Abstract

In this article the progress of the research on cement hydration mechanisms is critically reviewed, starting with the work of Le Chatelier and Michaelis during the late nineteenth century. Proposed mechanisms are discussed in the light of experimental data to highlight the role of new or improved analytical techniques. The focus of this article lies on the dormant period and the silicate reaction. Today many of the mechanisms proposed throughout time cannot withstand experimental evidence and need to be rejected, including the classical protective hydrate layer theory. However, it seems likely that hydrated surface species are involved in the mechanism. Theories that aim to explain the rate changes solely based on the nucleation and growth of portlandite can also not withstand experimental evidence. Nevertheless, the retardation of portlandite crystal growth through silicate ions is a relevant factor. Especially since it might present a mechanism for the nucleation of calcium silicate hydrate (C–S–H), backing up theories that propose C–S–H and portlandite to grow from the same nuclei. Finally, an overview over facts, that are currently considered to be valid and hence need to be regarded in the future mechanisms is given.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

More than 100 years after Cecil Desch introduced his presentation at the first International Symposium on the Chemistry of Cements in 1919 [1], with Although the use of calcareous cements dates from a very early period of human history, and has attained to so high a development in modern times as to have given rise to an industry of the greatest importance, our knowledge of the scientific nature of the materials and processes involved is even yet imperfect, in spite of many excellent investigations covering various parts of the subject. This statement has not lost relevance. Quite the reverse, efforts to reveal the true mechanisms of cement hydration, the detailed structure of calcium silicate hydrate, and the interaction with additives are topics of numerous intensive investigations today [2, 3]. Besides the scientific curiosity and industrial relevance, many modern approaches towards cement chemistry are driven by the demand for more environmentally friendly materials [4, 5]. The modern cement industry contributes significantly to the exhaustion of carbon dioxide and hence climate change. This is finally reflected in numerous national and international declarations of intend and stricter regulations [6, 7, 8].

Cement hydration refers to the chemical reaction between cement and water that leads to the hardening and setting of cement and other cementitious materials. It is a complex process involving various chemical reactions and physical changes that ultimately result in the formation of a solid, durable material known as hydrated cement paste. When brought into contact with water the clinker phases initially start to dissolve, releasing ions into solution. Upon reaching critical oversaturation, nucleation will occur, predominantly on the clinker surface. However, the different solubility of the clinker phases, the concentration changes in solution over time, nucleation poisoning effects, the constant change of the dissolving surface, the complex nature of the main hydration product (calcium silicate hydrate) and many other co-dependencies make this mechanism complex.

Throughout history, several mechanisms for the hydration of cement have been proposed. Progressive analytical methods and the interaction of different admixtures with cement have played a significant role in the development or rejection of hypotheses. The following article reviews the historical and current development in cement chemistry to show which influences have govern the development of theories explaining cement hydration mechanisms in the past and present. Special emphasis is put on the experimental data that led to the proposal of certain theories or their rejection.

The early theories: crystalloid and colloid theory

The first theories aiming at a holistic explanation of cement hydration were published at the end of the nineteenth century by Le Chatelier in 1887 [10] and Michaëlis in 1893 [9]. The apparent incompatibility of the two theories and the arising dispute launched vivid discussions and kept the authors in charge of further validating, explaining, and defending their theories [11, 13].

Crystalloid theory

Henry Le Chatelier [10, 11] developed a hypothesis referred to as “crystalloid theory”. He synthesised and investigated the properties and hydration of lime, calcium silicates, and aluminates as well as of multiple alumino-silicates and ferrites. Based on these experiments, he found only a few phases that were stable in an excess of lime as present in hydrating Portland cements. The observation that a continuous silica structure remained upon acidic attack led him to conclude that the essential phase, responsible for the hydraulic properties must be silicious. Furthermore, he concluded that it must contain lime since all constituents were attacked even by weak acids such as diluted acetic acid. Due to the low hydration activity that Le Chatelier found for dicalcium silicate, he identified tricalcium silicate as the “active element of hardening” [10], which was soon confirmed by other authors [14, 15]. He identified the hydration product as hydrated calcium silicate with the formula SiO2 \(\cdot\) CaO \(\cdot\) 1½ H2O. [10, 11].

Figure 1 illustrates the hydration process of Portland cement according to Le Chatelier’s theory. Initially, the anhydrous clinker dissolves due to its higher solubility compared to the hydrated compounds (Fig. 1—①). The time needed for the solution to become supersaturated with respect to the hydration products was correlated with a period of inactivity during which the temperature of the cement paste has not been observed to rise. After critical supersaturation was reached, crystalline hydration products were observed to precipitate rapidly, which was seen as the cause for renewed dissolution processes due to the reduced ion concentration in solution (Fig. 1—②&③). As precipitates, calcium hydroxide, calcium silicate hydrate, and calcium aluminate were identified by Le Chatelier. The precipitated calcium silicate hydrate crystals were described as long needles that group around centres of crystallisation as depicted in the last image of Fig. 1A. Although hydrated calcium ferrite was found in single-phase hydration experiments, it was not observed in in situ microscopy of the cement hydration. Hence, it was concluded that ferrites do not contribute to the setting of cement. According to Le Chatelier’s theory, strength is only based on the adhesion and cohesion of the fine crystals. [10, 11].

A The mechanism of cement hydration according to Le Chatelier: The dissolution of the anhydrous compounds ①is followed by precipitation of calcium silicate hydrate needles and hexagonal calcium hydroxide crystals from the supersaturated solution ②. The reduced ion concentration in the solution will restart the dissolution, and the crystalline hydration products will grow ③. For clarity, only the reaction of tricalcium silicate is shown that was identified as strength-giving by Le Chatelier. B: The mechanism of cement hydration according to Michaëlis: After the dissolution of clinker and gypsum, crystalline calcium sulphoaluminate needles are formed from tricalcium aluminate and calcium sulphate. Moreover, calcium aluminate and ferrite hydrate form as small hexagonal plates ①. A water-rich hydrogel forms around the clinker, embedding the prior formed crystals ②. Desiccation of the hydrogel through the hydration of the anhydrous clinker core will result in the final structure formation ③

Based on our current knowledge of cement hydration, many of the findings of Le Chatelier [10, 11] were accurate, especially his investigations of the clinker chemistry were later confirmed by other authors [15, 17, 25]. In particular, the petrographic study of Törnebohm [17] shall be mentioned here since the major clinker phases Alite and Belite were named by him. He further labelled the ferrite containing phase Celite. The fourth phase, whose composition he could not determine, was named Felite. Felite was later identified as a belite with anomalous crystallographic properties [16]. Moreover, Törnebohm [17] wrongly assumed alite and belite to be mixed phases with aluminate. Later it was found that only a small quantity of aluminate can be incorporated into the structure of alite that was proven to be a tricalcium silicate [18, 19].

Not all researchers initially agreed on calcium silicate hydrate as the primary strength-giving compound [20, 21]. The work of Richardson [20] shall be mentioned, who also identified the hydration of alite as strength-giving in 1904. However, he concluded that strength is entirely due to the crystallisation of calcium hydroxide [20], a point of view which later was also represented by Joisel [21] but cannot withstand experimental evidence [28].

Colloid theory

Le Chatelier’s [10, 11] proposal that all hydration products are crystalline and responsible for setting and strength has been a subject of dispute. Wilhelm Michaëlis developed a theory that rejected Chatelier’s concept of solely crystalline hydration products and was later referred to as “colloid theory”, which was first published in 1893 [9] and further elaborated in a publication from 1909 [12]. Michaëlis considered that crystals nucleate on the surface of the clinker from supersaturated solution and that these can be responsible for the development of setting and strength. Nevertheless, since water would be able to penetrate a crystalloid mortar, it could never be hydraulic, which he compared to the properties of plaster of Paris. Michaëlis concluded that the formation of colloids is the origin of the hydraulic properties of cement. Figure 1B illustrates the mechanism of cement hydration according to Michaëlis. After calcium sulphoaluminate, calcium aluminate, and ferrite hydrates have formed as crystals (Fig. 1B—①), a water-rich calcium hydrosilicate gel forms around the clinker, embedding the preformed crystals (Fig. 1B—②). The early colloidal gel is described as semi-permeable, allowing water to penetrate but retaining the calcium ions. The ongoing hydration of the clinker core extracts water from the inner layers of the gel, which is densified due to the water loss and calcium incorporation. Hydration eventually stops when no more water can penetrate the compact gel. Moreover, an anhydrous core might remain (Fig. 1B—③). Michaëlis demonstrated that cement stored underwater for years can be reground and will harden again due to the anhydrous clinker cores. Furthermore, he explained that the hydration in excess of water would not result in strength development since the hydrogel cannot desiccate. [9, 12].

