Abstract

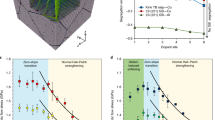

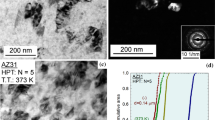

AlMg alloys have widespread industrial applications. Grain refinement techniques have been frequently used to achieve high strength in these alloys. Here, we report on the fabrication of epitaxial co-sputtered AlMg thin films with high-density growth twins. The microstructure evolution with varying Mg composition has been characterized. Nanoindentation and in-situ micropillar compression tests show that the strength of AlMg alloys increases with increasing Mg composition. The flow stress of epitaxial nanotwinned Al–10 at.% Mg thin film exceeds 800 MPa. The modified Hall–Petch plots incorporating the solid solution strengthening effect suggest that, compared to high angle grain boundaries, incoherent twin boundaries are equivalent barriers to the transmission of dislocations in nanotwinned AlMg alloys.

Similar content being viewed by others

References

J. Hirsch: Recent development in aluminium for automotive applications. Trans. Nonferrous Met. Soc. China 24, 1995 (2014).

J. Hirsch and T. Al-Samman: Superior light metals by texture engineering: Optimized aluminum and magnesium alloys for automotive applications. Acta Mater. 61, 818 (2013).

M.E. Fine: Precipitation hardening of aluminum alloys. Metall. Mater. Trans. A 6, 625 (1975).

J. Park and A. Ardell: Correlation between microstructure and calorimetric behavior of aluminum alloy 7075 and AlZnMg alloys in various tempers. Mater. Sci. Eng., A 114, 197 (1989).

D. Richard and P.N. Adler: Calorimetric studies of 7000 series aluminum alloys: I. Matrix precipitate characterization of 7075. Metall. Mater. Trans. A 8, 1177 (1977).

L.K. Berg, J. Gjønnes, V. Hansen, X.Z. Li, M. Knutson-Wedel, G. Waterloo, D. Schryvers, and L.R. Wallenberg: GP-zones in Al–Zn–Mg alloys and their role in artificial aging. Acta Mater. 49, 3443 (2001).

W. Han, G. Cheng, S. Li, S. Wu, and Z. Zhang: Deformation induced microtwins and stacking faults in aluminum single crystal. Phys. Rev. Lett. 101, 115505 (2008).

P. Chowdhury, H. Sehitoglu, H. Maier, and R. Rateick: Strength prediction in NiCo alloys—The role of composition and nanotwins. Int. J. Plast. 79, 237 (2016).

Y. Zhao, Y. Zhu, X. Liao, Z. Horita, and T. Langdon: Tailoring stacking fault energy for high ductility and high strength in ultrafine grained Cu and its alloy. Appl. Phys. Lett. 89, 121906 (2006).

K. Youssef, R. Scattergood, K. Murty, and C. Koch: Nanocrystalline Al–Mg alloy with ultrahigh strength and good ductility. Scr. Mater. 54, 251 (2006).

C. Koch, R. Scattergood, K. Darling, and J. Semones: Stabilization of nanocrystalline grain sizes by solute additions. J. Mater. Sci. 43, 7264 (2008).

T. Chookajorn, H.A. Murdoch, and C.A. Schuh: Design of stable nanocrystalline alloys. Science 337, 951 (2012).

A. Detor and C. Schuh: Microstructural evolution during the heat treatment of nanocrystalline alloys. J. Mater. Res. 22, 3233 (2007).

S. Zhao, C. Meng, F. Mao, W. Hu, and G. Gottstein: Influence of severe plastic deformation on dynamic strain aging of ultrafine grained Al–Mg alloys. Acta Mater. 76, 54 (2014).

P.V. Liddicoat, X-Z. Liao, Y. Zhao, Y. Zhu, M.Y. Murashkin, E.J. Lavernia, R.Z. Valiev, and S.P. Ringer: Nanostructural hierarchy increases the strength of aluminium alloys. Nat. Commun. 1, 63 (2010).

R.Z. Valiev, Y. Estrin, Z. Horita, T.G. Langdon, M.J. Zehetbauer, and Y. Zhu: Producing bulk ultrafine-grained materials by severe plastic deformation: Ten years later. JOM 68, 1216 (2016).

