Abstract

Incorporation of carbon black (CB) in natural rubber (NR) enhances the Mullins effect and Payne effect of their vulcanizates, but the strain softening mechanisms and the microstructure evolution in the vulcanizates have not been clearly concluded so far. We investigate the Mullins effect and Payne effect of CB filled NR vulcanizates by using cyclic tensile tests at different temperatures and dynamic rheological measurements combined with simultaneous electric conduction. During cyclic stretching, the normalized recovery hysteresis energy and accumulative softening energy for NR/CB vulcanizates with different loadings can be both superimposed on a master curve, indicating that the Mullins effect is mainly dominated by the rubber matrix. The irreversible simultaneous resistance evolution also reveals that the structural evolution of nanoparticles (NPs) network is not directly related to the Mullins effect. Moreover, the extension of linear viscoelastic region and the hysteresis of Payne effect for filled vulcanizates subjected to cyclic stretching indicate the destruction of CB aggregated structure and the interfacial layers between CB and rubber chains during cyclic stretching. This investigation would be illuminating for the microstructure evolution and strain softening of rubber nanocomposites under harsh service conditions.

Similar content being viewed by others

References

Murphy, W. N. The rational use of vulcanizable rubber. Am. J. Dent. Sci. 1891, 25, 124–128.

Yamashita, S.; Takahashi, S. Molecular mechanisms of natural rubber biosynthesis. Annu. Rev. Biochem. 2020, 89, 821–851.

Song, Y.; Zheng, Q. Concepts and conflicts in nanoparticles reinforcement to polymers beyond hydrodynamics. Prog. Mater. Sci. 2016, 84, 1–58.

Song, Y.; Zheng, Q. A. Linear viscoelasticity of polymer melts filled with nano-sized fillers. Polymer 2010, 51, 3262–3268.

Tan, Y.; Wang, L.; Xiao, J.; Zhang, X.; Wang, Y.; Liu, C.; Zhang, H.; Liu, C.; Xia, Y.; Sui, K. Synchronous enhancement and stabilization of graphene oxide liquid crystals: inductive effect of sodium alginates in different concentration zones. Polymer 2019, 160, 107–114.

van Beilen, J. B.; Poirier, Y. Establishment of new crops for the production of natural rubber. Trends Biotechnol. 2007, 25, 522–529.

Liu, J.; Wu, S.; Tang, Z.; Lin, T.; Guo, B.; Huang, G. New evidence disclosed for networking in natural rubber by dielectric relaxation spectroscopy. Soft Matter 2015, 11, 2290–2299.

Wu, J.; Qu, W.; Huang, G.; Wang, S.; Huang, C.; Liu, H. Super-resolution fluorescence imaging of spatial organization of proteins and lipids in natural rubber. Biomacromolecules 2017, 18, 1705–1712.

Harwood, J. A. C.; Mullins, L.; Payne, A. R. Strsss softening in natural rubber vulcanizates. 2. stress softening effects in pure gum and filler loaded rubbers. J. Appl. Polym. Sci. 1965, 9, 3011–3021.

Diani, J.; Fayolle, B.; Gilormini, P. A review on the Mullins effect. Eur. Polym. J. 2009, 45, 601–612.

Kakavas, P. A. Mechanical properties of bonded elastomer discs subjected to triaxial stress. J. Appl. Polym. Sci. 1996, 59, 251–261.

Merckel, Y.; Diani, J.; Brieu, M.; Caillard, J. Constitutive modeling of the anisotropic behavior of Mullins softened filled rubbers. Mech. Mater. 2013, 57, 30–41.

Payne, A. R.; Whittake. Re Effect of vulcanization on low-strain dynamic properties of filled rubbers. J. Appl. Polym. Sci. 1972, 16, 1191–1212.

Song, Y.; Du, M.; Yang, H.; Zheng, Q. Structure and viscoelasticity of rubber materials. Acta Polymerica Sinica (in Chinese) 2013, 1115–1130.

Chazeau, L.; Brown, J. D.; Yanyo, L. C.; Sternstein, S. S. Modulus recovery kinetics end other insights into the Payne effect for filled elastomers. Polym. Compos. 2000, 21, 202–222.

Payne, A. R. Elasticity of carbon black networks. J. Colloid Sci. 1964, 19, 744–754.

Nagaraja, S. M.; Mujtaba, A.; Beiner, M. Quantification of different contributions to dissipation in elastomer nanoparticle composites. Polymer 2010, 111, 48–52.

Leblanc, J. L. Simplified modeling calculations to enlighten the mechanical properties (modulus) of carbon black filled diene rubber compounds. J. Appl. Polym. Sci. 2011, 122, 599–607.

Meier, J. G.; Klueppel, M. Carbon black networking in elastomers monitored by dynamic mechanical and dielectric spectroscopy. Macromol. Mater. Eng. 2008, 293, 12–38.