Although the theories of Le Chatelier and Michaëlis seem to be counter-drafts at first sight, it appears that they are mainly divided by the nature of the hydration products and, hence, by the question of whether amorphous or crystalline compounds are responsible for strength. Furthermore, the concept of colloids, introduced in 1861 by Thomas Graham [145] but redefined in 1911 by Weimarn [146] and Ostwald [147], was yet vague and remained a point of dispute [22]. Le Chatelier stated in 1919 [11], “People evade defining what they call a colloid, but they seem to take the word in the sense of a body capable of hardening. And then the explanation comes down to this: cements harden because they have the property of hardening”. He claimed that finely ground crystals would also express colloidal properties until they recrystallise [11]. Indeed, Koyanagi [23] proposed that high-strength types of cement are characterised by exceptionally tiny crystals, whose large surface is responsible for the superior properties. Moreover, Weimarn [24] proposed in 1919 that real amorphous bodies do not exist but are micro-crystalline instead. In numerous experiments, he recrystallised substances that were considered as amorphous-colloidal.

In the following decades, variations and expansions of the original theories were proposed and discussed. Most of them position themselves between the crystalloid and colloid hypothesis, trying to examine a mechanism that can unite both.

Further developments: "thin film" and recrystallisation theories

Discussing the crystalloid and the colloid theory at the first International Symposium on the Chemistry of Cements 1919, the metallurgist Walter Rosenhain [13] proposed the mechanism illustrated in Fig. 2A. By analogy to textile fibres, he also rejects static friction and adhesion of crystallites as the sole cause for strength. The needle-like morphology of cement hydration products cannot be compared to elongated fibres and does not provide adequate frictional contact points [13]. Rosenhain observed that the adhesion of crystalline grains in metals is caused by a thin film of amorphous materials between the crystalline domains [26, 27]. Transferred to cement hydration, he describes hydrating cement to consist of crystalline grains surrounded by a solution, as illustrated in Fig. 2A after step ①. Removal of water either by hydration or percolation will induce further solidification. If the space between existing crystals is large enough, the solution can solidify by crystallisation (Fig. 2A—②). Nevertheless, when the film between crystals becomes too thin, the solution can only solidify as an undercooled liquid (Fig. 2A—③). The famous metallurgist claimed that this film is the cause of stiffness and strength of cement [13].

A The mechanism of cement hydration according to the "thin film" theory by Rosenhain [13]: After the initial dissolution of clinker, crystalline hydration products (hexagonal calcium hydroxide and calcium silicate hydrate needles) surrounded by solution are formed ①. Crystallisation will progress in large enough spaces between the existing crystal grains ②. Finally, the solidification of an amorphous film in spaces too small for crystal-formation will lead to the final structure formation. B The mechanism of cement hydration according to the recrystallisation (Ostwald ripening) theory by Baykoff [31]: After the initial dissolution and consequent supersaturation ③, an amorphous gel precipitates around the clinker, which undergoes recrystallisation due to the higher solubility of smaller aggregates ①. The strength of cement is attributed to the larger crystals growing from the gel ②. Please note that calcium hydroxide and calcium silicate hydrate are shown, although not specified by Rosenhain or Baykoff

Similarly, the work of Würzner [30] highlighted the role of thin films for strength. He demonstrated that water might begin to act as a binder in a sand mass if the water layer becomes sufficiently thin. The higher strength of cement with a lower water content was seen to confirm this mechanism [29]. Würzner showed that the removal of water creates a vacuum in the paste. As a consequence, the contact between particles of the paste becomes more and more intimate. This was seen as the primary cause of hardening in hydraulic binders [30].

The first expansion of Michaëlis colloid hypothesis was published in 1914 by R. J. Colony [25]. In an extensive petrographic study, thin sections of hydrated cement prepared under conditions comparable to practical application were analysed. It was observed that as primary precipitate, spherulitic calcium hydroxide is formed. In this matrix, isotropic grains assigned to aluminium or silicate hydrates and small patches of a so-called primary colloid, finely mixed with calcium hydroxide giving a layered structure, were found. These initially formed phases were observed for up to 24 h, after which they appeared to react in an undefined way to form an amorphous mass without any identifiable phases. Calcium hydroxide spherulites were found only in isolated patches and as lining of cavities or voids. Colony’s most important finding was that recrystallisation processes must occur after the formation of the amorphous mass. Secondary crystalline calcium hydroxide, calcium carbonate, and larger amounts of zeolitic matter were reported. He assumed that total recrystallisation might never be attained. However, the products of recrystallisation may contribute to the hardening of the cement [25].

Both, Rosenhain [13] and Colony [25] tended more towards the colloidal theory and hence highlighted the importance of the colloidal gel formed during cement hydration. Opposed to that, BaykoffFootnote 1 [31] published a mechanism for setting and hardening of cement that included the colloid only as an intermediate (Fig. 2B). According to Baykoff, all hydration products are initially precipitated from the supersaturated solution as colloidal hydrates (Fig. 2B—①); this precipitation is seen as the cause for the setting of cement. He specified that the conditions for the formation of a colloid are fulfilled since the solubility of a compound is sufficiently reduced when the solution becomes saturated. The precipitated mass, which he refers to as crystalline gel, then converts to "crystals of larger dimensions" due to the higher solubility of smaller crystals (Fig. 2B—②). A process now commonly referred to as Ostwald ripening [32]. The subsequent transformation of the gel to larger aggregates was correlated with the hardening of cement (Fig. 2B—③) [31]. The subsequent formation of larger crystals from a colloidal matrix was demonstrated in microscopic experiments of Koyanagi [23], who prepared thin paste preparations (< 10 µm) for in situ observation in transmission.

Protective layer theories

Both Colony [25] and Baykoff [31] had proposed a step of recrystallisation in their mechanisms of cement hydration. Furthermore, all authors describe the hydration products as crystalline matter embedded in an amorphous groundmass, although Baykoff proposed that the amorphous mass might recrystallise entirely with time. Le Chatelier’s suggestion of purely crystalline hydration products [10, 11] was rejected by most authors since more and more advanced imaging techniques clearly showed the formation of an X-ray amorphous mass of hydration products. The concept of micro-crystallinity that could unify the opposing theories was yet “hard to believe” at this time, as stated in the first edition of Lea & Desch’s Chemistry of Cement and Concrete in 1935 [33]. In 1935, Frederick Lea also introduced the now standard cement chemistry nomenclature that denoted the oxides CaO, Al2O3 and SiO2 as C, A and S in a short form [34].

Besides the origin of hydraulicity and phase formation, the characteristic heat development during cement hydration became a focus of interest. As already reported by Le Chatelier [10], there is a period of inactivity at the beginning of the hydration, during which he could not measure any temperature rise. After this period is overcome, setting was observed, which led to the conclusion that the period of inactivity must be the time required for critical supersaturation [10].

In 1934 Lerch and Bogue [35] introduced the differentiation of the hydration process in four hydration periods based on heat of hydration measurements. The characteristic heat development recorded in heat flow calorimetry soon became a standard measure for the different reaction phases. The method is a “sensitive index of the early hydration of the cement” [37], as pointed out in 1937 by Carlson, who contributed significantly to the establishment of isothermal heat flow calorimetry. In 1937 he published the first rate of heat plot; a schematic illustration is shown in Fig. 3 [36, 37]. The first period of heat development only lasted for a few minutes and is characterised by an initial rise in temperature. This first peak is followed by the previously mentioned period of inactivity, whose length was observed to depend on the cement’s composition. The so-called dormant period transitions into a period of renewed rapid heat production until the heat development peaks and finally slows down in the fourth period [35]. The fourth or deceleration period will not be the focus of the following discussion of hydration mechanisms.

