Abstract

In this study, the modified alkoxide sol–gel approach was used for the synthesis of ternary Ni–Ce–Mg–O oxide systems of variable composition. The prepared samples were characterized by thermal analysis, low-temperature nitrogen adsorption, transmission electron microscopy, X-ray diffraction, and temperature-programmed reduction. The presence of CeO2 in the oxide composition was found to affect such properties as texture, morphology, reducibility of Ni2+, and dispersion of Ni0 in the reduced samples. The catalytic properties of the Ni–Ce–Mg–O samples were examined with regard to dry reforming of methane (DRM) and catalytic pyrolysis of hydrocarbons with the formation of carbon nanofibers (CNF). It was found that the CeO2-containing samples demonstrate more stable performance in DRM and are less prone to coke formation. The Ni10Ce10 catalyst containing 10% NiO and 10% CeO2 within the MgO matrix demonstrated the highest CO2 and CH4 conversion values. Contrarily, the highest carbon yield was observed for the Ni15Ce5 sample (15 wt% NiO, 5 wt% CeO2). An increase in the CeO2 content diminished the carbon yield. The structure of the formed CNFs was affected by the type of substrate used (ethylene or a mixture of C2-C4 saturated hydrocarbons). Thus, the sol–gel technique was shown to be efficient for the preparation of ternary Ni–Ce–Mg–O systems with a high content of nickel and ceria species evenly distributed within the MgO matrix. Varying the ceria content, it is possible to balance between the DRM and catalytic pyrolysis modes of the catalyst operation.

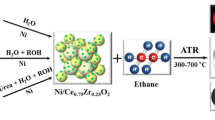

Graphical Abstract

Highlights

-

Ternary Ni–Ce–Mg–O oxide systems were prepared by the modified alkoxide sol–gel approach.

-

The presence of CeO2 affects texture, morphology, reducibility of Ni2+, and dispersion of Ni0 species.

-

The CeO2-containing samples are more stable in DRM and less prone to coke formation.

-

The highest carbon yield was observed for the sample containing 15 wt% NiO and 5 wt% CeO2.

-

The structure of the formed CNFs was affected by the type of hydrocarbons used.

Similar content being viewed by others

Data availability

Data is contained within the article. No datasets were generated or analyzed during the current study.

References

Abdullah B, Abd Ghani NA, Vo D-VN (2017) Recent advances in dry reforming of methane over Ni-based catalysts. J Clean Prod 162:170–185

Barroso-Quiroga MM, Castro-Luna AE (2010) Catalytic activity and effect of modifiers on Ni-based catalysts for the dry reforming of methane. Int J Hydrog Energy 35(11):6052–6056

Wang Y, Yao L, Wang S, Mao D, Hu C (2018) Low-temperature catalytic CO2 dry reforming of methane on Ni-based catalysts: a review. Fuel Process Technol 169:199–206

Gao N, Salisu J, Quan C, Williams P (2021) Modified nickel-based catalysts for improved steam reforming of biomass tar: a critical review. Renew Sustain Energy Rev 145:111023

Nieva MA, Villaverde MM, Monzón A, Garetto TF, Marchi AJ (2014) Steam-methane reforming at low temperature on nickel-based catalysts. Chem Eng J 235:158–166

Wang Z, Wang L, Cui Y, Xing Y, Su W (2022) Research on nickel-based catalysts for carbon dioxide methanation combined with literature measurement. J CO2 Util 63:102117

Gac W, Zawadzki W, Rotko M, Greluk M, Słowik G, Kolb G (2020) Effects of support composition on the performance of nickel catalysts in CO2 methanation reaction. Catal Today 357:468–482

Li J, Zhang J, Yang J-H (2022) Research progress and applications of nickel-based catalysts for electrooxidation of urea. Int J Hydrog Energy 47(12):7693–7712

Ma Y, Ma C, Wang Y, Wang K (2022) Advanced nickel-based catalysts for urea oxidation reaction: challenges and developments. Catalysts 12(3):337

