Abstract

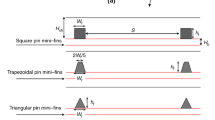

In this study, the flow pattern and heat transfer enhancement of a non-Newtonian nanofluid in the presence of fins in a corrugated channel were numerically investigated. The fluid flow is in the hydraulically laminar regime, and the channel is under a constant heat flux. A set of case studies are conducted for the flow through the corrugated channel to analyze the effect of the main contributing factors; Reynolds number, the number of corrugation, the height of fin, the arrangement of fins (Cases A, B, and C), and the nanofluid volume fraction, on the flow field and the heat transfer characteristics as well. Comparing the results of the finned cases with different cases (without fins) indicates that implementing fins leads to a considerable change in the flow and temperature fields, resulting in the enhancement of heat transfer. Furthermore, results showed that using two corrugations in the channel provides a better heat transfer rate than other corrugation numbers. The results indicate that increasing the height of fins from 5 to 10 mm, changes the flow pattern and velocity distribution in the vicinity of the fins, and the maximum velocity occurs right on the head of the fins. Moreover, the results show that by increasing the height of fins, the pressure drop increases in the vicinity of fins. The bulk temperature in the vicinity of the corrugations is higher than in other regions, and by increasing the height of fins, the maximum bulk temperature decreases in these regions. Besides, increasing the nanofluid volume fraction and Reynolds number increases the local and mean Nusselt numbers. Moreover, it was found that the maximum value of \({{{\text{Nu}}_{{{\text{m}}\_{\text{fin}}}} } \mathord{\left/ {\vphantom {{{\text{Nu}}_{{{\text{m}}\_{\text{fin}}}} } {{\text{Nu}}_{{\text{m}}} }}} \right. \kern-\nulldelimiterspace} {{\text{Nu}}_{{\text{m}}} }}\), at the highest Reynolds number (Re = 1000) occurs for case B with a fin height of Z = 7.5 mm. The results show that by optimizing the arrangement of fins, the mean Nusselt number can be improved 25.7 and 49.7%, compared to rectangular channel and smooth channel, respectively.

Similar content being viewed by others

Abbreviations

- \(c_{{\text{P}}}\) :

-

Specific heat coefficient \(({\text{J}} \,{\text{kg}}^{-1} \,{\text{K}}^{-1})\)

- \(h_{{\text{x}}}\) :

-

Local heat transfer coefficient (\({{\text{W}}{\text{m}}}^{{-2}}{\text{K}}^{{-1}}\))

- \(H\) :

-

Height of channel (\({\text{m}}\))

- \(K\) :

-

Thermal conductivity (\({{\text{W}}{\text{m}}}^{{-1}}{\text{K}}^{{-1}}\)),

- \(L_{1}\) :

-

Entrance length of channel (\({\text{m}}\))

- \(L_{2}\) :

-

Length of channel (\({\text{m}}\))

- \(L_{3}\) :

-

Exit length of channel (\({\text{m}}\))

- \(n\) :

-

Power-law index

- \({\text{Nu}}\) :

-

Nusselt number

- \(P\) :

-

Pressure (\({\text{Pa}}\))

- Pr:

-

Prandtl number

- \(q^{\prime\prime}\) :

-

Heat flux \(({{\text{W}}{\text{m}}}^{{-2}})\)

- \({\text{Re}}\) :

-

Reynolds number

- \(u\) :

-

U-component of the velocity vector (\({\text{m}}{\text{s}}^{-1}\))

- \(U\) :

-

Velocity magnitude (\({\text{m/s}}\))

- \(v\) :

-

Y-component of the velocity vector (\({\text{ms}}^{-1}\))

- \(W\) :

-

Fin thickness (\({\text{m}}\))

- \(x\) :

-

X coordinate (\({\text{m}}\))

- \(y\) :

-

Y coordinate (\({\text{m}}\))

- \(Z\) :

-

Height of fin (\({\text{m}}\))

- \(\varphi\) :

-

Volume fraction

- \(\kappa_{{\text{b}}}\) :

-

Boltzmann constant (\({\text{m}}^{2} \,{\text{kg}}\, {\text{s}}^{-2}\, {\text{K}}^{-1}\))

- \(\mu\) :

-

Dynamic viscosity (\({\text{N}}{\text{m}}\,{\text{s}}^{-1}\))

- \(\rho\) :

-

Density (\({\text{kg\,m}}^{-3}\))

