Abstract

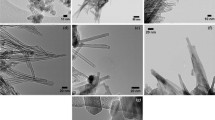

Tantalum nanoparticles have been synthesized by the single-step chemical reaction route. Simultaneous reduction of Tantalum Pentoxide (Ta2O5) with the in situ produced hydrogen and carbon at 600 °C is a new approach for the production of Ta nanopowder. ΔH values obtained from thermodynamic calculations are used to predict the entire mechanism of reduction of bulk Ta2O5 into Ta nanoparticles. The results of X-ray diffraction studies show that the final product consists of predominately nano α-Ta with β-Ta as the minority phase. The lattice strain in the final product was calculated using Williamson–Hall formula. The effect of lattice strain on thermal stability of the samples was analyzed by differential scanning calorimetry and thermal gravimetry in the air atmosphere. The morphology and particle size distribution of Ta nanosized powders have been analyzed by scanning electron microscope and transmission electron microscope. The results show that average crystallite size of the product Ta nanopowder is about 2–7 nm.

Similar content being viewed by others

References

Won CW, Nersisyan HH, Won HI, Lee JH. Refractory metal nanopowders: synthesis and characterization. Curr Opin Solid State Mater Sci. 2010;14:53–68.

Barnett R, Kilby KT, Fray DJ. Reduction of tantalum pentoxide using graphite and tin-oxide-based anodes via the FFC-Cambridge process. Metall Mater Trans B. 2009;40:150–7.

Wang Y, Cui Z, Zhang Z. Synthesis and phase structure of tantalum nanoparticles. Mater Lett. 2004;58:3017–20.

Xiang H, Xu Y, Zhang L, Cheng L. Synthesis and microstructure of tantalum carbide and carbon composite by liquid precursor route. Scr Mater. 2006;55:339–42.

Zhu H, Sadoway DR. Synthesis of nanoscale particles of Ta and Nb3Al by homogeneous reduction in liquid ammonia. J Mater Res. 2001;16:2544–9.

Othmer K. Encyclopedia of chemical technology. 3rd ed. New York: Wiley; 1978.

Kim BS, Choi YY. Kinetics of the chlorination of tantalum pentoxide with carbon tetrachloride gas. Mater Trans, JIM. 2005;46:2102–6.

Yuan B, Okabe TH. Production of fine tantalum powder by preform reduction process using Mg–Ag alloy reductant. J Alloys Compd. 2007;443:71–80.

Wu T, Jin X, Xiao W, Hu X, Wang D, Chen GZ. Thin pellets: fast electrochemical preparation of capacitor tantalum powders. Chem Mater. 2007;19:153–60.

Ayers JD, Anderson IE. Very fine metal powders. JOM. 1985;37:16–21.

Brutvan DR, Ripley RL, Seklemian HV. Ultrafine metal powders. Can Pat. 1965;702:612.

Park KY, Kim HJ, Suh YJ. Preparation of tantalum nanopowders through hydrogen reduction of TaCl5 vapor. Powder Technol. 2007;172:144–8.

Awasthi A, Bhatt YJ, Krishnamurthy N, Ueda Y, Garg SP. The reduction of niobium and tantalum pentoxides by silicon in vacuum. J Alloys Compd. 2001;315:187–92.

Baba M, Ono Y, Suzuki RO. Tantalum and niobium powder preparation from their oxides by calciothermic reduction in the molten CaCl2. J Phys Chem Solid. 2005;66:466–70.

De brito RA, Mederios FFP, Gomes UU, Costa FA, Silva AGP, Alves C Jr. Production of tantalum by aluminothermic reduction in plasma reactor. Int J Refract Met Hard Mater. 2008;26:433–7.

Park I, Okabe TH, Lee OY, Lee CR, Waseda Y. Semi-continuous production of tantalum powder by electrochemically mediated reaction (EMR). Mater Trans. 2002;43:2080–6.

Kumar A, Singh K, Pandey OP. Reduction of WO3 to nano-WC by thermo-chemical reaction route. Phys E. 2009;4:677–84.

Singla G, Singh K, Pandey OP. Structural and thermal properties of in situ reduced WO3 to W powder. Powder Technol. 2013;237:9–13.

Demazeau G. Solvothermal reactions: an original route for the synthesis of novel materials. J Mater Sci. 2008;43:2104–14.

Reddy KM, Rao TN, Joardar J. Stability of nanostructured W-C phases during carburization of WO3. Mater Chem Phys. 2011;128:121–6.

Bazhanov DI, Mutigullin IV, Knizhnik AA, Potapkin BV, Bagaturyants AA, Fonseca LRC, Stoker MW. Impact of strain on the surface properties of transition metal carbide films: first-principles study. J Appl Phys. 2010;107:0835211–6.

Read MH, Altman C. A new structure in tantalum thin films. Appl Phys Lett. 1965;7:51–2.

Díez VK, Apesteguía CR, Di Cosimo JI. Effect of the acid-base properties of Mg–Al mixed oxides on the catalysts deactivation during aldol condensation reactions. Lat Am Appl Res. 2003;33:79–86.

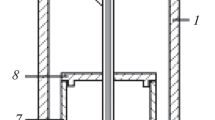

Kamberović Ž, Filipović D, Raić K, Tasić M, Anđić Z, Gavrilovski M. Reduction of ultra-fine tungsten powder with tungsten (VI) oxide in a vertical tube reactor. Mater Technol. 2011;45:27–32.

Dabhade VV, Mohan TRR, Ramakrishnan P. Nanocrystalline titanium powders by high energy attrition milling. Powder Technol. 2007;171:177–83.

Cheng HKF, Chong MF, Liu E, Zhou K, Li L. Thermal decomposition kinetics of multiwalled carbon nanotube/polypropylene nanocomposites. J Therm Anal Calorim. 2014;117:63–71.

Díaz-Ayala R, Arroyo-Ramírez L, Raptis RG, Cabrera CR. Thermal and surface analysis of palladium pyrazolates molecular precursors. J Therm Anal Calorim. 2014;115:479–88.

Haines PJ. Principles of thermal analysis and calorimetry. Cambridge: Royal Society of Chemistry; 2002.

Brown ME. Handbook of thermal analysis and calorimetry. 1st ed. New york: Elsevier Science; 1998.

Yoon JS, Park HH, Bae IS, Goto S, Kim BI. Production of tantalum powder by external continuous supply of feed materials and reductant. Mater Trans. 2005;46:272–6.

Debalina B, Kamaraj M, Chakravarthi SR, Vasa NJ, Sarathi R. Understanding the mechanism of nanoparticle formation in a wire explosion process by adopting the optical emission technique. Plasma Sci Technol. 2013;15:562–9.

Acknowledgements

One of the author (O. P. Pandey) is thankful to Department of Science and Technology (DST), New Delhi, India for which proposal has been submitted. The authors are also grateful to Central Research facilities (IIT Ropar) for providing XRD, IIT Roorkee for providing FE-SEM, SAI Labs, Thapar University for providing SEM and AIIMS, Delhi for providing TEM.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Brar, L.K., Singla, G., Kaur, N. et al. Thermal stability and structural properties of Ta nanopowder synthesized via simultaneous reduction of Ta2O5 by hydrogen and carbon. J Therm Anal Calorim 119, 175–182 (2015). https://doi.org/10.1007/s10973-014-4136-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-014-4136-1