Abstract

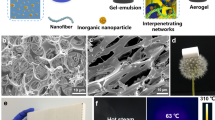

Phenolic aerogel was first fabricated by sol–gel polymerization and freeze-drying method. Then, it was soaked into aniline solvent for 1 day. Ultimately, polyaniline/phenolic (PANI/RF) composite aerogel was obtained after the aniline molecules inside the phenolic aerogel were polymerized into polyaniline. The microstructure, thermal and electrical properties of the composites were investigated. The experimental results showed that polyaniline wires adhere to the surface of the micro holes skeleton which can be observed from the SEM images. Thus, polyaniline wires will form much smaller network inside the RF network, exhibiting an interpenetrating 3D network structure. In addition, compared with RF aerogel, PNAI/RF aerogel had maintained the thermal performance well, which showed mildly decline in heat-resistance and increase in heat conductivity, respectively. What’s more, it exhibited superior electrical performance (good specific capacitance) as compared with that of RF aerogel which is non-conducting, In general, PANI/RF aerogel with low heat conductivity (0.021 W/mK), high electrical conductivity (0.12 S/cm) and specific capacitance (280 F/g) exhibited more excellent comprehensive performance than single RF aerogel.

Similar content being viewed by others

References

Y. Wang, S.J. Wang, C. Bian, Y.H. Zhong, X.L. Jing, Polym. Eng. Sci. 111, 239 (2015)

L.P. Bian, J.Y. Xiao, J.C. Zeng, S.L. Xing, C.P. Yin, A.Q. Jia, Mater. Design 54, 230 (2014)

U.A. Amran, S. Zakaria, C.H. Chia, S.N. Jaafar, R. Roslan, Ind. Crop. Prod. 72, 54 (2015)

R. Zhang, Y.G. Lu, L. Zhan, X.Y. Liang, G.P. Wu, L.C. Ling, Carbon 41, 1660 (2003)

S.A. Song, Y.S. Chung, S.S. Kim, Compos. Sci. Technol. 103, 85 (2014)

J.Y. Zhu, X. Yang, Z.B. Fu, C.Y. Wang, W.D. Wu, L. Zhang, J. Porous Mater. 23, 1217 (2016)

T. A. El-Brolossy, S. S. Ibrahim, E. A. Alkhudhayr, Polym. Compos. 36, 1242 (2014)

E. Cuce, P.M. Cuce, C.J. Wood, S.B. Riffat, Renew. Sust. Energ. Rev. 34, 273 (2014)

J.Y. Zhu, X. Yang, Z.B. Fu, C.Y. Wang, W.D. Wu, L. Zhang, Chem. Eur. J. 22, 2515 (2016)

R.J. Goldstein, E.R.G. Eckert, W.E. Ibele, S.V. Patankar, T.W. Simon, T.H. Kuehn, P.J. Strykowski, K.K. Tamma, A. Bar-Cohen, J.V.R. Heberlein, J.H. Davidson, J. Bischof, F.A. Kulacki, U. Kortshagen, S. Garrick, V. Srinivasan, Int. J. Heat. Mass Transf. 48, 819 (2005)

E.M. Sparrow, S.S. Kang, W. Chuck, Int. J. Heat. Mass Transf. 30, 1237 (1987)

S. P. Gumfekar, W. Wang, B. X. Zhao, Macromol. Mater. Eng. 229, 966 (2014)

H.B. Zhao, L. Yuan, Z.B. Fu, C.Y. Wang, X. Yang, J.Y. Zhu, J. Qu, H.B. Chen, D.A. Schiraldi, ACS Appl. Mater. Interfaces 8, 9917 (2016)

Y. E. Miao, W. Fan, D. Chen, T. Liu, ACS Appl. Mater. Interfaces 5, 4423 (2013)

M.A. Rahman, Y.C. Wong, G.S. Song, C. Wen, J. Porous Mater. 22, 1313 (2015)

Y.N. Meng, K. Wang, Y.J. Zhang, Z.X. Wei, Adv. Mater. 25, 6985 (2013)

F.H. Meng, Y. Ding, Adv. Mater. 23, 4098 (2011)

N.A. Peppas, J.Z. Hilt, A. Khademhosseini, R. Langer, Adv. Mater. 18, 1345 (2006)

R. A. Green, S. Baek, L. A. Polle-Warren, P. J. Martens, Sci. Technol. Adv. Mater. 11, 14107 (2010)

T.Y. Dai, Y.J. Jia, Polymer 52, 2550 (2011)

P.C. Rodrigues, G.P. Souza, J.D. Damottaneto, L. Akcelrud, Polymer 43, 5493 (2002)

R. Yao, Z.J. Yao, J.T. Zhou, Mater. Lett. 176, 199 (2016)

W.J. Jiang, W.J. Luo, R.L. Zong, W.Q. Yao, Z.P. Li, Y.F. Zhu, Small 12, 4370 (2016)

W.W. Li, F.X. Gao, X.Q. Wang, N. Zhang, M.M. Ma, Angew. Chem. Int. Ed. 55, 9196 (2016)

D.Y. Zhai, B.R. Liu, Y. Shi, L.J. Pan, W.B. Li, ACS Nano 7, 3540 (2013)

H.F. An, Y. Wang, X.Y. Wang, N. Li, L.P. Zheng, J. Solid State Electrochem. 14, 651 (2010)

R. Yao, Z.J. Yao, J.T. Zhou, Polym. Compos. (2015). doi:10.1002/pc.23811

T. Mori, T.E. Smith, J. Urban Econ. 89, 1 (2015)

S.J. Wang, Y. Wang, C. Bian, Y.H. Zhong, X.L. Jing, Appl. Surf. Sci. 331, 519 (2015)

J.Z. Feng, J. Feng, Y.G. Jiang, C.R. Zhang, Mater. Lett. 65, 3454 (2011)

Acknowledgements

This work is supported by the Opening Project of Jiangsu Key Laboratory of Advanced Structural Materials and Application Technology (PAPD) as well as National Natural Science Foundation of China (Funding No. 51672129).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yao, R., Yao, Z. & Zhou, J. Microstructure, thermal and electrical properties of polyaniline/phenolic composite aerogel. J Porous Mater 25, 495–501 (2018). https://doi.org/10.1007/s10934-017-0461-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-017-0461-7