- \(\tau\) :

-

Shear stress (\({\text{N\.m}}^{-2}\))

- \(T\) :

-

Temperature (\({\text{K}}\))

- \(_{{{\text{in}}}}\) :

-

Local value at inlet

- \(f\) :

-

Base fluid

- \(m\) :

-

Mean

- \({\text{nf}}\) :

-

Nanofluid

- \({\text{out}}\) :

-

Local value at outlet

- \(p\) :

-

Nanoparticle

References

Mozafari H, Eyvazian A, Hamouda AM, Crupi V, Epasto G, Gugliemino E. Numerical and experimental investigation of corrugated tubes under lateral compression. Int J Crashworthiness. 2018;23(4):461–73. https://doi.org/10.1080/13588265.2017.1345592.

Wang W, Zhang Y, Liu J, Wu Z, Li B, Sundén B. Entropy generation analysis of fully-developed turbulent heat transfer flow in inward helically corrugated tubes. Numer Heat Transf Part A Appl. 2018;73(11):788–805. https://doi.org/10.1080/10407782.2018.1459137.

Han H, Yang L, Chen X, Li B. Numerical and experimental study of flow and heat transfer in outwardly convex corrugated tubes with a twisted tape insert. Heat Transf Res. (2018). https://doi.org/10.1615/HeatTransRes.2018020644

Salami M, Khoshvaght-Aliabadi M, Feizabadi A. Investigation of corrugated channel performance with different wave shapes. J Therm Anal Calorim. 2019;138(5):3159–74. https://doi.org/10.1007/s10973-019-08361-y.

Hilo AK, Iborra AA, Sultan MT, Hamid MF. Effect of corrugated wall combined with backward-facing step channel on fluid flow and heat transfer. Energy. 2020;1(190):116294. https://doi.org/10.1016/j.energy.2019.116294.

Ajeel RK, Salim WI. Experimental assessment of heat transfer and pressure drop of nanofluid as a coolant in corrugated channels. J Therm Anal Calorim. 2020;13:1–3. https://doi.org/10.1007/s10973-020-09656-1.

Pahlevaninejad N, Rahimi M, Gorzin M. Thermal and hydrodynamic analysis of non-Newtonian nanofluid in wavy microchannel. J Therm Anal Calorim. 2020;9:1–5. https://doi.org/10.1007/s10973-019-09229-x.

Yang D, Pettersen B, Andersson HI, Narasimhamurthy VD. Analysis of vortex splitting characteristics in the wake of an inclined flat plate using Hilbert-Huang transform. Acta Mech. 2015;226(4):1085–104. https://doi.org/10.1007/s00707-014-1222-1.

Ali MS, Anwar Z, Mujtaba MA, Soudagar ME, Badruddin IA, Safaei MR, Iqbal A, Afzal A, Razzaq L, Khidmatgar A, Goodarzi M. Two-phase frictional pressure drop with pure refrigerants in vertical mini/micro-channels. Case Stud Therm Eng. 2021;1(23):100824. https://doi.org/10.1016/j.csite.2020.100824.

Miansari M, Aghajani H, Zarringhalam M, Toghraie D. Numerical study on the effects of geometrical parameters and Reynolds number on the heat transfer behavior of carboxy-methyl cellulose/CuO non-Newtonian nanofluid inside a rectangular microchannel. J Therm Anal Calorim. 2020;27:1–9. https://doi.org/10.1007/s10973-020-09447-8.

Hader M, Al-Kouz W. Performance of a hybrid photovoltaic/thermal system utilizing water-Al2O3 nanofluid and fins. Int J Energy Res. 2019;43(1):219–30. https://doi.org/10.1002/er.4253.

Tian MW, Rostami S, Aghakhani S, Goldanlou AS, Qi C. A techno-economic investigation of 2D and 3D configurations of fins and their effects on heat sink efficiency of MHD hybrid nanofluid with slip and non-slip flow. Int J Mech Sci. 2020;25:105975. https://doi.org/10.1016/j.ijmecsci.2020.105975.

Nygård F, Andersson HI. Numerical investigations of laminar flow characteristics in helically finned pipes. Acta Mech. 2011;222(3–4):321–30. https://doi.org/10.1007/s00707-011-0534-7.

Buyruk E, Karabulut K. Research of heat transfer augmentation in plate fin heat exchangers having different fin types. J Eng Thermophys. 2020;29(2):316–30. https://doi.org/10.1134/S1810232820020137.

