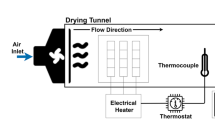

The novel drying process combines conduction and convection in cocurrent flow of the heat carrier and dried material for conductive heat and mass transfer and in countercurrent flow of the air–vapor mixture and dried material for convective heat and mass transfer. The study of heat transfer and drying kinetics allowed the optimization of the drying modes for water-atomized iron powders. The heat flux transferred by conduction through the inner wall of the drum to the dried iron powder is 3.45 · 106 W/m2 at the beginning of cocurrent flow and 0.4 · 106 W/m2 at the end. The heat consumption for drying at the optimum amount of the air supplied to the drum for convective heat transfer in countercurrent flow of 983 kg/h reduces to 415 kJ/kg compared to 511 kJ/kg at 300 kg/h. The relative specific moisture of the air–vapor mixture is 0.034–0.045 because of a large amount of dry air and high temperature, i.e., the mixture is very far from saturation and cannot condense on the dried powder.

Similar content being viewed by others

References

V. B. Akimenko V. Ya. Bulanov, G. G. Zalazinskii, and I. A. Gulyaev, Metallurgy of Iron and Alloyed Powders [in Russian], Metallurgiya, Moscow (1992), p. 256.

A. G. Bol’shechenko, A. K. Gaiduchenko, N. M. Golovach, et al., Drying Apparatus for Powder Materials [in Russian], USSR Inventor Certificate 1017891, Publ. May 15 (1983), Bulletin No. 18.

Yu. I. Dytnerskii, Processes and Apparatus of Chemical Technology [in Russian], Khimiya, Moscow (2002), Part. 2, p. 368.

O. D. Neikov, I. N. Logachev, and R. N. Shumilov, Aspiration of Particulate Mixtures in Process Equipment Dust-Removal [in Russian], Naukova Dumka, Kiev (1974), p. 128.

G. M. Gordon and I. L. Peisakhov, Monitoring of Dust Removal Facilities [in Russian], Metallurgiya, Moscow (1973), p. 384.

Acknowledgements

The authors thanks T. D. Kuzmina, Yu. B. Timofeev, and S. I. Golubev for the experiments performed at the Powder Metallurgy Plant, whose results were used for writing this paper. The authors are grateful to A. V. Samelyuk for electron microscopy analysis of the powder samples.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 54, No. 5–6 (503), pp. 142–153, 2015.

Rights and permissions

About this article

Cite this article

Neikov, O.D., Kolesnichenko, Y.V. & Tokhtuev, V.G. Drying of Water-Atomized Iron Powders. Powder Metall Met Ceram 54, 364–373 (2015). https://doi.org/10.1007/s11106-015-9723-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-015-9723-6