Abstract

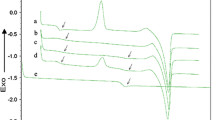

The influence of multiblock copolymers derived from ε-caprolactone and ethylene glycol on the morphology, interfacial tension and thermal properties of immiscible poly(lactic acid) (PLA)/poly(ε-caprolactone) (PCL) blends was studied. Multiblock copolymers of PCL and poly(ethylene glycol) (PEG) with similar molar masses, but different block lengths, were used as compatibilizers. PLA/PCL blends (80/20 wt%) containing 1, 3, and 5 wt% of multiblock copolymers were prepared in a corotating twin-screw extruder. The interfacial tension of the PLA/PCL blends were estimated by shear rheometry using the Palierne model and its morphology and thermal behavior were investigated by scanning electron microscopy (SEM), transmission electron microscopy (TEM) and differential scanning calorimetry (DSC). The interfacial tension of uncompatibilized PLA/PCL estimated by the Palierne model is 1.51 mN/m. Upon addition of 1 wt% of the multiblock copolymer with longer block lengths (C2000E6000) the interfacial tension decreases to a minimum value of 0.38 mN/m. This minimum value of interfacial tension was only achieved with 3 wt% of multiblock copolymer with shorter block lengths (C550E1500). These results indicate that multiblock copolymers with shorter block lengths require a higher amount to reach the interface saturation. Furthermore, when the interface saturation is reached there is a change in the blend’s fracture mode, from inter-particle to trans-particle, corroborating the increase in the interfacial adhesion estimated by the Palierne model. The presence of the C2000E6000 copolymer increased the crystallinity of the PLA matrix and contributed to the adhesion of the PLA/PCL blend.

Similar content being viewed by others

References

Wu D, Zhang Y, Zhang M, Zhou W (2008) Phase behavior and its viscoelastic response of polylactide/poly(ε-caprolactone) blend. Eur Polym J 44:2171–2183

Harrats C, Thomas S, Groeninckx G (2006) Micro- and nanostructured multiphase polymer blend systems: phase morphology and interfaces, 1st edn. CRC Press, New York

Cole PJ, Cook RF, Macosko CW (2003) Adhesion between immiscible polymers correlated with interfacial entanglements. Macromolecules 36:2808–2815

Anastasiadis SH, Gancarz I, Koberstein JT (1988) Interfacial tension of immiscible polymer blends: temperature and molecular weight dependence. Macromolecules 21:2980–2987

Shi D, Hu GH, Ke Z, Li RKY, Yin J (2006) Relaxation behavior of polymer blends with complex morphologies: Palierne emulsion model for uncompatibilized and compatibilized PP/PA6 blends. Polymer 47:4659–4666

Van Hemelrijck E, Van Puyvelde P, Velankar S, Macosko CW, Moldenaers P (2004) Interfacial elasticity and coalescence suppression in compatibilized polymer blends. J Rheol 48:143–158

Yang HS, Nam GJ, Kim HS, Lee JW (2002) Interrelationship between Interfacial Tension and Rheological Properties of LDPE/PS Blends. J Soc Rheol Japan 30:187–193

Finotti PFM, Costa LC, Capote TSO, Scarel-Caminaga RM, Chinelatto MA (2017) Immiscible poly(lactic acid)poly(ε-caprolactone) for temporary implants. J Mech Behav Biomed Mater 68:155–162

Nagarajan V, Mohanty AK, Misra M (2016) Perspective on Polylactic Acid (PLA) based Sustainable Materials for Durable Applications: Focus on Toughness and Heat Resistance. ACS Sustain Chem Eng 4:2899–2916

Cigana P, Favis BD, Jerome R (1996) Diblock copolymers as emulsifying agents in polymer blends: Influence of molecular weight, architecture, and chemical composition. J Polym Sci Part B Polym Phys 34:1691–1700

Van Hemelrijck E, Van Puyvelde P, Macosko CW, Moldenaers P (2005) The effect of block copolymer architecture on the coalescence and interfacial elasticity in compatibilized polymer blends. J Rheol 49:783

Cometa S, Chiellini F, Bartolozzi I, Chiellini E, De Giglio E, Sabbatini L (2010) Surface segregation assessment in poly(e-caprolactone)-poly(ethylene glycol) multiblock copolymer films. Macromol Biosci 10:317–327

You JH, Choi S, Kim J (2008) Synthesis and Microphase Separation of Biodegradable Poly ( ε -caprolactone ) - Poly ( ethylene glycol ) -Poly ( ε -caprolactone ) Multiblock Copolymer Films. Macromol Res 16:609–613

Haussler L, Pospiech D, Eckstein K, Janke A, Vogel E (1997) Effect of multiblock copolymers in polymer blends. J Appl Polym Sci 66:2293–2309

Xing P, Bousmina M, Rodrigue D (2000) Critical experimental comparison between five techniques for the determination of interfacial tension in polymer blends : model system of polystyrene / polyamide-6. Macromolecules 33:8020–8034

Retsos H, Anastasiadis H, Pispas S, Mays JW, Hadjichristidis N (2004) Interfacial tension in binary polymer blends in the presence of block copolymers. 2. Effects of additive architecture and composition. Macromolecules 37:524–537

Wagner M, Wolf BA (1993) Effect of block copolymers on the interfacial tension between two ‘immiscible’ homopolymers. Polymer 34:1460–1464

Wu D, Zhang Y, Yuan L, Zhang M, Zhou W (2010) Viscoelastic interfacial properties of compatibilized poly(ε- caprolactone)/polylactide blend. J Polym Sci Part B Polym Phys 48:756–765

Palierne JF (1990) Linear rheology of viscoelastic emulsions with interfacial tension. Rheol Acta 29:204–214

