Abstract

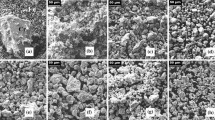

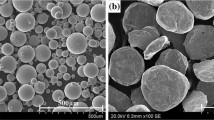

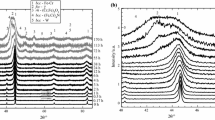

Fe–14Cr–3 W–0.4Ti–0.25Y2O3 ferritic steels were produced by ball milling of initial mixture of elemental powders with various amounts of process control agent (PCA), ethanol (0.25 mass%, 2.5 mass%, 4 mass% and 20 mass%) under an Ar atmosphere and spark plasma sintering (SPS) consolidation at 1070 °C. The influence of the quantity of PCA on the properties (microstructure, density and Vickers hardness) of the as-milled powders and of the consolidated steels was investigated. X-ray diffraction shows a bcc–α-phase with fine crystallite size, 6.7–11 nm, for all powders. The particle size and the lattice constant of α-ferrite of the as-milled powders decrease as the amount of PCA increases. The powder milled with the highest amount of PCA, 20 mass%, contains carbides (M3C) and oxides ((Fe,Cr)2O3). The thermal analysis shows that as the amount of PCA increases, (1) the Curie temperature, Tc, increases, (2) the temperature of α → γ transition, Tα→γ, decreases, (3) the mass loss with CO/CO2 degassing increases, and (4) the milling with PCA hinders the nitrogen incorporation from milling media and air. The density and Vickers hardness of the SPS-consolidated and post-SPS annealed steels show an increasing trend with the increase in the amount of PCA. Carbides and oxides were detected in the post-SPS annealed steels derived from the powders milled with 2.5 mass% PCA and 4 mass% PCA (M23C6 and (Fe,Cr)2O3), and 20 mass% PCA (M3C and (Fe,Cr)2O3). The obtained results were discussed in terms of: (1) dissolution into the alloy matrix of carbon and oxygen released after the disintegration of PCA, (2) carbides and oxides precipitation during milling and/or upon heating and (3) promotion of thermally activated processes (such as carbothermal reaction) upon heating which can develop as well at the contact points/particle surfaces during SPS consolidation and can influence the process of densification.

Similar content being viewed by others

References

Baluc N, Boutard JL, Dudarev SL, Rieth M, Brito Correia J, Fournier B, Henry J, Legendre F, Leguey T, Lewandowska M, Lindau R, Marquis E, Muńoz A, Radiguet B, Oksiuta Z. Review on the EFDA work programme on nano-structured ODS RAF steels. J Nucl Mater. 2011;417:149–53.

Shaigan N, Qu W, Ivey DG, Chen W. A review of recent progress in coatings, surface modifications and alloy developments for solid oxide fuel cell ferritic stainless steel interconnects. J Power Sources. 2010;195:1529–42.

Herting G, Odnevall Wallinder I, Leygraf C. Corrosion-induced release of chromium and iron from ferritic stainless steel grade AISI 430 in simulated food contact. J Food Eng. 2008;87:291–300.

Mihalache V. Thermal analysis of ball-milled Fe–14Cr–3 W–0.4Ti–0.25Y2O3 ferritic steel powder. evidence for contamination from the air. J Therm Anal Calorim. 2016;124:1179.

Mihalache V, Mercioniu I, Aldica G, Pasuk I. Thermal analysis, microstructure and impurity phases evolution in Fe14Cr ferritic steel powders ball-milled in air and under an argon atmosphere. J Therm Anal Calorim. 2018;134:463.

Suryanarayana C. Mechanical alloying and milling. New York: Marcel Dekker; 2004.

Nouri A, Wen C. Critical reviews in solid state and materials. Sciences. 2014;39:81–108.

Lü L, Lai MO. Mechanical alloying. Massachusetts: Kluwer Academic Publishers; 1998.

Mihalache V, Secu M, Grivel JC. Defect states and room temperature ferromagnetism in cerium oxide nanopowders prepared by decomposition of Ce-propionate. Mater Chem Phys. 2018;209:121–33.

Mihalache V, Walter M, Mercioniu I, Ordas N. The quality of Fe14Cr ODS powder alloys during milling and upon heating and its impact on the mechanical properties of consolidated steels. Metall Mater Trans A. 2019;50:3282.

Mihalache V, Mercioniu I, Velea A, Palade P. Effect of the process control agent in the ball-milled powders and SPS-consolidation temperature on the grain refinement, density and Vickers hardness of Fe14Cr ODS ferritic alloys. Powder Technol. 2019;347:103–13.

Lemoine C, Fnidiki A, Lemarchand D, Teillet J. Grain core study of Fe1–xCrx nanograins obtained by mechanical alloying. J Phys Condens Matter. 1999;11:8341.

