Abstract

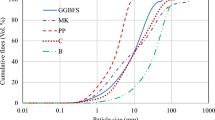

The influence of granite cutting waste and quartz sand on the early-stage hydration of calcium aluminate cement, Gorkal 70, was examined. The experiments were carried out at 25 and 50 °C temperature, when the water/cement ratio was equal to 0.5. It was determined that the mentioned additives have a significant influence on the calcium aluminate cement and its clinker hydration process at 25 °C: In the latter compound mixtures with granite cutting waste and quartz, the induction period was significantly shortened to 1 h, while, in case of calcium aluminate cement samples with additives, it was prolonged to 11 h in comparison with the pure system (10 h). It should be noted that the amount of granite cutting waste and quartz does not affect the hydration process, because the similar results were obtained, when 4 and 12% of additives were used. X-ray diffraction analysis data showed that the formation of products depends on the samples composition as well as hydration conditions. It was determined that, in clinker samples, the formation of final products at 25 °C proceeded through the intermediate compounds—C2AH8 and CAHX, while at 50 °C—directly. It was obtained that after 3 h of calcium aluminate cement hydration at 50 °C temperature two metastable hexagonal calcium aluminum hydrates, C2AH8 and CAHX, were formed. At the same time, in clinker samples, the stable phases—katoite and gibbsite, were formed. The obtained results were confirmed by simultaneous thermal analysis, microcalorimetry and X-ray diffraction analysis.

Similar content being viewed by others

References

Baltakys K, Ilijina A, Bankauskaite A. Thermal properties and application of silica gel waste contaminated with F− ions for C–S–H synthesis. J Therm Anal Calorim. 2015;121:145–54.

Eurostat Waste statistics. 2017. http://ec.europa.eu/eurostat/statisticsexplained/index.php/Waste_statistics. Accessed 16 Aug 2017.

Alyamac KE, Ince R. A preliminary concrete mix design for SCC with marble powders. Constr Build Mater. 2009;23:1201–10.

Tchadjie LN, Djobo JNY, Ranjbar N, Tchahoute HK, Kenne BBD, Elimbi A, Njopwouo D. Potential of using granite waste as raw material for geopolymer synthesis. Ceram Int. 2016;42:3046–55.

Soltan AMM, Kahl WA, EL-Raoof FA, El-Kaliouby BA, Serry MA, Abdel-Kader NA. Lightweight aggregates from mixtures of granite waste with clay. J Clean Prod. 2016;117:139–49.

Sharma NK, Kumar P, Kumar S, Thomas BS, Gupta RC. Properties of concrete containing polished granite waste as partial substitution of coarse aggregate. Constr Build Mater. 2017;151:158–63.

Lokeshwari M, Jagadish KS. Eco-friendly use of granite fines waste in building blocks. Procedia Environ Sci. 2016;35:618–23.

Singh S, Khan S, Khandelwal R, Chugh A, Nagar R. Performance of sustainable concrete containing granite cutting waste. J Clean Prod. 2016;119:86–98.

Monteiro SN, Pecanha LA, Vieira CMF. Reformulation of roofing tiles body with addition of granite waste from sawing operations. J Eur Ceram Soc. 2004;24:2349–56.

Vijayalakshmi M, Sekar ASS, Ganesh Prabhu G. Strength and durability properties of concrete made with granite industry waste. Constr Build Mater. 2013;46:1–7.

Li Y, Yu H, Zheng L, Wen J, Wu C, Tan Y. Compressive strength of fly ash magnesium oxychloride cement containing granite wastes. Constr Build Mater. 2013;38:1–7.

Singh S, Nagar R, Agrawal V, Rana A, Tiwari A. Sustainable utilization of granite cutting waste in high strength concrete. J Clean Prod. 2016;116:223–35.

Scrivener K, Capmas A. Calcium aluminate cements. In: Newman J, Choo BS, editors. Advanced concrete technology constituent materials. Oxford: Butterworth-Heinemann; 2003. p. 2/1–2/30.

Ukrainczyk N, Matusinovic T. Thermal properties of hydrating calcium aluminate cement pastes. Cem Concr Res. 2010;40:128–36.

Khaliq W, Khan HA. High temperature material properties of calcium aluminate cement concrete. Constr Build Mater. 2015;94:475–87.

Antonovic V, Keriene J, Boris R, Aleknevicius M. The effect of temperature on the formation of the hydrated calcium aluminate cement structure. Procedia Eng. 2013;57:99–106.

Scrivener KL, Cabiron JL, Letourneux R. High performance concretes from calcium aluminate cements. Cem Concr Res. 1999;29:1215–23.

