Abstract

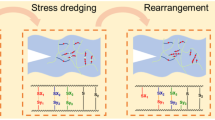

This research reports the remarkable effects of Zr-based metal–organic framework, i.e. UiO-66, on cross-linked network structure and mechanical behaviors of ethylene-propylene diene monomer (EPDM) rubber under sulfur vulcanization systems. To this end, EPDM rubber was vulcanized with conventional (CV), semi-efficient (SEV) and efficient (EV) vulcanization systems. In addition, EPDM nanocomposites containing 5 phr UiO-66 with all three vulcanization systems were also prepared, for the sake of comparison with their corresponding unfilled samples. While the unfilled EPDM vulcanizates showed expectable behaviors in cross-linking density estimated by swelling experiment and cure-rheometer parameters based on their sulfur content and accelerator/sulfur ratio in each vulcanization system, CV cured EPDM/UiO-66 nanocomposite exhibited completely distinctive characteristics. The special swelling behavior plus exclusive cure kinetics supported by dynamic mechanical analysis led us to postulate a distinctive bimodal cross-linked network morphology including a highly cross-linked rubber shell around UiO-66 along with a lightly cross-linked rubber matrix for CV cured system. This special morphology was attributed to higher sulfur content of CV system which was supposed to be adsorbed by UiO-66 due to its tendency toward sulfur and sulfur containing chemicals. Superior tensile and fatigue properties of CV cured EPDM/UiO-66 were also explained by such morphological model.

Similar content being viewed by others

Data availability

The datasets generated during and analysed during the current study are available from the corresponding author on reasonable request.

References

Ciesielski A (1999) An introduction to rubber technology. Rapra Technolgy LTD

Mark JE, Erman B, Roland M, Stratton A (2013) The science and technology of rubber, Academic press

Datta RN (2002) Rubber Curing Systems, Rapra Technology LTD

Thomas S, Stephen R (2010) Rubber nanocomposites: preparation, properties, and applications. John Wiley & Sons

Kim WS, Lee DH, Kim IJ, Son MJ, Kim W (2009) SBR/Organoclay nanocomposites for the application on tire thread compounds. Macromoleculalr Research 17(10):776–784

Peddini SK, Bosnyak CP, Henderson NM, Ellison CJ, Paul DR (2015) Nanocomposites from styrene butadiene rubber (SBR) and multiwall carbon nanotubes (MWCNT) part 2: Mechanical properties. Polymer 56:443–451

Jose T, Moni G, Salini S, Raju AJ, George JJ (2017) Multifunctional multi-walled carbon nanotube reinforced natural rubber nanocomposites. Ind Crops Prod 105:63–73

Kim JS, Yun JH, Kim I, Shim SE (2011) Electrical properties of graphene/SBR nanocomposite prepared by latex heterocoagulation process at room temperature. J Ind Eng Chem 17:325–330

Hernandez M, del Mar BM, Verdejo R, Ezquerra TA, Lopez-Manchado MA (2012) Overall performance of natural rubber/graphene nanocomposites. Compos Sci Technol 73:40–46

Xie ZT, Luo MC, Huang C, Wei LY, Liu YH, Fu X, Huang G, Wu J (2018) Effects of graphene oxide on the strain-induced crystallization and mechanical properties of natural rubber crosslinked by different vulcanization systems. Polymer 151:279–286

Liu H, Gao H, Hu G (2019) Highly sensitive natural rubber/pristine graphene strain sensor prepared by a simple method. Compos B 171:138–145

Vishvanathperumal S, Anand G (2021) Effect of Nanosilica on the Mechanical Properties, Compression Set, Morphology, Abrasion and Swelling Resistance of Sulphur Cured EPDM/SBR Composites, Silicon; In press

Rabiei S, Shojaei A (2016) Vulcanization kinetics and reversion behavior of natural rubber/styrene-butadiene rubber blend filled with nanodiamond–The role of sulfur curing system. Eur Polymer J 81:98–113

