Abstract

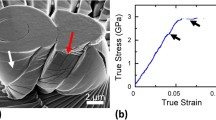

Nanocrystalline aluminum films with grain sizes of 50–100 nm were made through E-beam evaporation. The films were then subjected to high-rate shearing deformations with strain rates of 105–106 s−1, with local shear stresses of the order of 10 GPa. The experimental configuration is that of a compression–torsion Kolsky bar, where the specimen is a thin film (thickness 200 nm) mounted on a silicon wafer ring. Strain rates during the shearing are determined from the measured torsional waves in the bars. Site-specific TEM samples are prepared using focused ion beam micromachining to investigate the regions of large plastic deformation. Deformation twins and stacking faults are found to develop under the high-strain-rate shearing. The formation of twinning in pure aluminum with comparatively large grain sizes and the high-strain-rate promotion of twinning are discussed, and possible mechanisms are considered.

Similar content being viewed by others

References

Meyers MA, Voehringer O, Chen YJ (1999) A constitutive description of the slip-twinning transition in metals. In: Ankem S, Pande CS (eds) Advances in twinning, vol 204. The Minerals and Materials Society, Japan, pp 43–65

Tadmor EB, Bernstein N (2004) A first-principles measure for the twinnability of FCC metals. J Mech Phys Solids 52:2507–2519

Yamakov V, Wolf D, Phillpot SR, Mukherjee AK, Gleiter H (2002) Dislocation processes in the deformation of nanocrystalline aluminum by molecular-dynamics simulation. Nat Mater 1:45–48

Chen M, Ma E, Hemker KJ, Sheng H, Wang Y, Cheng X (2003) Deformation twinning in nanocrystalline aluminum. Science 300:1275–1277

Liao XZ, Zhou F, Lavernia EJ, Srinivasan SG, Baskes MI, He DW, Zhu YT (2003) Deformation mechanism in nanocrystalline aluminum: partial dislocation slip. Appl Phys Lett 83(4):632

Pond RC, Garcia-Garcia LMF (1981) Deformation twinning in aluminum. Inst Phys Conf Ser 61:495–498

Warner DH, Curtin WA, Qu Q (2007) Rate dependence of crack-tip processes predicts twinning trends in FCC metals. Nat Mater 6:876–881

Johari O, Thomas G (1964) Substructures in explosively deformed Cu and Cu-Al alloys. Acta Metall 12(10):1153–1159

Nolder RL, Thomas G (1964) The substructure of plastically deformed nickel. Acta Metall 12(2):227–240

Mahajan S, Chin GY (1973) Formation of deformation twins in f.c.c. crystals. Acta Matallurg 21:1353–1363

Venables JA (1964) The electron microscopy of deformation twins. J Phys Chem Solids 25:685–692

Liao XZ, Zhou F, Lavernia EJ, He DW, Zhu YT (2003) Deformation twins in nanocrystalline aluminum. Appl Phys Lett 83:5062–5064

Zhu YT, Liao XZ, Srinivasan SG, Zhao YH, Baskes MI, Zhou F, Lavernia EJ (2004) Nucleation and growth of deformation twins in nanocrystalline aluminum. Appl Phys Lett 85(21):5049

Zhu YT, Liao XZ, Srinivasan SG, Lavernia EJ (2005) Nucleation of deformation twins in nanocrystalline face-centered cubic metals processed by severe plastic deformation. J Appl Phys 98(3):034319

Wu XL, Liao XZ, Srinivasan SG, Zhou F, Lavernia EJ, Valiev RZ, Zhu YT (2008) New deformation twinning mechanism generates zero macroscopic strain in nanocrystalline metals. Phys Rev Lett 100:095701

Li B, Cao B, Ramesh K, Ma E (2009) A nucleation mechanism of deformation twins in pure aluminum. Acta Mater 57(15):4500–4507

Asaro RJ, Suresh S (2005) Mechanistic models for the activation volume and rate sensitivity in metals with nanocrystalline grains and nano-scale twins. Acta Mater 53:3369–3392

