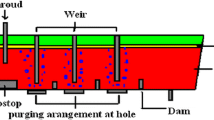

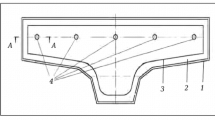

This article relates the experiences of the Chelyabinsk Metallurgical Combine and the Pervouralsk New Tube Plant in mastering the operation of continuous section casters. It examines how the startup of the strands is affected by the geometries of the submersible nozzle, the metering nozzle, and adjustments made to the process parameters. Recommendations are given to make the section caster more reliable during startup and casting.

Similar content being viewed by others

Author information

Authors and Affiliations

Corresponding author

Additional information

1From materials of the International Conference of Refractory Specialists and Metallurgists (April 3 – 4, 2014, Moscow).

Translated from Novye Ogneupory, No. 7, pp. 10 – 14, July, 2014.

Rights and permissions

About this article

Cite this article

Botnikov, S.A. Effect of the Geometry of the Metal Conduits of a Tundish and the Casting Parameters on the Performance of Continuous Section Casters1 . Refract Ind Ceram 55, 272–276 (2014). https://doi.org/10.1007/s11148-014-9706-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-014-9706-z