Palierne JF (1991) Erratum. Rheol Acta 269:263–269

Jacobs U, Fahrländer M, Winterhalter J, Friedrich C (1999) Analysis of Palierne’s emulsion model in the case of viscoelastic interfacial properties. J Rheol 43:1495

IngeoTM Biopolymer 3251D Technical Data Sheet (2018) Natureworks® LLC, Minnetonka. https://www.natureworksllc.com/Products/3-series-for-injection-molding. Accessed 15 Aug 2022

CAPATM 6500 Product data sheet (2019). Ingevity, North Charleston. https://www.ingevity.com/products/capa-6500/. Accessed 15 Aug 2022

Staffa LH, Bettini SHP, Chinelatto MA (2020) Synthesis of Poly(ether-ester-urethane) with a Controlled Molar Weight Based on Poly(ε-caprolactone) and Poly (ethylene glycol) Segments. Macromol Symp 394:2000050

CAPATM 2054J Product data sheet (2019). Ingevity, North Charleston. https://www.ingevity.com/products/capa-2054j/. Accessed 15 Aug 2022

CAPATM 2205 Product data sheet (2019). Ingevity, North Charleston. https://www.ingevity.com/products/capa-2205/. Accessed 15 Aug 2022

Ultrapeg® 1500 Technical Data sheet (2011) Oxiteno, Brazil. https://oxiteno.com/br/en/portfolio/polyethylene-glycols/. Accessed 15 Aug 2022

Ultrapeg® 6000 Technical Data sheet (2011) Oxiteno, Brazil. https://oxiteno.com/br/en/portfolio/polyethylene-glycols/. Accessed 15 Aug 2022

Finotti PFM, Costa LC, Chinelatto MA (2016) Effect of the chemical structure of compatibilizers on the thermal, mechanical and morphological properties of immiscible PLA/PCL blends. Macromol Symp 368:24–29

Dias PP, Chinelatto MA (2019) Effect of poly ( ε -caprolactone-b-tetrahydrofuran ) triblock copolymer concentration on morphological, thermal and mechanical properties of immiscible PLA / PCL blends. J Renew Mater 7:129–138

Ewoldt RH, Johnston MT, Caretta LM (2015) In: Spagnolie, S. (ed) Complex Fluids in Biological Systems. Biological and Medical Physics, Biomedical Engineering. Springer, New York, NY

Garlotta D (2002) A literature review of poly(lactic acid). J Polym Environ 9:63–84

Bousmina M (1999) Effect of interfacial tension on linear viscoelastic behavior of immiscible polymer blends. Rheol Acta 38:251–254

Noroozi N, Schafer LL, Hatzikiriakos SG (2012) Thermorheological properties of poly (e-caprolactone)/polylactide blends. Polym Eng Sci 52:2348–2359

Fortelný I, Ostafińska A, Michálková D, Jůza J, Mikešová J, Šlouf M (2015) Phase structure evolution during mixing and processing of poly(lactic acid)/polycaprolactone (PLA/PCL) blends. Polym Bull 72:2931–2947

Urquijo J, Guerrica-Echevarría G, Eguiazábal JI (2015) Melt processed PLA/PCL blends: Effect of processing method on phase structure, morphology, and mechanical properties. J Appl Polym Sci 132:1–9

Wu S (1971) Calculation of interfacial tension in polymer systems. J Polym Sci Part C Polym Symp 34:19–30

Lamnawar K, Maazouz A, Cabrera G, Al-Itry R (2018) Interfacial tension properties in biopolymer blends: From deformed drop retraction method (DDRM) to shear and elongation rheology-application to blown film extrusion. Int Polym Process 33:411–424

Eastwood EA, Dadmun MD (2002) Multiblock copolymers in the compatibilization of polystyrene and poly(methyl methacrylate) blends: Role of polymer architecture. Macromolecules 35:5069–5077

Díaz MF, Barbosa SE, Capiati NJ (2007) Reactive compatibilization of PE/PS blends. Effect of copolymer chain length on interfacial adhesion and mechanical behavior. Polymer 48:1058–1065

Thomas S, Grohens Y, Jyotishkumar P (2015) Characterization of polymer blends: miscibility, morphology and interfaces, 1st edn. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, Germany

Gu L, Macosko W (2021) Evaluating PE/PLA interfacial tension using ternary immiscible polymer blends. J Appl Polym Sci 138:1–5

Jandas PJ, Mohanty S, Nayak SK (2018) Cold crystallization kinetics of biodegradable polymer blend; controlled by reactive interactable and nano nucleating agent. Advanced Composites and Hybrid Materials 1:624–634

Leclair A, Favis BD (1996) The role of interfacial contact in immiscible binary polymer blends and its influence on mechanical properties. Polymer 37:4723–4728

Broz ME, VanderHart DL, Washburn NR (2003) Structure and mechanical properties of poly(D, L-lactic acid)/poly(ε-caprolactone) blends. Biomaterials 24:4181–4190

Acknowledgements

This study was financed by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001, Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) – SWE scholarship—Finance Code 202952/2018-5/SWE and Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP) – Finance Code 2018/23542-7. Machgraphe/Brazil for supervision during the blend preparation stage. Soft Matter, Rheology and Technology department from KU Leuven for the assistance during the rheometry tests.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest related to this research work. This manuscript was not under consideration by any other journal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Staffa, L.H., Huysecom, AS., Bettini, S.H.P. et al. Effect of molecular structure of PEG/PCL multiblock copolymers on the morphology and interfacial properties of PLA/PCL blends. J Polym Res 29, 388 (2022). https://doi.org/10.1007/s10965-022-03239-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03239-4