Z. Horita, T. Fujinami, M. Nemoto, and T.G. Langdon: Equal-channel angular pressing of commercial aluminum alloys: Grain refinement, thermal stability and tensile properties. Metall. Mater. Trans. A 31, 691 (2000).

T.J. Rupert, J.C. Trenkle, and C.A. Schuh: Enhanced solid solution effects on the strength of nanocrystalline alloys. Acta Mater. 59, 1619 (2011).

J. Hu, Y. Shi, X. Sauvage, G. Sha, and K. Lu: Grain boundary stability governs hardening and softening in extremely fine nanograined metals. Science 355, 1292 (2017).

C. Koch, D. Morris, K. Lu, and A. Inoue: Ductility of nanostructured materials. MRS Bull. 24, 54 (1999).

H. Wang, A. Tiwari, A. Kvit, X. Zhang, and J. Narayan: Epitaxial growth of TaN thin films on Si(100) and Si(111) using a TiN buffer layer. Appl. Phys. Lett. 80, 2323 (2002).

R. Valiev: Nanostructuring of metals by severe plastic deformation for advanced properties. Nat. Mater. 3, 511 (2004).

L. Lu, X. Chen, X. Huang, and K. Lu: Revealing the maximum strength in nanotwinned copper. Science 323, 607 (2009).

K. Lu, F. Yan, H. Wang, and N. Tao: Strengthening austenitic steels by using nanotwinned austenitic grains. Scr. Mater. 66, 878 (2012).

D. Bufford, Y. Liu, J. Wang, H. Wang, and X. Zhang: In situ nanoindentation study on plasticity and work hardening in aluminium with incoherent twin boundaries. Nat. Commun. 5, 4864 (2014).

I.J. Beyerlein, X. Zhang, and A. Misra: Growth twins and deformation twins in metals. Annu. Rev. Mater. Res. 44, 329 (2014).

X. Zhang, H. Wang, X. Chen, L. Lu, K. Lu, R. Hoagland, and A. Misra: High-strength sputter-deposited Cu foils with preferred orientation of nanoscale growth twins. Appl. Phys. Lett. 88, 173116 (2006).

Y. Zhang, J. Wang, H. Shan, and K. Zhao: Strengthening high-stacking-fault-energy metals via parallelogram nanotwins. Scr. Mater. 108, 35 (2015).

O. Anderoglu, A. Misra, F. Ronning, H. Wang, and X. Zhang: Significant enhancement of the strength-to-resistivity ratio by nanotwins in epitaxial Cu films. J. Appl. Phys. 106, 24313 (2009).

Q. Li, S.C. Xue, J. Wang, S. Shao, A.H. Kwong, A. Giwa, Z. Fan, Y. Liu, Z.M. Qi, J. Ding, H. Wang, J.R. Greer, H.Y. Wang, and X.H. Zhang: High-strength nanotwinned Al alloys with 9R phase. Adv. Mater. 30, 1704629 (2018).

L. Velasco and A.M. Hodge: Growth twins in high stacking fault energy metals: Microstructure, texture and twinning. Mater. Sci. Eng., A 687, 93 (2017).

D. Bufford, Z. Bi, Q. Jia, H. Wang, and X. Zhang: Nanotwins and stacking faults in high-strength epitaxial Ag/Al multilayer films. Appl. Phys. Lett. 101, 223112 (2012).

D. Bufford, Y. Liu, Y. Zhu, Z. Bi, Q. Jia, H. Wang, and X. Zhang: Formation mechanisms of high-density growth twins in aluminum with high stacking-fault energy. Mater. Res. Lett. 1, 51 (2013).

X. Zhang, D. Bufford, H. Wang, and Y. Liu: Method for Producing High Stacking Fault Energy (SFE) Metal Films, Foils, and Coatings with High-density Nanoscale Twin Boundaries. United States Patent No. 10023977 (2014).

K. Yu, D. Bufford, Y. Chen, Y. Liu, H. Wang, and X. Zhang: Basic criteria for formation of growth twins in high stacking fault energy metals. Appl. Phys. Lett. 103, 181903 (2013).

