Abstract

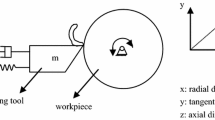

A new approach to analyze the stability of cutting processes when considering the deformation of the workpiece is proposed in this article. In past studies, the workpiece was assumed to be rigid and no deformation was considered. In those studies, the stability of the cutting process was analyzed by merely the dynamic equation of tools. However, the workpiece does have deformation when there is external force exerting on it. Such deformation will change the chip thickness and have an effect on the critical chip thickness of stability. To describe the cutting in turning process, partial differential equations are used and a set of dynamic equations will be considered based on the interaction between the tool and the workpiece. After performing the Laplace transformation, stability can be analyzed based on the length, radius, natural frequency, deflection, aspect ratio and material stiffness of the workpieces. The effect of the critical chip width under different spindle speed will also be discussed in this article. By considering the deformation of the workpiece under different conditions, the results show that the critical chip width of the deformed case is always larger than the rigid body case.

Similar content being viewed by others

References

Tobias SA (1961) Machine tool vibration. Wiley, New York

Koenigs Berger F, Tlusty J (1971) Structure of machine tools. Pergamon Press, Oxford.

Merchant ME (1944) Basic mechanics of the metal-cutting process. Trans ASME J Appl Mech 11(3)A–168–A–175

Kegg RL (1965) Cutting dynamics in machine tool chatter. J Eng Ind 87(4):464–470

Merritt HE (1965) Theory of self excited machine tool chatter. J Eng Ind 87(4):447–454

King RI (1985) Handbook of high speed machining technology. Chapman and Hall, New York

Welbourn DB, Smith JD (1970) Machine tool dynamics – an introduction. Cambridge University Press, London.

Gradisek J, Govekar E, Grabec I (1996) A chaotic cutting process and determining optimal cutting parameter values using neural networks. Int J Mach Tools Manuf 36(10):1161–1172

Rao Balkrishua C, Shin Yung C (1999) A comprehensive dynamic cutting force model for chatter prediction in turning. Int J Mach Tools Manuf 39(10):1631–1654

Altintas Y, Budak E (1995) Analytical prediction of stability lobes in milling. Ann CIRP 44(1):357–362

Minis I, Yanushevsky T (1993) A new theoretical approach for the prediction of machine tool chatter in milling. Trans ASME J Eng Ind 115(1):1–8

Smith S, Tlusty J (1993) Efficient simulation programs for chatter in milling. Ann CIRP 42(1):463–466

Weck M, Altintas Y, Beer C (1994) CAD assisted chatter free NC tool path generation in milling. Int J Mach Tool Des Res 34(6):879–891

Tarng YS, Kao JY, Lee EC (2000) Chatter suppression in turning operations with a turned vibration absorber. J Mater Process Technol 105(1–2):55–60

Pitstra WC, Pieper JK (2000) Controller designs for constant cutting force turning machine control. ISA Trans 39(2):191–203

Soliman E, Ismail F (1997) Chatter suppression by adaptive speed modulation. Int J Mach Tools Manuf 37(3):355–369

Olgac N, Hosek M (1998) A new perspective and analysis for regeneration machine tool chatter. Int J Mach Tools Manuf 38(7):783–798

Meirovitch L (1967) Analytical methods in vibrations. Macmillan, New York

Rao SS (1985) Mechanical vibrations. Addison-Wesley, Boston

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, CK., Tsao, YM. A stability analysis of regenerative chatter in turning process without using tailstock. Int J Adv Manuf Technol 29, 648–654 (2006). https://doi.org/10.1007/s00170-005-2573-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-005-2573-5