On the basis of the investigation of the specific features of formation of the morphology of the edges of samples of the SiSiC ceramic under the conditions of diamond grinding, we determine the main kinds of crumbling and their geometric parameters. We also establish the relationship between the depth of grinding, the longitudinal and transverse feeds, and the geometric parameters of crumbling.

Similar content being viewed by others

References

G. S. Batkis, N. M. Livshits, V. K. Khaisanov, et al., “Face seals of new generation for centrifugal and screw compressors,” Vestnik Kazan Tekhnol. Univ., No. 9, 408 – 417 (2010).

N. P. Kirillov, V. V. Burenin, V. I. Polyanskii, et al., “Structures of face seals for the rotating shafts of centrifugal pumps of the systems of rocket charging,” Vestnik Mosk. Avtomobil.-Dorozh. Gos. Tekh. Univ., No. 1, 18 – 22 (2012).

A. I. Golubev, Face Seals of Rotating Shafts [in Russian], Mashinostroenie, Moscow (1974).

OST 26-06-1493–87. Face Seals of Pump Shafts. Types. Main Parameters and Sizes [in Russian].

O. V. Dushko, A. P. Umanskii, and D. O. Pushkarev, “Composite wear-resistant materials based on silicon carbide,” Ogneupory Tekh. Keram., No. 2, 22 – 24 (2005).

V. P. Paranosenkov, A. A. Chikina, and M. A. Andreev, “Structural materials based on self-bonded silicon carbide,” Ogneupory Tekh. Keram., No. 7, 37 – 40 (2006).

V. V. Kuzin, S. Yu. Fedorov, and S. N. Grigor’ev, “Correlation of diamond grinding regimes with SiSiC-ceramic surface condition journal,” Refract. Ind. Ceram., 58(2), 214 – 219 (2017).

J. Dai, H. Su, H. Hu, et al., “The influence of grain geometry and wear conditions on the material removal mechanism in silicon carbide grinding with single grain,” Ceram. Int., 43(15), 11973 – 11980 (2017).

S. Agarwal, “Optimizing machining parameters to combine high productivity with high surface integrity in grinding silicon carbide ceramics,” Ceram. Int., 42(15), 6244 – 6262 (2016).

V. Kuzin, “A model of forming the surface layer of ceramic parts based on silicon nitride in the grinding process,” Key Eng. Mater., 496, Precision Machining, 127 – 131 (2012).

Q. Zhang, S. To, Q. Zhao, et al., “Surface generation mechanism of WC/Co and RB – SiC/Si composites under high spindle speed grinding (HSSG),” Int. J. Refract. Met. Hard Mater., 56, 123 – 131 (2016).

J. Cao, Y.Wu, D. Lu, et al., “Material removal behavior in ultrasonic-assisted scratching of SiC ceramics with a single diamond tool,” Int. J. Machine Tools Manufact., 79, 49 – 61 (2014).

O. V. Dushko and V. M. Shumyacher, Diamond Grinding of Silicon-Carbide Ceramics for Machine Building [in Russian], VolgGASU, Volgograd (2009).

Q. Zhang, S. To, Q. Zhao, et al., “Amorphization and segregation based surface generation of reaction-bonded Si/SiC composites under microgrinding,” Int. J. Machine Tools Manufact., 95, 78 – 81 (2015).

V. Kuzin, S. Grigor’ev, M. Volosova, and M. Fedorov, “Designing of details taking into account the degradation of structural ceramics in exploitation,” Appl. Mech. Mater., 752/753, 268 – 271 (2015).

V. Kuzin, S. Grigoriev, S. Fedorov, and M. Fedorov, “Surface defects formation in grinding of silicon nitride ceramics,” Appl. Mech. Mater., 752/753, 402 – 406 (2015).

V. V Kuzin, S. Yu. Fedorov, and S. N. Grigor’ev, “Features of Al2O3 – TiC-ceramic specimen edge morphology formation during diamond grinding,” Refract. Ind. Ceram., 58(3), 319 – 323 (2017).

V. V Kuzin, S. Yu. Fedorov, and S. N. Grigor’ev, “Specific features of the morphology of formation of the edges of Y–TZP-ceramic specimens during diamond grinding,” Novye Ogneupory, No. 7, 63 – 65 (2017).

V. V Kuzin, S. Yu. Fedorov, and S. N. Grigor’ev, “Level of the defectiveness of the edges of Si3N4–ceramic specimens after diamond grinding,” Novye Ogneupory, No. 9, 65 – 68 (2017).

The present work was financially supported by the Ministry of Education and Science of Russian Federation within the framework of Government Order for MGTU “STANKIN” in the field of scientific activities (Task 9.1372.2017/4.6).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 11, pp. 65 – 69, November, 2017

Rights and permissions

About this article

Cite this article

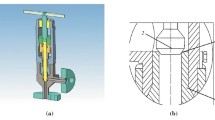

Kuzin, V.V., Fedorov, S.Y. & Grigor’ev, S.N. Technological Provision of the Quality of Ring Edges of Silicon-Carbide Friction Couples for the End Seals of the Pumps. Refract Ind Ceram 58, 647–651 (2018). https://doi.org/10.1007/s11148-018-0162-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-018-0162-z