Y. Liu, D. Bufford, H. Wang, C. Sun, and X. Zhang: Mechanical properties of highly textured Cu/Ni multilayers. Acta Mater. 59, 1924 (2011).

K. Yu, Y. Liu, S. Rios, H. Wang, and X. Zhang: Strengthening mechanisms of Ag/Ni immiscible multilayers with fcc/fcc interface. Surf. Coat. Technol. 237, 269 (2013).

D. Medlin, G. Campbell, and C.B. Carter: Stacking defects in the 9R phase at an incoherent twin boundary in copper. Acta Mater. 46, 5135 (1998).

J. Wang, A. Misra, and J. Hirth: Shear response of Σ3 {112} twin boundaries in face-centered-cubic metals. Phys. Rev. B 83, 064106 (2011).

D. Bufford, H. Wang, and X. Zhang: High strength, epitaxial nanotwinned Ag films. Acta Mater. 59, 93 (2011).

O. Anderoglu, A. Misra, H. Wang, F. Ronning, M.F. Hundley, and X. Zhang: Epitaxial nanotwinned Cu films with high strength and high conductivity. Appl. Phys. Lett. 93, 083108 (2008).

S. Xue, W. Kuo, Q. Li, Z. Fan, J. Ding, R. Su, H. Wang, and X. Zhang: Texture-directed twin formation propensity in Al with high stacking fault energy. Acta Mater. 144, 226 (2018).

P. Gallagher: The influence of alloying, temperature, and related effects on the stacking fault energy. Metall. Trans. 1, 2429 (1970).

O. Johari and G. Thomas: Substructures in explosively deformed Cu and Cu–Al alloys. Acta Metall. 12, 1153 (1964).

A. Rohatgi, K.S. Vecchio, and G.T. Gray: The influence of stacking fault energy on the mechanical behavior of Cu and Cu–Al alloys: Deformation twinning, work hardening, and dynamic recovery. Metall. Mater. Trans. A 32, 135 (2001).

L. Velasco, M.N. Polyakov, and A.M. Hodge: Influence of stacking fault energy on twin spacing of Cu and Cu–Al alloys. Scr. Mater. 83, 33 (2014).

Y. Zhang, N.R. Tao, and K. Lu: Effect of stacking-fault energy on deformation twin thickness in Cu–Al alloys. Scr. Mater. 60, 211 (2009).

P-L. Sun, Y. Zhao, J. Cooley, M. Kassner, Z. Horita, T. Langdon, E. Lavernia, and Y. Zhu: Effect of stacking fault energy on strength and ductility of nanostructured alloys: An evaluation with minimum solution hardening. Mater. Sci. Eng., A 525, 83 (2009).

M. Chandran and S. Sondhi: First-principle calculation of stacking fault energies in Ni and Ni–Co alloy. J. Appl. Phys. 109, 103525 (2011).

T. Schulthess, P. Turchi, A. Gonis, and T-G. Nieh: Systematic study of stacking fault energies of random Al-based alloys. Acta Mater. 46, 2215 (1998).

G.H. Campbell, D.K. Chan, D.L. Medlin, J.E. Angelo, and C.B. Carter: Dynamic observation of the fcc to 9r shear transformation in a copper Σ = 3 incoherent twin boundary. Scr. Mater. 35, 837 (1996).

F. Ernst, M.W. Finnis, D. Hofmann, T. Muschik, U. Schönberger, U. Wolf, and M. Methfessel: Theoretical prediction and direct observation of the 9R structure in Ag. Phys. Rev. Lett. 69, 620 (1992).

J. Wang, O. Anderoglu, J.P. Hirth, A. Misra, and X. Zhang: Dislocation structures of Σ3 {112} twin boundaries in face centered cubic metals. Appl. Phys. Lett. 95, 021908 (2009).

J. Wang, N. Li, O. Anderoglu, X. Zhang, A. Misra, J. Huang, and J. Hirth: Detwinning mechanisms for growth twins in face-centered cubic metals. Acta Mater. 58, 2262 (2010).

L. Liu, J. Wang, S. Gong, and S. Mao: High resolution transmission electron microscope observation of zero-strain deformation twinning mechanisms in Ag. Phys. Rev. Lett. 106, 175504 (2011).

