Abstract

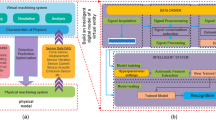

The chatter not only brings about poor surface quality of the workpiece but also causes the tool wear and then leads to the increase in production cost over time. For this reason, it would be imperative that the chatter signal should be checked in an accurate manner whenever required. Because the chatter belongs to the nonlinear vibration phenomenon during the machining process, varied chatter characteristics will be presented under the different material, cutting speed and depth cutting conditions. Therefore, the machining learning method is used by many research programs by combining the database in order to analyze the vigorously changed data. To the chatter signal, thousands and even tens of thousands lots of data should be collected for use as training data and it would be extremely difficult for ordinary manufacturers and laboratories. It is because that not only will the tool be consumed but massive materials and time will also be required as far as the data collection is concerned. In this research, the “chaotic error map” is employed to accelerate the data processing in that 94.8% accuracy and 99.62% precision can be achieved simply with 60 lots of data only. Through the attractor properties of the chaotic system in the 3D space the input signal will be allowed to move along the attractor. Through such process, it transfers the highly variated chatter data to the consistent output result between the same classes. Further, this research is also the first program that proposes the fractional-order (FO) convolutional neural network (hereafter briefed as FOCNN) for chatter detection. Through the computation of fractional-order, it reduces 42.3% of trainable parameters when compared with the CNN having approximate training conditions while enhancing 3.8% of accuracy. Accordingly, our technique is also practical in use for the machining process.

Similar content being viewed by others

Data availability

Enquiries about data availability should be directed to the authors.

References

Ding, H., Gao, R.X., Isaksson, A.J., Landers, R.G., Parisini, T., Yuan, Y.: State of AI-based monitoring in smart manufacturing and introduction to focused section. IEEE/ASME Trans. Mechatron. 25, 2143–2154 (2020). https://doi.org/10.1109/TMECH.2020.3022983

Tehranizadeh, F., Rahimzadeh-Berenji, K., Budak, E.: Dynamics and chatter stability of crest-cut end mills. Int. J. Mach. Tools Manuf. 171, 103813 (2021). https://doi.org/10.1016/j.ijmachtools.2021.103813

Drive, F., Drive, F.: 2016 International Symposium on Flexible Automation Comparison of On-Line Chatter Detection Algorithms In Turning. Pp. 1–3 (2016)

Zhang, B., Katinas, C., Shin, Y.C.: Robust wheel wear monitoring system for cylindrical traverse grinding. IEEE/ASME Trans. Mechatron. 25, 2220–2229 (2020). https://doi.org/10.1109/TMECH.2020.3007047

Gradišek, J., Baus, A., Govekar, E., Klocke, F., Grabec, I.: Automatic chatter detection in grinding. Int. J. Mach. Tools Manuf. 43, 1397–1403 (2003). https://doi.org/10.1016/S0890-6955(03)00184-6

Zhang, Z., Li, H., Meng, G., Tu, X., Cheng, C.: Chatter detection in milling process based on the energy entropy of VMD and WPD. Int. J. Mach. Tools Manuf. 108, 106–112 (2016). https://doi.org/10.1016/j.ijmachtools.2016.06.002

Urbikain, G., Olvera, D., López-de-Lacalle, L.N., Beranoagirre, A., Elías-Zuñiga, A.: Prediction methods and experimental techniques for chatter avoidance in turning systems: a review. Appl. Sci. 9, 4718 (2019). https://doi.org/10.3390/app9214718

Siddhpura, M., Paurobally, R.: A review of chatter vibration research in turning. Int. J. Mach. Tools Manuf. 61, 27–47 (2012). https://doi.org/10.1016/j.ijmachtools.2012.05.007

Chen, C.-K., Tsao, Y.-M.: A stability analysis of regenerative chatter in turning process without using tailstock. Int. J. Adv. Manuf. Technol. 29, 648–654 (2006). https://doi.org/10.1007/s00170-005-2573-5