Wang C, Yang B, Gu Q, Han Y, Tian M, Su Y, Pan X, Kang Y, Huang C, Liu H, Liu X, Li L, Wang X (2021) Near 100% ethene selectivity achieved by tailoring dual active sites to isolate dehydrogenation and oxidation. Nat Commun 12(1):5447. https://doi.org/10.1038/s41467-021-25782-2

Gulyaeva YK, Alekseeva MV, Ermakov DY, Bulavchenko OA, Zaikina OO, Yakovlev VA (2020) High-loaded nickel based sol–gel catalysts for methylcyclohexane dehydrogenation. Catalysts 10(10):1198

Barati Dalenjan M, Rashidi A, Khorasheh F, Ardjmand M (2022) Effect of Ni ratio on mesoporous Ni/MgO nanocatalyst synthesized by one-step hydrothermal method for thermal catalytic decomposition of CH4 to H2. Int J Hydrog Energy 47(22):11539–11551. https://doi.org/10.1016/j.ijhydene.2022.01.185

Afonnikova SD, Veselov GB, Bauman YI, Gerasimov EY, Shubin YV, Mishakov IV, Vedyagin AA (2023) Synthesis of Ni-Cu-CNF composite materials via carbon erosion of Ni-Cu bulk alloys prepared by mechanochemical alloying. J Compos Sci 7(6):238

Jang W-J, Shim J-O, Kim H-M, Yoo S-Y, Roh H-S (2019) A review on dry reforming of methane in aspect of catalytic properties. Catal Today 324:15–26. https://doi.org/10.1016/j.cattod.2018.07.032

Xie X, Otremba T, Littlewood P, Schomäcker R, Thomas A (2013) One-pot synthesis of supported, nanocrystalline nickel manganese oxide for dry reforming of methane. ACS Catal 3(2):224–229. https://doi.org/10.1021/cs3003963

Gould TD, Izar A, Weimer AW, Falconer JL, Medlin JW (2014) Stabilizing Ni catalysts by molecular layer deposition for harsh, dry reforming conditions. ACS Catal 4(8):2714–2717. https://doi.org/10.1021/cs500809w

Nikoo MK, Amin NAS (2011) Thermodynamic analysis of carbon dioxide reforming of methane in view of solid carbon formation. Fuel Process Technol 92(3):678–691. https://doi.org/10.1016/j.fuproc.2010.11.027

Jafarbegloo M, Tarlani A, Mesbah AW, Sahebdelfar S (2015) Thermodynamic analysis of carbon dioxide reforming of methane and its practical relevance. Int J Hydrog Energy 40(6):2445–2451. https://doi.org/10.1016/j.ijhydene.2014.12.103

Vedyagin AA, Mishakov IV, Tsyrulnikov PG (2015) The features of the CO disproportionation reaction over iron-containing catalysts prepared by different methods. React Kinet Mech Catal 117(1):35–46. https://doi.org/10.1007/s11144-015-0936-y

Usman M, Wan Daud WMA, Abbas HF (2015) Dry reforming of methane: Influence of process parameters—a review. Renew Sustain Energy Rev 45:710–744. https://doi.org/10.1016/j.rser.2015.02.026

Wang D, Littlewood P, Marks TJ, Stair PC, Weitz E (2022) Coking can enhance product yields in the dry reforming of methane. ACS Catal 12(14):8352–8362. https://doi.org/10.1021/acscatal.2c02045

Ay H, Üner D (2015) Dry reforming of methane over CeO2 supported Ni, Co and Ni–Co catalysts. Appl Catal B Environ 179:128–138. https://doi.org/10.1016/j.apcatb.2015.05.013

Zhang J, Li F (2015) Coke-resistant Ni@SiO2 catalyst for dry reforming of methane. Appl Catal B Environ 176-177:513–521. https://doi.org/10.1016/j.apcatb.2015.04.039