Shamsabadi H, Rashidi S, Esfahani JA. Entropy generation analysis for nanofluid flow inside a duct equipped with porous baffles. J Therm Anal Calorim. 2019;135(2):1009–19. https://doi.org/10.1007/s10973-018-7350-4.

Ghanbari S, Javaherdeh K. Investigation of applying nanoporous graphene non-Newtonian nanofluid on rheological properties and thermal performance in a turbulent annular flow with perforated baffles. J Therm Anal Calorim. 2020;139(1):629–47. https://doi.org/10.1007/s10973-019-08389-0.

Rashidi S, Akbarzadeh M, Karimi N, Masoodi R. Combined effects of nanofluid and transverse twisted-baffles on the flow structures, heat transfer and irreversibilities inside a square duct–a numerical study. Appl Therm Eng. 2018;5(130):135–48. https://doi.org/10.1016/j.applthermaleng.2017.11.048.

Shamsi MR, Akbari OA, Marzban A, Toghraie D, Mashayekhi R. Increasing heat transfer of non-Newtonian nanofluid in rectangular microchannel with triangular ribs. Phys E. 2017;1(93):167–78. https://doi.org/10.1016/j.physe.2017.06.015.

Sheikholeslami M, Keramati H, Shafee A, Li Z, Alawad OA, Tlili I. Nanofluid MHD forced convection heat transfer around the elliptic obstacle inside a permeable lid drive 3D enclosure considering lattice Boltzmann method. Phys A. 2019;1(523):87–104. https://doi.org/10.1016/j.physa.2019.02.014.

Sheikholeslami M. Influence of magnetic field on Al2O3-H2O nanofluid forced convection heat transfer in a porous lid driven cavity with hot sphere obstacle by means of LBM. J Mol Liq. 2018;1(263):472–88. https://doi.org/10.1016/j.molliq.2018.04.111.

Hoseinzadeh S, Otaghsara ST, Khatir MZ, Heyns PS. Numerical investigation of thermal pulsating alumina/water nanofluid flow over three different cross-sectional channel. Int J Numer Meth Heat Fluid Flow. 2019. https://doi.org/10.1108/HFF-09-2019-0671.

Sarafraz MM, Safaei MR, Tian Z, Goodarzi M, Bandarra Filho EP, Arjomandi M. Thermal assessment of nano-particulate graphene-water/ethylene glycol (WEG 60: 40) nano-suspension in a compact heat exchanger. Energies. 2019;12(10):1929. https://doi.org/10.3390/en12101929.

Goodarzi M, Tlili I, Tian Z, Safaei MR. Efficiency assessment of using graphene nanoplatelets-silver/water nanofluids in microchannel heat sinks with different cross-sections for electronics cooling. Int J Numer Meth Heat Fluid Flow. 2019. https://doi.org/10.1108/HFF-12-2018-0730.

Sarafraz MM, Tian Z, Tlili I, Kazi S, Goodarzi M. Thermal evaluation of a heat pipe working with n-pentane-acetone and n-pentane-methanol binary mixtures. J Therm Anal Calorim. 2020;139(4):2435–45. https://doi.org/10.1007/s10973-019-08414-2.

Ahmadi MH, Mohseni-Gharyehsafa B, Ghazvini M, Goodarzi M, Jilte RD, Kumar R. Comparing various machine learning approaches in modeling the dynamic viscosity of CuO/water nanofluid. J Therm Anal Calorim. 2020;139(4):2585–99. https://doi.org/10.1007/s10973-019-08762-z.

Ahmed HE, Yusoff MZ. Impact of delta-winglet pair of vortex generators on the thermal and hydraulic performance of a triangular channel using Al2O3–water nanofluid. J Heat Transf. (2014). https://doi.org/10.1115/1.4025434

Bahiraei M, Jamshidmofid M, Goodarzi M. Efficacy of a hybrid nanofluid in a new microchannel heat sink equipped with both secondary channels and ribs. J Mol Liq. 2019;1(273):88–98. https://doi.org/10.1016/j.molliq.2018.10.003.

Tahir S, Mital M. Numerical investigation of laminar nanofluid developing flow and heat transfer in a circular channel. Appl Therm Eng. 2012;1(39):8–14. https://doi.org/10.1016/j.applthermaleng.2012.01.035.

