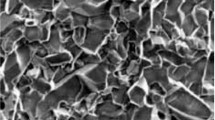

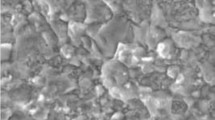

Results are provided for a study of the effect of surface grinding regimes with a diamond wheel on surface condition of tetragonal polycrystalline zirconium dioxide partly stabilized with zirconium oxide (Y-TZP) a correlation is established for grinding depth, longitudinal and transverse feed with surface waviness, treated surface morphology, and surface layer structure of ceramic based on zirconium dioxide.

Similar content being viewed by others

References

S. Ramesh, M. Mohaymen Khan, H. C. Alexander Chee, et al., “Sintering behaviour and properties of graphene oxide-doped Y-TZP ceramics,” Ceram. Internat., 42(15), 1762 – 1765 (2016).

J. Gui and Zh. Xie, “Phase transformation and slow crack growth study of Y–TZP dental ceramic,” Mater. Sci. Eng: A, 676, 531 – 535 (2016.).

G. K. R. Pereira, T. Silvestri, R. Camargo, et al., “Mechanical behavior of a Y–TZP ceramic for monolithic restorations: effect of grinding and low-temperature aging,” Mater. Sci. Eng: C, 63, 70 – 77 (2016).

M. Holthausa grosse, S. Twardy, J. Stolle, et al., “Micromachining of ceramic surfaces: hydroxyapatite and zirconia,” J. Materials Processing Technol., 212, 614 – 624 (2012.).

V. Kuzin, S. Grigoriev, M. Fedorov, et al.. “Surface modification of zirconia (Y–TZP) ceramics induced by pulsed laser machining,” Appl. Mechan. Materials, 752/753, 481 – 484 (2015).

P. S. P. Anand, N. Arunachalam, and L. Vijayaraghavan, “Grinding behavior of yttrium partially stabilized zirconia using diamond grinding wheel,” Adv. Materials Res., 1136, 15 – 20 (2016).

G. K. R. Pereira, M. Amaral, R. Simoneti, et al., “Effect of grinding with diamond-disc and -bur on the mechanical behavior of a Y–TZP ceramic,” J. Mechanical Behavior of Biomedical Materials, 37, 133 – 140 (2014).

J.-J. Canneto, M. Cattani-Lorente, S. Durual, et al., “Grinding damage assessment on four high-strength ceramics,” Dental Materials, 32(2), 171 – 182 (2016).

S. Ban, T. Sakakibara, K. Yoshihara, et al., “Surface properties of dental zirconia after clinical grinding and polishing,” Key Engineering Materials, 529/530, 501 – 506 (2013).

V. V. Kuzin and S. Yu. Fedorov, “Correlation of diamond grinding regimes with Al2O3 ceramic surface condition,” Novye Ogneupory, No. 7, 65 – 70 (2016).

V. V. Kuzin and S. Yu. Fedorov, “Correlation of diamond grinding regimes with Al2O3–TiC ceramic surface condition,” Novye Ogneupory, No. 9, 63 – 68 (2016).

V. Kuzin, “A model of forming the surface layer of ceramic parts based on silicon nitride in the grinding process,” Key Engineering Materials. Precision Machining, 496, 127 – 131 (2012).

V. V. Kuzin, “Increasing the operational stability of nitride-ceramic cutters by optimizing their grinding Conditions,” Russ. Eng. Res., 23(12), 32 – 36 (2003).

V. Kuzin, S. Grigoriev, M. Volosova, and M. Fedorov, “Designing of details taking into account degradation of structural ceramics at exploitation,” Appl. Mechan. Mater., 752/753, 268 – 271 (2015).

V. V. Kuzin,” Technology for machining high refractory ceramic parts based on silicon nitride,” Refract. Indust. Ceram., 47(4), 204 – 208 (2006).

V. Kuzin, S. Grigoriev, S. Fedorov, and M. Fedorov, “Surface defects formation in grinding of silicon nitride ceramics, Appl. Mechan. Mater., 752/753, 402 – 406 (2015).

V. V. Kuzin, “Technological aspects of diamond grinding of the nitride ceramics,” Russ. Eng. Res., 24(1), 23 – 28 (2004).

The work was conducted with financial support of the Russian Scientific Fund within the scope of an agreement 14-29-00297 of August 6, 2014.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 11, pp. 60 – 65, November, 2016.

Rights and permissions

About this article

Cite this article

Kuzin, V.V., Fedorov, S.Y. & Grigor’ev, S.N. Correlation of Diamond Grinding Regime with Surface Condition of Ceramic Based on Zirconium Dioxide. Refract Ind Ceram 57, 625–630 (2017). https://doi.org/10.1007/s11148-017-0035-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-017-0035-x