Abstract

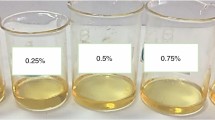

In this study, the rheological behavior and tribological properties of a nano-lubricant containing SiO2 nanoparticles in SAE40 engine oil are experimentally investigated. Nano-lubricant has been prepared with two-step method using an ultrasonic homogenizer. The rheological behavior of nano-lubricant checked out in all studied temperatures (ranging from 15˚C to 65˚C) and different solid volume fractions (ranging from 0 to 1%) and it shows non-Newtonian behavior (pseudoplastic). Also, an accurate correlation is presented for the prediction of nano-lubricant’s viscosity based on experimental data. A pin-on-disk tribometer was performed to investigate the tribological behavior of nano-lubricant. Results revealed that in φ = 0.1%, the wear rate and friction coefficient have been decreased by 50% and 18.46%, respectively, compared with the base oil. In addition, the nano-lubricant with optimum concentration and base oil was tested in the operational condition of diesel engines at the same condition and the abrasive elements of these engine oils were analyzed. Other important factors including pour point and flash point were also determined which showed that the addition of SiO2 nanoparticles to the base oil in φ = 0.1% will cause a 3.8% improvement in flash point compared with the base oil.

Similar content being viewed by others

Abbreviations

- R:

-

Regression coefficient

- Wr:

-

Wear rate (\({{\mathrm{mm}}^{3}}{\mathrm{N}^{-1} \mathrm{m}^{-3}}\))

- \(\Delta \mathrm{m}\) :

-

Mass reduction

- L:

-

Distance (m)

- F:

-

Exerted load (N)

- φ:

-

Solid volume fraction

- τ:

-

Shear stress (Pa)

- \(\dot{\gamma }\) :

-

Shear rate (\({s}^{-1}\))

- ρ:

-

Density (\({\mathrm{g}} \, {{\mathrm{mm}}^{-3}}\))

- ANOVA:

-

Analysis of variance

- SAE:

-

Society of automotive engineers

- SEM:

-

Scanning electron microscopy

- XRD:

-

X-ray diffraction

References

Lee C-G, Hwang Y-J, Choi Y-M, Lee J-K, Choi C, Oh J-M. A study on the tribological characteristics of graphite nano lubricants. Int J Precis Eng Manuf. 2009;10(1):85–90.

Sarafraz M, Arya A, Nikkhah V, Hormozi F. Thermal performance and viscosity of biologically produced silver/coconut oil nanofluids. Chem Biochem Eng Q. 2016;30(4):489–500.

Salari E, Peyghambarzadeh M, Sarafraz M, Hormozi F. Boiling heat transfer of alumina nano-fluids: role of nanoparticle deposition on the boiling heat transfer coefficient. 2016.

Izadi M, Mohebbi R, Sajjadi H, Amiri Delouei A. LTNE modeling of Magneto-Ferro natural convection inside a porous enclosure exposed to nonuniform magnetic field. Phys A: Stat Mecha Appl. 2019;535:122394.

Yuan M, Mohebbi R, Rashidi MM, Yang Zh. MHD forced convection of MWCNT–Fe 3 O 4/water hybrid nanofluid in a partially heated τ-shaped channel using LBM. J Therm Anal Calorim. 2019;136(4):1723–35.

Delouei AA, Sajjadi H, Mohebbi R, Izadi M. Experimental study on inlet turbulent flow under ultrasonic vibration: Pressure drop and heat transfer enhancement. Ultrason Sonochem. 2019;51:151–9.

Hemmat-Esfe M, Esfandeh S. Investigation of rheological behavior of hybrid oil based nanolubricant-coolant applied in car engines and cooling equipments. Applied Thermal Engineering. 2017.

Alirezaie A, Saedodin S, Hemmat-Esfe M, Rostamian SH. Investigation of rheological behavior of MWCNT (COOH-functionalized)/MgO-Engine oil hybrid nanofluids and modelling the results with artificial neural networks. J Mol Liq. 2017;241:173–81.

Hemmat-Esfe M, Zabihi F, Rostamian H, Esfandeh S. Experimental investigation and model development of the non-Newtonian behavior of CuO-MWCNT-10w40 hybrid nano-lubricant for lubrication purposes. J Mol Liq. 2018;249:677–87.