Papon, A.; Merabia, S.; Guy, L.; Lequeux, F.; Montes, H.; Sotta, P.; Long, D. R. Unique nonlinear behavior of nano-filled elastomers: from the onset of strain softening to large amplitude shear deformations. Macromolecules 2012, 45, 2891–2904.

Majeste, J.; Vincent, F. A kinetic model for silica-filled rubber reinforcement. J. Rheol. 2015, 59, 405–427.

Clough, J. M.; Creton, C.; Craig, S. L.; Sijbesma, R. P. Covalent bond scission in the Mullins effect of a filled elastomer: real-time visualization with mechanoluminescence. Adv. Funct. Mater. 2016, 26, 9063–9074.

Stoeckelhuber, K. W.; Svistkov, A. S.; Pelevin, A. G.; Heinrich, G. Impact of filler surface modification on large scale mechanics of styrene butadiene/silica rubber composites. Macromolecules 2011, 44, 4366–4381.

Coquelle, E.; Bossis, G. Mullins effect in elastomers filled with particles aligned by a magnetic field. Int. J. Solids Struct. 2006, 43, 7659–7672.

Song, Y.; Zeng, L.; Zheng, Q. Reconsideration of the rheology of silica filled natural rubber compounds. J. Phys. Chem. B 2010, 121, 5867–5875.

Qian, D.; Meng, F. Modelling Mullins effect induced by chain delamination and reattachment. Polymer 2021, 222, 123608.

Li, X.; Tian, C.; Li, H.; Liu, X.; Zhang, L.; Hong, S.; Ning, N.; Tian, M. Combined effect of volume fractions of nanofillers and filler-polymer interactions on 3D multiscale dispersion of nanofiller and Payne effect. Compos. Part A-Appl. Sci. Manuf. 2022, 152, 106722.

Wang, S.; Chester, S. A. Modeling thermal recovery of the Mullins effect. Mech. Mater. 2018, 126, 88–98.

Ma, C.; Ji, T.; Robertson, C. G.; Rajeshbabu, R.; Zhu, J.; Dong, Y. Molecular insight into the Mullins effect: irreversible disentanglement of polymer chains revealed by molecular dynamics simulations. Phys. Chem. Chem. Phys. 2017, 19, 19468–19477.

Song, Y.; Zheng, Q. Application of two phase model to linear dynamic rheology of filled polymer melts. Polymer 2011, 52, 6173–6179.

Li, Z.; Song, Y.; Zheng, Q. Payne effect and weak overshoot in rubber nanocomposites. Chinese J. Polym. Sci. 2022, 40, 85–92.

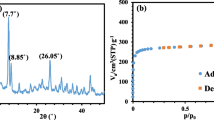

Shi, X.; Sun, S.; Zhao, A.; Zhang, H.; Zuo, M.; Song, Y.; Zheng, Q. Influence of carbon black on the Payne effect of filled natural rubber compounds. Compos. Sci. Technol. 2021, 203, 108586.

Song, Y.; Xu, Z.; Wang, W.; Zheng, Q. Payne effect of carbon black filled natural rubber nanocomposites: Influences of extraction, crosslinking, and swelling. J. Rheol. 2021, 65, 807–820.

Zhong, X.; Song, Y.; Zheng, Q.; Wang, W. Influence of coagents on Payne effect of butadiene rubber vulcanizates. Polymer 2021, 212, 123298.

Xu, H.; Xia, X.; Hussain, M.; Song, Y.; Zheng, Q. Linear and nonlinear rheological behaviors of silica filled nitrile butadiene rubber. Polymer 2018, 156, 222–227.

Yang, R.; Song, Y.; Zheng, Q. Payne effect of silica-filled styrene-butadiene rubber. Polymer 2017, 116, 304–313.

Hussain, M.; Yasin, S.; Akram, M. A.; Xu, H.; Song, Y.; Zheng, Q. Influence of ionic liquids on structure and rheological behaviors of silica-filled butadiene rubber. Ind. Eng. Chem. Res. 2019, 58, 18205–18212.

Xu, Y.; Xu, H.; Zheng, Q.; Song, Y. Influence of ionic liquids on rheological behaviors of polyisoprene rubber/silica compounds. Polymer 2019, 183, 121898.

Le, H. H.; Pham, T.; Henning, S.; Klehm, J.; Wiessner, S.; Stoeckelhuber, K. W.; Das, A.; Hoang, X. T.; Do, Q. K.; Wu, M.; Vennemann, N.; Heinrich, G.; Radusch, H. J. Formation and stability of carbon nanotube network in natural rubber: effect of non-rubber components. Polymer 2015, 73, 111–121.

Huang, M.; Tunnicliffe, L. B.; Zhuang, J.; Ren, W.; Yan, H.; Busfield, J. J. C. Strain- dependent dielectric behavior of carbon black reinforced natural rubber. Macromolecules 2016, 49, 2339–2347.

