Abstract

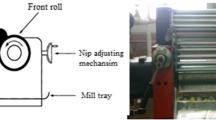

Using a two-roll mixing mill and the vulcanization process, complex of resorcinol and hexamethylenetetramine modified halloysite nanotubes (RH-HNTs) natural rubber/ethylene-propylene-diene monomer (NR/EPDM) nanocomposites were created. The mole percent uptake of chlorinated (chloroform, carbon tetrachloride, and dichloromethane) as well as aromatic (toluene, xylene, benzene, and mesitylene) and aliphatic (n-hexane, n-heptane, and n-pentane) solvents through RH-HNTs filled NR/EPDM nanocomposites has been studied. In order to analyse the compatibility between rubber matrix and nanotubes and the reinforcing effect of RH-HNTs as nanofiller in the NR/EPDM matrix, the current work aims to explore the curing characteristics, mechanical properties, abrasion resistance, and swelling resistance. In-depth research has been done on the mole percent uptake of organic solvents via membranes as a function of RH-HNTs content, solvent type, and temperature between 23 and 60 °C. The results showed that RH-HNTs could significantly increase the strength of NR/EPDM vulcanizates while also reducing scorch and optimum cure time. Investigations on the mechanical characteristics and swelling resistance revealed an increase in both with increasing RH-HNTs loading. At 8 phr RH-HNTs filler loading, the cross-link density measurements showed better strengthening. High concentrations of RH-HNTs particles create a regional nanofiller-nanofiller network in the NR/EPDM rubber. The mechanical characteristics of the composites were considerably enhanced as a result.

Similar content being viewed by others

Availability of data and materials

Not Applicable.

References

Vilgis TA, Heinrich G (1994) Disorder-induced enhancement of polymer adsorption-A model for the rubber-polymer interaction in filled rubbers. Macromolecules 27(26):7846–7854

Senthilvel K, Vishvanathperumal S, Prabu B (2016) L John Baruch, Studies on the morphology, cure characteristics and mechanical properties of acrylonitrile butadiene rubber with hybrid filler (carbon black/silica) composite. Polym Polym Compos 24(7):473–480

Vishvanathperumal S, Gopalakannan S (2016) Reinforcement of ethylene vinyl acetate with carbon black/silica hybrid filler composites. Appl Mech Mater 852:16–22

Anand G, Vishvanathperumal S (2022) Properties of SBR/NR Blend: The Effects of Carbon Black/Silica (CB/SiO2) Hybrid Filler and Silane Coupling Agent. Silicon 14(14):9051–9060

Sadasivuni KK, Ponnamma D, Kumar B, Strankowski M, Cardinaels R, Moldenaers P, Thomas S, Grohens Y (2014) Dielectric properties of modified graphene oxide filled polyurethane nanocomposites and its correlation with rheology. Compos Sci Technol 104:18–25

Vishvanathperumal S, Navaneethakrishnan V, Anand G, Gopalakannan S (2020) Evaluation of crosslink density using material constants of ethylene–propylene–diene monomer/styrene–butadiene rubber with different nanoclay loading: finite element analysis-simulation and experimental. Adv Sci Eng Med 12(5):632–642

Vishvanathperumal S, Anand G (2021) Effect of nanosilica and crosslinking system on the mechanical properties and swelling resistance of EPDM/SBR nanocomposites with and without TESPT. Silicon 13:3473–3497

Sundar R, Mohan SK, Vishvanathperumal S (2022) Effect of Surface Modified Halloysite Nanotubes (mHNTs) on the Mechanical Properties and Swelling Resistance of EPDM/NBR Nanocomposites. Polymer Korea 46(6):728–743

Anirudhan TS, Alexander S (2014) Multiwalled carbon nanotube based molecular imprinted polymer for trace determination of 2, 4-dichlorophenoxyaceticacid in natural water samples using a potentiometric method. Appl Surf Sci 303:180–186

