Abstract

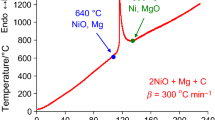

The mechanism of copper (II) oxide and molybdenum (VI) oxide co-reduction by Mg + C mixture was investigated at non-isothermal conditions by carrying out simultaneous differential thermal (DTA) and thermogravimetric (TG) analyses combined with X-ray diffraction (XRD) analysis of intermediate and final products. The whole process was found to involve several phenomena: interaction between oxides with CuMoO4 salt formation, high-exothermic reactions occurring directly between metal oxides and magnesium, as well as low-exothermic carbothermal reactions. In order to better understand the complex nature of calorimetric and TG curves, the behaviour of each single reagent as well as that of binary, ternary and quaternary mixtures was studied at linear heating. It was revealed that the simultaneous reduction of Cu and Mo oxides proceeds more easily by carbon than by magnesium. Only due to the decisive role of carbon on the reaction pathway, the combined and complete reduction of oxides by Mg/C reducing mixture becomes possible at relatively low temperatures. The sequence of chemical reactions possibly occurring during the heating process on the basis of DTA/TG curves and XRD analyses results of quenched reaction products has been proposed.

Similar content being viewed by others

References

Davis JR. Copper and copper alloys. USA: ASM International; 2001.

Chen G, Wu G, Jiang L, Zhu D, Sun D. Microstructure and mechanical properties of high densification Mo/Cu composites. Key Eng Mater. 2007;353–358:2883–6.

Johnson JL, German RM. Role of solid-state skeletal sintering during processing of Mo–Cu composites. Metall Mater Trans A. 2001;32:605–13.

Hu B-Q, Bai P-K, Wang Y-Z. Sintering and processing nanocomposite powder of Mo-8 wt% Cu. J Funct Mater. 2012;43(8):1031–3.

Li Z, Han S-L, Jiang Y-L, Zhao D-F, Meng F. Fabrication and sintering property of Mo–Cu composite powder by mechano-thermochemical method. Mater Sci Eng Powder Metall. 2011;16(5):774–80.

Peng S, Jigui C, Lei W, Jingsong Z, Yifang W, Yanbo C. Preparation and characterization of Mo–15Cu superfine powders by a gelatification-reduction process. J Alloy Compd. 2009;476:226–30.

Aokui S, Wang Dezhi W, Zhuangzhi ZX. Synthesis of ultra-fine Mo–Cu nanocomposites by coreduction of mechanical-activated CuMoO4–MoO3 mixtures at low temperature. J Alloy Compd. 2010;505:588–91.

Li Z, Zhai Y. Preparation of Mo60Cu40 composite nano-powder by hydrogen reaction. Rare Metal Mater Eng. 2010;39(1):6–9.

Popa F, Chicinaş I, Isnard O, Pop V. Heat-treatment influence on Ni–Fe–Cu–Mo nanocrystalline alloy obtained by mechanical alloying. J Therm Anal Calorim. 2012;110(1):295–9.

Adorno AT, Silva RAG, Carvalho TM. (α + γ1) Complex phase formation in the Cu-10 mass% Al-6 mass% Ag alloy. J Therm Anal Calorim. 2009;97(1):127–30.

Zhao M, Wang J, Liu W, Zhou M. Preparation and reduction behavior of Mo–Cu powders by Sol–Gel. J Phys Conf Ser. 2009;188(1):2–6.

Kang Z, Chen W, Ding B. Fabrication of composite nanopowders of MoCu by sol–gel. Rare Metal Mater Eng. 2005;34(6):990–3.

Aydinyan SV, Manukyan KHV, Kharatyan SL. Combustion synthesis of Mo–Cu nanocomposites by co-reduction of molybdenum and copper oxides. In: XII International Symposium on SHS, South Padre Island, TX, USA. 2013. pp 100–101.

Wiesmann M, Ehrenberg H, Miehe G, Peun T, Weitzel H, Fuess H. p-T phase diagram of CuMoO4. J Solid State Chem. 1997;132:88–97.

Ehrenberg H, Weitzel H, Paulus H, Wiesmann M, Wltschek G, Geselle M, Fuess H. Crystal structure and magnetic properties of CuMoO4 at low temperature (g-phase). J Phys Chem Solids. 1997;58:153.

Tali R, Tabachenko VV, Kovba LM, Dem’yanets LN. The crystal strucure of CuMoO4-III. Russ J Inorg Chem. 1991;36:927.

Nassau K, Shiever JW. Cupric oxide-molybdenum oxide phase diagram in air and in oxygen. J Am Ceram Soc. 1969;52(1):36–40.

Tadeusz M, Jacek Z. Subsolidus phase diagram of Cu2O–CuO–MoO3 system. J Solid State Chem. 1980;31(2):135–43.

Manukyan K, Aydinyan S, Aghajanyan A, Grigoryan Y, Niazyan O, Kharatyan S. Reaction pathway in the MoO3 + Mg + C reactive mixtures. Int J Refract Metals Hard Mater. 2012;31:28–32.

Baghdasaryan AM, Niazyan OM, Khachatryan HL, Kharatyan SL. DTA/TG study of tungsten oxide and ammonium tungstate reduction by (Mg + C) combined reducers at non-isothermal conditions. Int J Refract Metals Hard Mater. 2014;43:216–21.

Acknowledgements

The authors acknowledge the financial support of the State Committee of Science of the Republic of Armenia (Project #13_1D192).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kirakosyan, H., Minasyan, T., Niazyan, O. et al. DTA/TG study of CuO and MoO3 co-reduction by combined Mg/C reducers. J Therm Anal Calorim 123, 35–41 (2016). https://doi.org/10.1007/s10973-015-4919-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4919-z