Schematic illustration of the hydration periods based on the rate of heat development. For OPC approximately 2–5mW/g are reached during the main reaction (period III to period IV). During the initial period much higher values in the range of 100mW/g are obtained, however, due to the rapidity of the heat evolution the values reported to literature fluctuate significantly. Adapted from [36, 37]

Lerch et al. [35] described the initial rise in temperature caused by the heat of wetting and stirring. Lerch and Bogue [35] followed Le Chatelier’s [10] explanation of subsequent saturation and supersaturation for the observed dormant period. Microscopic observation supported this theory since calcium hydroxide crystals and colloidal hydrates were observed to form only after a few hours [35]. After critical supersaturation, rapid precipitation and the renewed dissolution of clinker enhances the heat flow in period III. A layer of hydration products around the clinker was suggested to eventually retard the water penetration and consequently the heat flow in period IV [35].

Beginning of the dormant period

While Lerch and Bogue initially only explained the deceleration period based on a protective layer theory [35], they soon extended that concept to the origins of the dormant period [38]. It was proposed that upon contact with water, a film of hydrated calcium silicate hydrate forms around the reacting tricalcium silicate, restricting further reaction (Fig. 4—①). As illustrated in Fig. 4, hydration was suggested to only progress by diffusion of water through the membrane (Fig. 4—②) or by reaction of the highly hydrated outer product with a lesser hydrated or anhydrous inner product (Fig. 4—③). Furthermore, ferric oxide-containing compounds induced a substantial retardation of the silicate reaction, which was explained by the formation of a layer of amorphous calcium ferrite around the tricalcium silicate clinker. The proposed mechanism for the silicate reaction is similar to the colloidal theory of Michaëlis [9, 12], although it was not referred to by the authors. Bogue and Lerch [38] have neither observed a hydrated calcium silicate film nor a calcium ferrite film directly; however, the formation of a hydration product layer became soon the predominant explanation of the origin of the dormant period.

A Mechanism of the protective layer theory of tricalcium silicate hydration proposed by Bogue et al. [38]. Upon the first contact with water, a layer of amorphous hydration product forms around the clinker grains ①. Hydration can advance by diffusion of water through the film ② or by reaction with the higher hydrated outer products, creating a gradient of hydration from the outer product to the inner product ③. With time the hydration products become more uniform in hydration. B: Early hydration of tricalcium silicate and origin of the dormant period according to Kalousek [44]: After initial dissolution, a calcium silicate hydrate gel is formed around the clinker, restricting the water penetration ①. The initial C–S–H was assumed to have a low calcium content since the concentration in the solution is below supersaturation (c < cs). After supersaturation (c > cs), the initial film is transformed to a gel with higher calcium content and higher water permeability, causing the end of the dormant period ②

The formation of a layer was also proposed as an explanation of the retarding effect of sulphate. Based on the chemical analysis of different clinkers and their pore solution in combination with the corresponding setting times, Roller [39] proposed in 1934 that the direct hydration of tricalcium aluminate (Eq. 1) is hindered by the formation of a stable tetracalcium aluminate hydrate layer around the tricalcium aluminate in the presence of high calcium hydroxide concentrations (Eq. 2).

Roller [39] clarified that calcium hydroxide is provided by the hydrolysis of tricalcium silicate. Gypsum and other reactive calcium compounds were suggested to supplement the retarding action of tricalcium silicate by providing additional calcium hydroxide through reaction with alkali hydroxides. If the calcium hydroxide concentration is not sufficiently high, sulphoaluminate hydrate (ettringite) was observed to form rapidly, which was seen to cause the quick set indirectly by decomposing the protective tetracalcium aluminate hydrate film. [39]

Other authors like Forsén [40] proposed the possibility of a retarding monosulphoaluminate hydrate (3CaO·Al2O3·CaSO4·32H2O) film in the presence of gypsum. Moreover, Jones [41] suggested in 1945 that in high sulphated systems, the trisulphate compound 3CaO·Al2O3·3CaSO4·32H2O (ettringite), which is in equilibrium with saturated calcium sulphate solutions, must be formed. He, however, considered that a local temperature increase during tricalcium aluminate hydration might favour the formation of the monosulphate. Jones also especially highlighted the importance of protective coatings in the Portland cement–water system [41].

Today, the retardation of the aluminate reaction by a protective barrier is widely rejected. Minard et al. [42] showed that trisulphate and monosulphate form already at the beginning of the hydration, but SEM images prove that the surface is not sufficiently covered for a significant retardation of the aluminate dissolution. Also Lerch [43] rejected the protective sulphoaluminate hydrate layer theories of Roller [39], Forsén [40] and Jones [41] since they cannot account for the rapidity of the aluminate dissolution after sulphate depletion.

Minard et al. propose that sulphate adsorption on the tricalcium aluminate surface blocks the dissolution centres and hence causes the retardation until the sulphate is consumed [42]. A concurring theory was already proposed in 1946 by Lerch [43]. He ascribed the reduced aluminate dissolution to the high sulphate and hydroxide ion concentrations in solution and the rapid reaction to the renewed dissolution after sulphate is consumed by the formation of calcium sulphoaluminate. Since the aluminate reaction is not the focus of this review, the interested reader is referred to the extensive review of the early development of cement chemistry, published by Hans Kühl [46] that included the reactions of all clinker phases.

One of Lerch’s [43] critics was Georg Kalousek [44], who argued that the retardation of the aluminate reaction by a protective layer of hydration products is more tenable. Nevertheless, discussing Lerch’s publication, Kalousek pointed out a less emphasised detail regarding the silicate reaction: The calorimetric curve of pure tricalcium silicate was comparable to cement with low alumina and alkali content. Thus, the dormant period had to be explained by the silicate reaction alone. Kalousek was the first to propose the formation of a protective calcium silicate hydrate layer around the clinker as an explanation for the dormant period after initial dissolution (Fig. 4B:—①) [44]. Over time, many other authors investigated tricalcium silicate as a model compound for the hydration of cement. Therefore, the hydration of tricalcium silicate, not cement with all clinker phases, will be the focus of the following sections.

Kalousek [44] assumed that the initially formed calcium silicate hydrate must be less permeable for water than its conversion product. The latter was assumed to be richer in lime since the solution gradually becomes supersaturated with respect to calcium hydroxide during the dormant period (Fig. 4B—②) [44].

The formation of a hydration product layer was seen to be supported by microscopic evidence [47–50] and could conveniently account for the observed rate reduction. The protective layer theory hence became the predominant explanation of the dormant period. Nevertheless, the chemistry of the layer and the mechanisms ending the period of low activity were yet under debate.

End of the dormant period

Conversion of the protective layer

The existence of more than one calcium silicate hydrate was evidenced by Taylor in 1950 [51]. He synthesised a phase with a calcium to silicon ratio between 1 and 1.5, the so-called C–S–H I, by co-precipitation of calcium nitrate and sodium silicate. A second phase, called C–S–H II with a calcium to silicon ratio of approximately 2, stable in the presence of calcium hydroxide solution, was synthesised by hydration of tricalcium silicate.

The formation of two different types of C–S–H during different stages of hydration was confirmed in 1954 by Van Bemst [53], who explained hydration kinetics based on a dissolution/supersaturation mechanism. His work is based on the investigation of systems with varying water content and the characterisation of the hydration products by differential scanning calorimetry (DSC). Initially, when the pore solution has not yet reached supersaturation with respect to calcium hydroxide, C–S–H I precipitates from the solution. After supersaturation with respect to calcium hydroxide, the condition for C–S–H formation is fulfilled which is supposed to result in the formation of the calcium-rich C–S–H II directly on the clinker surface. Van Bemst’s findings, however, suggest the formation of a hydration product layer after the dormant period since supersaturation with respect to calcium hydroxide is reached only at the end of the dormant period. [52, 53].

