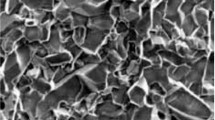

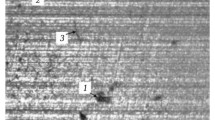

Correlation of the structure of Al2O3 ceramics with specimen polished surface roughness and morphology is established. On basis of this the physical nature of surface layer formation during diamond grinding of fine-grained and coarse-grained ceramics is been revealed.

Similar content being viewed by others

References

K. Kitajima, G. O. Cai, N. Kurnagai, et al., “Study on mechanism of ceramics grinding,” An. of the CIRP, 14, 367 – 371 (1992).

I. L. Shakupa and D. A. Klimov, “Machining of ceramic materials based on aluminum oxide, and silicon nirtride and carbide,” Steklo Keram., No. 6, 16 – 18 (2004).

L. Tanovic, P. Bojanic, and M. Popovic, “Mechanisms in oxide-carbide ceramic BOK60 grinding,” Int. J. Adv. Manufacturing Technol., 58, 9 – 12 (2011).

Y. Ling, H. Huang, K. Ramesh, and T. Huang,” High speed versus conventional grinding in high removal rate machining of alumina and alumina-titania,” Int. J. Machine Tools and Manufacture, 45, 897 – 907 (2005).

V. V. Kuzin, “Technology for machining high refractory ceramic parts based on silicon nitride,” Refract. Indust. Ceram., 47(4), 204 – 208 (2006).

H. Huang and Y. C. Liu, “Experimental investigations of machining characteristics and removal mechanisms of advanced ceramics in high speed deep grinding,” Machine Tools & Manufacture, 43, 811 – 823 (2003).

V. V. Kuzin, S. Yu. Fedorov, and A. E. Seleznev, “Effect of conditions of diamond grinding on tribological behavior of alumina-based ceramics,” J. Friction and Wear, 37, No. 4, 371 – 376 (2016).

C. Jianyi, S. Jianyun, H. Hui, and X. Xipeng, “Grinding characteristics in high speed grinding of engineering ceramics with brazed diamond wheels,” J. Mater. Process. Technol., 210, 899 – 906 (2010).

V. V. Kuzin, “Increasing the operational stability of nitride-ceramic cutters by optimizing their grinding conditions,” Russian Engineering Research, 23(12), 32 – 36 (2003).

T. Matsuo, M. Touge, and H. Yamada, “High-precision surface grinding of ceramics with superfine grain diamond cup wheels,” CIRP Annals — Manufacturing Technology, 46, 249 – 252 (1997).

V. Kuzin, “A model of forming the surface layer of ceramic parts based on silicon nitride in the grinding process,” Key Eng. Mater. Precision Machining, 496, 127 – 131 (2012).

Zong-Han Xie, Robert J. Moon, Mark Hoffman, et al., “Role of microstructure in the grinding and polishing of α-sialon ceramics,” J. Eur. Ceram. Soc., 23, 2351 – 2360 (2003).

Wei Liu, Zhaohui Deng, Yuanyuan Shang, et al., “Effects of grinding parameters on surface quality in silicon nitride grinding,” Ceram. Internat., 43, Part B, 1571 – 1577 (2017).

V. V. Kuzin and S. Yu. Fedorov, “Roughness of high hardness ceramic correlation of diamond grinding regimes with Al2O3 ceramic surface condition,” Refract. Indust. Ceram., 57(4), 388 – 393 (2016).

V. V. Kuzin and S. Yu. Fedorov, “Correlation of diamond grinding regimes with Al2O3–TiC-ceramic surface condition,” Refract. Indust. Ceram., 57(5), 52 – 525 (2017).

V. V. Kuzin, S. Yu. Fedorov, and S. N. Grigor’ev, “Correlation of diamond grinding regime with surface condition of ceramic based on zirconium dioxide,” Refract. Indust. Ceram., 57(6), 625 – 630 (2017).

V. V. Kuzin, S. Yu. Fedorov, and S. N. Grigor’ev, “Correlation of diamond grinding regimes with Si3N4-ceramic surface quality,” Refract. Indust. Ceram., 58(1), 78 – 81 (2017).

V. V. Kuzin, S. Yu. Fedorov, and S. N. Grigor’ev, “Correlation of diamond grinding regimes with SiSiC-ceramic surface condition,” Refract. Indust. Ceram., 58(2), 214 – 219 (2017).

V. V. Kuzin, S. Yu. Fedorov, and S. N. Grigor’ev, “Features of Al2O3–TiC-ceramic specimen edge morphology formation during diamond grinding,” Refract. Indust. Ceram., 58(3), 319 – 323 (2017).

V. V. Kuzin, S. Yu. Fedorov, and S. N. Grigor’ev, “Production process planning for preparing Si3N4-ceramic objects taking account of edge defectiveness,” Refract. Indust. Ceram., 58(5), 562 – 565 (2018).

V. V. Kuzin, “Technological provision of the quality of ring edges of silicon-carbide friction couples for the end seals of the pumps,” Refract. Indust. Ceram., 58(6), 647 – 651 (2018).

V. V. Kuzin, S. N. Grigor’ev, S. Yu. Fedorov, et al., “Spark plasma sintering of Al2O3-ceramic workpieces for small size circular cutters,” Novye Ogneupory, No. 11, 64 – 68 (2018).

Work was performed with financial support of the RF Ministry of Education and Science within the scope of fulfilling a state assignment in the sphere of scientific activity, project No. 9.1372.2017/4.6.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 1, pp. 65 – 68, January, 2019.

Rights and permissions

About this article

Cite this article

Kuzin, V.V., Grigor’ev, S.N. & Fedorov, S.Y. Correlation of Al2O3-Ceramic Structure with the Mechanism of Surface Layer Formation for Workpieces During Diamond Grinding. Refract Ind Ceram 60, 82–85 (2019). https://doi.org/10.1007/s11148-019-00313-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-019-00313-1