Wang, A., Jin, W., Wang, G., Li, X.: Analysis on dynamics of a cutting tool with the thermal distortion in turning process. Nonlinear Dyn. 86, 1183–1191 (2016). https://doi.org/10.1007/s11071-016-2956-1

Totis, G.: RCPM—a new method for robust chatter prediction in milling. Int. J. Mach. Tools Manuf. 49, 273–284 (2009). https://doi.org/10.1016/j.ijmachtools.2008.10.008

Chen, S., Meng, Y., Tang, H., Tian, Y., He, N., Shao, C.: Robust deep learning-based diagnosis of mixed faults in rotating machinery. IEEE/ASME Trans. Mechatronics. 25, 2167–2176 (2020). https://doi.org/10.1109/TMECH.2020.3007441

Serin, G., Ugur Gudelek, M., Murat Ozbayoglu, A., Unver, H.O.: Estimation of parameters for the free-form machining with deep neural network. In; Proceedings of 2017 IEEE International Conference Big Data, Big Data 2017. 2018–Janua, 2102–2111 (2017). https://doi.org/10.1109/BigData.2017.8258158

Yesilli, M.C., Tymochko, S., Khasawneh, F.A., Munch, E.: Chatter diagnosis in milling using supervised learning and topological features vector. In; Proceedings of 18th IEEE International Conference on Machine Learning and Applications ICMLA 2019, pp. 1211–1218 (2019). https://doi.org/10.1109/ICMLA.2019.00200

Fan, C., Ding, Q.: Analysis and resistance of dynamic degradation of digital chaos via functional graphs. Nonlinear Dyn. 103, 1081–1097 (2021). https://doi.org/10.1007/s11071-020-06160-x

Rao, B.C., Shin, Y.C.: A comprehensive dynamic cutting force model for chatter prediction in turning. Int. J. Mach. Tools Manuf. 39, 1631–1654 (1999). https://doi.org/10.1016/S0890-6955(99)00007-3

Lin, S., Zhang, W.: Chattering reduced sliding mode control for a class of chaotic systems. Nonlinear Dyn. 93, 2273–2282 (2018). https://doi.org/10.1007/s11071-018-4324-9

Elias, J., Narayanan Namboothiri, V.N.: Cross-recurrence plot quantification analysis of input and output signals for the detection of chatter in turning. Nonlinear Dyn. 76, 255–261 (2014). https://doi.org/10.1007/s11071-013-1124-0

Vela-Martínez, L., Jáuregui-Correa, J.C., Rubio-Cerda, E., Herrera-Ruiz, G., Lozano-Guzmán, A.: Analysis of compliance between the cutting tool and the workpiece on the stability of a turning process. Int. J. Mach. Tools Manuf. 48, 1054–1062 (2008). https://doi.org/10.1016/j.ijmachtools.2007.10.016

Gardini, L., Grebogi, C., Lenci, S.: Chaos theory and applications: a retrospective on lessons learned and missed or new opportunities. Nonlinear Dyn. 102, 643–644 (2020). https://doi.org/10.1007/s11071-020-05903-0

Gou, X.-F., Zhu, L.-Y., Chen, D.-L.: Bifurcation and chaos analysis of spur gear pair in two-parameter plane. Nonlinear Dyn. 79, 2225–2235 (2015). https://doi.org/10.1007/s11071-014-1807-1

Lu, K., Lian, Z., Gu, F., Liu, H.: Model-based chatter stability prediction and detection for the turning of a flexible workpiece. Mech. Syst. Signal Process. 100, 814–826 (2018). https://doi.org/10.1016/j.ymssp.2017.08.022

Pu, Y.-F.: Fractional-order Euler-Lagrange equation for fractional-order variational method: a necessary condition for fractional-order fixed boundary optimization problems in signal processing and image processing. IEEE Access. 4, 10110–10135 (2016). https://doi.org/10.1109/ACCESS.2016.2636159

Rahimi, M.H., Huynh, H.N., Altintas, Y.: On-line chatter detection in milling with hybrid machine learning and physics-based model. CIRP J. Manuf. Sci. Technol. 35, 25–40 (2021). https://doi.org/10.1016/j.cirpj.2021.05.006