Kirca O. Temperature effect on calcium aluminate cement based composite binders. Ankara: Middle East Technical University; 2006.

Rodger SA, Double DD. The chemistry of hydration of high alumina cement in the presence of accelerating and retarding admixtures. Cem Concr Res. 1984;14:73–82.

Pacewska B, Nowacka M, Antonovic V, Aleknavicius M. Investigation of early hydration of high aluminate cement based binder at different ambient temperatures. J Therm Anal Calorim. 2012;109:717–26.

Pacewska B, Nowacka M, Aleknavicius M, Antonovic V. Early hydration of calcium aluminate cement blended with FCC catalyst at two temperatures. Procedia Eng. 2013;57:844–50.

Quillin K, Osborne G, Majumdar A, Singh B. Effects of w/c ratio and curing conditions on strength development in BRECEM concretes. Cem Concr Res. 2001;31:627–32.

Xu L, Wang P, Zhang G. Calorimetric study on the influence of calcium sulfate on the hydration of Portland cement–calcium aluminate cement mixtures. J Therm Anal Calorim. 2012;110:725–31.

Pacewska B, Wilińska I, Bukowska M. Calorimetric investigations of the influence of waste aluminosilicate on the hydration of different cements. J Therm Anal Calorim. 2009;97:61–6.

Pacewska B, Wilińska I, Nowacka M. Studies on the influence of different fly ashes and Portland cement on early hydration of calcium aluminate cement. J Therm Anal Calorim. 2011;106:859–68.

Boris R, Antonovič V, Keriene J, Stonys R. The effect of carbon fiber additive on early hydration of calcium aluminate cement. J Therm Anal Calorim. 2016;125:1061–70.

Montes M, Pato E, Carmona-Quiroga PM, Blanco-Varela MT. Can calcium aluminates activate ternesite hydration? Cem Concr Res. 2018;103:204–15.

Juenger MCG, Winnefeld F, Provis JL, Ideker JH. Advances in alternative cementitious binders. Cem Concr Res. 2011;41:1232–43.

Parr C, Simonin F, Touzo B, Wohrmeyer C, Valdelievre B, Namba A. The impact of calcium aluminate cement hydrate samples. J Tech Assoc Refract. 2005;25:78–88.

Dambrauskas T, Baltakys K, Skamat J, Kudzma A. Hydration peculiarities of high basicity calcium silicate hydrate samples. J Therm Anal Calorim. 2017. https://doi.org/10.1007/s1097301763206.

Gawlicki M, Nocun-Wczelik W, Bak L. Calorimetry in the studies of cement hydration. J Therm Anal Calorim. 2012;109:537–44.

Antonovic V, Aleknevicius M, Keriene J, Pundienė I, Stonys R. Investigating the hydration of deflocculated calcium aluminate cement-based binder with catalyst waste. J Therm Anal Calorim. 2012;109:537–44.

Smigelskyte A, Siauciunas R. Influence of raw meal compaction pressure on OPC clinker mineral composition and heat flow. J Therm Anal Calorim. 2017. https://doi.org/10.1007/s109730176479x.

Pacewska B, Nowacka M. Studies of conversion progress of calcium aluminate cement hydrates by thermal analysis method. J Therm Anal Calorim. 2014;117:653–60.

Rivas-Mercury JM, Pena P, de Aza AH, Turrillas X. Dehydration of Ca3Al2(SiO4)y(OH)4(3 − y) (0 < y < 0.176) studied by neutron thermodiffractometry. J Eur Ceram Soc. 2008;28:1737–48.

Eisinas A, Doneliene J, Baltakys K, Urbutis A. Hydrothermal synthesis of calcium aluminium hydrate-based adsorbent for the removal of CO2. J Therm Anal Calorim. 2017. https://doi.org/10.1007/s10973-017-6368-3.

Cardoso FA, Innocentini MDM, Akiyoshi MM, Pandolfelli VC. Effect of curing time on the properties of CAC bonded refractory castables. J Eur Ceram Soc. 2004;24:2073–8.

Ukrainczyk N, Matusinovic T, Kurajica S, Zimmermann B, Sipusic J. Dehydration of a layered double hydroxide—C2AH8. Thermochim Acta. 2007;464:7–15.

Acknowledgements

This research was funded by a Grant (No. S-MIP-17-92) from the Research Council of Lithuania.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baltakys, K., Sarapajevaite, G. & Dambrauskas, T. The influence of different additives on the early-stage hydration of calcium aluminate cement. J Therm Anal Calorim 134, 89–99 (2018). https://doi.org/10.1007/s10973-018-7153-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7153-7