Aramouni NAK, Touma JG, Tarboush BA, Zeaiter J, Ahmad MN (2018) Catalyst design for dry reforming of methane: analysis review. Renew Sustain Energy Rev 82:2570–2585. https://doi.org/10.1016/j.rser.2017.09.076

Djaidja A, Libs S, Kiennemann A, Barama A (2006) Characterization and activity in dry reforming of methane on NiMg/Al and Ni/MgO catalysts. Catal Today 113(3):194–200. https://doi.org/10.1016/j.cattod.2005.11.066

Omoregbe O, Danh HT, Nguyen-Huy C, Setiabudi HD, Abidin SZ, Truong QD, Vo D-VN (2017) Syngas production from methane dry reforming over Ni/SBA-15 catalyst: effect of operating parameters. Int J Hydrog Energy 42(16):11283–11294. https://doi.org/10.1016/j.ijhydene.2017.03.146

Hambali HU, Jalil AA, Abdulrasheed AA, Siang TJ, Abdullah TAT, Ahmad A, Vo D-VN (2020) Fibrous spherical Ni-M/ZSM-5 (M: Mg, Ca, Ta, Ga) catalysts for methane dry reforming: the interplay between surface acidity-basicity and coking resistance. Int J Energy Res 44(7):5696–5712. https://doi.org/10.1002/er.5327

Goula MA, Charisiou ND, Siakavelas G, Tzounis L, Tsiaoussis I, Panagiotopoulou P, Goula G, Yentekakis IV (2017) Syngas production via the biogas dry reforming reaction over Ni supported on zirconia modified with CeO2 or La2O3 catalysts. Int J Hydrog Energ 42(19):13724–13740. https://doi.org/10.1016/j.ijhydene.2016.11.196

Li R-j, Zhang J-p, Shi J, Li K-z, Liu H-l, Zhu X (2022) Regulation of metal-support interface of Ni/CeO2 catalyst and the performance of low temperature chemical looping dry reforming of methane. J Fuel Chem Technol 50(11):1458–1470. https://doi.org/10.1016/s1872-5813(22)60032-x

da Fonseca RO, Ponseggi AR, Rabelo-Neto RC, Simões RCC, Mattos LV, Noronha FB (2022) Controlling carbon formation over Ni/CeO2 catalyst for dry reforming of CH4 by tuning Ni crystallite size and oxygen vacancies of the support. J CO2 Util 57:101880. https://doi.org/10.1016/j.jcou.2021.101880

Titus J, Goepel M, Schunk SA, Wilde N, Gläser R (2017) The role of acid/base properties in Ni/MgO-ZrO2–based catalysts for dry reforming of methane. Catal Commun 100:76–80. https://doi.org/10.1016/j.catcom.2017.06.027

Zeng F, Zhang J, Xu R, Zhang R, Ge J (2022) Highly dispersed Ni/MgO-mSiO2 catalysts with excellent activity and stability for dry reforming of methane. Nano Res 15(6):5004–5013. https://doi.org/10.1007/s12274-022-4180-2

Zanganeh R, Rezaei M, Zamaniyan A (2013) Dry reforming of methane to synthesis gas on NiO–MgO nanocrystalline solid solution catalysts. Int J Hydrog Energy 38(7):3012–3018. https://doi.org/10.1016/j.ijhydene.2012.12.089

Jafarbegloo M, Tarlani A, Mesbah AW, Muzart J, Sahebdelfar S (2016) NiO–MgO solid solution prepared by Sol–Gel method as precursor for Ni/MgO methane dry reforming catalyst: effect of calcination temperature on catalytic performance. Catal Lett 146(1):238–248. https://doi.org/10.1007/s10562-015-1638-9

Usman M, Wan Daud WMA (2016) An investigation on the influence of catalyst composition, calcination and reduction temperatures on Ni/MgO catalyst for dry reforming of methane. RSC Adv 6(94):91603–91616. https://doi.org/10.1039/C6RA15256B

