Abstract

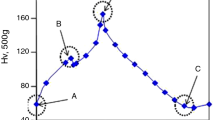

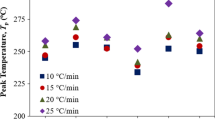

2219Al alloys microalloyed with varying Cd contents were processed by casting technique. Differential scanning calorimetry (DSC) was performed from 323 to 823 K at four different heating rates of 283, 289, 293 and 298 K min−1, to investigate the precipitation kinetics of the alloys. The heating cycle of DSC curves exhibited an endothermic peak in the intermediate temperature range from 603 to 713 K corresponding to the precipitation reaction, whereas an endothermic drift at elevated temperatures representing melting of the alloy phases. All the peak temperatures increased with an increase in heating rate, indicating the precipitation reaction to be kinetically controlled. A new methodology was proposed to model the kinetic rate equation, governing the endothermic precipitation peaks. Activation energy and related kinetic parameters were evaluated for the alloys, and the influence of Cd additions was investigated. Activation energy was observed to decrease by around 8.3%, due to microalloying with 0.06 mass% of Cd, thus kinetically favouring the precipitation reaction. Functional forms of mole fraction transformed were optimized, so that the present model of rate equation may achieve a proper fit with the experimental results of the corresponding reaction peaks. The transformation rate predicted from the rate equation and the estimated kinetic parameters, was successfully compared with the experimental data with fairly good accuracy. Such correlation with the experimental results validates the adapted analytical procedure, establishes the confidence and prediction capability of the present kinetic model and the accuracy of the kinetic parameters evaluated. X-ray diffraction (XRD) studies were resorted on the age-hardened alloys, to identify the possible precipitating phase(s). XRD patterns indicated the precipitation of θ-phase (CuAl2) within the Al matrix, which controlled the strengthening mechanism. The DSC and XRD results were further supported with the microstructural characterization of morphology and composition of different phases, as observed under SEM and EDS analysis. Trace contents of Cd exhibited to have significant potential to control the precipitation kinetics, activation energy, precipitating phases and respective microstructural evolution of the investigated 2219Al alloy system, during age-hardening treatment.

Similar content being viewed by others

Data availability

Not Applicable.

Code availability

Not Applicable.

References

Elagin VI. Ways of developing high-strength and high-temperature structural aluminium alloys in the 21st century. Met Sci Heat Treat. 2007;49:427–34.

Ron CC, Banbury CA. Aluminum: Physical Properties, Characteristics and alloys. Euro Alum Asst 1994;1–60.

Rambabu P, Prasad NE, Kutumbarao VV, Wanhill RJH. Aluminium alloys for aerospace applications. Aero Mat Mat Tech. 2017;1:29–52.

Rafael N, Adams JH, Ammons M, Avery HS, Barnhurst RJ, Bean JC, Wu MH. Metals handbook properties and selection: non-ferrous alloys and special purpose materials. Netharland: ASM International; 1990. p. 507–63.

Banerjee S, Robi PS, Srinivasan A, Lakavath PK. Effect of trace additions of Sn on microstructure and mechanical properties of Al-Cu-Mg alloys. Mat Des. 2010;31:4007–15.

Kaibyshev RI, Kazakulov D, Gromov F, Muskin DR, Neih LTG. Superplasticity in 2219 Al-Alloys. Script Matter. 2001;44:2411–7.

Sercombe TB, Schaffer GB. On the use of trace additions of Sn to enhance sintered 2xxx series Al powder alloys. Mat Sci Eng A. 1999;268:32–9.

Raju PN, Rao KS, Reddy GM, Kamaraj M, Rao KP. Microstructure and high temperature stability of age-hardenable AA2219 aluminium alloy modified by Sc, Mg and Zr additions. Mat Sci Eng A. 2007;464:192–201.

Miao LX, Lin PQ, Ge LC, Bin HY, Bin LW, Jie LW. Microstructure and mechanical properties of Al-Cu-Mg-Mn-Zr alloy with trace amounts of Ag. Mat Sci Eng A. 2009;525:128–32.

Vietz JT, Polmear IJ. The influence of small additions of silver on the ageing of aluminium alloys. J I Met. 1966;94(12):410–8.

Miao WF, Laughlin DE. Effects of Cu content and presaging on precipitation characteristics in aluminium alloy 6022. Metall Mat Trans A. 2000;31((A)):361–71.

Wilm A. German patent. Patent no: DRP244554. Germany.1906.

Hornbogen E. Hundred years of precipitation hardening. J Li Met. 2012;1:127–32.

Callister WD. Mat Sci Engg: an introduction. In: 2nd ed. Wiley:New Jersey; 1997.

Unlu N, Gable BM, Shiflet GJ, Starke EA. The effect of cold work on the precipitation of Ω and θ’ in a ternary Al-Cu-Mg alloy. Metall Mat Trans A. 1990;34(12):2757–69.

Chakrabarti DJ, Cheong BK, Laughlin DE. Precipitation strengthening of aluminium alloys AA6111. Auto Alloys. 1998;II:27–44.

Reich L, Ringer SP, Hono K. Origin of the initial rapid age-hardening in an Al-1.7at.%Mg-1.1at.% Cu alloy. Phil Magazine Let A. 1999;79:639–44.

Papazian JM. Calorimetric studies of precipitation and dissolution kinetics in aluminum alloys 2219 and 7075. Metall Trans A. 1981;12(2):269–80.

Kissinger HE. Reaction Kinetics in Differential Thermal Analysis. Anal Chem. 1957;29(11):1702–6.