Ganeche PS, Balasubramanian P, Vishvanathperumal S (2022) Halloysite Nanotubes (HNTs)-Filled Ethylene-Propylene-Diene Monomer/Styrene-Butadiene Rubber (EPDM/SBR) Composites: Mechanical, Swelling, and Morphological Properties. Silicon 14:6611–6620

Yah WO, Takahara A, Lvov YM (2012) Selective modification of halloysite lumen with octadecylphosphonic acid: new inorganic tubular micelle. J Am Chem Soc 134(3):1853–1859

Liu M, Jia Z, Jia D, Zhou C (2014) Recent advance in research on halloysite nanotubes-polymer nanocomposite. Prog Polym Sci 39(8):1498–1525

Cavallaro G, Lazzara G, Milioto S, Palmisano G, Parisi F (2014) Halloysite nanotube with fluorinated lumen: Non-foaming nanocontainer for storage and controlled release of oxygen in aqueous media. J Colloid Interface Sci 417:66–71

Solomon D (1968) Clay minerals as electron acceptors and/or electron donors in organic reactions. Clays Clay Miner 16:31–39

Cavallaro G, Lazzara G, Milioto S (2013) Sustainable nanocomposites based on halloysite nanotubes and pectin/polyethylene glycol blend. Polym Degrad Stab 98(12):2529–2536

Deen I, Zhitomirsky I (2014) Electrophoretic deposition of composite halloysite nanotube–hydroxyapatite–hyaluronic acid films. J Alloy Compd 586:S531–S534

Yuan P, Tan D, Annabi-Bergaya F (2015) Properties and applications of halloysite nanotubes: recent research advances and future prospects. Appl Clay Sci 112:75–93

Zhao Y, Abdullayev E, Vasiliev A, Lvov Y (2013) Halloysite nanotubule clay for efficient water purification. J Colloid Interface Sci 406:121–129

Pasbakhsh P, Churchman GJ, Keeling JL (2013) Characterisation of properties of various halloysites relevant to their use as nanotubes and microfibre fillers. Appl Clay Sci 74:47–57

Hashemifard SA, Ismail AF, Matsuura T (2011) Mixed matrix membrane incorporated with large pore size halloysite nanotubes (HNT) as filler for gas separation: experimental. J Colloid Interface Sci 359(2):359–370

Yuan P, Southon PD, Liu Z, Green MER, Hook JM, Antill SJ, Kepert CJ (2008) Functionalization of halloysite clay nanotubes by grafting with γ-aminopropyltriethoxysilane. J Phys Chem C 112:15742–15751

Abdullayev E, Sakakibara K, Okamoto K, Wei W, Ariga K, Lvov Y (2011) Natural tubule clay template synthesis of silver nanorods for antibacterial composite coating. ACS Appl Mater Interfaces 3:4040–4046

Arcudi F, Cavallaro G, Lazzara G (2014) Selective functionalization of halloysite cavity by click reaction: structured filler for enhancing mechanical properties of bionanocomposite films. J Phys Chem C 118:15095–15101

Liu M, Chang Y, Yang J, You Y, He R, Chen T, Zhou C (2016) Functionalized halloysite nanotube by chitosan grafting for drug delivery of curcumin to achieve enhanced anticancer efficacy. J Phys Chem B 4:2253–2263

Jia Z, Luo Y, Guo B, Yang B, Du M, Jia D (2009) Reinforcing and flame-retardant effects of halloysite nanotubes on LLDPE. Polym-Plast Technol Eng 48:607–613

Liu M, Guo B, Zou Q, Du M, Jia D (2008) Interactions between halloysite nanotubes and 2,5-bis(2-benzoxazolyl) thiophene and their effects on reinforcement of polypropylene/halloysite nanocomposites. Nanotechnology 19:205709–205709

Zhao M, Liu P (2007) Preparation of halloysite nanotubes/polystyrene (HNTs/PS) core-shell particles via soap-less microemulsion polymerization. J Macromol Sci B Phys 46:891–897

Marney DCO, Russell LJ, Wu DY, Nguyen T, Cramm D, Rigopoulos N, Wright N, Greaves M (2008) The suitability of halloysite nanotubes as a fire retardant for nylon 6. Polym Degrad Stab 93:1971–1978

