Abstract

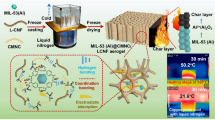

The microencapsulation of flame retardants can avoid the problems of water absorption and loss. In this paper, hydrophobic microcapsule-encapsulated ammonium polyphosphate (HMAPP) was prepared by ion exchange and Stöber method and applied to the preparation of hydrophobic flame-retardant kraft paper by impregnation. The microscopic morphology and element analysis of the hydrophobic microcapsules tested by TEM and SEM showed that nano-scale particles with a size of about 100 nm have been successfully prepared, and the core–shell structure has been formed. HMAPP constructed a rough structure with low surface energy on the surface of kraft paper and provided the kraft paper with hydrophobic property. The water contact angle of kraft paper reached 122.7 ° after treated by HMAPP, while it also enhanced the physical strength of the paper. Kraft had the self-extinguishing phenomenon after treated by HMAPP, which attached to the surface of kraft paper were heated and melted to release ammonia to dilute combustible gas and oxygen, and formed a flame-retardant layer containing SiO2 particles, phosphoric acid, metaphosphoric acid, pyrophosphoric acid, and carbon flakes on the fiber surface. There were C–C, C–O–C bonds in the carbon layer after flame-retardant treatment, indicating that the pentose contained in fiber has not been completely destroyed. In addition, the presence of Si and P elements in the residual carbon indicates that the decomposed flame retardant adheres to the surface of the fiber to block the heat transfer and flame spread.

Similar content being viewed by others

References

Zhao P, Li X, Zhang M, Liu S, Liang W, Liu Y. Highly flame-retarding cotton fabrics with a novel phosphorus/nitrogen intumescent flame retardant. Korean J Chem Eng. 2014;31:1592–7.

Jiang W, Jin F, Park S. Synthesis of a novel phosphorus-nitrogen-containing intumescent flame retardant and its application to fabrics. J Ind Eng Chem. 2015;27:40–3.

Qiu X, Li Z, Li X, Zhang Z. Flame retardant coatings prepared using layer by layer assembly: a review. Chem Eng J. 2018;334:108–22.

Weil ED. Fire-protective and flame-retardant coatings - a state-of-the-art review. J Fire Sci. 2010;29:259–96.

Alongi J, Malucelli G. Cotton flame retardancy: state of the art and future perspectives. RSC Adv. 2015;5:24239–63.

Shao N, Xue F, Hou L, Li D, Gao Y, Zhu X. Effects of ternary potassium containing intumescent flame retardant coating on the combustion and thermal degradation properties of reconstituted tobacco sheet. Thermochim Acta. 2019;678: 178310.

Li L, Hu H, Hu H. Effect of ammonium polyphosphate modified with 3-(Methylacryloxyl) propyltrimethoxy silane on the flammability and thermal degradation of pine-needles. Polym Polym Compos. 2014;22:837–42.

Zhou L, Guo C, Li L. Influence of ammonium polyphosphate modified with 3-(methylacryloxyl) propyltrimethoxy silane on mechanical and thermal properties of wood flour–polypropylene composites. J Appl Polym Sci. 2011;122:849–55.

Jiang D, Pan M, Cai X, Zhao Y. Flame retardancy of rice straw-polyethylene composites affected by in situ polymerization of ammonium polyphosphate/silica. Compos A Appl Sci Manuf. 2018;109:1–9.

Guan Y, Huang J, Yang J, Shao Z, Wang Y. An effective way to flame-retard biocomposite with ethanolamine modified ammonium polyphosphate and its flame retardant mechanisms. Ind Eng Chem Res. 2015;54:3524–31.

Sun Y, Yuan B, Shang S, Zhang H, Shi Y, Yu B, et al. Surface modification of ammonium polyphosphate by supramolecular assembly for enhancing fire safety properties of polypropylene. Compos B Eng. 2020;181: 107588.

Jiang M, Zhang Y, Yu Y, Zhang Q, Huang B, Chen Z, et al. Flame retardancy of unsaturated polyester composites with modified ammonium polyphosphate, montmorillonite, and zinc borate. J Appl Polym Sci. 2019;136:47180.

Yang G, Liu J, Xu B, Liu Z, Ma F, Zhang Q. Effect of silicon-containing nitrogen and phosphorus flame-retardant system on the mechanical properties and thermal and flame-retardant behaviors of corrugated cardboard. J Therm Anal Calorim. 2020;145(5):2321–34.

Liu Z, Dai M, Hu Q, Liu S, Gao X, Ren F, et al. Effect of microencapsulated ammonium polyphosphate on the durability and fire resistance of waterborne intumescent fire-retardant coatings. J Coat Technol Res. 2019;16:135–45.

Wang B, Sheng H, Shi Y, Hu W, Hong N, Zeng W, et al. Recent advances for microencapsulation of flame retardant. Polym Degrad Stab. 2015;113:96–109.

