Abstract

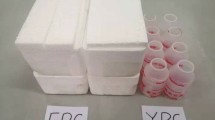

Ultrafine materials with unique characteristics have a broad range of utilization. The motivation of this paper was to investigate the size effect on the thermo-oxidative degradation behaviors and chemical kinetics of polystyrene (PS) solid particles. In this study, microscopic PS particles with four different-diameter distributions, containing 5, 10, 15, and 50 μm, were picked as tested samples. Then, the thermogravimetry analysis test of PS samples was conducted under an air atmosphere with three different heating rates. Activation energies were calculated and validated by multiple traditional kinetic approaches, and a linear relationship between activation energy and the reciprocal of the particle diameter has been concluded. A distributed activation energy model (DAEM) with two pseudo-components was developed and employed to decouple the polyurethane pyrolysis in the air atmosphere. A set of nth-order reactions is hypothesized to occur with a constant pre-exponential factor and having a continuous activation energy distribution pattern conforming to the Gaussian density function in each kinetic process. A multi-parameter optimization program was developed to calculate ten DAEM parameters based on the experimental data from three different heating rates by avoiding the ill condition resulting from the kinetic compensation effect. Moreover, the numerical relationship between activation energies and particle diameter has been analyzed. The results of this study are instructive for the determination method of kinetic triplets, the modification of reaction models, and especially the construction of waste polymer kinetics and combustion models.

Similar content being viewed by others

References

Zhang D, Jiang L, Lu S, Cao C-Y, Zhang H-P. Particle size effects on thermal kinetics and pyrolysis mechanisms of energetic 5-amino-1h-tetrazole. Fuel. 2018;217:553–60.

Huang C, Chen X, Yuan B, Zhang H, Dai H, He S, et al. Suppression of wood dust explosion by ultrafine magnesium hydroxide. J Hazard Mater. 2019;378: 120723.

Shafirovich E, Teoh SK, Varma A. Combustion of levitated titanium particles in air. Combust Flame. 2008;152(1–2):262–71.

Mishra DP, Azam S. Experimental investigation on effects of particle size, dust concentration and dust-dispersion-air pressure on minimum ignition temperature and combustion process of coal dust clouds in a GG furnace. Fuel. 2018;227:424–33.

Jang BN, Wilkie CA. The thermal degradation of polystyrene nanocomposite. Polymer. 2005;46(9):2933–42.

Kruse TM, Woo OS, Wong H-W, Khan SS, Broadbelt LJ. Mechanistic modeling of polymer degradation: a comprehensive study of polystyrene. Macromolecules. 2002;35(20):7830–44.

Faravelli T, Pinciroli M, Pisano F, Bozzano G, Dente M, Ranzi E. Thermal degradation of polystyrene. J Anal Appl Pyrol. 2001;60(1):103–21.

Kruse TM, Woo OS, Broadbelt LJ. Detailed mechanistic modeling of polymer degradation: application to polystyrene. Chem Eng Sci. 2001;56(3):971–9.

Schröder UK, Ebert KH, Hamielec AW. On the kinetics and mechanism of thermal degradation of polystyrene, 2. Formation of volatile compounds. Die Makromol Chem: Macromol Chem Phys. 1984;185(5):991–1001.

McNeill I, Zulfiqar M, Kousar T. A detailed investigation of the products of the thermal degradation of polystyrene. Polym Degrad Stab. 1990;28(2):131–51.

Zhou J, Qiao Y, Wang W, Leng E, Huang J, Yu Y, et al. Formation of styrene monomer, dimer and trimer in the primary volatiles produced from polystyrene pyrolysis in a wire-mesh reactor. Fuel. 2016;182:333–9.

Li M, Jiang L, He J-J, Sun J-H. Kinetic triplet determination and modified mechanism function construction for thermo-oxidative degradation of waste polyurethane foam using conventional methods and distributed activation energy model method. Energy. 2019;175:1–13.

Ozawa T. A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn. 1965;38(11):1881–6.

Flynn JH, Wall LA. General treatment of the thermogravimetry of polymers. J Res Nat Bur Stand. 1966;70(6):487–523.

Kissinger HE. Reaction kinetics in differential thermal analysis. Anal Chem. 1957;29(11):1702–6.

Akahira T, Sunose T. Method of determining activation deterioration constant of electrical insulating materials. Res Rep Chiba Inst Technol. 1971;16:22–31.

Wanjun T, Yuwen L, Hen Z, Cunxin W. New approximate formula for Arrhenius temperature integral. Thermochim Acta. 2003;408(1–2):39–43.

Wanjun T, Donghua C, Cunxin W. Kinetic study on the thermal dehydration of CaCO3· H2O by the master plots method. AIChE J. 2006;52(6):2211–6.

Friedman HL. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci Polym Symp. 1964;6:183–95.

Doyle C. Estimating thermal stability of experimental polymers by empirical thermogravimetric analysis. Anal Chem. 1961;33(1):77–9.

Doyle CD. Kinetic analysis of thermogravimetric data. J Appl Polym Sci. 1961;5(15):285–92.

Doyle CD. Series approximations to the equation of thermogravimetric data. Nature. 1965;207(4994):290.

Coats AW, Redfern JP. Kinetic parameters from thermogravimetric data. Nature. 1964;201(4914):68.

Farjas J, Roura P. Isoconversional analysis of solid state transformations. J Therm Anal Calorim. 2011;105(3):757–66.

Vyazovkin S. A unified approach to kinetic processing of nonisothermal data. Int J Chem Kinet. 1996;28(2):95–101.

Klinar D, Golob J, Krajnc M. The curing of diallylterephthalate determination of the kinetic triplet A, Ea, app, f (alpha) using the isoconversional method. Acta Chim Slov. 2003;50(3):473–90.

Li M, Liu L, Jiang L, Gou F-H, Sun J-H. Application of distributed activation energy models to polymer pyrolysis: effects of distributed model selection, characteristics, validation, and sensitivity analysis. Fuel. 2019;254: 115594.

Várhegyi G, Bobály B, Jakab E, Chen H. Thermogravimetric study of biomass pyrolysis kinetics. A distributed activation energy model with prediction tests. Energy Fuels. 2010;25(1):24–32.

Nugroho YS, McIntosh A, Gibbs B. Low-temperature oxidation of single and blended coals. Fuel. 2000;79(15):1951–61.

Kissinger HE. Variation of peak temperature with heating rate in differential thermal analysis. J Res Natl Bur Stand. 1956;57(4):217–21.

Acknowledgements

The authors would like to thank the National Natural Science Foundation of China (NSFC, Grants 52306145, 52176114), Natural Science Foundation of Jiangsu Province (BK20230929), China Postdoctoral Science Foundation (2023M731693), and the Jiangsu Funding Program for Excellent Postdoctoral Talent.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, M., Zhang, D., Han, ZX. et al. Thermal oxidation characteristics of polystyrene with different particle sizes based on the traditional kinetic approaches and distributed activation energy model. J Therm Anal Calorim 149, 993–1001 (2024). https://doi.org/10.1007/s10973-023-12755-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12755-4