Abstract

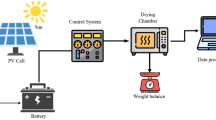

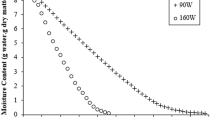

The experimental sensitivity analysis of the novel ohmic assisted drying system (OAD: simultaneous use of ohmic heating and convectional air drying), which was developed as an alternative to the traditional method, was carried out for the first time. Within the scope of the study, changes in drying time, drying characteristics and some quality parameters were examined by changing the controlled parameters (applied voltage, temperature and air velocity) of the new OAD system. For this purpose, potato, which is an important commercial food in the European continent, was used as raw material. The optimum levels of OAD were calculated as approximately 60 °C for drying temperature, 112 V for applied voltage and any value between 1.07 and 1.98 m/s for air velocity to minimise drying time, browning index and to maximise effective diffusivity corresponding to accelerated drying period, b* colour value. According to the results, a 32–38% improvement was achieved in drying time compared to the traditional method. In addition, no negative effect was observed on the quality properties of potato slices dried under optimum conditions compared to the control samples. Moreover, it appears as an advantage that the new method provides partial pre-gelatinisation of starch molecules, which is important for the food industry. OAD will also save both time and economy by removing the need for the blanching stage in drying processes due to the obtained significant enzyme inactivation. Considering the results, it is seen that the newly developed technique has a promising potential both for the food industry and the literature.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Abdi, H., & Williams, L. J. (2010). Tukey’s Honestly Significant Difference (HSD) Test. In N. J. Salkind (Ed.), Encyclopedia of Research Design (pp. 1-5). Thousand Oaks, CA: Sage.

Ahmed, M., Akter, M. S., & Eun, J.-B. (2010). Peeling, drying temperatures, and sulphite-treatment affect physicochemical properties and nutritional quality of sweet potato flour. Food Chemistry, 121(1), 112–118. https://doi.org/10.1016/j.foodchem.2009.12.015

Akkara, M., & Kayaardı, S. (2014). Effect of advanced preservation techniques on meat quality. Akademik Gıda, 12(4), 79–85.

Akpınar, E. K. (2006). Mathematical modelling of thin layer drying process under open sun of some aromatic plants. Journal of Food Engineering, 77(4), 864–870. https://doi.org/10.1016/j.jfoodeng.2005.08.014

Andreou, V., Dimopoulos, G., Tsonas, T., Katsimichas, A., Limnaios, A., Katsaros, G., & Taoukis, P. (2021). Pulsed electric fields-assisted drying and frying of fresh zucchini. Food and Bioprocess Technology. https://doi.org/10.1007/s11947-021-02705-z

AOAC. (2005). Official methods of analysis of AOAC International. AOAC International.

Arikan, M. F., Ayhan, Z., Soysal, Y., & Esturk, O. (2012). Drying characteristics and quality parameters of microwave-dried grated carrots. Food and Bioprocess Technology, 5(8), 3217–3229. https://doi.org/10.1007/s11947-011-0682-8

Askari, G. R., Emam-Djomeh, Z., & Mousavi, S. M. (2009). An investigation of the effects of drying methods and conditions on drying characteristics and quality attributes of agricultural products during hot air and hot air/microwave-assisted dehydration. Drying Technology, 27(7–8), 831–841. https://doi.org/10.1080/07373930902988106

Barreto, I. M. A., Tribuzi, G., Marsaioli Junior, A., Carciofi, B. A. M., & Laurindo, J. B. (2019). Oil–free potato chips produced by microwave multiflash drying. Journal of Food Engineering, 261, 133–139. https://doi.org/10.1016/j.jfoodeng.2019.05.033

Bender, D., Gratz, M., Vogt, S., Fauster, T., Wicki, B., Pichler, S., & Schoenlechner, R. (2019). Ohmic heating—a novel approach for gluten-free bread baking. Food and Bioprocess Technology, 12(9), 1603–1613. https://doi.org/10.1007/s11947-019-02324-9

Bi, J., Chen, Q., Zhou, Y., Liu, X., Wu, X., & Chen, R. (2014). Optimization of short- and medium-wave infrared drying and quality evaluation of jujube powder. Food and Bioprocess Technology, 7(8), 2375–2387. https://doi.org/10.1007/s11947-013-1245-y

Canizares, D., & Mauro, M. A. (2015). Enhancement of quality and stability of dried papaya by pectin-based coatings as air-drying pretreatment [journal article]. Food and Bioprocess Technology, 8(6), 1187–1197. https://doi.org/10.1007/s11947-015-1483-2

Cemeroğlu, B. S. (2013). Gıda analizleri. Bizim Grup Basımevi.