George N, Venugopal B, John H, Mathiazhagan A, Joseph R (2019) Nanosilica decorated multiwalled carbon nanotubes (CS hybrids) in natural rubber latex. Polymer 161:170–180

Jafarpour E, Shojaei A, Ahmadijokani F (2020) High-performance styrene-butadiene rubber nanocomposites based on carbon nanotube/nanodiamond hybrid with synergistic thermal conduction characteristics and electrically insulating properties. Polymer 196:122470

Vishvanathperumal S, Anand G (2020) Effect of nanoclay/nanosilica on the mechanical properties, abrasion and swelling resistance of EPDM/SBR composites. SILICON 12:1925–1941

Wang Y, Wang F, Dong S, He H, Lu Y, Shi J, Liu J, Zhu H (2020) Ultra-small SiO2 nanoparticles highly dispersed on non-covalent functionalized reduced graphene oxide nanoplatelets for high-performance elastomer applications. Compos Sci Technol 198:108297

Li HY, Zhao SN, Zang SQ, Li J (2020) Functional metal–organic frameworks as effective sensors of gases and volatile compounds. Chem Soc Rev 49:6364–6401

Molavi H, Shojaei M (2019) Mixed-matrix composite membranes based on UiO-66-derived MOFs for CO2 separation. ACS Appl Mater Interfaces 11:9448–9461

Molavi H, Shojaei A, Mousavi SA (2018) Improving mixed-matrix membrane performance via PMMA grafting from functionalized NH2-UiO-66. J Mater Chem A 6:2775–2791

Molavi H, Hakimian A, Shojaei A, Raeiszadeh M (2018) Selective dye adsorption by highly water stable metal-organic framework: Long term stability analysis in aqueous media. Appl Surf Sci 445:424–436

Jun BM, Al-Hamadani YAJ, Son A, Park CM, Jang M, Jang A, Kim NC, Yoon Y (2020) Applications of metal-organic framework based membranes in water purification: A review. Sep Purif Technol 247:116947

Liu W et al (2021) A multifunctional aminated UiO-67 metal-organic framework for enhancing antitumor cytotoxicity through bimodal drug delivery. J Chem Eng 412:127899

Lawson HD, Walton SP, Chan C (2021) Metal−organic frameworks for drug delivery: A design perspective. ACS Appl Mater Interfaces 13:7004–7020

Férey G (2008) Hybrid porous solids: past, present, future. Chem Soc Rev 37(1):191–214

Farha OK et al (2012) Metal–organic framework materials with ultrahigh surface areas: is the sky the limit? J Am Chem Soc 134(36):15016–15021

Stock N, Biswas S (2012) Synthesis of metal-organic frameworks (MOFs): routes to various MOF topologies, morphologies, and composites. Chem Rev 112(2):933–969

Mueller U et al (2006) Metal–organic frameworks—prospective industrial applications. J Mater Chem 16(7):626–636

Hong DH, Suh MP (2014) Enhancing CO2 separation ability of a metal-organic framework by post-synthetic ligand exchange with flexible aliphatic carboxylates. Chem Eur J 20(2):426–434

Cavka JH et al (2008) A new zirconium inorganic building brick forming metal organic frameworks with exceptional stability. J Am Chem Soc 130(42):13850–13851

Hu Z, Zhao D (2015) De facto methodologies toward the synthesis and scale-up production of UiO-66-type metal–organic frameworks and membrane materials. Dalton Trans 44(44):19018–19040

Kim M, Cohen SM (2012) Discovery, development, and functionalization of Zr (iv)-based metal–organic frameworks. CrystEngComm 14(2):4096–4104

Schoenecker PM, Carson CG, Jasuja H, Flemming CJJJ, Walton KS (2012) Effect of water adsorption on retention of structure and surface area of metal–organic frameworks. Ind Eng Chem Res 51(18):6513–6519