Donoso E. Calorimetric study of the dissolution of Guinier-Preston zones and η′ phase in Al-4.5at.%Zn-1.75at.%Mg. Mat Sci Eng. 1985;74:39–41.

Varschavsky A, Donoso E. Non-isothermal short-range-order kinetics of binary alloys as influenced by solute-vacancy complexes Thermochim. Acta Mater. 1983;69:341–6.

Johnson WA, Mehl KF. Calorimetric study of precipitation kinetics of Al-Cu-Mg and Al-Cu-Mg-006 wt% Sn alloys. Trans TMS AIME. 1939;135:416–22.

Avrami M. Kinetics of phase change. I General Theory J Chem Phys. 1939;7:177.

Clout A, Buanz ABM, Timothy JP, Reinhard C. Simultaneous differential scanning calorimetry-synchrotron X-ray powder diffraction: a powerful technique for physical form characterisation in pharmaceutical materials. Anal Chem. 2016;88:10111–7.

Gaber A, Gaffar MA, Mostafa MS, Zeid EFA. Precipitation kinetics of Al–1.12 Mg2Si–0.35 Si and Al–1.07 Mg2Si–033 Cu alloys. J Al Com. 2007;429:167–75.

Gupta AK, Lloyd DJ. Study of precipitation kinetics in a super puity A1–08 Pct Mg-09 Pct Si alloy using differential scanning calorimetry. Metall Mat Trans A. 1999;30A:879–84.

Luo A, Lloyd DJ, Gupta A, Youdelis WV. Precipitation and dissolution kinetics in Al-Li-Cu-Mg alloy 8090. Acta Mater. 1993;41:769–76.

Hutchinson CR, Ringer SP. Precipitation processes in Al-Cu-Mg alloys microalloyed with Si. Metall Mat Trans A. 2000;31:2721–3.

Bassani E, Gariboldi RD. Thermal analysis of Al-Cu-Mg-Si alloy with Ag/Zr additions. J Therm Anal Cal. 2008;91:29–35.

Li W, Cui SJ, Han, Xu C. Effect of silicon on the casting properties of Al-50%Cu alloy. Rare Met, 2006;25;133–135.

Mohamed AMA, Samuel FH, Samuel AM, Doty HW, Valtierra S. Influence of Tin addition on the microstructure and mechanical properties of Al-Si-Cu-Mg and Al-Si-Mg casting alloys. Metall Mater Trans A. 2008;39(3):490–501. https://doi.org/10.1007/s11661-007-9454-5.

Wang J, Yi D, Su X, Yin F. Influence of deformation ageing treatment on microstructure and properties of aluminium alloy 2618. Mat Chart. 2008;59:965–8.

Banerjee S. Mechanical Properties and High Temperature Deformation Behaviour of Al-Cu-Mg Alloys Microalloyed with Tin Doctoral Thesis. Assam: IIT Guwahati; 2011. p. 25–176.

Banerjee S, Robi PS, Srinivasan A. Calorimetric Study of Precipitation Kinetics of Al-Cu-Mg and Al-Cu-Mg-0.06 wt.% Sn Alloys. Met Mat Int. 2010;16(4):523–31.

Ghosh KS, Gao N. Determination of kinetic parameters from calorimetric study of solid state reactions in 7150 Al-Zn-Mg alloy. Trans Nonferrous Met Soc. 2011;21:1199–209.

Silva RAG, Adorno AT, Carvalho TM. Precipitation reaction in alpha-Cu-Al-Ag alloys. Revi Matéria. 2011;16(3):747–53.

Bhowmick S. DSC and XRD analysis of Al-Cu alloys microalloyed with Cd M Tech thesis. Assam: Tezpur University; 2019. p. 1–60.

Maksimovic V, Slavicazec V, Radmilovic Jovanovic MT. The effect of microalloying with silicon and germanium on microstructure and hardness of a commercial aluminium alloy. J Serb Chem Soc. 2003;68(11):893–901.

Mondolfo LF. Aluminum alloys: structure and properties. 1st ed. London: Butterworths; 1976.

Mandal PK, Robi PS. Influence of microalloying with silver on microstructure and mechanical properties of Al-Cu alloy. Mat Sci Eng A. 2018;722:99–111.

Murray JL. Experimental Description of the Al-Cu Binary Phase Diagram. Int Met Rev. 1985;30:211–34.

Gogoi S. Effect of Rolling and Age-Hardening on the Mechanical Properties of Microalloyed 2219Al Alloy. M.Tech Thesis. Assam: Tezpur University; 2017. p. 10–176.

Acknowledgements

The authors are thankful to the Department of Mechanical Engineering, Tezpur University, for the useful assistance in various experimental procedures. Authors further express their gratitude to the Department of Physics and Sophisticated Analytical Instrumentation Centre (SAIC), Tezpur University, for performing XRD and SEM analysis. The authors acknowledge the help received from the Department of Mechanical Engineering, IIT Guwahati, during preparation of DSC samples.

Funding

This research work was supported by Department of Science and Technology (DST) [Grant no: SERC/ET-0403/2012, Year: 2013].

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by SG, SB and SB. The first draft of the manuscript was written by SG, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflicts of interest

Not Applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gogoi, S., Banerjee, S. & Bhowmick, S. Modelling precipitation kinetics and investigating age-hardening behaviour of 2219Al alloys microalloyed with Cd. J Therm Anal Calorim 147, 12437–12453 (2022). https://doi.org/10.1007/s10973-022-11449-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11449-7