Liu M, Guo B, Du M, Cai X, Jia D (2007) Properties of halloysite nanotubes-epoxy resin hybrids and the interfacial reactions in the systems. Nanotechnology 18:281–287

Liu C, Luo YF, Jia ZX, Zhong BC, Li SQ, Guo BC, Jia DM (2011) Enhancement of mechanical properties of poly(vinyl chloride) with polymethyl methacrylate-grafted halloysite nanotube, Express. Polym Lett 5:591–603

Liu M, Guo B, Du M, Jia D (2007) Drying induced aggregation of halloysite nanotubes in polyvinyl alcohol/halloysite nanotubes solution and its effect on properties of composite film. Appl Phys A 88:391–395

Jia Z, Guo B, Jia D (2014) Advances in rubber/halloysite nanotubes nanocomposites. J Nanosci Nanotechnol 14:1758–1771

Liu M, Jia Z, Jia D, Zhou C (2014) Recent advance in research on halloysite nanotubes-polymer nanocomposite. Prog Polym Sci 39:1498–1525

Hayeemasae N, Sensem Z, Surya I, Sahakaro K, Ismail H (2020) Synergistic effect of maleated natural rubber and modified palm stearin as dual compatibilizers in composites based on natural rubber and halloysite nanotubes. Polymers 12(4):766

Ismail H, Salleh SZ, Ahmad Z (2011) Curing characteristics, mechanical, thermal, and morphological properties of halloysite nanotubes (HNTs)-filled natural rubber nanocomposites. Polym-Plast Technol Eng 50:681–688

Pasbakhsh P, Ismail H, Fauzi MNA, Bakar AA (2009) Influence of maleic anhydride grafted ethylene propylene diene monomer (MAH-g-EPDM) on the properties of EPDM nanocomposites reinforced by halloysite nanotubes. Polym Testing 28:548–559

Pasbakhsh P, Ismail H, Fauzi MNA, Bakar AA (2010) EPDM/modified halloysite nanocomposites. Appl Clay Sci 48:405–413

Lei Y, Tang Z, Zhu L, Guo B, Jia D (2011) Functional thiol ionic liquids as novel interfacial modifiers in SBR/HNTs composites. Polymer 52:1337–1344

Rybinski P, Janowska G, Jozwiak M, Paja AK (2012) Thermal properties and flammability of nanocomposites based on diene rubbers and naturally occurring and activated halloysite nanotubes. J Therm Anal Calorim 107:1243–1249

Du M, Guo B, Lei Y, Liu M, Jia D (2008) Carboxylated butadieneestyrene rubber/halloysite nanotube nanocomposites: interfacial interaction and performance. Polymer 49:4871–4876

Rooj S, Das A, Heinrich G (2011) Tube-like natural halloysite/fluoroelastomer nanocomposites with simultaneous enhanced mechanical, dynamic mechanical and thermal properties. Eur Polymer J 47:1746–1755

Guo B, Chen F, Lei Y, Liu X, Wan J, Jia D (2009) Styrene-butadiene rubber/halloysite nanotubes nanocomposites modified by sorbic acid. Appl Surf Sci 255:7329–7336

Guo B, Lei Y, Chen F, Liu X, Du M, Jia D (2008) Styrene-butadiene rubber/halloysite nanotubes nanocomposites modified by methacrylic acid. Appl Surf Sci 255:2715–2722

Jia Z, Luo Y, Yang S, Du M, Guo B, Jia D (2011) Styrene-butadiene rubber/halloysite nanotubes composites modified by epoxidized natural rubber. J Nanosci Nanotechnol 11:10958–10962

Jia Z-X, Luo Y-F, Yang S-Y, Guo B-C, Du M-L, Jia D-M (2011) Morphology, interfacial interaction and properties of styrene-butadiene rubber/modified halloysite nanotube nanocomposites. Chin J Polym Sci 27:857–864

Prakash PC, Gurumoorthi G, Navaneethakrishnan V, Vishvanathperumal S (2023) Effect of Nanographene Oxide on the Mechanical Properties of EPDM/SBR Nano-composites. Polymer Korea 47(4):427–439

