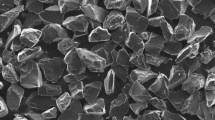

Physical and mechanical properties and microstructure of hot-pressed aluminum matrix composites with different contents of hardening particles of B4C and SiC are studied. The composites are tested for compressive strength and subjected to metallographic and fractographic analyses. The apparent density, the open porosity and the microhardness of the powder materials are determined. It is shown that the Al + 12.5% B4C + 12.5% SiC composite possess the highest resistance to compressive plastic deformation and the highest microhardness. The high fineness of the B4C particles provides the highest fragmentation of the grain structure of the aluminum solid solution.

Similar content being viewed by others

Notes

Here and below in the article the contents of the compounds are given in weight percent except for the specially mentioned cases.

References

M. Hamza and S. Mondal, “Effect of reinforcement with ceramic microparticles on the structure and properties of aluminum matrix composites,” Metalloved. Term. Obrab. Met., No. 3, 30 – 33 (2022).

X. Zhang, Y. Chen, and J. Hu, “Recent advances in the development of aerospace materials,” Prog. Aerospace Sci., 97, 22 – 34 (2018).

A. I. Rudskoy, K. N. Volkov, Yu. A. Sokolov, and S. Yu. Kondrat’ev, Digital Production Systems: Technologies, Simulation, Optimization [in Russian], POLITEKh-PRESS, St. Petersburg (2020), 828 p.

T. Prater, “Friction stir welding of metal matrix composites for use in aerospace structures,” Acta Astron., 93, 366 – 373 (2014).

K. I. Portnoy, S. E. Salibekov, I. L. Svetlov, and V. M. Chubarov, Structure and Properties of Composite Materials [in Russian], Mashinostroenie, Moscow (1979), 255 p.

N. B. Pugacheva, N. S. Michurov, and T. M. Burkova, “The structure and properties of the 30Al – 70SiC metal matrix composite material,” Diagn., Resource Mechan. Mater. Struct. (Electronic resource), Is. 6, 6 – 18 (2015).

M. Alizadeh, M. Chaffari, H. Akbari beni, and R. Amini, “Properties of high specific strength Al – 4 wt.% Al2O3 /B4C nano-composite produced by accumulative roll bonding process,” Mater. Des., 50, 427 – 432 (2013).

V. Yu. Dorofeeva and S. N. Egorova, Particle Intergrowth in Formation of Powder Hot-Deformed Materials [in Russian], ZAO Metallurgizdat, Moscow (2003), 152 p.

Y. Z. Li, Q. Z.Wang,W. G.Wang, et al., “Effect of interfacial reaction on age-hardening ability of B4C/6061 Al composites,” Mater. Sci. Eng., 620, 445 – 453 (2015).

Y. Z. Li, Q. Z. Wang, W. G. Wang, et al., “Interfacial reaction mechanism between matrix and reinforcement in B4C/6061 Al composites,” Mater. Chem. Phys., 154, 107 – 117 (2015).

Z. No, Y. Liu, J. Geng, and T. Wang, “The effects of temperatures on microstructure evolution and mechanical properties of B4C – AA2024 composite strips prepared by semi-solid powder rolling,” Mater. Sci. Eng., 652, 305 – 314 (2016).

K. D. Dipti, C. M. Puma, S. Saranjit, and K. T. Ratish, “Properties of ceramics reinforced aluminum matrix composites (review),” Int. J. Mech. Mater. Eng., 12, 1 – 16 (2014).

J. Onoro, M. D. Salvador, and L. E. G. Cambronero, “High-temperature mechanical properties of aluminum alloys reinforced with boron carbide particles,” Mater. Sci. Eng., 499(1 – 2), 421 – 426 (2009).

L. E. G. Cambronero, E. Sanchez, J. M. Ruiz-Roman, and J. M. Ruiz-Prieto, “Mechanical characterisation of AA705 aluminum alloy reinforced with ceramics,” J. Mater. Proc. Technol., 143 – 144, 378 – 383 (2003).