J. Gu, L. Zhang, S. Ni, and M. Song: Formation of large scaled zero-strain deformation twins in coarse-grained copper. Scr. Mater. 125, 49 (2016).

S. Xue, Z. Fan, O.B. Lawal, R. Thevamaran, Q. Li, Y. Liu, K. Yu, J. Wang, E.L. Thomas, and H. Wang: High-velocity projectile impact induced 9R phase in ultrafine-grained aluminium. Nat. Commun. 8, 1653 (2017).

K. Ma, H. Wen, T. Hu, T.D. Topping, D. Isheim, D.N. Seidman, E.J. Lavernia, and J.M. Schoenung: Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater. 62, 141 (2014).

M. Zha, Y. Li, R.H. Mathiesen, R. Bjørge, and H.J. Roven: Microstructure evolution and mechanical behavior of a binary Al–7Mg alloy processed by equal-channel angular pressing. Acta Mater. 84, 42 (2015).

R. Kapoor and J. Chakravartty: Deformation behavior of an ultrafine-grained Al–Mg alloy produced by equal-channel angular pressing. Acta Mater. 55, 5408 (2007).

G. Fan, H. Choo, P. Liaw, and E. Lavernia: Plastic deformation and fracture of ultrafine-grained Al–Mg alloys with a bimodal grain size distribution. Acta Mater. 54, 1759 (2006).

Z. Shan, E. Stach, J. Wiezorek, J. Knapp, D. Follstaedt, and S. Mao: Grain boundary-mediated plasticity in nanocrystalline nickel. Science 305, 654 (2004).

G.P.M. Leyson, W.A. Curtin, L.G. Hector, Jr., and C.F. Woodward: Quantitative prediction of solute strengthening in aluminium alloys. Nat. Mater. 9, 750 (2010).

R.L. Fleischer: Solution hardening by tetragonal dist ortions: Application to irradiation hardening in F.C.C. crystals. Acta Metall. 10, 835 (1962).

R.L. Fleischer: Substitutional solution hardening. Acta Metall. 11, 203 (1963).

E. Hall: The deformation and ageing of mild steel: III discussion of results. Proc. Phys. Soc., London, Sect. B 64, 747 (1951).

J. Wyrzykowski and M. Grabski: The Hall–Petch relation in aluminium and its dependence on the grain boundary structure. Philos. Mag. A 53, 505 (1986).

N. Hansen: Hall–Petch relation and boundary strengthening. Scr. Mater. 51, 801 (2004).

A. Misra, J. Hirth, and R. Hoagland: Length-scale-dependent deformation mechanisms in incoherent metallic multilayered composites. Acta Mater. 53, 4817 (2005).

M.D. Sangid, T. Ezaz, H. Sehitoglu, and I.M. Robertson: Energy of slip transmission and nucleation at grain boundaries. Acta Mater. 59, 283 (2011).

N. Tsuji, Y. Ito, Y. Saito, and Y. Minamino: Strength and ductility of ultrafine grained aluminum and iron produced by ARB and annealing. Scr. Mater. 47, 893 (2002).

R. Hayes, D. Witkin, F. Zhou, and E. Lavernia: Deformation and activation volumes of cryomilled ultrafine-grained aluminum. Acta Mater. 52, 4259 (2004).

M. Mata, M. Anglada, and J. Alcalá: Contact deformation regimes around sharp indentations and the concept of the characteristic strain. J. Mater. Res. 17, 964 (2002).

W. Yu, S. Shen, Y. Liu, and W. Han: Nonhysteretic superelasticity and strain hardening in a copper bicrystal with a Σ3 {112} twin boundary. Acta Mater. 124, 30 (2017).

ACKNOWLEDGMENTS

We acknowledge financial support from Department of Energy BES (Grant No. DE-SC0016337) on performing micropillar preparation experiments. Han W. and H.W. acknowledge the support from the Office of Naval Research (N00014-16-1-2778). Accesses to the Microscopy Facilities at School of Materials Engineering and Life Science at Purdue University are also acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Xue, S., Li, Q., Fan, Z. et al. Strengthening mechanisms and deformability of nanotwinned AlMg alloys. Journal of Materials Research 33, 3739–3749 (2018). https://doi.org/10.1557/jmr.2018.372

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.372