Ceylan, İ., Aktaş, M., & Doğan, H. (2006). Apple drying at kiln by solar energy. Journal of Polytechnic, 9(4), 289–294. https://doi.org/10.2339/2006.9.4.289-294

Cheyne, A., Barnes, J., Gedney, S., & Wilson, D. I. (2005). Extrusion behaviour of cohesive potato starch pastes: II. Microstructure–process interactions. Journal of Food Engineering, 66(1), 13–24. https://doi.org/10.1016/j.jfoodeng.2004.02.036

Choi, Y., & Okos, M. R. (1986). Thermal properties of liquid foods-review. In M. Okos (Ed.), Physical and Chemical Properties of Food. American Society of Agricultural Engineers.

Coles, N., & Hall, P. (2012, 27–29 Oct. 2012). Water, energy and food security. 2012 IEEE Conference on Technology and Society in Asia (T&SA),

Crank, J. (1975). The mathematics of diffusion. Clarendon Press.

Cunningham, S. E., McMinn, W. A. M., Magee, T. R. A., & Richardson, P. S. (2008a). Effect of processing conditions on the water absorption and texture kinetics of potato. Journal of Food Engineering, 84(2), 214–223. https://doi.org/10.1016/j.jfoodeng.2007.05.007

Cunningham, S. E., McMinn, W. A. M., Magee, T. R. A., & Richardson, P. S. (2008b). Experimental study of rehydration kinetics of potato cylinders. Food and Bioproducts Processing, 86(1), 15–24. https://doi.org/10.1016/j.fbp.2007.10.008

Dalla Rosa, M., Lerici, C. R., Pinnavaia, G., & Cencic, L. (1989). Sul grado di gelatinizzazione dell'amido in alimenti diversi. Tecnica Molitoria.

Doymaz, İ. (2004). Convective air drying characteristics of thin layer carrots. Journal of Food Engineering, 61(3), 359–364. https://doi.org/10.1016/S0260-8774(03)00142-0

Eren, İ., & Kaymak-Ertekin, F. (2007). Optimization of osmotic dehydration of potato using response surface methodology. Journal of Food Engineering, 79(1), 344–352. https://doi.org/10.1016/j.jfoodeng.2006.01.069

Fadavi, A., Salari, S., Mansouri, A., & Hoseini, S. (2020). Effects of vacuum and juice concentration on electrical conductivity by the ohmic method: A case study of sour cherry. Food and Bioprocess Technology, 13(7), 1146–1153. https://doi.org/10.1007/s11947-020-02463-4

Fernandes, F. A. N., Rodrigues, S., Cárcel, J. A., & García-Pérez, J. V. (2015). Ultrasound-assisted air-drying of apple (Malus domestica L.) and its effects on the vitamin of the dried product. Food and Bioprocess Technology, 8(7), 1503–1511. https://doi.org/10.1007/s11947-015-1519-7

Gallay, W., & Puddington, I. E. (1943). The hydration of starch below the gelatinization temperature. Canadian Journal of Research, 21b(9), 179–185. https://doi.org/10.1139/cjr43b-024

Ganthavorn, C., Nagel, C. W., & Powers, J. R. (1991). Thermal inactivation of asparagus lipoxygenase and peroxidase. Journal of Food Science, 56(1), 47–49. https://doi.org/10.1111/j.1365-2621.1991.tb07972.x

Giovanelli, G., Zanoni, B., Lavelli, V., & Nani, R. (2002). Water sorption, drying and antioxidant properties of dried tomato products. Journal of Food Engineering, 52(2), 135–141. https://doi.org/10.1016/S0260-8774(01)00095-4

Giri, S. K., & Prasad, S. (2007). Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms. Journal of Food Engineering, 78(2), 512–521. https://doi.org/10.1016/j.jfoodeng.2005.10.021