Vishvanathperumal S, Anand G (2020) Effect of nanoclay/nanosilica on the mechanical properties, abrasion and swelling resistance of EPDM/SBR composites. Silicon 12(8):1925–1941

Cook S (1998) Solutions to Basic Problems of Poor Physical Properties of NR/EPDM Blends, Blends of Natural Rubber, 1st edn. Chapman & Hall, London

Shershnev VA (1982) Vulcanization of polybutadiene and other hydrocarbon elastomers. Rubber Chem Technol 55(3):537–574

Mastromatteo RP, Mitchell JM, Brett TJ (1971) New accelerators for blends of EPDM. Rubber Chem Technol 44(4):1065–1079

Prakash PC, Srinivasan D, Navaneethakrishnan V, Vishvanathperumal S (2023) Effect of modified nanographene oxide loading on the swelling and compression set behavior of EPDM/SBR nano-composites. J Inorg Organomet Polym Mater 1–18. (In-Press). https://doi.org/10.1007/s10904-023-02803-9

El-Sabbagh SH (2003) Compatibility study of natural rubber and ethylene-propylene diene rubber blends. Polym Testing 22:93–100

Ghosh AK, Debnath SC, Naskar N, Basu DK (2001) NREPDM covulcanization: a novel approach. J Appl Polym Sci 81:800–808

Chang YW, Shin YS, Chun H, Nah C (1999) Effects of trans-polyoctylene rubber (TOR) on the properties of NR/EPDM Blends. J Appl Polym Sci 73:749–756

Pasbakhsh P, Ismail H, Ahmad Fauzi MN, Abu Bakar A (2009) Influence of maleic anhydride grafted ethylene propylene diene monomer (MAH-g-EPDM) on the properties of EPDM nanocomposites reinforced by halloysite nanotubes. Polym Test 28:548–559

Mohammad Javad Azizli (2020) Mohammad Barghamadi, Katayoon Rezaeeparto, Masoud Mokhtary, Somayeh Parham, Compatibility, mechanical and rheological properties of hybrid rubber NR/EPDM-g-MA/EPDM/graphene oxide nanocomposites: Theoretical and experimental analyses. Compos Commun 22

Lei Y, Tang Z, Zhu L, Guo B, Jia D (2012) Thiol-containing ionic liquid for the modification of styrene–butadiene rubber/silica composites. J Appl Polym Sci 123(2):1252–1260

Zhixin J, Yuanfang L, Shuyan Y, Mingliang D, Baochun G, Demin J (2011) Styrene-butadiene rubber/halloysite nanotubes composites modified by epoxidized natural rubber. J Nanosci Nanotechnol 11(12):10958–10962

Arayapranee W, Rempel GL (2008) A comparative study of the cure characteristics, processability, mechanical properties, ageing, and morphology of rice husk ash, silica and carbon black filled 75: 25 NR/EPDM blends. J Appl Polym Sci 109(2):932–941

Alipour A, Naderi G, Bakhshandeh GR, Vali H, Shokoohi S (2011) Elastomer nanocomposites based on NR/EPDM/organoclay: morphology and properties. Int Polym Proc 26(1):48–55

Motaung TE, Luyt AS, Thomas S (2011) Morphology and properties of NR/EPDM rubber blends filled with small amounts of titania nanoparticles. Polym Compos 32(8):1289–1296

Ravi Theja MS, Kilari N, Vishvanathperumal S, Navaneethakrishnan V (2021) Modeling tensile modulus of nanoclay-filled ethylene–propylene–diene monomer/styrene–butadiene rubber using composite theories. J Rubber Res 24(5):847–856

Vishvanathperumal S, Navaneethakrishnan V, Gopalakannan S (2018) The effect of nanoclay and hybrid filler on curing characteristics, mechanical properties and swelling resistance of ethylene vinyl acetate/styrene butadiene rubber blend composite. J Adv Microsc Res 13(4):469–476

