, Materials 3, 3794 (2010)

T. Adschiri, K. Kanazawa, K. Arai, J. Am. Ceram. Soc. 75, 1019 (1992)

Z. Fang, Rapid production of micro- and nano-particles using supercritical water (Springer, Germany, 2010), pp. 11–25

H. Hayashi, A. Ueda, A. Suino, K. Hiro, Y. Hakuta, J. Solid State Chem. 182, 2985 (2009)

M. Taguchi, S. Takami, T. Adschiri, T. Nakane, K. Sato, T. Naka, Cryst. Eng. Comm. 14, 2117 (2012)

Z. Shu, X. Jiao, D. Chen, Cryst. Eng. Comm. 15, 4288 (2013)

D.S.S. Padovini, D.S.L. Pontes, C.J. Dalmaschio, F.M. Pontes, E. Longo, RSC Adv. 4, 38484 (2014)

J. Rouquerolt, D. Avnir, C.W. Fairbridge, D.H. Everett, J.H. Haynes, N. Pernicone, J.D.F. Ramsay, K.S.W. Sing, K.K. Unger, Pure Appl. Chem. 66, 1739 (1994)

H. Wu, P. Badrinarayanan, M.R. Kessler, J. Am. Ceram. Soc. 95, 3643 (2012)

P.S. Liu, G.F. Chen, Porous materials: processing and applications (Elsevier, Cambridge, MA, 2014), pp. 113–182

S.A. Johnson, P.J. Ollivier, T.E. Mallouk, Science 283, 5404 (1999)

H. Ehrlich, P. Simon, M. Motylenko, M. Wysokowski, V.V. Bazhenov, R. Galli, A.L. Stelling, D. Stawski, M. Ilan, H. Stocker, B. Abendroth, R. Born, T. Jesionowski, K.J. Kurzydlowski, D.C. Meyer, J. Mater. Chem. B 1, 5092 (2013)

M. Wysokowski, M. Motylenko, V.V. Bazhenov, D. Stawski, I. Petrenko, A. Ehrlich, T. Behm, Z. Kljajic, A.L. Stelling, T. Jesionowski, H. Ehrlich, Front. Mater. Sci. 7, 248 (2013)

A. Tavakoli, M. Sohrabi, A. Kargari, Chem. Pap. 61, 151 (2007)

W. Li, H. Huang, H. Li, W. Zhang, H. Liu, Langmuir 24, 8358 (2008)

A. Kierys, R. Zaleski, W. Buda, S. Pikus, M. Dziadosz, J. Goworek, Colloid Polym. Sci. 291, 1463 (2013)

I.M. Hung, D.T. Hung, K.Z. Fung, M.H. Hon, J. Eur. Ceram. Soc. 26, 2627 (2006)

N. Tangchupong, W. Khaodee, B. Jongsomjit, N. Laosiripojana, P. Praserthdam, S. Assabumrungrat, Fuel Process. Technol. 91, 121 (2010)

A. Gaber, M.A. Abdel-Rahim, A.Y. Abdel-Latief, M.N. Abdel-Salam, Int. J. Electrochem. Sci. 9, 81 (2014)

H. Hobbs, S. Briddon, E. Lester, Green Chem. 11, 484 (2009)

Z. Li, Y. Liu, W. Kwapinski, J.J. Leahy, Mater. Chem. Phys. 145, 82 (2014)

Y. Sakka, F. Tang, H. Fudouzi, T. Uchikoshi, Sci. Technol. Adv. Mater. 6, 915 (2005)

M.M.S. Sanad, M.M. Rashad, E.A. Abdel-Aal, M.F. El-Shahat, J. Eur. Ceram. Soc. 32, 4249 (2012)

Q. Yang, Z. Lu, J. Liu, X. Lei, Z. Chang, L. Luo, X. Sun, Prog. Nat. Sci.: Mater. Int. 23, 351 (2013)

H. Cheng, J. Ma, Z. Zhao, L. Qi, Chem. Mater. 7, 663 (1995)

H.J. Noh, D.S. Seo, H. Kim, J.K. Lee, Mater. Lett. 57, 2425 (2003)

R.F. Egerton, Physical principles of electron microscopy: an introduction to TEM, SEM, and AEM (Springer, New York, 2005), pp. 11–16

R. Espinoza-Gonzalez, E. Mosquera, I. Moglia, R. Villarroel, V.M. Fuenzalida, Ceram. Int. 40, 15577 (2014)

Z.Y. Yuan, T.Z. Ren, A. Vantomme, B.L. Su, Chem. Mater. 16, 5096 (2004)

L.H. Chen, S.T. Xu, X.Y. Li, G. Tian, Y. Li, J.C. Rooke, G.S. Zhu, S.L. Qiu, Y.X. Wei, X.Y. Yang, Z.M. Liu, B.L. Su, J. Colloid Interf. Sci. 377, 368 (2012)

S. Park, M.K. Seo, Interface science and composites (Elsevier Ltd., USA, 2011), pp. 70–77

C. Lecoeur, B. Daffos, R. Lin, L. Divay, P. Le Barny, M. PhamThi, P.L. Taberna, P. Simon, Mater. Renew. Sustain Energy 2, 13 (2013)

M. Hosokawa, K. Nogi, M. Naito, T. Yokoyama, Nanoparticle technology handbook, 1st edn. (Elsevier, Amsterdam, 2007), pp. 270–272

Y. Sawaki, K. Matsuo, M. Kishimoto, J. Ceram. Soc. Jpn. 112, S17 (2004)

E. Tani, M. Yoshimura, S. Somiya, J. Ceram. Soc. 66, 11 (1983)

G. Stefanic, S. Music, K. Molcanov, J. Alloy. Compd. 387, 300 (2005)

H. Nishizawa, N. Yamasaki, K. Matsuoka, H. Mitsushio, J. Am. Ceram. Soc. 65, 343 (1982)

S. Pabisch, B. Feichtenschlager, G. Kickelbick, H. Peterlik, Chem. Phys. Lett. 521, 91 (2012)

K.H. Stern, Metallurgical and ceramic protective coatings (Chapman & Hall, London, 1996), pp. 203–204

H. Toraya, M. Yoshimura, S. Somiya, J. Am. Ceram. Soc. 67, C119 (1984)

Acknowledgments

This research was partly supported by a grant from the Directorate General of Higher Education, Ministry of Education and Art of Indonesia through a research Grant Desentralisasi—Penelitian Unggulan Perguruan Tinggi contract no. 016457.8/IT2.7/PN.01.00/2014. This research was also supported by a grant from the Precursory Research for Embryonic Science and Technology Program of the Japan Science and Technology Agency (JST) and in collaboration with the Department of Chemical Engineering, Sepuluh Nopember Institute of Technology (ITS), Indonesia and the Department of Chemical Engineering, Nagoya University, Japan.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Machmudah, S., Prastuti, O.P., Widiyastuti et al. Macroporous zirconia particles prepared by subcritical water in batch and flow processes. Res Chem Intermed 42, 5367–5385 (2016). https://doi.org/10.1007/s11164-015-2372-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-015-2372-z