Hemmat-Esfe M, Tatar A, Ahangar MRH, Rostamian H. A comparison of performance of several artificial intelligence methods for predicting the dynamic viscosity of TiO2/SAE 50 nano-lubricant. Phys E. 2018;96:85–93.

Izadi F, Ranjbarzadeh R, Kalbasi R, Afrand M. A new experimental correlation for non-Newtonian behavior of COOH-DWCNTs/antifreeze nanofluid. Phys E. 2018;98:83–9.

Kharabati, S., Saedodin S., and Rostamian S. H. 2021 "Experimental investigation of thermal and rheological behavior of silica/soybean oil nano lubricant in low-temperature performance of internal combustion engine." Energy Sources, Part A: Recovery, Utilization, and Environmental Effects. 1–15.

Aghaei A, Khorasanizadeh H, Sheikhzadeh GA. Measurement of the dynamic viscosity of hybrid engine oil-Cuo-MWCNT nanofluid, development of a practical viscosity correlation and utilizing the artificial neural network. Heat Mass Transf. 2018;54(1):151–61.

Saedodin S, Kashefi MH, Bahrami Z. Experimental study on the rheological behavior of nanolubricant-containing MCM-41 nanoparticles with viscosity measurement. J Therm Anal Calorim. 2019;137(5):1499–511.

Sanukrishna S, Prakash MJ. Experimental studies on thermal and rheological behaviour of TiO2-PAG nanolubricant for refrigeration system. Int J Refrig. 2018;86:356–72.

Rostamian S.H, Saedodin S, Asghari SA, Salarian AH. 2020 Effect of C60-SiO2 hybrid nanoparticles on thermophysical and tribological properties of a multigrade engine oil: an experimental study. Journal of Thermal Analysis and Calorimetry, 1–13.

Parvar, M., Saedodin S, Rostamian SH. Experimental study on the thermal conductivity and viscosity of transformer oil-based nanofluid containing ZnO nanoparticles. Journal of Heat and Mass Transfer Research, 2020.

Mohebbi R, Amiri Delouei A, Jamali A, Izadi M, Mohamad AA. Pore-scale simulation of non-Newtonian power-law fluid flow and forced convection in partially porous media: thermal lattice Boltzmann method. Phys A. 2019;525:642–56.

Krishnakumar T, Viswanath S, Varghese SM. Experimental studies on thermal and rheological properties of Al2O3–ethylene glycol nanofluid. Int J Refrig. 2018;89:122–30.

Hemmat-Esfe M, Arani AAA, Madadi MR, Alirezaie A. A study on rheological characteristics of hybrid nano-lubricants containing MWCNT-TiO2 nanoparticles. J Mol Liq. 2018;260:229–36.

Sepyani K, Afrand M, Hemmat-Esfe M. An experimental evaluation of the effect of ZnO nanoparticles on the rheological behavior of engine oil. J Mol Liq. 2017;236:198–204.

Nadooshan AA, Hemmat-Esfe M, Afrand M. Prediction of rheological behavior of SiO 2-MWCNTs/10W40 hybrid nanolubricant by designing neural network. J Therm Anal Calorim. 2018;131(3):2741–8.

Soltani O, Akbari M. Effects of temperature and particles concentration on the dynamic viscosity of MgO-MWCNT/ethylene glycol hybrid nanofluid: experimental study. Phys E. 2016;84:564–70.

Hemmat-Esfe M, Afrand M, Gharehkhani S, Rostamian H, Toghraie D, Dahari M. An experimental study on viscosity of alumina-engine oil: effects of temperature and nanoparticles concentration. Int Commun Heat Mass Transfer. 2016;76:202–8.

Vakili-Nezhaad G, Dorany A. Investigation of the effect of multiwalled carbon nanotubes on the viscosity index of lube oil cuts. Chem Eng Commun. 2009;196(9):997–1007.

Afrand M, Najafabadi KN, Sina N, Safaei MR, Kherbeet AS, Wongwises S, et al. Prediction of dynamic viscosity of a hybrid nano-lubricant by an optimal artificial neural network. Int Commun Heat Mass Transfer. 2016;76:209–14.

