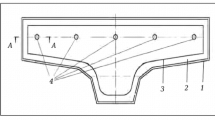

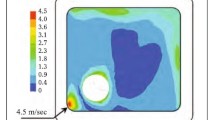

The equipment installed in the chambers of a continuous-caster tundish is examined. An improvement made to this equipment is ensuring the efficient formation of flows of metal in the tundish and creating the conditions necessary for improving the quality of the cast metal.

Similar content being viewed by others

References

O. B. Isaev et al., Modeling Modern Processes for the Secondary Treatment and Continuous Casting of Steel [in Russian] (Ed.: E. Kh. Shakhpazov), Metallurgizdat, Moscow (2008).

K. N. Vdovin, M. V. Semenov, and V. V. Tochilkin, Refining Steel in the Tundish of a Continuous Caster: Monograph [in Russian], MGTU, Magnitogorsk (2006).

K. N. Vdovin, I. M. Tochilkin, and I. M. Yachikov, Continuous Casting of Steel: Monograph [in Russian], Izd-vo Magnitogorskogo Gos. Tekh. Un-ta, Magnitogorsk (2012).

K. N. Vdovin, V. V. Tochilkin, and I. M. Yachikov, Continuous Casting of Steel. Fluid Mechanics of Continuous Casting Machines: Monograph [in Russian], Izd-vo Magnitogorskogo Gos. Tekh. Un-ta, Magnitogorsk (2014).

K. N. Vdovin, E. A. Mel’nichuk, A. V. Nefedov, and V. V. Tochilkin, “Intake chamber of the tundish in a continuous slabcasting machine,” Steel in Translation, 44(3), 186 – 189 (2014).

J. Zekeli and N. El-Kadakh, “Computer-aided design (CAD – CAM method) of a tundish,” in: Injection Metallurgy ‘86: Conf. Proc. [Russian translation] (Ed.: V. A. Kudrin). Metallurgiya, Moscow (1990), pp. 134 – 146.

K. N. Vdovin, O. A. Marochkin, and V. V. Tochilkin, “Creating a stream simulator to improve the wear resistance of refractories during the casting of steel on continuous section casters,” Refractories and Industrial Ceramics, 54(6), 435 – 437 (2014).

K. N. Vdovin, O. A. Marochkin, and V. V. Tochilkin, “Improvement of steel pouring in section CBCM,” Metallurgist, 58(3/4), 306 – 309.

RUS 60411 Patent for Useful Model. Tundish for the Continuous Casting of Metal, G. S. Senichev, V. V. Tochilkin, K. N. Vdovin, V. M. Korneev, V. A. Osipov, A. V. Sarychev, N. V. Vedeshkin, S. N. Ushakov, and A. A. Khomenko. Publ. 14.09.2006.

RUS 91016 Patent for Useful Model. Tundish for the Continuous Casting of Metal, S. N. Ushakov, K. N. Vdovin, V. V. Tochilkin, S. V. Prokhorov, A. A. Khomenko, O. A. Filatova, V. A. Artyushin, I. R. Shaigulin, and I. S. Cheusov. Publ. 12.10.2009.

K. N. Vdovin, V. V. Tochilkin, O. A. Marochkin, et al., “New plastic refractory linings for protecting a metal stream during pouring into a CBCM,” Refractories and Industrial Ceramics, 55(4), 318 – 320 (2014).

M. V. Semenov and V. V. Tochilkin, “Technique for calculating the effectiveness of the elements of the intermediate ladle of a CBCM,” Russian Engineering Research, 27(6), 347 – 349 (2007).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 11, pp. 3 – 7, November, 2015.

Rights and permissions

About this article

Cite this article

Vdovin, K.N., Tochilkin, V.V. & Yachikov, I.M. Designing Refractories for the Tundish of a Continuous Caster. Refract Ind Ceram 56, 569–573 (2016). https://doi.org/10.1007/s11148-016-9889-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-016-9889-6