Gomes, C. F., Sarkis, J. R., & Marczak, L. D. F. (2018). Ohmic blanching of Tetsukabuto pumpkin: Effects on peroxidase inactivation kinetics and color changes. Journal of Food Engineering, 233, 74–80. https://doi.org/10.1016/j.jfoodeng.2018.04.001

Gong, C., Liao, M., Zhang, H., Xu, Y., Miao, Y., & Jiao, S. (2020). Investigation of hot air–assisted radio frequency as a final-stage drying of pre-dried carrot cubes. Food and Bioprocess Technology, 13(3), 419–429. https://doi.org/10.1007/s11947-019-02400-0

Goullieux, A., & Pain, J.-P. (2005). Ohmic heating In D.-W. Sun (Ed.), Emerging technologies for food processing (pp. 469–505). Academic Press. https://doi.org/10.1016/B978-012676757-5/50020-7

Graves, S., Piepho, H. P., Selzer, L., & Dorai-Raj, S. (2019). Visualizations of paired comparisons. Retrieved 01.05. from https://cran.r-project.org/web/packages/multcompView/multcompView.pdf

Hutchings, J. B. (1977). The importance of visual appearance of foods to the food processor and the consumer. Journal of Food Quality, 1(3), 267–278. https://doi.org/10.1111/j.1745-4557.1977.tb00945.x

Icier, F. (2010). Ohmic blanching effects on drying of vegetable byproduct. Journal of Food Process Engineering, 33(4), 661–683. https://doi.org/10.1111/j.1745-4530.2008.00295.x

Icier, F., Cokgezme, O. F., & Sabanci, S. (2017). Alternative thawing methods for the blanched/non-blanched potato cubes: Microwave, ohmic, and carbon fiber plate assisted cabin thawing. Journal of Food Process Engineering, 40(2), e12403. https://doi.org/10.1111/jfpe.12403

Jaeger, H., Roth, A., Toepfl, S., Holzhauser, T., Engel, K.-H., Knorr, D., . . . Steinberg, P. (2016). Opinion on the use of ohmic heating for the treatment of foods. Trends in Food Science & Technology, 55, 84–97. https://doi.org/10.1016/j.tifs.2016.07.007

James, G., Witten, D., Hastie, T., & Tibshirani, R. (2013). Linear model selection and regularization. In An introduction to statistical learning: with applications in R (pp. 203–264). Springer New York. https://doi.org/10.1007/978-1-4614-7138-7_6

Jun, S., & Sastry, S. (2005). Modeling and optimization of ohmic heating of foods inside a flexible package. Journal of Food Process Engineering, 28(4), 417–436. https://doi.org/10.1111/j.1745-4530.2005.00032.x

Karacabey, E., Turan, M. S., Özçelik, Ş, & G., Baltacıoğlu, C., & Küçüköner, E. (2016). Optimisation of pre-drying and deep-fat-frying conditions for production of low-fat fried carrot slices. Journal of the Science of Food and Agriculture, 96(13), 4603–4612. https://doi.org/10.1002/jsfa.7678

Khraisheh, M. A. M., McMinn, W. A. M., & Magee, T. R. A. (2004). Quality and structural changes in starchy foods during microwave and convective drying. Food Research International, 37(5), 497–503. https://doi.org/10.1016/j.foodres.2003.11.010

Kim, A.-N., Lee, K. Y., Rahman, M. S., Kim, H.-J., Chun, J., Heo, H. J., & Choi, S.-G. (2020). Effect of water blanching on phenolic compounds, antioxidant activities, enzyme inactivation, microbial reduction, and surface structure of samnamul (Aruncus dioicus var kamtschaticus). International Journal of Food Science & Technology, 55(4), 1754–1762. https://doi.org/10.1111/ijfs.14424

Kirk, J., Dennison, D., Kokoczka, P., & Heldman, D. (1977). Degradation of ascorbic acid in a dehydrated food system. Journal of Food Science, 42(5), 1274–1279. https://doi.org/10.1111/j.1365-2621.1977.tb14477.x

Kudra, T., & Mujumdar, A. S. (2009). Advanced drying technologies. CRC Press.