Fnidiki A, Lemoine C, Teillet J. Structural and magnetic properties of grain boundaries in Fe60Cr40 alloy synthesized by mechanical alloying. J Phys Condens Matter. 2002;14:7221.

Azzaza S, Alleg S, Sunol JJ. Microstructure characterization and thermal stability of the ball milled iron powders. J Therm Anal Calorim. 2015;119(2):1037–46.

Alleg S, Souilah S, Sun˜ol JJ. Thermal stability of the nanostructured powder mixtures prepared by mechanical alloying. In: Elkordy AA, editor. Applications of calorimetry in a wide context—differential scanning calorimetry, isothermal titration calorimetry and microcalorimetry. Vienna: InTech Publisher; 2013. p. 21–48.

Hebda M, Gadek S, Skałon M, Kazior J. Effect of mechanical alloying and annealing on the sintering behaviour of AstaloyCrL powders with SiC and carbon addition. J Therm Anal Calorim. 2013;113:395–403.

Calderon RO, Gierl-Mayer C, Danninger H. Application of thermal analysis techniques to study the oxidation/reduction phenomena during sintering of steels containing oxygen sensitive alloying elements. J Therm Anal Calorim. 2017;127:91–105.

Kirakosyan H, MinasyanT Niazyan O, Aydinyan S, Kharatyan S. DTA/TG study of CuO and MoO3 co-reduction by combined Mg/C reducers. J Therm Anal Calorim. 2016;123:35.

Hryha E, Nyborg L. Thermogravimetry study of the effectiveness of different reducing agents during sintering of Cr-prealloyed PM steels. J Therm Anal Calorim. 2014;118:825–34.

Wang Y, Wang L, Yu J, Chou KC. Kinetics of carbothermic reduction of synthetic chromite. J Min Metall Sect B Metall. 2014;50:15–21.

Mori T, Yang J, Kuwabara M. Mechanism of carbothermic reduction of chromium oxide. ISIJ Int. 2007;47:1387.

Zhang Yan-ling, Liu Yang, Wei Wen-jie. Carbothermal reduction process of the Fe–Cr–O system. Int J Miner Metall Mater. 2013;20:931.

Danninger H, Gierl C, Kremel S, Leitner G, Jaenicke-Roessler K, Yu Y. Degassing and deoxidation processes during sintering of unalloyed and alloyed PM steels. Powder Metall Prog. 2002;2(3):125–40.

Zadra M, Molinari A. High carbon nickel-free austenitic steel. Powder Metall Prog. 2005;5:173–84.

Hebda M, Debecka H, Kazior J. Dilatometric study of low-alloy steels with silicon carbide addition. J Therm Anal Calorim. 2016;125:1319–26.

Alvarenga HD, Van De Putte T, Van Steenberge N, Sietsma J, Terryn H. Influence of carbide morphology and microstructure on the kinetics of superficial decarburization of C–Mn steels. Metal Mater Trans A. 2015;46A:123–33.

Inoue A, Masumoto T. Carbide reactions (M3C → M7C3 → M23C6 → MC6) during tempering of rapidly solidified high carbon Cr–W and Cr–Mo steels. Metal Mater Trans A. 1980;11A:739–47.

Calliari I, Dabalà M, Ramous E, Zanesco M, Gianotti E. Microstructure of a nitrided steel previously decarburized. J Mater Eng Perform. 2006;15(6):693–8.

Sung JH, Kong JH, Yoo DK, On HY, Lee DJ, Lee HW. Phase changes of the AISI 430 ferritic stainless steels after high-temperature gas nitriding and tempering heat treatment. Mater Sci Eng A. 2008;489:38–43.

Acknowledgements

This work was supported by the CCDI-UEFISCDI PN-III-P1-1.2-PCCDI-2017-0871: Project 47PCCDI/2018 and Core Program PN19-03 (contract no. 21 N/08.02.2019) of Romanian Ministry of Research and Innovation and was partially supported by the European Community in the framework of the European Fusion Development Agreement (EFDA) under project WP13-MAT-01-ODSFS-01. The views and opinions expressed in this paper do not necessarily reflect those of the European Commission. The authors gratefully acknowledge N. Ordas (from Ceit-IK4 and TECNUN, University of Navarra, Spain) for her technical and experimental support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mihalache, V., Aldica, G., Pasuk, I. et al. Thermal analysis and microstructure of oxide dispersion strengthened ferritic steels produced by ball milling with different amounts of process control agent. J Therm Anal Calorim 138, 2515–2528 (2019). https://doi.org/10.1007/s10973-019-08593-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08593-y