Zhu B, Asaro RJ, Krysl P, Bailey R (2005) Transition of deformation mechanisms and its connection to grain size distribution in nanocrystalline metals. Acta Mater 53(18):4825–4838

Ramesh KT (2008) High strain rate and impact experiments. In: Sharpe WN Jr (ed) Handbook of experimental solid mechanics. Springer, Berlin, pp 929–960

Yadav S, Ramesh TK (1995) The mechanical behavior of tungsten-based composites at very high strain rates. Mater Sci Eng A 203:140–153

Volinsky AA, Moody NR, Gerberich WW (2002) Interfacial toughness measurements for thin films on substrates. Acta Mater 50(3):441–466

Yu MH, Bhushan B (1996) Contact analysis of three-dimensional rough surfaces under frictionless and frictional contact. Wear 200:265–280

Hyun S, Pei L, Molinari J-F, Robbins MO (2004) Finite-element analysis of contact between elastic self-affine surfaces. Phys Rev E 70:026117

Pei L, Hyun S, Molinari J-F, Robbins MO (2005) Finite element modeling of elasto-plastic contact between rough surfaces. J Mech Phys Solids 53:2385–2409

Gianola DS, Van Petegem S, Legros M, Brandstetter S, Van Swygenhoven H, Hemker KJ (2006) Stress assisted discontinuous grain growth and its effect on the deformation behavior of nanocrystalline aluminum thin films. Acta Mater 54:2253–2263

Duffy J, Campbell JD, Hawley RH (1971) On the use of torsional split Hopkinson bar to study rate effects in 1100-O aluminum. ASME J Appl Mech 37:83–91

Rupert TJ, Gianola DS, Gan Y, Hemker KJ (2009) Experimental observations of stress-driven grain boundary migration. Science 326:1686–1690

Li J, Malis T, Dionne S (2006) Recent advances in FIB-TEM specimen preparation techniques. Mater Charact 57:64–70

Giannuzzi LA, Stevie FA (1990) A review of focused ion beam milling techniques for TEM specimen preparation. Micron 30:197–204

Giannuzzi LA, Kempshall BW, Schwarz SM, Lomness JK, Prenitzer BI, Stevie FA (2005) In: Giannuzzi LA, Stevie FA (eds) Introduction to focused ion beams-instrumentation, theory, techniques and practice. Springer, Berlin, pp 201–228

Zhu YT (2006) Deformation twins formed in nanocrystalline materials. Mater Sci Forum 503–504:125–132

Hirth JP, Lothe J (1982) Theory of dislocations, 2nd edn. Wiley, New York

Liao XZ, Srinivasan SG, Zhao YH, Baskes MI, Zhu YT, Zhou F, Lavernia EJ, He DW (2004) Formation mechanism of wide stacking faults in nanocrystalline Al. Appl Phys Lett 84:3564–3566

Mishin Y, Farkas D, Mehl MJ, Papaconstantopoulos DA (1999) Interatomic potentials for monoatomic metals from experimental data and ab initio calculations. Phys Rev B 59:3393–3407

Daphalapurkar NP, Ramesh KT (2012) Orientation dependence of the nucleation and growth of partial dislocations and possible twinning mechanisms in aluminum. J Mech Phys Solids 60(2):277–294

Acknowledgments

The authors are grateful for financial support from the Army Research Laboratory, the discussion with Prof. Hemker at the Johns Hopkins University, and the technical assistance of Dr. Kenneth Livi with the STEM. This work was performed under the auspices of the Center for Advanced Metallic and Ceramic Systems at Johns Hopkins. This research was sponsored by the Army Research Office through Grant Number DAAD190110536, and in part by the Army Research Laboratory (ARMAC-RTP) under ARMAC-RTP Cooperative Agreement Number DAAD19-01-2-0003.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cao, B., Daphalapurkar, N.P. & Ramesh, K.T. Ultra-high-strain-rate shearing and deformation twinning in nanocrystalline aluminum. Meccanica 50, 561–574 (2015). https://doi.org/10.1007/s11012-014-9952-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-014-9952-7