Kuhn, M. (2016). The desirability package. Retrieved 15.05 from https://cran.r-project.org/web/packages/desirability/vignettes/desirability.pdf

Lebovka, N. I., Praporscic, I., Ghnimi, S., & Vorobiev, E. (2005). Does electroporation occur during the ohmic heating of food? Journal of Food Science, 70(5), E308–E311. https://doi.org/10.1111/j.1365-2621.2005.tb09969.x

Lebovka, N. I., Shynkaryk, M. V., & Vorobiev, E. (2006). Drying of potato tissue pretreated by ohmic heating. Drying Technology, 24(5), 601–608. https://doi.org/10.1080/07373930600626677

Lebovka, N. I., Shynkaryk, N. V., & Vorobiev, E. (2007). Pulsed electric field enhanced drying of potato tissue. Journal of Food Engineering, 78(2), 606–613. https://doi.org/10.1016/j.jfoodeng.2005.10.032

Leeratanarak, N., Devahastin, S., & Chiewchan, N. (2006). Drying kinetics and quality of potato chips undergoing different drying techniques. Journal of Food Engineering, 77(3), 635–643. https://doi.org/10.1016/j.jfoodeng.2005.07.022

Lenth, R. V. (2009). Response-Surface Methods in R, Using rsm. 2009, 32(7), 17. https://doi.org/10.18637/jss.v032.i07

Lewicki, P. P. (1998). Effect of pre-drying treatment, drying and rehydration on plant tissue properties: A review. International Journal of Food Properties, 1(1), 1–22. https://doi.org/10.1080/10942919809524561

Lin, T. M., Durance, T. D., & Scaman, C. H. (1998). Characterization of vacuum microwave, air and freeze dried carrot slices. Food Research International, 31(2), 111–117. https://doi.org/10.1016/S0963-9969(98)00070-2

Liu, L., Wang, Y., Zhao, D., An, K., Ding, S., & Wang, Z. (2014). Effect of carbonic maceration pre-treatment on drying kinetics of chilli (Capsicum annuum L.) flesh and quality of dried product [journal article]. Food and Bioprocess Technology, 7(9), 2516–2527. https://doi.org/10.1007/s11947-014-1253-6

Liu, Y., & Shi, Y.-C. (2006). Phase and state transitions in granular starches studied by dynamic differential scanning calorimetry. Starch - Stärke, 58(9), 433–442. https://doi.org/10.1002/star.200500448

Liu, Z.-L., Staniszewska, I., Zielinska, D., Zhou, Y.-H., Nowak, K. W., Xiao, H.-W., & Zielinska, M. (2020). Combined hot air and microwave-vacuum drying of cranberries: Effects of pretreatments and pulsed vacuum osmotic dehydration on drying kinetics and physicochemical properties. Food and Bioprocess Technology, 13(10), 1848–1856. https://doi.org/10.1007/s11947-020-02507-9

Mazza, G. (1983). Dehydration of carrots. International Journal of Food Science & Technology, 18(1), 113–123. https://doi.org/10.1111/j.1365-2621.1983.tb00249.x

Mebane Jr., W. R., & Sekhon, J. S. (2011). Genetic optimization using derivatives: The rgenoud package for R. 2011, 42(11), 26. https://doi.org/10.18637/jss.v042.i11

Mitch, E. L. (1984). Potato starch: Production and uses. In Starch: Chemistry and technology (pp. 479–490). Elsevier.

Moreno-Perez, L. F., Gasson-Lara, J. H., & Ortega-Rivas, E. (1996). Effect of low temperature-long time blanching on quality of dried sweet potato. Drying Technology, 14(7–8), 1839–1857. https://doi.org/10.1080/07373939608917177

Moses, J. A., Norton, T., Alagusundaram, K., & Tiwari, B. K. (2014). Novel drying techniques for the food industry. Food Engineering Reviews, 6(3), 43–55. https://doi.org/10.1007/s12393-014-9078-7

Mudahar, G. S., Toledo, R. T., & Jen, J. J. (1990). A response surface methodology approach to optimize potato dehydration process. Journal of Food Processing and Preservation, 14(2), 93–106. https://doi.org/10.1111/j.1745-4549.1990.tb00831.x

Mujumdar, A. S., & Beke, J. (2003). Grain drying: Basic principles. In A. Chakraverty, A. S. Mujumdar, G. S. V. Raghavan, & H. S. Ramaswamy (Eds.), Handbook of Postharvest Technology: Cereals, Fruits, Vegetables, Tea, and Spices. Marcel Dekker, Inc.