De Coste JB, Peterson GW, Schindler BJ, Killops KL, Browe MA, Mahle JJ (2013) The effect of water adsorption on the structure of the carboxylate containing metal–organic frameworks Cu-BTC, Mg-MOF-74, and UiO-66. J Mater Chem A 1(38):11922–11932

Kandiah M et al (2010) Synthesis and stability of tagged UiO-66 Zr-MOFs. Chem Mater 22(24):6632–6640

Wu H, Yildirim T, Zhou W (2013) Exceptional mechanical stability of highly porous zirconium metal–organic framework UiO-66 and its important implications. J Phys Chem Lett 4(6):925–930

Datta S (2001) Synthetic elastomers, Chap 3 of rubber technologist’s handbook. In: White JR, De SK (eds) RAPRA Technology LTD

Jia X, Yu Y, Li G, Sui G, Li P, Yang X (2010) Effects of curing systems and polysulfonamide pulp on the curing characteristics, mechanical properties, and swelling behavior of ethylene–propylene–diene elastomer composites. J Appl Polym Sci 118(2):1060–1067

Tian M, Yin S, Zou H, Su L, Zhang L (2011) Static and dynamic mechanical properties and fracture morphology of EPDM composites containing silicate nanofibers and short PA-66 microfibers. Compos B 42:1937–1944

Zheng H, Zhang Y, Peng Z, Zhang Y (2004) Influence of clay modification on the structure and mechanical properties of EPDM/montmorillonite nanocomposites. Polym Testing 23:217–223

Ahmadi SJ, Huang Y, Li W (2005) Fabrication and physical properties of EPDM–organoclay nanocomposites. Compos Sci Technol 65:1069–1076

Li P, Yin L, Song G, Sun J, Wang L, Wang H (2008) High-performance EPDM/organoclay nanocomposites by melt extrusion. Appl Clay Sci 40(1–4):38–44

Wang ZH, Lu YL, Liu J, Dang ZM, Zhang LQ, Wang W (2011) Preparation of nanoalumina/EPDM composites with good performance in thermal conductivity and mechanical properties. Polym Adv Technol 22(12):2302–2310

Yuan Z, Li W, Li C, Ye L (2019) Construction of multiple cross-linking networks in EPDM rubber: Synergistic reinforcing effect of graphene-zinc dimethacrylate on EPDM and improvement mechanism of sealing resilience. Compos A 121:254–264

Allahbakhsh A, Mazinani S (2015) Influences of sodium dodecyl sulfate on vulcanization kinetics and mechanical performance of EPDM/graphene oxide nanocomposites. RSC Adv 5:46694–46704

Datta RN, Ingham FAA (2001) Rubber additives-compounding ingredients, Chap 6 of Rubber Technologist’s Handbook. In: White JR, De SK (eds), RAPRA Technology LTD

Zou H, Qiu G, Liu G, Soddemann M, Xu J (2020) A novel approach to investigating effect of sulfur as a coagent on the quasi-static and cyclic–dynamic fatigue properties of peroxide cured EPDM. Polym Eng Sci 60(3):455–463

Akiba M, Hashima AS (1997) Vulcanization and cross-linking in elastomers. Prog Polym Sci 22:475–521

Flory PJ, Rehner J Jr, Rehner J (1943) Statistical mechanics of cross-linked polymer networks I. Rubberlike elasticity. J Chem Phys 11(11):512–520

Pasbakhsh P, Ismail H, Fauzi MNA, Bakar AA (2010) EPDM/modified halloysite nanocomposites. Appl Clay Sci 48(3):405–413

Molavi H, Zamani M, Aghajanzadeh M, Kheiri Manjili H, Danafar H, Shojaei A (2018) Evaluation of UiO-66 metal organic framework as an effective sorbent for Curcumin’s overdose. Appl Organomet Chem 32(4):e4221

George SC, Knorgen M, Thomas S (1999) Effect of nature and extent of cross-linking on swelling and mechanical behavior of styrene butadiene rubber membranes. J Membr Sci 163:1–17