Vishvanathperumal S, Gopalakannan S (2017) Swelling properties, compression set behavior and abrasion resistance of ethylene-propylene-diene rubber/styrene butadiene rubber blend nanocomposites. Polymer Korea 41(3):433–442

Jia Z-X, Luo Y-F, Yang S-Y, Guo B-C, Ming-liang Du, Jia D-M (2009) Morphology, interfacial interaction and properties of styrene-butadiene rubber/modified halloysite nanotubes nanocomposites. Chin J Polym Sci 27(6):857–864

Poikelispää M, Das A, Dierkes W, Vuorinen J (2013) Synergistic effect of plasma-modified halloysite nanotubes and carbon black in natural rubber—butadiene rubber blend. J Appl Polym Sci 127(6):4688–4696

Jia Z, Guo B, Jia D (2014) Advances in rubber/halloysite nanotubes nanocomposites. J Nanosci Nanotechnol 14(2):1758–1771

Liu L, Jia D, Luo Y, Guo B (2006) Preparation, structure and properties of nitrile–butadiene rubber–organoclay nanocomposites by reactive mixing intercalation method. J Appl Polym Sci 100(3):1905–1913

Yue D, Liu Y, Shen Z (2006) Study on preparation and properties of carbon nanotubes/rubber composites. J Mater Sci 41:2541–2544

Faghihi M, Shojaei A (2009) Properties of alumina nanoparticle-filled nitrile–butadiene-rubber/phenolic-resin blend prepared by melt mixing. Polym Compos 30:1290–1298

Sadhu S, Bhowmick AK (2004) Preparation and properties of nanocomposites based on acrylonitrile–butadiene rubber, styrene–butadiene rubber, polybutadiene rubber. Polymer physics 42:1573–1585

Kader M, Kim K, Lee Y-S, Nah C (2006) Preparation and properties of nitrile rubber/montmorillonite nanocomposites via latex blending. J Mater Sci 41:7341–7352

Ismail H, Pasbakhsh P, Ahmad Fauzi MN, Abu BA (2008) Morphological, thermal and tensile properties of halloysite nanotubes filled ethylene propylene diene monomer (EPDM) nanocomposites. Polym Testing 27:841–850

Du M, Guo B, Jia D (2010) Newly emerging applications of halloysite nanotubes: a review. Polym Int 59:574–582

Gent AN, Pulford CTR (1983) Mechanisms of rubber abrasion. J Appl Polym Sci 28:943–960

Pal K, Rajasekar R, Kang DJ, Zhang ZX, Pal SK, Das CK, Kim JK (2010) Effect of fillers on natural rubber/high styrene rubber blends with nano silica: morphology and wear. Mater Des 31(2):677–686

Wang Q, Yang F, Yang Q, Chen J, Guan H (2010) Study on mechanical properties of nano-Fe3O4 reinforced nitrile butadiene rubber. Mater Des 31(2):1023–1028

Xu D, Karger-Kocsis J, Major Z, Thomann AR (2009) Unlubricated rolling wear of HNBR/FKM/MWCNT compounds against steel. J Appl Polym Sci 112(3):1461–1470

Seehra MS, Yalamanchi M, Singh V (2012) Structural characteristics and swelling mechanism of two commercial nitrile-butadiene elastomers in various fluids. Polym Testing 31(4):564–571

Dhanasekar S, Baskar S, Vishvanathperumal S (2023) Halloysite nanotubes effect on cure and mechanical properties of EPDM/NBR nanocomposites. J Inorg Organomet Polym Mater 1–13. (In-Press). https://doi.org/10.1007/s10904-023-02754-1

Lucht LM, Peppas NA (1987) Transport of penetrants in the macromolecular structure of coals. V. Anomalous transport in pretreated coal particles. J Appl Polym Sci 33(5):1557–1566

Aminabhavi TM, Khinnavar RS (1993) Diffusion and sorption of organic liquids through polymer membranes: 10. Polyurethane, nitrile-butadiene rubber and epichlorohydrin versus aliphatic alcohols (C1-C5). Polymer 34(5):1006–1018