Al-Doghachi FAJ, Rashid U, Taufiq-Yap YH (2016) Investigation of Ce(iii) promoter effects on the tri-metallic Pt, Pd, Ni/MgO catalyst in dry-reforming of methane. RSC Adv 6(13):10372–10384. https://doi.org/10.1039/C5RA25869C

Akbari E, Alavi SM, Rezaei M (2018) CeO2 promoted Ni-MgO-Al2O3 nanocatalysts for carbon dioxide reforming of methane. J CO2 Util 24:128–138. https://doi.org/10.1016/j.jcou.2017.12.015

Santander JA, Tonetto GM, Pedernera MN, López E (2017) Ni/CeO2–MgO catalysts supported on stainless steel plates for ethanol steam reforming. Int J Hydrog Energy 42(15):9482–9492. https://doi.org/10.1016/j.ijhydene.2017.03.169

Khajenoori M, Rezaei M, Meshkani F (2014) Characterization of CeO2 promoter of a nanocrystalline Ni/MgO catalyst in dry reforming of methane. Chem Eng Technol 37(6):957–963

Khajenoori M, Rezaei M, Meshkani F (2015) Dry reforming over CeO2-promoted Ni/MgO nano-catalyst: effect of Ni loading and CH4/CO2 molar ratio. J Ind Eng Chem 21:717–722

Jang W-J, Kim H-M, Shim J-O, Yoo S-Y, Jeon K-W, Na H-S, Lee Y-L, Jeong D-W, Bae JW, Nah IW, Roh H-S (2018) Key properties of Ni–MgO–CeO2, Ni–MgO–ZrO2, and Ni–MgO–Ce(1−x)Zr(x)O2 catalysts for the reforming of methane with carbon dioxide. Green Chem 20(7):1621–1633. https://doi.org/10.1039/C7GC03605A

Jeon K-W, Kim H-M, Kim B-J, Lee Y-L, Na H-S, Shim J-O, Jang W-J, Roh H-S (2021) Synthesis gas production from carbon dioxide reforming of methane over Ni-MgO catalyst: combined effects of titration rate during co-precipitation and CeO2 addition. Fuel Process Technol 219:106877. https://doi.org/10.1016/j.fuproc.2021.106877

Che G, Lakshmi BB, Martin CR, Fisher ER, Ruoff RS (1998) Chemical vapor deposition based synthesis of carbon nanotubes and nanofibers using a template method. Chem Mater 10(1):260–267

Pinilla JL, Utrilla R, Lázaro MJ, Moliner R, Suelves I, García AB (2011) Ni-and Fe-based catalysts for hydrogen and carbon nanofilament production by catalytic decomposition of methane in a rotary bed reactor. Fuel Process Technol 92(8):1480–1488

Yao D, Wang C-H (2020) Pyrolysis and in-line catalytic decomposition of polypropylene to carbon nanomaterials and hydrogen over Fe-and Ni-based catalysts. Appl Energy 265:114819

Yao D, Li H, Dai Y, Wang C-H (2021) Impact of temperature on the activity of Fe-Ni catalysts for pyrolysis and decomposition processing of plastic waste. Chem Eng J 408:127268

Veselov GB, Karnaukhov TM, Bauman YI, Mishakov IV, Vedyagin AA (2020) Sol-gel-prepared Ni-Mo-Mg-O system for catalytic transformation of chlorinated organic wastes into nanostructured carbon. Materials 13(19):4404

Yao D, Yang H, Hu Q, Chen Y, Chen H, Williams PT (2021) Carbon nanotubes from post-consumer waste plastics: investigations into catalyst metal and support material characteristics. Appl Catal B Environ 280:119413

Shoukat R, Khan MI (2021) Carbon nanotubes: a review on properties, synthesis methods and applications in micro and nanotechnology. Microsyst Technol 27:4183–4192