Nguyen, T. K., Mondor, M., & Ratti, C. (2018). Shrinkage of cellular food during air drying. Journal of Food Engineering, 230, 8–17. https://doi.org/10.1016/j.jfoodeng.2018.02.017

Nieto, A., Castro, M. A., & Alzamora, S. M. (2001). Kinetics of moisture transfer during air drying of blanched and/or osmotically dehydrated mango. Journal of Food Engineering, 50(3), 175–185. https://doi.org/10.1016/S0260-8774(01)00026-7

Park, Y. W. (1987). Effect of freezing, thawing, drying, and cooking on carotene retention in carrots, broccoli and spinach. Journal of Food Science, 52(4), 1022–1025. https://doi.org/10.1111/j.1365-2621.1987.tb14266.x

Pimpaporn, P., Devahastin, S., & Chiewchan, N. (2007). Effects of combined pretreatments on drying kinetics and quality of potato chips undergoing low-pressure superheated steam drying. Journal of Food Engineering, 81(2), 318–329. https://doi.org/10.1016/j.jfoodeng.2006.11.009

Raghavan, G. V., Rennie, T. J., Sunjka, P. S., Orsat, V., Phaphuangwittayakul, W., & Terdtoon, P. (2005). Overview of new techniques for drying biological materials with emphasis on energy aspects. Brazilian Journal of Chemical Engineering, 22(2), 195–201. https://doi.org/10.1590/S0104-66322005000200005

Rakesh, V., Datta, A. K., Walton, J. H., McCarthy, K. L., & McCarthy, M. J. (2012). Microwave combination heating: Coupled electromagnetics- multiphase porous media modeling and MRI experimentation. AIChE Journal, 58(4), 1262–1278. https://doi.org/10.1002/aic.12659

Ratti, C. (2001). Hot air and freeze-drying of high-value foods: A review. Journal of Food Engineering, 49(4), 311–319. https://doi.org/10.1016/S0260-8774(00)00228-4

Reis, F. R. (2017). Impact of blanching on the performance of subsequent drying. In New Perspectives on Food Blanching (pp. 123–136). Springer.

Rodrigues, R. M., Genisheva, Z., Rocha, C. M. R., Teixeira, J. A., Vicente, A. A., & Pereira, R. N. (2019). Ohmic heating for preservation, transformation and extraction. In F. Chemat & E. Vorobiev (Eds.), Green Food Processing Techniques (1st ed., pp. 159–192). Academic Press

Sakr, M., & Liu, S. (2014). A comprehensive review on applications of ohmic heating (OH). Renewable and Sustainable Energy Reviews, 39, 262–269. https://doi.org/10.1016/j.rser.2014.07.061

Schadle, E. R., Burns, E. E., & Talley, L. J. (1983). Forced air drying of partially freeze-dried compressed carrot bars. Journal of Food Science, 48(1), 193–196. https://doi.org/10.1111/j.1365-2621.1983.tb14821.x

Seyhun, N., Ramaswamy, H. S., Zhu, S., Sumnu, G., & Sahin, S. (2013). Ohmic tempering of frozen potato puree. Food and Bioprocess Technology, 6(11), 3200–3205. https://doi.org/10.1007/s11947-012-1002-7

Sievert, C. (2020). Interactive web-based data visualization with R, plotly, and shiny. Chapman and Hall/CRC. https://plotly-r.com

Singleton, V. L., & Rossi, J. A. (1965). Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. American Journal of Enology and Viticulture, 16(3), 144–158. http://www.ajevonline.org/content/16/3/144.abstract

Turgut, S. S., Küçüköner, E., Feyissa, A. H., & Karacabey, E. (2021). A novel drying system – simultaneous use of ohmic heating with convectional air drying: System design and detailed examination using CFD. Innovative Food Science & Emerging Technologies, 102727. https://doi.org/10.1016/j.ifset.2021.102727