Bahmani MH, Sheikhzadeh G, Zarringhalam M, Akbari OA, Alrashed AA, Shabani GA, Goodarzi M. Investigation of turbulent heat transfer and nanofluid flow in a double pipe heat exchanger. Adv Powder Technol. 2018;29(2):273–82. https://doi.org/10.1016/j.apt.2017.11.013.

Bagherzadeh SA, Jalali E, Sarafraz MM, Akbari OA, Karimipour A, Goodarzi M, Bach QV. Effects of magnetic field on micro cross jet injection of dispersed nanoparticles in a microchannel. Int J Numer Meth Heat Fluid Flow. 2019. https://doi.org/10.1108/HFF-02-2019-0150.

Pour MS, Nassab SG. Numerical investigation of forced laminar convection flow of nanofluids over a backward facing step under bleeding condition. J Mech. 2012;28(2):N7-12. https://doi.org/10.1017/jmech.2012.45.

Togun H, Safaei MR, Sadri R, Kazi SN, Badarudin A, Hooman K, Sadeghinezhad E. Numerical simulation of laminar to turbulent nanofluid flow and heat transfer over a backward-facing step. Appl Math Comput. 2014;15(239):153–70. https://doi.org/10.1016/j.amc.2014.04.051.

Soltani S, Etemad SG, Thibault J. Pool boiling heat transfer of non-Newtonian nanofluids. Int Commun Heat Mass Transf. 2010;37(1):29–33. https://doi.org/10.1016/j.icheatmasstransfer.2009.08.005.

Hojjat M, Etemad SG, Bagheri R. Laminar heat transfer of non-Newtonian nanofluids in a circular tube. Korean J Chem Eng. 2010;27(5):1391–6. https://doi.org/10.1007/s11814-010-0250-3.

Hojjat M, Etemad SG, Bagheri R, Thibault J. Rheological characteristics of non-Newtonian nanofluids: experimental investigation. Int Commun Heat Mass Transf. 2011;38(2):144–8. https://doi.org/10.1016/j.icheatmasstransfer.2010.11.019.

Ghanbari Ashrafi T, Hoseinzadeh S, Sohani A, Shahverdian MH. Applying homotopy perturbation method to provide an analytical solution for Newtonian fluid flow on a porous flat plate. Math Methods Appl Sci. 2021;44(8):7017–30. https://doi.org/10.1002/mma.7238.

Giwa SO, Sharifpur M, Goodarzi M, Alsulami H, Meyer JP. Influence of base fluid, temperature, and concentration on the thermophysical properties of hybrid nanofluids of alumina–ferrofluid: experimental data, modeling through enhanced ANN, ANFIS, and curve fitting. J Therm Anal Calorim. 2021;143(6):4149–67. https://doi.org/10.1007/s10973-020-09372-w.

Moraveji MK, Haddad SM, Darabi M. Modeling of forced convective heat transfer of a non-Newtonian nanofluid in the horizontal tube under constant heat flux with computational fluid dynamics. Int Commun Heat Mass Transf. 2012;39(7):995–9. https://doi.org/10.1016/j.icheatmasstransfer.2012.05.003.

Akbari OA, Toghraie D, Karimipour A, Marzban A, Ahmadi GR. The effect of velocity and dimension of solid nanoparticles on heat transfer in non-Newtonian nanofluid. Phys E. 2017;1(86):68–75. https://doi.org/10.1016/j.physe.2016.10.013.

Rozati SA, Montazerifar F, Ali Akbari O, Hoseinzadeh S, Nikkhah V, Marzban A, Abdolvand H, Goodarzi M. Natural convection heat transfer of water/Ag nanofluid inside an elliptical enclosure with different attack angles. Math Methods Appl Sci. 2020. https://doi.org/10.1002/mma.7036.

Targui N, Kahalerras H. Analysis of fluid flow and heat transfer in a double pipe heat exchanger with porous structures. Energy Convers Manag. 2008;49(11):3217–29. https://doi.org/10.1016/j.enconman.2008.02.010.

Kefayati GH. Simulation of natural convection and entropy generation of non-Newtonian nanofluid in a porous cavity using Buongiorno’s mathematical model. Int J Heat Mass Transf. 2017;1(112):709–44. https://doi.org/10.1016/j.ijheatmasstransfer.2017.04.121.