Kshetri T, Tran DT, Nguyen DC, Kim NH, Lau K-t, Lee JH (2020) Ternary graphene-carbon nanofibers-carbon nanotubes structure for hybrid supercapacitor. Chem Eng J 380:122543

Wu S-L, Kuo J-H, Wey M-Y (2019) Thermal degradation of waste plastics in a two-stage pyrolysis-catalysis reactor over core-shell type catalyst. J Anal Appl Pyrolysis 142:104641. https://doi.org/10.1016/j.jaap.2019.104641

Li Y, Zhang B, Tang X, Xu Y, Shen W (2006) Hydrogen production from methane decomposition over Ni/CeO2 catalysts. Catal Commun 7(6):380–386. https://doi.org/10.1016/j.catcom.2005.12.002

Ahmed W, Awadallah AE, Aboul-Enein AA (2016) Ni/CeO2–Al2O3 catalysts for methane thermo-catalytic decomposition to COx-free H2 production. Int J Hydrog Energy 41(41):18484–18493. https://doi.org/10.1016/j.ijhydene.2016.08.177

Yang W, Chu W, Jiang C, Wen J, Sun W (2011) Cerium oxide promoted Ni/MgO catalyst for the synthesis of multi-walled carbon nanotubes. Chin J Catal 32(6):1323–1328. https://doi.org/10.1016/S1872-2067(10)60247-1

Vedyagin AA, Mishakov IV, Karnaukhov TM, Krivoshapkina EF, Ilyina EV, Maksimova TA, Cherepanova SV, Krivoshapkin PV (2017) Sol–gel synthesis and characterization of two-component systems based on MgO. J Sol-Gel Sci Technol 82(2):611–619

Veselov GB, Stoyanovskii VO, Cherepanova SV, Vedyagin AA (2023) Sol–gel prepared Co–Mg–O oxide systems: redox behavior, thermal stability and catalytic performance in CO oxidation. React Kinet Mech Catal 136(1):233–250. https://doi.org/10.1007/s11144-022-02336-1

Veselov GB, Karnaukhov TM, Stoyanovskii VO, Vedyagin AA (2022) Preparation of the nanostructured Ni-Mg-O oxide system by a sol–gel technique at varied pH. Nanomaterials 12(6):952

Veselov GB, Stoyanovskii VO, Vedyagin AA (2023) Ternary Ni-Ce-Mg-O composites: in-depth optical spectroscopy study and catalytic performance in CO oxidation. J Compos Sci 7(6):251

Patterson AL (1939) The scherrer formula for X-ray particle size determination. Phys Rev 56(10):978–982. https://doi.org/10.1103/PhysRev.56.978

Strydom C, Van Vuuren C (1987) The thermal decomposition of cerium (III) nitrate. J Therm Anal Calorim 32(1):157–160

Małecka B, Łącz A, Drożdż E, Małecki A (2015) Thermal decomposition of d-metal nitrates supported on alumina. J Therm Anal Calorim 119(2):1053–1061

Thommes M, Kaneko K, Neimark AV, Olivier JP, Rodriguez-Reinoso F, Rouquerol J, Sing KSW (2015) Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution. IUPAC Tech Rep 87(9-10):1051–1069. https://doi.org/10.1515/pac-2014-1117

Sing KSW, Williams RT (2004) Physisorption hysteresis loops and the characterization of nanoporous materials. Adsorpt Sci Technol 22(10):773–782. https://doi.org/10.1260/0263617053499032

Karnaukhov T, Vedyagin AA, Mishakov IV, Bedilo A, Volodin AM (2018) Synthesis and characterization of nanocrystalline M-Mg-O and carbon-coated MgO systems Mater Sci Forum 917:157–161. https://doi.org/10.4028/www.scientific.net/MSF.917.157

Prieur D, Bonani W, Popa K, Walter O, Kriegsman KW, Engelhard MH, Guo X, Eloirdi R, Gouder T, Beck A, Vitova T, Scheinost AC, Kvashnina K, Martin P (2020) Size dependence of lattice parameter and electronic structure in CeO2 nanoparticles. Inorg Chem 59(8):5760–5767. https://doi.org/10.1021/acs.inorgchem.0c00506