Chen L, Xie H, Yu W, Li Y. Rheological behaviors of nanofluids containing multi-walled carbon nanotube. J Dispersion Sci Technol. 2011;32(4):550–4.

Hemmat-Esfe M, Afrand M, Rostamian SH, Toghraie D. Examination of rheological behavior of MWCNTs/ZnO-SAE40 hybrid nano-lubricants under various temperatures and solid volume fractions. Exp Thermal Fluid Sci. 2017;80:384–90.

Shababi K, Firouzi M, Fakhar A 2018 An experimental study on rheological behavior of SAE50 engine oil. Journal of Thermal Analysis and Calorimetry 1–10.

Asadi A, Asadi M, Rezaei M, Siahmargoi M, Asadi F. The effect of temperature and solid concentration on dynamic viscosity of MWCNT/MgO (20–80)–SAE50 hybrid nano-lubricant and proposing a new correlation: an experimental study. Int Commun Heat Mass Transfer. 2016;78:48–53.

Asadi M, Asadi A. Dynamic viscosity of MWCNT/ZnO–engine oil hybrid nanofluid: an experimental investigation and new correlation in different temperatures and solid concentrations. Int Commun Heat Mass Transfer. 2016;76:41–5.

Esfe MH, Bahiraei M, Hajmohammad MH, Afrand M. Rheological characteristics of MgO/oil nanolubricants: Experimental study and neural network modeling. Int Commun Heat Mass Transfer. 2017;86:245–52.

Dardan E, Afrand M, Isfahani AM. Effect of suspending hybrid nano-additives on rheological behavior of engine oil and pumping power. Appl Therm Eng. 2016;109:524–34.

Zhou LH, Wei XC, Ma ZJ, Mei B. Anti-friction performance of FeS nanoparticle synthesized by biological method. Appl Surf Sci. 2017;407:21–8.

Shahnazar S, Bagheri S, Hamid SBA. Enhancing lubricant properties by nanoparticle additives. Int J Hydro Energy. 2016;41(4):3153–70.

Wan Q, Jin Y, Sun P, Ding Y. Tribological behaviour of a lubricant oil containing boron nitride nanoparticles. Procedia Eng. 2015;102:1038–45.

Aldana PU, Dassenoy F, Vacher B, Le Mogne T, Thiebaut B. WS2 nanoparticles anti-wear and friction reducing properties on rough surfaces in the presence of ZDDP additive. Tribol Int. 2016;102:213–21.

Sgroi M, Asti M, Gili F, Deorsola FA, Bensaid S, Fino D, et al. Engine bench and road testing of an engine oil containing MoS2 particles as nano-additive for friction reduction. Tribol Int. 2017;105:317–25.

Wu H, Zhao J, Xia W, Cheng X, He A, Yun JH et al. 2017 A study of the tribological behaviour of TiO2 nano-additive water-based lubricants. Tribology International

Rodrigues A, Österle W, Gradt T, Azevedo C. Impact of copper nanoparticles on tribofilm formation determined by pin-on-disc tests with powder supply: Addition of artificial third body consisting of Fe3O4. Cu Graph Tribol Int. 2017;110:103–12.

Ingole S, Charanpahari A, Kakade A, Umare S, Bhatt D, Menghani J. Tribological behavior of nano TiO2 as an additive in base oil. Wear. 2013;301(1–2):776–85.

Mosleh M, Shirvani KA. In-situ nanopolishing by nanolubricants for enhanced elastohydrodynamic lubrication. Wear. 2013;301(1–2):137–43.

Demas NG, Erck RA, Lorenzo-Martin C, Ajayi OO, Fenske GR. Experimental evaluation of oxide nanoparticles as friction and wear improvement additives in motor oil. Journal of Nanomaterials. 2017

Viesca J, Battez AH, González R, Chou R, Cabello J. Antiwear properties of carbon-coated copper nanoparticles used as an additive to a polyalphaolefin. Tribol Int. 2011;44(7–8):829–33.

Chinas-Castillo F, Spikes H. Mechanism of action of colloidal solid dispersions. J Tribol. 2003;125(3):552–7.

Hu ZS, Lai R, Lou F, Wang L, Chen Z, Chen G, et al. Preparation and tribological properties of nanometer magnesium borate as lubricating oil additive. Wear. 2002;252(5–6):370–4.