Various authors took up the hypothesis of an initially formed metastable calcium silicate hydrate "protective" coating, responsible for the rate reduction, which is later transitioned into a less protective hydrate [54, 60,61,62,63]. However, the determination of the calcium to silicon ratio of the hydrates showed a decreasing trend over the course of hydration, opposing Kalousek’s proposal of a low-lime protective hydrate converted later by uptake of calcium ions from solution [54].

The delamination theory proposed by Kantro et al. [54, 55] is based on an initial hydrate, consisting of alternate calcium silicate hydrate and calcium hydroxide layers (Fig. 5A—①). Upon calcium hydroxide dissolution, layers of calcium silicate hydrate are liberated and form a second intermediate with lower calcium to silicon ratio (Fig. 5A—②). Dissolution and precipitation of the secondary C–S–H are supposed to result in the formation of the final thicker hydration product (Fig. 5A—③) [54,55]. The delamination theory was supported by electron microscopy that showed the formation of exfoliating sheets observed in a wet cell [56]. Moreover, needles that were interpreted to consist of rolled-up sheets were reported [47] and Grudemo [57] reported flakes with rolled edges for artificial C–S–H prepared from silica and lime. Nevertheless, Grudemo [57] emphasised that the rolling of the sheets might be a secondary effect caused by dehydration during electron microscopy. This was underlined by the observation of unrolled sheets when a wet cell has been used to prevent drying [57].

A Illustration of Kantro et al.’s [54, 55] delamination theory to explain the development of the surface during the dormant period. Initially, a high-lime hydrate consisting of C–S–H and CH layers is formed around the clinker, inhibiting the progression of the hydration ①. The dissolution of calcium hydroxide from the layers liberates C–S–H sheets as secondary intermediate ②. Dissolution and precipitation of the metastable sheets lead to the formation of the final stable C–S–H sheets ③. B: The key element of Powers [73] osmotic pressure hydration mechanism is the formation of a transition zone between the anhydrous core and protective layer (light blue) ②. The larger silicate ions are restricted from a fast diffusion through the layer, which will cause a concentration gradient from the solution to the transition zone. Consequently, water will continuously diffuse to the interspace, causing a rise in pressure (dark blue). The dormant period is terminated by the rupture of the protective layer ③

Kantro et al. [54, 55] did not focus on an explanation of the termination of the dormant period. Their model is based on the observed maximum of the specific surface area during the dormant period. Detailed electron micrographic studies of the first minutes of C3S hydration by Ménétier et al. [50] seem to support Kantro et al.’s mechanism: 15 min after water contact a drastic change of the hydration product morphology was visible. The surface seems to have peeled and a porous honeycomb-like structure was recorded [50]. Their theory, as proposed, however, can hardly account for the duration of the dormant period. At the beginning of the dormant period, the concentration gradient in the solution from the primary high Ca-intermediate to the solution composition is high, while at the end of the dormant period, the solution reaches supersaturation with respect to calcium hydroxide [59]. Since the concentration difference is the driving force for the dissolution of interlayer calcium hydroxide, the reaction rate should be rather reduced at the end of the dormant period based on the proposed mechanism instead of accelerated.

Stein and Stevels [60] extended the delamination mechanism by a vital detail. They observed an accelerating effect of amorphous silica onto tricalcium silicate hydration, which seemed to be consistent with Kantro et al.’s [54, 55] delamination theory. The observed accelerating effect of silica was correlated with the measured reduced calcium ion concentration in solution during the first minutes after water contact. The reduced calcium concentration will promote the dissolution of calcium hydroxide from the primary product and hence the formation of calcium silicate hydrate nuclei. The consumption of ions by the formed nuclei further accelerated the conversion of the primary intermediate [60]. Later however, the authors emphasised that the accelerated transformation is due to the formation of additional nuclei [61, 62]. This autocatalytic conversion added an essential element to Kantro et al.’s mechanism [54, 55] since the formation of additional nuclei was suited to explain the observed acceleration of the hydration rate. Further support to Stein et al.’s [60] & Kantro et al.’s [54, 55] delamination theory was given by the investigation of de Jong et al. [61], who proposed, based on electron micrographs, that the second foil-like hydrate is further transformed into a needle-like third product [61], which Kantro et al. had interpreted as the rolled-up secondary product [54, 55].

Kawada et al. [63] emphasised the role of silicate polymerisation for C–S–H nucleation. Comparable to Kantro et al.’s [54, 55] mechanism, they proposed that the initial hydrate will liberate calcium hydroxide ions from tricalcium silicate into the solution. The loss of calcium ions will reduce the distance of the nesosilicate units of tricalcium silicate that will form the three-periodic structure of the stable product. When the solution becomes saturated in calcium hydroxide, a secondary intermediate is formed on the decalcified surface of tricalcium silicate. Stable nuclei were proposed to be liberated from that surface once the supersaturation of the solution with respect to the secondary intermediate becomes sufficiently high. Kawada et al. [63] suggested that due to the liberation of nuclei, the secondary product layer becomes thinner, promoting the penetration of water to the anhydrous core. The driving force for the liberation of the nuclei formed on the surface remained unclear. Investigating the effect of calcium chloride and -sulphate (gypsum), the authors proposed that nucleation in the presence of these additives is more rapid due to the higher supersaturation, accelerating the hydration [63].

The enhanced silicate polymerisation due to calcium leaching proposed by Kawada et al. [63] is a concept also proposed by Young and co-workers [59], who investigated nucleation and growth processes during C3S hydration. The formation of a metastable C-S–H with a C/S-ratio of approximately 1.5 is also compatible with thermodynamic considerations of Gartner and Jennings [64] for C–S–H I and II. Furthermore, the importance of silicate polymerisation was highlighted by cross-polarisation solid-state nuclear magnetic resonance (29Si-CP-MAS-NMR) investigations [65, 66]. The indirect excitation of the silicon nuclei by surrounding protons allowed the differentiation of hydrated silicon species from anhydrous. It was found that upon contact with water, monomeric hydrated silicates are formed, which were suggested to form the layer responsible for the rate reduction observed after the initial reaction. The addition of calcium chloride resulted in a shortened dormant period and an enhanced formation of silicate monomers at earlier times, which appeared to contradict their function as a protective hydrate [67]. However, near the end of the induction period a lower quantity of monomers was formed compared to hydration without chlorides and the addition of sucrose, a well-known retarder, resulted in the slower formation of silicate monomers. Rodger et al. [65] emphasised that their findings are also in accordance with the delayed portlandite nucleation theory (as discussed in Sect. 5.3), which does not require the formation of a protective layer. Most recently, Aretxabaleta et al. [148] demonstrated by atomistic simulation methods, that the condensation of dimeric silicates might be a crucial step during the nucleation of C–S–H from portlandite precursor monolayers in their proposed nucleation model.

Tricalcium silicate, whose hydration was stopped during the dormant period, dried, and rehydrated again, showed a significantly shortened or no dormant period after rehydration [68]. This was interpreted as that the decisive changes during the dormant period must be in the solid, seemingly supporting the concept of a protective hydrate layer. Furthermore, the hydration in the presence of long-time pre-hydrated tricalcium silicate resulted in an elongation of the dormant period. This was seen to be caused by additional calcium ions in solution, inhibiting the conversion of the protective layer [68]. Indeed, several hydration experiments demonstrated that the introduction of additional calcium hydroxide resulted in an elongation of the dormant period [61, 69, 72].

Rupture of the protective layer

Parallel to the conversion theory, hydration mechanisms based on the formation of a protective layer, but with an alternative concept for the end of the dormant period, were suggested. These mechanisms considered the renewed hydration activity to be caused by the physical removal of the inhibiting hydrate layer.