Steinhauser, D.; Moewes, M.; Klueppel, M. Carbon black networking in elastomers monitored by simultaneous rheological and dielectric investigations. J. Phys. Condens. Matter 2016, 28, 495103.

Beutier, C.; David, L.; Sudre, G.; Cassagnau, P.; Heuillet, P.; Cantaloube, B.; Serghei, A. In-situ coupled mechanical/electrical investigations of EPDM/CB composite materials: the electrical signature of the mechanical Mullins effect. Compos. Sci. Technol. 2022, 218, 109144.

Taniguchi, Y.; Mai, T.; Yamaguchi, M.; Tsunoda, K.; Urayama, K. Investigating multiaxial Mullins effect of carbon-black-reinforced elastomers using electrical resistivity measurements. ACS Appl. Polym. Mater. 2022, 4, 1139–1149.

Zhao, A.; Shi, X.; Sun, S.; Zhang, H.; Zuo, M.; Song, Y.; Zheng, Q. Insights into the Payne effect of carbon black filled styrene-butadiene rubber compounds. Chinese J. Polym. Sci. 2021, 39, 81–90.

Holt, A. P.; Sangoro, J. R.; Wang, Y. Y.; Agapov, A. L.; Sokolov, A. P. Chain and segmental dynamics of poly(2-vinylpyridine) nanocomposites. Macromolecules 2013, 46, 4168–4173.

Flory, P. J.; Rehner, J. Statistical mechanics of cross-linked polymer networks. II. Swelling. J. Chem. Phys. 1943, 11, 521–526.

Huneau, B. Strain-induced crystallization of natural rubber: a review of X-ray diffraction investigations. Rubber Chem. Technol. 2011, 84, 425–452.

Li, Z.; Xu, H.; Xia, X.; Song, Y.; Zheng, Q. Energy dissipation accompanying Mullins effect of nitrile butadiene rubber/carbon black nanocomposites. Polymer 2019, 171, 106–114.

Li, Z.; Wen, F.; Hussain, M.; Song, Y.; Zheng, Q. Scaling laws of Mullins effect in nitrile butadiene rubber nanocomposites. Polymer 2020, 193, 122350.

Hou, F.; Song, Y.; Zheng, Q. Influence of liquid isoprene rubber on strain softening of carbon black filled isoprene rubber nanocomposites. Chinese J. Polym. Sci. 2021, 39, 887–895.

Song, Y.; Zheng, Q. A guide for hydrodynamic reinforcement effect in nanoparticle-filled polymers. Crit. Rev. Solid State Mat. Sci. 2016, 41, 318–346.

Hu, Z.; Zhou, J.; Song, Y.; Zheng, Q.; Wang, W. Strain softening of natural rubber composites filled with carbon black and aramid fiber. J. Rheol. 2023, 67, 157–168.

Perez-Aparicio, R.; Vieyres, A.; Albouy, P.; Sanseau, O.; Vanel, L.; Long, D. R.; Sotta, P. Reinforcement in natural rubber elastomer nanocomposites: breakdown of entropic elasticity. Macromolecules 2013, 46, 8964–8972.

Aranguren, M. I.; Mora, E.; Degroot, J. V.; Macosko, C. W. Effect of reinforcing fillers on the rheology of polymer melts. J. Rheol. 1992, 36, 1165–1182.

Nasr, G. M. Vulcanization conditions: How they affect the electrical conductivity of SBR loaded with the percolation concentration of FEF-black. Polym. Test. 1996, 15, 585–591.

Li, B.; You, W.; Peng, L.; Huang, X.; Yu, W. Revealing the shear effect on the interfacial layer in polymer nanocomposites through nanofiber reorientation. Macromolecules 2023, 56, 3050–3063.

Kluppel, M.; Schramm, J. A generalized tube model of rubber elasticity and stress softening of filler reinforced elastomer systems. Macromol. Theor. Simul. 2000, 9, 742–754.

Suzuki, N.; Ito, M.; Yatsuyanagi, F. Effects of rubber/filler interactions on deformation behavior of silica filled SBR systems. Polymer 2005, 46, 193–201.

Wolff, S.; Wang, M. J.; Tan, E. H. Filler elastomer interactions. 7. study on bound rubber. Rubber Chem. Technol. 1993, 66, 163–177.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Nos. 51790503, 52273084 and 51873181).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare no interest conflict.

Electronic Supplementary Information for

Rights and permissions

About this article

Cite this article

Shi, XY., Sun, SH., Yang, L. et al. Microstructure Evolution and Strain Softening of Carbon Black Filled Natural Rubber Vulcanizates. Chin J Polym Sci 41, 1947–1957 (2023). https://doi.org/10.1007/s10118-023-3025-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-023-3025-0