Liu G, Li X, Qin B, Xing D, Guo Y, Fan R. Investigation of the mending effect and mechanism of copper nano-particles on a tribologically stressed surface. Tribol Lett. 2004;17(4):961–6.

Zhou J, Yang J, Zhang Z, Liu W, Xue Q. Study on the structure and tribological properties of surface-modified Cu nanoparticles. Mater Res Bull. 1999;34(9):1361–7.

Rastogi R, Yadav M, Bhattacharya A. Application of molybdenum complexes of 1-aryl-2, 5-dithiohydrazodicarbonamides as extreme pressure lubricant additives. Wear. 2002;252(9–10):686–92.

Ginzburg B, Shibaev L, Kireenko O, Shepelevskii A, Baidakova M, Sitnikova A. Antiwear effect of fullerene C 6 0 additives to lubricating oils. Russ J Appl Chem. 2002;75(8):1330–5.

Xiaodong Z, Xun F, Huaqiang S, Zhengshui H. Lubricating properties of Cyanex 302-modified MoS2 microspheres in base oil 500SN. Lubr Sci. 2007;19(1):71–9.

Lee J, Cho S, Hwang Y, Lee C, Kim SH. Enhancement of lubrication properties of nano-oil by controlling the amount of fullerene nanoparticle additives. Tribol Lett. 2007;28(2):203–8.

Nasiri-Khuzani G, Asoodar M, Rahnama M, Sharifnasab H. 2012 Evaluation of engine parts wear using nano lubrication oil in agricultural tractors. Global Journal of Science Frontier Research 12(8-D).

Jatti VS, Singh T. 2015 Copper oxide nano-particles as friction-reduction and anti-wear additives in lubricating oil. Journal of Mechanical Science and Technology

Chen S, Liu W. Oleic acid capped PbS nanoparticles: synthesis, characterization and tribological properties. Mater Chem Phys. 2006;98(1):183–9.

Jiao D, Zheng S, Wang Y, Guan R, Cao B. The tribology properties of alumina/silica composite nanoparticles as lubricant additives. Appl Surf Sci. 2011;257(13):5720–5.

Koshy CP, Rajendrakumar PK, Thottackkad MV. Evaluation of the tribological and thermo-physical properties of coconut oil added with MoS2 nanoparticles at elevated temperatures. Wear. 2015;330:288–308.

Ran X, Yu X, Zou Q. Effect of particle concentration on tribological properties of ZnO nanofluids. Tribol Trans. 2017;60(1):154–8.

Ahmadi H, Rashidi A, Nouralishahi A, Mohtasebi SS. Preparation and thermal properties of oil-based nanofluid from multi-walled carbon nanotubes and engine oil as nano-lubricant. Int Commun Heat Mass Transfer. 2013;46:142–7.

Ahmadi H, Rashidi A, Mohtasebi SS, Alaei M. Experimental evaluation of engine oil properties containing copper oxide nanoparticles as a nanoadditive. Int J Ind Chem. 2013;4(1):28.

Einstein A. Eine neue bestimmung der moleküldimensionen. Ann Phys. 1906;324(2):289–306.

Saitô N. Concentration dependence of the viscosity of high polymer solutions I. J Phys Soc Japan. 1950;5(1):4–8.

Brinkman H. The viscosity of concentrated suspensions and solutions. J Chem Phys. 1952;20(4):571–571.

Batchelor G. The effect of Brownian motion on the bulk stress in a suspension of spherical particles. J Fluid Mech. 1977;83(1):97–117.

Wang X-Q, Mujumdar AS. Heat transfer characteristics of nanofluids: a review. Int J Therm Sci. 2007;46(1):1–19.

Chen H, Ding Y, Tan C. Rheological behaviour of nanofluids. New J Phys. 2007;9(10):367.

Holman, J.P. Experimental methods for engineers. 2001.

Acknowledgements

Special thanks to the Science and Technology Park of Semnan University, which provided the conditions for this research.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kashefi, M.H., Saedodin, S. & Rostamian, S.H. Effect of silica nano-additive on flash point, pour point, rheological and tribological properties of lubricating engine oil: an experimental study. J Therm Anal Calorim 147, 4073–4086 (2022). https://doi.org/10.1007/s10973-021-10812-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10812-4