Osmotic pressure

The first to propose a rupture of the protective calcium silicate hydrate layer was Powers in 1961 [73]. Assuming that the hydration product layer is not in direct contact with the anhydrous core, he proposed the formation of an aqueous transition zone (Fig. 5B—②). Initially, the protective layer was assumed to be thin and permeable, allowing a relatively unrestricted diffusion of silicate, calcium, and hydroxide ions into the pore solution (Fig. 5B—①). The more the hydration product layer grows, the more the diffusion of ions will be hindered. Powers specifically assumed the initial reduction in hydration activity to be caused by the hindered diffusion of silicate ions through the protective layer. Due to the contact with the anhydrous core, the solution within the transition zone would become more concentrated than the solution outside the protective layer. The resulting concentration gradient between pore solution and interlayer is seen as the driving force for the continuous diffusion of water molecules into the transition zone, causing a rise in pressure. Once the pressure in the transition zone would reach a critical level, the dormant period would be terminated by the rupture of the protective layer (Fig. 5B—③). [73]

The decrease in the silicate ion concentration in solution during the dormant period seems compatible with Power’s proposal [74, 75]. A higher concentration difference to the interlayer should result in a higher diffusion rate and increased osmotic pressure. However, osmotic pressure based on silicate diffusion alone cannot explain the retardation by extra calcium and hydroxide ions, as discussed in the conversion theories above. Nevertheless, it is reasonable to assume that if the diffusion of one ionic species is hindered, also others cannot pass the protective layer without a delay. An increased ionic concentration outside the transition zone would lower the impetus for osmotic pressure built up, hence elongating the time needed for a collapse of the layer and the duration of the dormant period. However, the acceleration observed in the presence of calcium chloride or calcium sulphate would not be explainable. In any case the pore solution is slowly approaching supersaturation with respect to calcium hydroxide during the dormant period, even in an unaltered system. Thus, the contribution of a calcium or hydroxide ion concentration gradient must be negligible, at least at the end of the dormant period. Another explanation could be that an elevated calcium hydroxide concentration indirectly alters the silicate concentration gradient by reducing the dissolution of tricalcium silicate and, hence, the silicate concentration in the transition zone. Whether this explanation might be valid would strongly depend on the diffusion kinetics since the transition zone is assumed by Powers [73] to be supersaturated due to the direct contact to the clinker surface in the absence of additives.

Powers [73] elaborated that the growing layer of hydration products is repeatedly torn during the acceleration stage of hydration until the pressure can no longer cause its rupture, initiating the deceleration period. Based on the proposed mechanism, it would also be possible to explain the expansion of cement pastes, starting at the end of the dormant period by the rising pressure and expansion of the transition zone. To account for the relatively low expansion compared to the degree of hydration, Powers proposed the formation of products at the inner wall of the protective layer, effectively keeping the transition zone at a constant thickness. The formation of inner products also explains the observation of hydration products in the shape of the original clinker grains [76]. Furthermore, the formation of two distinct types of C–S–H during different stages of hydration, which led various authors to the assumption that it must be transformed during the dormant period, can be explained by the inner and outer product formation [73].

Power’s [73] mechanism is suited to describe many of the main features of cement hydration. He, nevertheless, did not comment on structure formation. An extension of his mechanism was developed by Double et al. [77] and Birchall et al. [81, 82] based on the analogy to silicate gardens. Such chemical gardens were already observed by Glauber in 1646 [78]; they are created by placing a metal salt in a highly alkaline solution, for example, sodium silicate solution. The dissolution of the metal salt (e.g. ferric chloride) results in the formation of a gelatinous, semi-permeable membrane inhibiting further dissolution. As described by Powers [73] for cement hydration, osmotic pressure will arise from the diffusion of water into the membrane space. The rupture of the membrane will result in the precipitation of the product along the direction of the burst, creating tubular structures [79]. Based on the structural precipitation of silicate gardens, Double et al. [77] proposed the formation of calcium silicate hydrate needles by extrusion through cracks in the protective layer. His in situ electron microscopic studies of cement confirmed that initially, gelatinous C–S–H was formed, while elongated needles were observed only later. Furthermore, the needles indeed appeared to be hollow [77, 80], as was already reported by Copeland et al. [47]. Nevertheless, a high water content (water to cement ratio, w/c = 10) was necessary to record these micrographs with a wet cell [80].

Investigations explicitly targeting the rupture of the protective layer due to the osmotic pressure were carried out by Jennings et al. [83], who diluted hydrating clinker after 1–2 h with demineralised water. Elongated hollow fibres were formed in the diluted specimen, which supports the formation of a membrane and the extrusion by osmotic pressure. It was, nevertheless, emphasised that the experiments shall not be seen as strong evidence for the formation of osmotic pressure in undiluted systems. The authors argued that the membrane might be imperfect or might not separate from the anhydrous core. Additionally, it was found that hollow needles observed in undiluted pastes showed a composition close to ettringite [83]. The results of Barnes et al. [84] in 1980 also oppose rupture-extrusion theory. Barnes et al. [84] investigated hydrated cement, tricalcium silicate, tricalcium aluminate and tetra calcium aluminate ferrite with gypsum to compare the hydration products formed in the different systems. The absence of any hollow or tubular structure in hydrated tricalcium silicate, compared to the formation of hollow needles in cement, C3A and C4AF, led Barnes et al. [84] to the conclusion that the hollow structures are caused not by C–S–H but by ettringite. This is supported by elemental analysis and conclusive with Jennings findings [83].

Compressed layer

Another concept for the rupture of the "protective" layer was given in analogy to protective oxide films formed on metals by Ball [86]. He adapted the method of Pilling and Bedworth [85] to characterise the hydrate films [86]. The Pilling-Bedworth ratio describes the relation of product volume to the original volume occupied by the reactant, which should be 1 for optimal passivation. Ratios below 1 will be porous and not protective. In contrast, ratios > > 1 will initially result in the formation of a highly compressed oxide layer, that will finally fail due to its high volume [85, 86]. Ball [86] determined a Pilling-Bedworth (product/reactant volume) ratio of 1.2 for the early hydrate with a high water and low calcium content. Upon ageing, the molecular weight was assumed to rise, resulting in an even higher product/reactant volume ratio. The stress in these films will eventually be released by spalling, causing the end of the dormant period. Furthermore, the connection between film and substrate was discussed. Factors causing a worse cohesion should result in a shortened dormant period since delamination would be favoured, which was correlated with the accelerating effect of crystal defects of the tricalcium silicate surface [86, 87]. Moreover, the proposed structure development was seen to be confirmed by electron micrographs showing initially uniform films starting to crack and delaminate [50]. The morphological change, interpreted as spalling due to the high Pilling-Bedworth ratio, nevertheless, already started after 15 min. Thus, it can hardly account for the end of the dormant period, which occurs after several hours [50, 86].

Is there evidence for the existence of continuous layers?

A key element of the protective layer theories is the formation of a continuous hydration product shell around tricalcium silicate. Direct observation methods such as (high resolution) scanning electron and atomic force microscopy, nevertheless, revealed that the surface of the anhydrous clinker is only covered to a small percentage at the beginning of the dormant period [70, 88, 89]. To account for this, it had been proposed that the protective layer could not be distinguished from clinker by electron microscopic methods because it is close fitted or only a few atomic layers in thickness [60, 61, 90]. This hypothesis was supported by hydrogen depth analysis of Schweitzer and Livingston et al. [91, 92], who determined the thickness of the initial hydrate to 1.1 nm, equal to a few unit cells based on nuclear resonance reaction analysis.

More recently, experimental methods were complemented by computational methods. The simulation of the hydration mechanism allows to test various parameters and theories in a short time and, hence, offers a valuable tool to test proposed mechanisms of cement hydration. Parameters for the models, nevertheless, must be assumed based on an incomplete experimental database. Bullard et al. [93] found that their model, a combination of protective layer and nucleation and growth mechanism, can account for several experimental observations [93]. A good fit, however, can never prove a certain mechanism [2, 94]. Nonetheless, the discrepancy of the protective layer theory with microscopical evidence and the question of whether it is sufficiently impermeable to the diffusion of ionic species became its biggest point of criticism [2, 67, 95, 96].

Hydration driven by dissolution, nucleation, and growth

The basic idea that tricalcium silicate hydration kinetics during the dormant period is solely based on dissolution, nucleation and growth principles was already proposed by Le Chatelier [10]. The growing rejection of the protective layer theories led to a reconsideration of this fundamental approach. Dissolution and precipitation in the calcium-silicate-hydrate system are phenomena that cannot be contemplated separately. However, the decisive question became whether the dormant period is caused by slow dissolution of tricalcium silicate or by delayed nucleation of calcium silicate hydrate or calcium hydroxide. Several authors proposed theories that aim to explain the reduction in rate after the initial period and the acceleration at the end of the dormant period without the necessity of a "protective" hydration product layer.