Phuoc TX, Howard BH, Martello DV, Soong Y, Chyu MK (2008) Synthesis of Mg(OH)2, MgO, and Mg nanoparticles using laser ablation of magnesium in water and solvents. Opt Lasers Eng 46(11):829–834

Arena F, Licciardello A, Parmaliana A (1990) The role of Ni2+ diffusion on the reducibility of NiO/MgO system: a combined TRP-XPS study. Catal Lett 6(1):139–149. https://doi.org/10.1007/BF00764063

Parmaliana A, Arena F, Frusteri F, Giordano N (1990) Temperature-programmed reduction study of NiO–MgO interactions in magnesia-supported Ni catalysts and NiO–MgO physical mixture. J Chem Soc Faraday Trans 86(14):2663–2669. https://doi.org/10.1039/FT9908602663

Shan W, Guo H, Liu C, Wang X (2012) Controllable preparation of CeO2 nanostructure materials and their catalytic activity. J Rare Earths 30(7):665–669. https://doi.org/10.1016/S1002-0721(12)60109-4

Tsoncheva T, Roggenbuck J, Tiemann M, Ivanova L, Paneva D, Mitov I, Minchev C (2008) Iron oxide nanoparticles supported on mesoporous MgO and CeO2: a comparative physicochemical and catalytic study. Microporous Mesoporous Mater 110(2):339–346. https://doi.org/10.1016/j.micromeso.2007.06.021

Taira K, Murao R (2021) High dispersion of CeO2 on CeO2/MgO prepared under dry conditions and its improved redox properties. Energies 14(23):7922. https://doi.org/10.3390/en14237922

Chen J, Zhu J, Zhan Y, Lin X, Cai G, Wei K, Zheng Q (2009) Characterization and catalytic performance of Cu/CeO2 and Cu/MgO-CeO2 catalysts for NO reduction by CO. Appl Catal A Gen 363(1):208–215. https://doi.org/10.1016/j.apcata.2009.05.017

Afonnikova SD, Popov AA, Bauman YI, Plyusnin PE, Mishakov IV, Trenikhin MV, Shubin YV, Vedyagin AA, Korenev SV (2022) Porous Co-Pt nanoalloys for production of carbon nanofibers and composites. Materials 15(21):7456. https://doi.org/10.3390/ma15217456

Ghaemi F, Ali M, Yunus R, Othman RN (2019) Synthesis of carbon nanomaterials using catalytic chemical vapor deposition technique. In: Synthesis, technology and applications of carbon nanomaterials. Elsevier, pp 1–27

Acknowledgements

Characterization of the samples was performed using the equipment of the Center of Collective Use “National Center of Catalysts Research” and Krasnoyarsk regional Center of the Collective Use (KSS SB RAS). The authors are grateful to M.N. Volochaev for his assistance in TEM analysis and A.A. Pochtar for providing the thermal analysis.

Funding

This study was funded by the Ministry of Science and Higher Education of the Russian Federation within the governmental order for Boreskov Institute of Catalysis (project No. FWUR-2024-0034).

Author information

Authors and Affiliations

Contributions

Conceptualization, G.B.V. and A.A.V.; methodology, G.B.V., A.A.V., and I.V.M.; investigation, G.B.V. and S.D.A.; writing—original draft preparation, G.B.V. and S.D.A.; writing—review and editing, A.A.V. and I.V.M.; funding acquisition, I.V.M. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Veselov, G.B., Afonnikova, S.D., Mishakov, I.V. et al. Sol–gel-prepared ternary Ni–Ce–Mg–O oxide systems: the role of CeO2 in balancing between dry reforming of methane and pyrolysis of hydrocarbons. J Sol-Gel Sci Technol 109, 859–877 (2024). https://doi.org/10.1007/s10971-024-06336-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-024-06336-6