Kefayati GH, Sidik NA. Simulation of natural convection and entropy generation of non-Newtonian nanofluid in an inclined cavity using Buongiorno’s mathematical model (Part II, entropy generation). Powder Technol. 2017;1(305):679–703. https://doi.org/10.1016/j.powtec.2016.10.077.

Bahiraei M, Alighardashi M. Investigating non-Newtonian nanofluid flow in a narrow annulus based on second law of thermodynamics. J Mol Liq. 2016;1(219):117–27. https://doi.org/10.1016/j.molliq.2016.03.007.

Koo J, Kleinstreuer C. Laminar nanofluid flow in microheat-sinks. Int J Heat Mass Transf. 2005;48(13):2652–61. https://doi.org/10.1016/j.ijheatmasstransfer.2005.01.029.

Hoseinzadeh S, Sohani A, Shahverdian MH, Shirkhani A, Heyns S. Acquiring an analytical solution and performing a comparative sensitivity analysis for flowing Maxwell upper-convected fluid on a horizontal surface. Therm Sci Eng Prog. 2021;1(23):100901. https://doi.org/10.1016/j.tsep.2021.100901.

Ahmadi AA, Arabbeiki M, Ali HM, Goodarzi M, Safaei MR. Configuration and optimization of a minichannel using water–alumina nanofluid by non-dominated sorting genetic algorithm and response surface method. Nanomaterials. 2020;10(5):901. https://doi.org/10.3390/nano10050901.

Peng Y, Parsian A, Khodadadi H, Akbari M, Ghani K, Goodarzi M, Bach QV. Develop optimal network topology of artificial neural network (AONN) to predict the hybrid nanofluids thermal conductivity according to the empirical data of Al2O3–Cu nanoparticles dispersed in ethylene glycol. Phys A. 2020;1(549):124015. https://doi.org/10.1016/j.physa.2019.124015.

Hosseini SM, Safaei MR, Goodarzi M, Alrashed AA, Nguyen TK. New temperature, interfacial shell dependent dimensionless model for thermal conductivity of nanofluids. Int J Heat Mass Transf. 2017;1(114):207–10. https://doi.org/10.1016/j.ijheatmasstransfer.2017.06.061.

Jordaan H, Stephan Heyns P, Hoseinzadeh S. Numerical development of a coupled one-dimensional/three-dimensional computational fluid dynamics method for thermal analysis with flow maldistribution. J Therm Sci Eng Appl. 2021;13(4):041017. https://doi.org/10.1115/1.4049040.

Zhao H, Liu Z, Zhang C, Guan N, Zhao H. Pressure drop and friction factor of a rectangular channel with staggered mini pin fins of different shapes. Exp Therm Fluid Sci. 2016;1(71):57–69. https://doi.org/10.1016/j.expthermflusci.2015.10.010.

Hoseinzadeh S, Sohani A, Ashrafi TG. An artificial intelligence-based prediction way to describe flowing a Newtonian liquid/gas on a permeable flat surface. J Therm Anal Calorim. 2021;26:1–7. https://doi.org/10.1007/s10973-021-10811-5.

Tian Z, Abdollahi A, Shariati M, Amindoust A, Arasteh H, Karimipour A, Goodarzi M, Bach QV. Turbulent flows in a spiral double-pipe heat exchanger: optimal performance conditions using an enhanced genetic algorithm. Int J Numer Meth Heat Fluid Flow. 2019. https://doi.org/10.1108/HFF-04-2019-0287.

Bagherzadeh SA, D’Orazio A, Karimipour A, Goodarzi M, Bach QV. A novel sensitivity analysis model of EANN for F-MWCNTs–Fe3O4/EG nanofluid thermal conductivity: outputs predicted analytically instead of numerically to more accuracy and less costs. Phys A. 2019;1(521):406–15. https://doi.org/10.1016/j.physa.2019.01.048.

Paul TC, Mahamud R, Khan JA. Multiphase modeling approach for ionic liquids (ILs) based nanofluids: improving the performance of heat transfer fluids (HTFs). Appl Therm Eng. 2019;25(149):165–72. https://doi.org/10.1016/j.applthermaleng.2018.12.039.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Naderifar, A., Nikian, M., Javaherdeh, K. et al. Numerical investigation of the effect of fins on heat transfer enhancement of a laminar non-Newtonian nanofluid flow through a corrugated channel. J Therm Anal Calorim 147, 9779–9791 (2022). https://doi.org/10.1007/s10973-022-11222-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11222-w