Turgut, S. S., Küçüköner, E., & Karacabey, E. (2018). Improvements in drying characteristics and quality parameters of tomato by carbonic maceration pretreatment. Journal of Food Processing and Preservation, 42(2), e13282. https://doi.org/10.1111/jfpp.13282

Vega-Gálvez, A., Ah-Hen, K., Chacana, M., Vergara, J., Martínez-Monzó, J., García-Segovia, P., . . . Di Scala, K. (2012). Effect of temperature and air velocity on drying kinetics, antioxidant capacity, total phenolic content, colour, texture and microstructure of apple (var. Granny Smith) slices. Food Chemistry, 132(1), 51–59. https://doi.org/10.1016/j.foodchem.2011.10.029

Wang, J., Xiao, H.-W., Ye, J.-H., Wang, J., & Raghavan, V. (2019). Ultrasound pretreatment to enhance drying kinetics of kiwifruit (Actinidia deliciosa) slices: Pros and cons. Food and Bioprocess Technology, 12(5), 865–876. https://doi.org/10.1007/s11947-019-02256-4

Wang, R., Zhang, M., & Mujumdar, A. S. (2010). Effects of vacuum and microwave freeze drying on microstructure and quality of potato slices. Journal of Food Engineering, 101(2), 131–139. https://doi.org/10.1016/j.jfoodeng.2010.05.021

Wang, W.-C., & Sastry, S. K. (2000). Effects of thermal and electrothermal pretreatments on hot air drying rate of vegetable tissue. Journal of Food Process Engineering, 23(4), 299–319. https://doi.org/10.1111/j.1745-4530.2000.tb00517.x

Wang, X. Y., Kozempel, M. G., Hicks, K. B., & Seib, P. A. (1992). Vitamin C stability during preparation and storage of potato flakes and reconstituted mashed potatoes. Journal of Food Science, 57(5), 1136–1139. https://doi.org/10.1111/j.1365-2621.1992.tb11282.x

Weisberg, S. (2018). Package ‘alr3’ Retrieved 20.05 from https://cran.r-project.org/web/packages/alr3/alr3.pdf

Wootton, M., Weeden, D., & Munk, N. (1971). Rapid method for the estimation of starch gelatinization in processed foods. Food Technol Australia.

Yan, W.-Q., Zhang, M., Huang, L.-L., Mujumdar, A. S., & Tang, J. (2013). Influence of microwave drying method on the characteristics of the sweet potato dices. Journal of Food Processing and Preservation, 37(5), 662–669. https://doi.org/10.1111/j.1745-4549.2012.00707.x

Zhao, D., An, K., Ding, S., Liu, L., Xu, Z., & Wang, Z. (2014). Two-stage intermittent microwave coupled with hot-air drying of carrot slices: Drying kinetics and physical quality. Food and Bioprocess Technology, 7(8), 2308–2318. https://doi.org/10.1007/s11947-014-1274-1

Zhong, T., & Lima, M. (2003). The effect of ohmic heating on vacuum drying rate of sweet potato tissue. Bioresource Technology, 87(3), 215–220. https://doi.org/10.1016/S0960-8524(02)00253-5

Zhou, X., Xu, R., Zhang, B., Pei, S., Liu, Q., Ramaswamy, H. S., & Wang, S. (2018). Radio frequency-vacuum drying of kiwifruits: Kinetics, uniformity, and product quality. Food and Bioprocess Technology, 11(11), 2094–2109. https://doi.org/10.1007/s11947-018-2169-3

Acknowledgements

This research was financially supported by “Süleyman Demirel University Scientific Research Projects Office”, Turkey (Project ID: FDK-2019-6978). Sebahattin Serhat Turgut is supported under postgraduate scholarship (2211-C) of “The Scientific and Technical Research Council of Turkey (TÜBİTAK)”. The authors thank all supporting organisations.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Turgut, S.S., Karacabey, E. & Küçüköner, E. A Novel System—the Simultaneous Use of Ohmic Heating with Convective Drying: Sensitivity Analysis of Product Quality Against Process Variables. Food Bioprocess Technol 15, 440–458 (2022). https://doi.org/10.1007/s11947-022-02765-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-022-02765-9