Adsorbed water layer theory

Fuji and Kondo [88, 89] proposed a mechanism for the dormant period based on the slow dissolution caused by free energy reduction in the tricalcium silicate surface due to water adsorption. The formation of a water layer, 3–4 molecules in thickness, is in accordance with the absence of a hydration product layer seen in electron microscopy. The water layer theory is based on the rapid rise of bound water during the first minutes of hydration, which cannot be accounted to hydration products alone. Fuji et al. [88, 89] proposed that during the initial period, one mole layer of tricalcium silicate dissolves congruently resulting in the precipitation of foil-like C–S–H I through solution and in the topochemical formation of C–S–H II nuclei. The formation of C–S–H I and needle-like C–S–H II through different paths was suggested because of the observed differences of the morphological features and in accordance with Van Bemst’s concept of C-S–H formation [52]. The dormant period is thus assumed to be initiated by the adsorption of water molecules resulting in a stabilisation of the dissolving surface (Fig. 6—①) and thus slowdown of reaction. Based on the determined heat of wetting and heat of hydration, the authors determined an energy reduction by 32% compared to an exposed clinker surface without water layer. Once critical supersaturation with respect to calcium hydroxide would trigger the precipitation of calcium hydroxide (Fig. 6—②), the dormant period is supposed to end through the growth and secondary nucleation of C-S–H II on calcium hydroxide (Fig. 6—③) [88, 97].

Water layer theory of Fuji et al. [88, 89]. After initial dissolution and nucleation of C–S–H I in solution (grey) and II on the surface (black), a water layer forms around the clinker, reducing the surface enthalpy and initiating the dormant period ①. The end of the dormant period is triggered when critical supersaturation (cs*) of calcium hydroxide causes precipitation ②. Secondary nucleation of C–S–H II on calcium hydroxide nuclei and the resulting growth will finally start the acceleration period ③

The concept of surface energy reduction due to water adsorption received little attention in the literature; a general point of criticism of theories regarding the dissolution as rate-determining step, however, was expressed by Bellmann et al. in 2015 [74]. The authors determined the rate of tricalcium silicate dissolution by in situ solution analytics. To prevent precipitation, small quantities of C3S were dissolved in solutions of different calcium hydroxide concentrations. It was found that the dissolution rate of C3S was always higher than the overall reaction rate, even under conditions of supersaturation with respect to calcium hydroxide. The authors point out that such a discrepancy between true dissolution and overall reaction rate could be explained by the formation of a protective layer [74]. However, Scrivener et al. [98] criticised that the tricalcium silicate investigated by [74] contained unusually high quantities of zinc and had a dormant period longer than 6 h. Moreover, local supersaturation in vicinity to the clinker surface might not be preventable even in high dissolution, complicating the determination of a true dissolution rate [99].

The relevance of the interaction of the anhydrous clinker surface and water was also studied by Fierens and Verhaegen [100, 101]. Nevertheless, the water adsorption was not seen as a cause for the dormant period but as an essential step towards renewed hydration activity.

Ion double layer theory

In 1976, a concept for the slow dissolution during the dormant period focused on superficial ion interaction was proposed by Tadros et al. [102]. Their theory is based on the positive surface charge of tricalcium silicate particles during early hydration determined by zeta potential measurements. The authors elaborate that calcium ions dissolve more readily than silicate ions which results in a silica-rich surface [102]. The differences in solubility might originate from the crystallographic structure of C3S, as pointed out by Jeffrey [103] and demonstrated by Ramachandran et al. [104]. After dissolution, positively charged calcium ions adsorb on the negatively charged surface, reducing the clinker mineral dissolution and initiating the dormant period (Fig. 7A—①) [102].

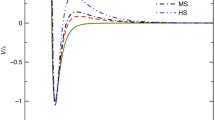

A According to Tadros et al. [102], rate reduction during the dormant period is caused by the formation of a positively charged surface through calcium ion adsorption (green) ①. The precipitation of calcium hydroxide is inhibited by silicate ions (red) ② until a critical supersaturation (cs*) 1.5 – 2 times higher than calcium hydroxide saturation, is reached. The generated nuclei initiate the growth of portlandite and calcium silicate hydrate, which act as ion sink, accelerating C3S dissolution and ending the dormant period ③. B Delayed growth of calcium hydroxide due to silicate poisoning according to Young et al. [59]. After initial dissolution, nuclei form on the clinker surface ① whose growth is hindered by silicate adsorption ②. The rising chemical potential in the solution retards the dissolution of C3S. Only when the overly high critical supersaturation cs* with respect to calcium hydroxide is reached the growth of C–S–H and CH is initiated, which will reduce the ion concentration in solution and restart the C3S dissolution ③

Investigations of Stein et al. [105] on model systems support the sorption of Ca2+ on C3S by recording a charge reversal stimulated by introduced calcium ions. Similarly, the surface charge of hydrating tricalcium silicate was followed in detail by Suzuki et al. [106], who found the initial negative charge to reverse after 20 min and a renewed reversal to negative charge after 60 min. Surface sensitive X-ray photon spectroscopy (XPS) studies were also conclusive with the concept. The analyses showed an initial decrease in surface C/S, which recovered to almost 3 and could be correlated with calcium ion adsorption after the initial dissolution [50, 107, 108]. Barret and Ménétier [107, 128], however, proposed the formation of a superficially hydroxylated layer mechanism to explain the observed phenomena as discussed in Sect. 5.5. In addition, it remains unclear why surface sorbed calcium ions should prevent or strongly slow down alit dissolution.

Tadros et al. [102] suggested that the same nuclei could initiate the growth of Ca(OH)2 and of C–S–H by incorporation of silicate ions. Calcium hydroxide may nucleate but could be prevented from growing (Fig. 7A—②). The dormant period would be terminated when critical supersaturation is reached to enhance the growth of hydration products, which act as sinks for ions in solution and thus enhance C3S dissolution (Fig. 7A—③) [102].

Delayed growth of calcium hydroxide

Intending to explain the high supersaturation with respect to calcium hydroxide at the end of the dormant period, Tadros et al. [102] investigated the influence of sodium silicate on calcium hydroxide precipitation. A significant reduction in the growth rate was found to correlate positively with the silicate concentration [102]. The poisoning of portlandite nucleation by silica was initially proposed by Greening in a private communication to Young [109]. It was later supported by experimental evidence highlighting that dissolution and precipitation of different ionic species in cement are strongly related. Young et al. [59, 110] proposed a mechanism entirely based on the delayed growth of calcium hydroxide.

Although there was a broad agreement that nucleation and growth determine the end of the dormant period, it was unclear whether the nucleation and growth of C–S–H or of portlandite triggers it. Young and co-workers [109] suggested that the nucleation and growth of calcium hydroxide is the decisive factor controlling the onset of the acceleration stage in hydration.

It was proposed that during the dormant period, calcium hydroxide nucleates (Fig. 7B—①) but is prevented from growing through the adsorption of silicate ions from solution (Fig. 7B—②). The dissolution of tricalcium silicate becomes more and more hindered as the ionic concentration in solution increases until a high level of supersaturation with respect to calcium hydroxide is reached (Fig. 7B—③) resulting in the growth of portlandite. The growth of calcium hydroxide will reduce calcium and hydroxide concentration in the solution, increase undersaturation with respect to alite and thereby terminate the dormant period. One indication for hindered growth of calcium hydroxide is the formation of portlandite crystals as short prisms, presumably due to adsorption of silicate ions preferentially on the 001 crystal site [109]. Furthermore, silicate inclusions were found in portlandite crystals formed during cement hydration [111]. To validate the hypothesis that silicate hinder portlandite growth, the influence of different admixtures was investigated. Organic retarders prolonged the dormant period and raised the maximum level of supersaturation with respect to portlandite; the organic retards were assumed to adsorb on calcium hydroxide nuclei similar to silicate ions [109]. In contrast, inorganic accelerators such as calcium salts were assumed to accelerate hydration by providing rapid supersaturation and hence promoting the growth of calcium hydroxide crystals [59, 112]. Young et al. [59] concluded that the impact of all these admixtures could be explained by their influence on calcium hydroxide crystal growth, supporting the proposed mechanism.