Valentin JL, Carretero-Gonzalez J, Mora-Barrantes I, Chasse W (2008) Saalwachter, Uncertainties in the determination of cross-link density by equilibrium swelling experiments in natural rubber. Macromolecules 41:4717–4729

Mostafa A, Abouel-Kasem A, Bayoumi MR, El-sebaie MG (2009) Effect of carbon black loading on the swelling and compression set behavior of SBR and NBR rubber compounds. Mater Des 30:1561–1568

Saatchi MM, Shojaei A (2012) Effect of carbon-based nanoparticles on the cure characteristics and network structure of styrene–butadiene rubber vulcanizate. Polym Int 61:664–672

Habeeb SA, Diwan AA, Albozahid M (2021) A compressive review on swelling parameters and physical properties of natural rubber nano composites. Egypt J Chem 64(10):5713–5724

Ahmadi M, Shojaei A (2013) Cure kinetic and network structure of NR/SBR composites reinforced by multiwalled carbon nanotube and carbon blacks. Thermochem Acta 566:238–248

Hosseini SM, Razzaghi-Kashani M (2018) Catalytic and networking effects of carbon black on the kinetics and conversion of sulfur vulcanization in styrene butadiene rubber. Soft Matter 14:9194–9208

Boonstra BB (1979) Role of particulate fillers in elastomer reinforcement: a review. Polymer 20:690–704

Coran AY (2003) Chemistry of the vulcanization and protection of elastomers: A review of the achievements. J Appl Polym Sci 87:24–30

Sadequl AM, Ishiaku US, Ismail H, Poh BT (1998) The effect of accelerator/sulphur ratio on the scorch time of epoxidized natural rubber. Eur Polym J 34(1):51–57

Falco AD, Marzocca AJ, Corcuera MA, Eceiza A, Mondragon I, Rubiolo GH, Goyanes S (2009) Accelerator adsorption onto carbon nanotubes surface affects the vulcanization process of styrene–butadiene rubber composites. J Appl Polym Sci 113:2851–2857

Walton I, Chen C, Rimsza JM, Nenoff TM, Walton KS (2020) Enhanced sulfur dioxide adsorption in UiO-66 through crystal engineering and chalcogen bonding. Cryst Growth Des 20(9):6139–6146

Zhang X-F, Wang Z, Feng Y, Zhong Y, Liao J, Wang Y, Yao J (2018) Adsorptive desulfurization from the model fuels by functionalized UiO-66 (Zr). Fuel 234:256–262

Wei W, Zhang K, Qiao Z, Jiang J (2019) Functional UiO-66 for the removal of sulfur-containing compounds in gas and liquid mixtures: A molecular simulation study. Chem Eng J 356:737–745

Daraee M, Saeedirad R, Rashidi A (2019) Adsorption of hydrogen sulfide over a novel metal organic framework–metal oxide nanocomposite: TOUO-x (TiO2/UiO-66). J Solid State Chem 278:120866

De SK, White JR (eds) (2001) Rubber technologist's handbook. Vol. 1. iSmithers Rapra Publishing

National Center for Biotechnology Information. "PubChem Compound Summary for CID 7232,N-Cyclohexyl-2-benzothiazolesulfenamide"PubChem, https://pubchem.ncbi.nlm.nih.gov/compound/N-Cyclohexyl-2-benzothiazolesulfenamide. Accessed 28 Oct 2021

Park S-J, Seo M-K, Nah C (2005) Influence of surface characteristics of carbon blacks on cure andcmechanical behaviors of rubber matrix compoundings. J Colloid Interface Sci 291:229–235

Leblanc JL (2002) Rubber-filler interactions and rheological properties of filled compounds. Prog Polym Sci 27:627–687

Bhattacharya M, Bhowmick AK (2008) Polymer–filler interaction in nanocomposites: New interface area function to investigate swelling behavior and Young’s modulus. Polymer 49:4808–4818