Jian, B.-L., Wang, C.-C., Chang, J.-Y., Su, X.-Y., Yau, H.-T.: Machine tool chatter identification based on dynamic errors of different self-synchronized chaotic systems of various fractional orders. IEEE Access. 7, 67278–67286 (2019). https://doi.org/10.1109/ACCESS.2019.2917094

Chen, H.K., Lee, C.I.: Anti-control of chaos in rigid body motion. Chaos, Solitons Fractals 21, 957–965 (2004). https://doi.org/10.1016/j.chaos.2003.12.034

Scherer, R., Kalla, S.L., Tang, Y., Huang, J.: The Grünwald-Letnikov method for fractional differential equations. Comput. Math. with Appl. 62, 902–917 (2011). https://doi.org/10.1016/j.camwa.2011.03.054

Yau, H.-T., Wu, S.-Y., Chen, C.-L., Li, Y.-C.: Fractional-order chaotic self-synchronization-based tracking faults diagnosis of ball bearing systems. IEEE Trans. Ind. Electron. 63, 3824–3833 (2016). https://doi.org/10.1109/TIE.2016.2522941

Yi-Fei, Pu., Zhou, J.-L., Yuan, X.: Fractional differential mask: a fractional differential-based approach for multiscale texture enhancement. IEEE Trans. Image Process. 19, 491–511 (2010). https://doi.org/10.1109/TIP.2009.2035980

Mathieu, B., Melchior, P., Oustaloup, A., Ceyral, C.: Fractional differentiation for edge detection. Signal Process. 83, 2421–2432 (2003). https://doi.org/10.1016/S0165-1684(03)00194-4

Engel, I., Bershad, N.J.: A transient learning comparison of Rosenblatt, backpropagation, and LMS algorithms for a single-layer perceptron for system identification. IEEE Trans. Signal Process. 42, 1247–1251 (1994). https://doi.org/10.1109/78.295190

Hinton, G.E., Srivastava, N., Krizhevsky, A., Sutskever, I., Salakhutdinov, R.R.: Improving neural networks by preventing co-adaptation of feature detectors. (2012)

Srivastava, N., Hinton, G., Krizhevsky, A., Ilya-Sutskever, R.S.: Dropout: a simple way to prevent neural networks from overfitting. J. Mach. Learn. Res. 15, 1929–1958 (2014)

Nussbaumer, H.J.: The Fast Fourier Transform. Presented at the (1981)

Patra, S., Bruzzone, L.: A batch-mode active learning technique based on multiple uncertainty for SVM classifier. IEEE Geosci. Remote Sens. Lett. 9, 497–501 (2012). https://doi.org/10.1109/LGRS.2011.2172770

Zhu, W., Zhuang, J., Guo, B., Teng, W., Wu, F.: An optimized convolutional neural network for chatter detection in the milling of thin-walled parts. Int. J. Adv. Manuf. Technol. 106, 3881–3895 (2020). https://doi.org/10.1007/s00170-019-04899-1

Tran, M.-Q., Liu, M.-K., Tran, Q.-V.: Milling chatter detection using scalogram and deep convolutional neural network. Int. J. Adv. Manuf. Technol. 107, 1505–1516 (2020). https://doi.org/10.1007/s00170-019-04807-7

Acknowlegments

This work was supported by the Advanced Institute of Manufacturing with High-tech Innovations (AIM-HI) from The Featured Areas Research Center Program within the framework of the Higher Education Sprout Project by the Ministry of Education (MOE) in Taiwan.

Funding

This work was supported by the Ministry of Science and Technology Taiwan Under Grants MOST 110-2221-E-194-037, 111-2218-E-194-007, 111-2221-E-194-052, 111-2634-F-005-001 and 111-2218-E-002-033.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have not disclosed any competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kuo, PH., Tseng, YR., Luan, PC. et al. Novel fractional-order convolutional neural network based chatter diagnosis approach in turning process with chaos error mapping. Nonlinear Dyn 111, 7547–7564 (2023). https://doi.org/10.1007/s11071-023-08252-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-023-08252-w