A. I. Rudskoy, K. N. Volkov, S. Yu. Kondrat’ev, and Yu. A. Sokolov, Physical Processes and Technologies of Production of Metallic Powders from Melt [in Russian], Izd. Politekh. Univ., St. Petersburg (2018), 610 p.

I. Topcu, H. O. Gulsoy, N. Kadioglu, and A. N. Gullioglu, “Processing and mechanical properties of B4C reinforced aluminum matrix composites,” J. Alloys Compd., 482(1 – 2), 516 – 521 (2009).

R. M. Mohanty, K. Balasubramanian, and S. K. Seshadri, “Boron carbide — reinforced aluminum 1100 matrix composites: Fabrication and properties,” Mater. Sci. Eng., 498(1 – 2), 42 – 52 (2008).

S. V. Gladkovsky, S. V. Kuteneva, D. A. Dvoynikov, and V. E. Veselova, “Parametrization of powder for Al/B4C metal matrix composites using the static image analysis method,” AIP Conf. Proc., 2053-040026, 1 – 5 (2018).

Yu. A. Sokolov, N. V. Pavlushin, and S. Yu. Kondrat’ev, “Novel additive technologies based on ion beams,” Russian Eng. Res., 36(12), 1012 – 1016 (2016).

A. I. Rudskoy, S. Yu. Kondrat’ev, and Yu. A. Sokolov, “New approach to synthesis of powder and composite materials by electron beam. Part 1. Technological features of the process,” Metal Sci. Heat Treat., 58(1 – 2), 27 – 32 (2016).

D. I. Kryuchkov and A. V. Nesterenko, “A review of experimental studies of deformation behavior of aluminum matrix composite materials discretely reinforced with silicon carbide in the state of high-temperature superplasticity and under creep,” Obrab. Met. (Tekhnol., Oborud., Instr.), 22(2), 130 – 157 (2020).

Y. N. Zan, Y. T. Zhou, Z. Y. Liu, et al., “Microstructure and mechanical properties of (B4C + Al2O3)/Al composites designed for neutron absorbing materials with both structural and functional usages,” Mater. Sci. Eng., 773, 1 – 9 (2020).

H. S. Chen, W. X. Wang, Y. L. Li, et al., “The design, microstructure and tensile properties of B4C particulate reinforced 6061 Al neutron absorber composites,” J. Alloys Compd., 632, 23 – 29 (2015).

H. W. Kim, Y. H. Koh, and H. E. Kim, “Reaction sintering and mechanical properties of B4C with addition of ZrO2 ,” J. Mater. Res., 15, 2431 – 2436 (2000).

S. I. Gubenko, “Role of inclusion-matrix interfaces in development of relaxation processes near nonmetallic inclusions,” Metalloved. Term. Obrab. Met., No. 5(779), 3 – 10 (2020).

Y. L. Li, W. X. Wang, J. Zhou, and H. S. Chen, “Hot deformation behaviors and processing maps of B4C/Al6061 neutron absorber composites,” Mater. Charact., 124, 107 – 116 (20170.

H. S. Chen, W. X. Wang, Y. L. Li, et al., “The design, microstructure and mechanical properties of B4C/Al6061 neutron absorber composites fabricated by SPS,” Mater. Des., 94, 360 – 367 (2016).

The authors acknowledge the help of D. V Zaitsev (UrFU) and K. G. Zemlyanoy(UrFU) in the determination of the physical and mechanical properties of the composites. The work has been performed with the use of the equipment of TSKP “Plastometry” of IMASh UrO RAN within the state assignments to IMASh UrO RAN on topic No. AAAA-A18-118020790147-4 and to IFM UrO RAN on topic No. 122021000032-5 “Pressure”.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1pp. 55 – 62, January, 2023

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gladkovskii, S.V., Petrova, S.V., Cherkasova, T.S. et al. Structure, Physical and Mechanical Properties of Aluminum Matrix Composites Reinforced with Carbide Particles. Met Sci Heat Treat 65, 54–61 (2023). https://doi.org/10.1007/s11041-023-00891-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-023-00891-5