Marzocca AJ, Mansilla MA (2007) Analysis of network structure formed in styrene–Butadiene rubber cured with sulfur/TBBS system. J Appl Polym Sci 103:1105–1112

Salgueiro W, Marzocca A, Somoza A, Consolati G, Cerveny S, Quasso F, Goyanes S (2004) Dependence of the network structure of cured styrene butadiene rubber on the sulphur content. Polymer 45:6037–6044

Ahmadi M, Shojaei A (2015) Reinforcing mechanisms of carbon nanotubes and high structure carbon black in natural rubber/styrene-butadiene rubber blend prepared by mechanicalmixing−effect of bound rubber. Polym Int 64:1627–1638

Hashemi MJ, Shojaei A (2017) Morphology development and mechanical properties of unsaturated polyester resin containing nanodiamonds. Polym Int 66:950–959

Li ZH, Zhang J, Chen SJ (2008) Effects of carbon blacks with various structures on vulcanization and reinforcement of filled ethylene-propylene-diene rubber. Express Polym Lett 2(10):695–704

Litvinov VM, Steeman PAM (1999) EPDM-carbon black interactions and reinforcement mechanisms as detectde by low-resolution HNMR. Macromolecules 32:8476–8490

Fukahori Y (2005) New progress in the theory and model of carbon black reinforcement of elastomers. J Appl Polym Sci 95:60–67

Hosseini SM, Razzaghi-Kashani M (2014) Vulcanization kinetics of nano-silica filled styrene butadiene rubber. Polymer 55:6426–6434

Frohlich J, Niedermeier W, Luginsland H-D (2005) The effect of filler–filler and filler–elastomer interaction on rubber reinforcement. Compos A 36:449–460

Yue Y, Zhang H, Zhang Z, Chen Y (2013) Polymer–filler interaction of fumed silica filled polydimethylsiloxane investigated by bound rubber. Compos Sci Technol 86:1–8

Song L, Li Z, Chen L, Zhou H, Lu A, Li L (2016) The effect of bound rubber on vulcanization kinetics in silica filled silicone rubber. RSC Adv 6(103):101470–101476

Bokobza L (2004) The reinforcement of elastomeric networks by fillers. Macromol Mater Eng 289:607–621

Harwood JAC, Payne AR (1968) Hysteresis and strength of rubbers. J Appl Polym Sci 12:889–901

Kraus G (1978) Reinforcement of elastomers by carbon black. Rubber Chem Technol 51:297–321

Payne AR, Whittaker RE (1971) Influence of hysteresis on tensile and fatigue failure in rubbers. J Appl Polym Sci 15:1941–1948

Che Mat NS, Ismail H, Othman N (2017) Curing characteristics and mechanical and aging properties of ethylene propylene diene monomer/calcium carbonate/bentonite hybrid composites. J Elastomers Plast 49(5):397–407

El Maanaoui H, Meier J (2021) Lifetime prediction with temperature dependence for EPDM and NR elastomers based on fatigue crack growth mechanical measurements and filler distribution. Polymer 228:123909

Abraham F, Alshuth T, Jerrams S (2001) Dependence on mean stress and stress amplitude of fatigue life of EPDM elastomers. Plast, Rubber Compos 30(9):421–425

Liu Y, Chen J, Li G, Liu X, Liao X, Yang Q (2014) Effect of physical and chemical cross-linking structure on fatigue behavior of styrene butadiene elastomer. J Appl Polym Sci 131:40917

Acknowledgements

Authors are grateful for the financial support received from Sharif University of Technology in this research.

Funding

This research was financially supported by research deputy of Sharif University of Technology. The authors acknowledge their support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interest or personal relationships that could have influenced the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abdi, B., Shojaei, A. & Molavi, H. Superior fatigue and mechanical properties of ethylene-propylene diene monomer rubber incorporated with Zr-based metal–organic framework. J Polym Res 30, 30 (2023). https://doi.org/10.1007/s10965-022-03415-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03415-6