Although their mechanism does not include the formation of a protective layer, it is compatible with protective layer theories. Furthermore, it was emphasised that C–S–H and calcium hydroxide nucleation cannot be considered independently. They might even grow from the same nuclei, as proposed earlier by other authors [59, 88, 102, 113] and recently backed-up by atomistic simulations [148].

Support to the concept of early nucleation and delayed growth of calcium hydroxide is given by the investigation of doped and pure tricalcium silicate hydration by Slegers et al. [114], who detected portlandite reflexes significantly before supersaturation was reached in solution. Although the authors suggest that this might be due to local supersaturation, it might also be explained by silicate poisoning. Furthermore, the 001-reflex intensity of Ca(OH)2 was unusually low [114], indicating either preferential orientation or a higher defect density in the c direction of the crystal lattice. This could correlate with the preferential adsorption of silicate ions in the 001 sites of portlandite, as suggested by Young et al. [109]. The work of Ings and co-workers [49] on tricalcium silicate single crystals was also seen as an indication of portlandite formation before the end of the induction period [115]. However, while the authors indeed presented SEM micrographs showing calcium hydroxide spherules within 30 min, the calorimetric curve of the ground single crystalline material showed the end of the induction period already after approximately 25 min. The confusion might originate from the axis being shown in seconds. Moreover, image c in the same graph displays the calorimetric curve of the polycrystalline C3S, whose induction period was terminated after approximately 2.5 h [49]. A recent experimental study suggested that the inhibition of the crystallisation of portlandite could be a reason of the slowdown of alite hydration [149].

Hydration experiments, where calcium oxide or hydroxide had been added, were considered to contradict the delayed calcium hydroxide growth mechanism since they showed a retardation of the hydration [61, 71, 72]. However, it should be emphasised that Young et al. [59, 109] did not propose a delayed nucleation of calcium hydroxide, but the delayed growth due to silicate poisoning after relatively fast nucleation. Hence, the addition of crystal seeds does not necessarily overcome the barrier that retards the growth of the existing nuclei as it would be expected. Additionally, by adding small quantities of calcium hydroxide, the pore solution is less undersaturated with respect to C3S. Consequently, the dissolution is reduced, and the reaction is retarded. This correlation of solution composition and dissolution is the focus of the slow dissolution theory of Juilland et al. [67]. The barrier preventing calcium hydroxide from growing can only be overcome when the soluble silica is depleted, or the critical supersaturation with respect to calcium hydroxide is reached. Indeed it was shown that the addition of higher quantities of Ca(OH)2 leads to a less pronounced retardation of the reaction [61]. Moreover, the addition of ultrafine calcium hydroxide to pastes was shown to accelerate the hydration significantly, which was attributed to additional nucleation on its surface [116]. Alternatively, the enhanced solubility of the nano-sized material might trigger critical supersaturation rapidly. If a combination with a protective layer is considered, the arguments discussed before, including the effect of additional calcium and hydroxide ions in solution, also apply to Young’s mechanism.

Although the effect of additional calcium and hydroxide ions is difficult to explain, it does not refute Young’s theory of delayed growth of calcium hydroxide. Investigations of the portlandite and C–S–H precipitation kinetics, however, appear to contradict the delayed growth of calcium hydroxide growth hypothesis. Fierens and Verhaegen [101] report that the acceleration stage was initiated although the calcium hydroxide concentration in solution was still under portlandite solubility and proposed C–S–H nucleation as a trigger. Consistently, Damidot et al. [69] found that the endothermic calorimetry peak related to calcium hydroxide precipitation occurs within the main exothermic reaction in diluted suspensions. Thus, portlandite growth cannot be the (only) trigger for acceleration [69]. Moreover, it was found that an acceleration of the C–S–H growth rate occurs even under conditions that avoid portlandite precipitation. This indicates that the growth of C–S–H might at least co-determine the onset of the acceleration [117,118].

Delayed nucleation of C–S–H

Fierens and Verhaegen [119] investigated the thermoluminescence of anhydrous C3S and found a strong correlation between the probability of escape of trapped electrons to the length of the period of latency. Experiments with very pure C3S hint that the origin of the electrons trapped in excited surface centres are crystal defects. In contrast to Young et al. [59, 109], they propose C–S–H nucleation to control the dormant period.

C3S shows two thermoluminescence peaks. Samples irradiated with ultra-violet light for 15 min before mixing showed a more than 80% shortened dormant period and approximately doubled growth rate constant. Furthermore, the first thermoluminescence peak vanished after contact with water (vapour or liquid), while a third peak developed. It was concluded that the higher number of trapped electrons induced by irradiation is positively correlated with surface centres which can produce nuclei for potential C–S–H growth by water adsorption. The second thermoluminescence peak remained unaltered, indicating that C–S–H nucleation only occurs on preferential sites [119, 120]. The strong correlation of crystal nucleation and growth to defect sites has already been elaborated in 1949 by Frank et al. [121]. Moreover, the growth of hydration products in etch pits formed at defect sites was also considered by Nicoleau et al. [122]. The locally increased supersaturation in etch pits and the reduction in high-energy surfaces formed during dissolution were considered as possible reasons. Nicoleau et al. [122] highlighted the role of surface development on C3S during hydration and proposed a mechanism emphasising the dissolution topography (Sect. 5.6.2).

Fierens and Verhaegen’s [119] mechanism of delayed C–S–H nucleation is illustrated in Fig. 8. Initially, small quantities of the anhydrous clinker dissolve independently from the surface centres. Through chemisorption of water, nuclei of C–S–H are formed on excited surface centres (Fig. 8—①). Only when a sufficient number of nuclei overcome the critical radius, growth of C–S–H will initiate and terminate the dormant period (Fig. 8—②). Pore solution analytics of pastes with C3S subjected to different heat treatments showed that the acceleration period is initiated, although the concentrations of calcium and hydroxide are below critical supersaturation. The growth of C–S–H will liberate calcium ions into solution, and only when the critical supersaturation with respect to calcium hydroxide is reached portlandite will nucleate and grow (Fig. 8—③). Fierens and Verhaegen [101], in accordance with Damidot et al. [69], hence, reject the calcium hydroxide nucleation as an impetus for the renewed hydration activity.

Rate reduction due to delayed C–S–H nucleation proposed by Fierens and Verhaegen [119]. After initial dissolution, C–S–H nuclei are formed on preferential sites (grey) by water adsorption ①. Crystal growth can only progress when a sufficient number of nuclei overcome the potential barrier correlated with the critical radius rc ②. The growth of C–S–H induces a renewed dissolution of C3S and terminates the dormant period. Calcium hydroxide will nucleate after the end of the dormant period when its critical supersaturation (cs*) is achieved ③

Fierens and Verhaegen [100] concluded that the reduced hydration activity during the dormant period and the renewed hydration activity during the acceleration stage are caused by nucleation kinetics, not by a protective layer. This assumption is supported by modelling approaches of Garrault et al. and Thomas [117, 123]. They demonstrated that early hydration could be closely approximated by C–S–H growth kinetics without the consideration of a protective layer hindering C3S dissolution. The two models differ in the growth mode that is considered; Thomas [123] works with isotropic growth, while Garrault et al. [117] consider different rates perpendicular and parallel to the surface. Both models underscore the role of nucleation on the C3S surface in contrast to the Avrami nucleation model that regards nucleation to occur randomly in a fixed volume [124, 125]. Fierens and Verhaegen’s proposal is, however, also compatible with the slow dissolution theories of Tadros et al. [102] and Fuji et al. [88].