Ragupathy K, Prabaharan G, Pragadish N, Vishvanathperumal S (2023) Effect of silica nanoparticles and modified silica nanoparticles on the mechanical and swelling properties of EPDM/SBR blend nanocomposites. Silicon 1–14. (In-Press). https://doi.org/10.1007/s12633-023-02497-1

Stephen R, Joseph K, Oommen Z, Thomas S (2007) Molecular transport of aromatic solvents through microcomposites of natural rubber (NR), carboxylated styrene butadiene rubber (XSBR) and their blends. Compos Sci Technol 67(6):1187–1194

Aravinth V, Gurumoorthi G, Vishvanathperumal S, Navaneethakrishnan V (2023) Effect of Modified Nanographene Oxide on the Mechanical and Swelling Properties of Silicone Rubber Nanocomposites. Polymer Korea 47(3):288–302

Unnikrishnan G, Thomas S (1996) Molecular transport of benzene and methyl-substituted benzenes into filled natural rubber sheets. J Appl Polym Sci 60(7):963–970

Das RK, Ragupathy K, Kumar TS, Vishvanathperumal S (2023) Effect of Halloysite Nanotubes (HNTs) on Mechanical Properties of EPDM/NBR Blend-Nanocomposites. Polymer Korea 47(2):221–232

Flory PJ, Rehner J Jr (1943) Statistical mechanics of cross-linked polymer networks II Swelling. J Chem Phys 11(11):521–526

Vishvanathperumal S, Gopalakannan S (2019) Effects of the nanoclay and crosslinking systems on the mechanical properties of ethylene-propylene-diene monomer/styrene butadiene rubber blends nanocomposite. Silicon 11(1):117–135

Aravinth V, Navaneethakrishnan V, Vishvanathperumal S, Gurumoorthi G (2023) Effect of modified nanographene oxide (mGO)/carbon nanotubes (CNTs) hybrid filler on the cure, mechanical and swelling properties of silicone rubber composites. J Inorg Organomet Polym Mater 1–20. (In-Press). https://doi.org/10.1007/s10904-023-02818-2

Vishvanathperumal S, Anand G (2022) Effect of nanosilica on the mechanical properties, compression set, morphology, abrasion and swelling resistance of sulphur cured EPDM/SBR composites. Silicon 14(7):3523–3534

Govindan K, Ramabalan S, Vishvanathperumal S, Chockalingam S (2023) Influence of halloysite nanotubes on mechanical and swelling properties of silicone rubber compound. J Polym Res 30(8):1–17

Dhanasekar S, Baskar S, Vishvanathperumal S (2023) Cure characteristics, compression set, swelling behaviors, abrasion resistance and mechanical properties of nanoclay (Cloisite 15A, Cloisite 20A and Cloisite 30B) filler filled EPDM/NBR blend system. J Polym Res 30(10):375

Author information

Authors and Affiliations

Contributions

Dr. G. Sundaravadivel – Experimental work and prepared all figures was done. Mr. K. Parthasarathy – Wrote the main manuscript text. Dr. S. Vishvanathperumal –Supervise the overall work. Dr. V. Navaneethakrishnan - Removal of plagiarism from the main manuscript. And then all authors reviewed the main manuscript.

Corresponding author

Ethics declarations

Ethics approval

This study was approved by the E.G.S. Pillay Engineering College, Nagapattinam, and S.A. Engineering College, Chennai, Tamilnadu, India.

Consent to participate

No human subjects or animals were involved in this study.

Consent for publication

The contents of this manuscript are completely unpublished and free from any copyright restrictions. Furthermore, the material within this manuscript is not being reviewed for publication elsewhere.

Competing interests

All authors have declared no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sundaravadivel, G., Parthasarathy, K., Vishvanathperumal, S. et al. Effect of complex of resorcinol and hexamethylenetetramine modified halloysite nanotubes (RH-HNTs) on the mechanical and swelling characteristics of NR/EPDM nanocomposites. J Polym Res 30, 383 (2023). https://doi.org/10.1007/s10965-023-03763-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03763-x