Yan H, Wei J, Yin B, Yang M. Effect of the surface modification of ammonium polyphosphate on the structure and property of melamine–formaldehyde resin microencapsulated ammonium polyphosphate and polypropylene flame retardant composites. Polym Bull. 2015;72:2725–37.

Chen D, Li J, Ren J. Combustion properties and transference behavior of ultrafine microencapsulated ammonium polyphosphate in ramie fabric-reinforced poly(L-lactic acid) biocomposites. Polym Int. 2011;60:599–606.

Ma X, Kirker GT, Jiang M, Wu Y. Dual protection of wood surface treated with melamine-modified urea-formaldehyde resin mixed with ammonium polyphosphate against both fire and decay. For Prod J. 2016;66:280–3.

Liu X, Hao J, Gaan S. Recent studies on the decomposition and strategies of smoke and toxicity suppression for polyurethane based materials. RSC Adv. 2016;6:74742–56.

Chen P, Yan K, Leng J, Zhang F, Jiao L. Synergistic smoke suppression effect of epoxy cross-linked structure and ferrocene on epoxy-based intumescent flame-retardant coating. Plast Rubber Compos. 2018;47:258–65.

Singh H, Jain AK. Ignition, combustion, toxicity, and fire retardancy of polyurethane foams: a comprehensive review. Journal of applied polymer science. 2008;111(2):1115.

Agulhon P, Robitzer M, David L, Quignard F. structural regime identification in ionotropic alginate gels: influence of the cation nature and alginate structure. Biomacromol. 2011;13:215–20.

Wang Q, Zhang L, Liu Y, Zhang G, Zhu P. Characterization and functional assessment of alginate fibers prepared by metal-calcium ion complex coagulation bath. Carbohyd Polym. 2020;232: 115693.

Ehterami A, Salehi M, Farzamfar S, Samadian H, Vaez A, Sahrapeyma H, et al. A promising wound dressing based on alginate hydrogels containing vitamin D3 cross-linked by calcium carbonate/d-glucono-δ-lactone. Biomed Eng Lett. 2020;10:309–19.

Zou X, Tao C, Yan L, Yang F, Lv H, Yan H, et al. One-step sol-gel preparation of ultralow-refractive-index porous coatings with mulberry-like hollow silica nanostructures. Surf Coat Technol. 2018;341:57–63.

Fang F, Xiao D, Zhang X, Meng Y, Cheng C, Bao C, et al. Construction of intumescent flame retardant and antimicrobial coating on cotton fabric via layer-by-layer assembly technology. Surf Coat Technol. 2015;276:726–34.

Zhu H, Xu S. Preparation of flame-retardant rigid polyurethane foams by combining modified melamine-formaldehyde resin and phosphorus flame retardants. ACS Omega. 2020;5:9658–67.

Zhou S, Ning M, Xu Y, Hu Y, Shu J, Wang C, et al. Thermal degradation and combustion behavior of reconstituted tobacco sheet treated with ammonium polyphosphate. J Anal Appl Pyrol. 2013;100:223–9.

Rosace G, Castellano A, Trovato V, Iacono G, Malucelli G. Thermal and flame retardant behaviour of cotton fabrics treated with a novel nitrogen-containing carboxyl-functionalized organophosphorus system. Carbohyd Polym. 2018;196:348–58.

Wang N, Liu Y, Xu C, Liu Y, Wang Q. Acid-base synergistic flame retardant wood pulp paper with high thermal stability. Carbohyd Polym. 2017;178:123–30.

Zhao B, Liu Y, Zhang C, Liu D, Li F, Liu Y. A novel phosphoramidate and its application on cotton fabrics: synthesis, flammability and thermal degradation. J Anal Appl Pyrol. 2017;125:109–16.

Colleoni C, Donelli I, Freddi G, Guido E, Migani V, Rosace G. A novel sol-gel multi-layer approach for cotton fabric finishing by tetraethoxysilane precursor. Surf Coat Technol. 2013;235:192–203.

Tan Y, Shao Z, Yu L, Long J, Qi M, Chen L, et al. Piperazine-modified ammonium polyphosphate as monocomponent flame-retardant hardener for epoxy resin: flame retardance, curing behavior and mechanical property. Polym Chem. 2016;7:3003–12.

Pham LH, Pham LT, Hoang D, Kim J. Effective phosphorus/phosphorus-nitrogen fire retardants applied to biocomposites based on polypropylene-wood flour: flammability, thermal behavior, and mechanical properties. Macromol Res. 2019;27:1185–92.

Acknowledgements

The authors gratefully acknowledge Moe Key Laboratory of Wooden Material Science and Application, Beijing Forestry University, China.

Funding

This work was supported by the National Natural Science Foundation of China [No. 31670564].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, G., Zhang, Q., Li, Y. et al. Hydrophobic microcapsule modification of nitrogen–phosphorus flame retardant and its application in lignocellulosic materials. J Therm Anal Calorim 147, 13217–13229 (2022). https://doi.org/10.1007/s10973-022-11761-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11761-2