The correlation of defect sites on C3S with the length of the dormant period is supported by investigations of other authors [87, 126]. Fierens and Verhaegen [100] demonstrated that anhydrous C3S, exposed to water vapour for one hour before mixing in liquid water, showed a significant reduction in the duration of the dormant period but no increase in rate during the acceleration stage. This effect was explained by the prefabrication of nuclei on C3S surface centres; the number of surface centres and, hence, growth kinetics remain unaffected. Moreover, the combination of irradiation and water vapour resulted in an even greater effect [100]. Pre-hydration experiments of Garrault et al. [118] in different lime solutions additionally supported Fierens and Verhaegen’s [100] results. A higher number of nuclei was reported to be formed in a lower concentrated solution, which resulted in a shortened dormant period [118].

Especially the results of the vapour pre-hydration experiments seem to indicate that C–S–H nucleation and growth is rate directing; the results are, however, also conclusive with the slow dissolution theories. Hydration in higher undersaturation caused by C–S–H precipitation and growth would be expected to enhance the dissolution rate [67, 107, 127]. Nevertheless, Juilland et al. [67] emphasised that the lack of hydration products observed by SEM and AFM and the formation of visible, evenly distributed etch pits are not conclusive with the formation of hydrates on surface centres. Finally, it shall be mentioned that even the isolated nucleation of C–S–H itself is a very complex subject. Research indicated that it follows a non-classical multi-step mechanism [150, 151].

Superficially hydroxylated layer theory

A mechanism focusing on the reduced dissolution of tricalcium silicate has been proposed by Barret et al. [107, 128]. To explain the observed characteristic development of C/S in the first minutes, the concept of superficial hydroxylation of tricalcium silicate was introduced [107, 128].

According to their mechanism, the tricalcium silicate surface layer is hydroxylated immediately, resulting in the simultaneous liberation of hydroxyl ions into solution (Fig. 9—①). To balance the charge in solution, calcium ions are readily dissolved from the same surface planes in a second step. This results in a decrease in the superficial C/S as it was determined by XPS (Fig. 9—②) [107, 108]. Once there is no longer an excess of hydroxyl ions in the solution, the calcium ion liberation slows down. For the sake of electroneutrality, further calcium ion liberation must be accompanied by the dissolution of hydroxylated silicates or hydroxyl ions from the underlying atomic layers that are not exposed yet (Fig. 9—③). Hence, the overall dissolution rate depends on the dissolution of hydroxylated silicates, which is assumed to be significantly lower, initiating the dormant period. [107, 128]. Similarly, Bellmann and co-workers [66] reported the observation of a surface phase on C3S containing uncondensed silicate monomers close to hydrogen atoms (either hydroxyl groups or water molecules, a phase distinct from anhydrous tricalcium silicate and from the calcium–silicate–hydrate (C–S–H) phase.

Superficially hydroxylated layer theory according to Barret et al. [107, 128]. Initially, hydroxyl ions are liberated into solution, and a superficially hydroxylated layer is formed ①. This is accompanied by the dissolution of calcium ions for the sake of electroneutrality ②. At this point, further calcium ion liberation depends on the slow dissolution of the hydroxylated silicate layer that blocks the underlying layers from dissolving ③

Similar behaviour was reported earlier for magnesium-containing minerals, whose dissolution results in the formation of a magnesium-depleted surface layer, assumed to govern further dissolution by a diffusion barrier [129]. A superficial cation depletion is a common concept in mineral weathering [130]. The proposed transformation of an initial fast dissolution to a step-retreat dissolution is a fundamental phenomenon observed often in crystal dissolution [131]. A dependence of the dissolution mechanism on the degree of undersaturation was reported by Lasaga and Lüttge [132]: Etch pits will form under highly undersaturated conditions; step-retreat dissolution will govern when the undersaturation is low. Additionally, it was proposed that etch pits might also act as an origin for the in-parallel occurring step-retreat dissolution [132].

The presence of a hydroxylated surface layer is supported by dissolution rate evaluations of Nicoleau et al. [133], who found a strong difference between the solubility of anhydrous C3S and the solubility of a hydroxylated surface. The dissolution kinetics were interpreted to be independent of hydrate precipitation, a protective layer as the explanation of the observed phenomena was excluded [133]. However, similar results based also on C3S dissolution experiments by Bellmann et al. [74], were interpreted by [74] assuming the formation of a protective layer. It also should be noted that both studies [74, 133] found a lower solubility of the surface species compared to anhydrous C3S and that the studies differed mainly in the naming of the observed phenomena.

Etch pit and dissolution topography

Etch pit theory

Juilland et al. [67] applied fundamental dissolution principles to tricalcium silicate dissolution, introducing a mechanism for the initial and induction period based on dissolution only without the effect of any kind of surface species. Dissolution depends mainly on the solution chemistry: Initially, when the undersaturation of the solution is high with respect to tricalcium silicate, etch pits open at dislocation sites and dissolution is fast (Fig. 10A—①). The critical value of undersaturation is reached within a short time, which will restrict the dissolution to a slower step-retreat mechanism starting from the existing etch pits as it was also proposed by Barret et al. [107, 128] (Fig. 10A—②). At the end of the induction period, the growth of C–S–H was considered to act most likely as rate-determining step. The growth of C–S–H triggers the renewed hydration activity by reducing the concentration in the solution below the critical value of undersaturation, allowing etch pits to dissolve again (Fig. 10A -). Juilland et al. [67] did not specify what activates the fast C–S–H development, but they suggested the formation of active growth sites or a sufficiently large surface area.

A Etch pit dissolution theory according to Juilland et al. [67]. After initial etch pit formation in high undersaturated solution ① the further dissolution is restrained to the slower step-retreat mechanism after a critical concentration (cc) is exceeded ②. C–S–H grows slowly, consuming ions from solution. Once the critical concentration is undercut again, the faster etch pit dissolution restarts and ends the dormant period. B Dissolution governed by undersaturation and topography according to Nicoleau et al. [122]. Initially, etch pits are opened in high undersaturation ①. The reaction slows down when the undersaturation is decreased by dissolution and slow C–S–H growth. It cannot be compensated by the dissolving surface of C3S, yet ②. Once the dissolving surface is sufficiently high, dissolution will be accelerated ③

Hydration experiments in calcium hydroxide solutions of different concentrations supported the etch pit dissolution theory. The tricalcium silicate surface roughened and showed the formation of etch pits within 2 min of hydration in water, while the surface remained smooth when it was hydrated in saturated calcium hydroxide solutions [67], i.e. at a lower degree of undersaturation. An increase in dissolution rate with undersaturation was also confirmed by Garrault et al. and Nonat et al. [118, 134], who also identified the lime concentration as a decisive parameter controlling C3S hydration. The mechanism is also in agreement with the findings of Maycock et al. [87], Fierens and Verhaegen [101] and Odler et al. [126], who correlated the defect density of tricalcium silicate to the length of the dormant period. Moreover, the defect density of various crystals was positively correlated with their dissolution rate [135, 137].

A point of criticism on Juilland et al.’s [67] etch pit dissolution theory was that the solubility of alite is much higher than that of the minerals (albite, smectite, gibbsite and labradorite) for which the theory of Lasaga and Lüttge [132] was initially validated [138]. Furthermore, the assumed values for the interfacial energy and the rate increase during the acceleration stage were pointed out to be unusually high [138]. Gartner [138] alternatively suggested that by cation depletion, a protective surface layer, sufficiently thick to control the overall dissolution rate, is formed. Such surface layers were also found for the magnesium-containing minerals serpentine, forsterite and enstatite [129, 138]. Gartner [138] point out that such a mechanism could also explain the retardation by vapour pre-hydration, a statement that is, however, in contrast to the findings of Fierens and Verhaegen [100], who found a significant acceleration by vapour pre-hydration. Juilland et al. [139] elaborated that the exceptional interfacial energy and the rate increase might be explained by the fact that alite is a synthetic phase, only stable at high temperatures. They refined their model by proposing that at the end of the dormant period, reaction kinetics are no longer governed by dissolution but by diffusion of dissolved species from the anhydrous surface into solution. Furthermore, they elaborate that the effect of crystal defect density can hardly be explained by a protective layer mechanism [139]. However, the protective oxide films of Ball [86] include the coherence of layer and substrate, which might be reduced by a higher number of tricalcium silicate surface defects.

Dissolution topography theory