Abstract

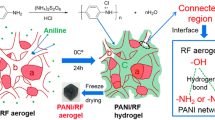

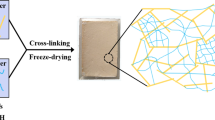

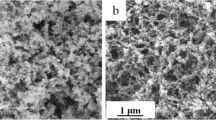

In this study, a novel approach was introduced to reduce the brittle behavior of phenolic aerogels. Hydroxy-terminated polybutadiene (HTPB) resin, a low-molecular weight rubbery material, was used to modify novolac-type phenolic aerogels. The aerogels were prepared by two-step sol–gel polymerization at high temperature/pressure process followed by ambient pressure drying. First, HTPB chains were introduced into the novolac network during the gelation and then, were consolidated in the novolac structure through reaction with toluene diisocyanate (TDI). The resulting aerogels containing different amounts of HTPB (0–50 wt%) exhibited low bulk density in the range of 0.14–0.23 g/cm3. By increasing the amount of HTPB, the change was observed in microstructure, morphology, and physical properties which corresponded well with mechanical properties and thermal conductivity variations. The measured compression modulus of the aerogels was found to decrease from 96.0 (for pure novolac) to 11.8 MPa with addition of HTPB, indicating some extent of flexibility in the network.

Similar content being viewed by others

References

Soleimani Dorcheh A, Abbasi MH (2008) Silica aerogel; synthesis, properties and characterization. J Mater Process Tech 199:10–26. doi:10.1016/j.jmatprotec.2007.10.060

Pierre AC, Pajonk GM (2002) Chemistry of aerogels and their applications. Chem Rev 102:4243–4265

Brinker CJ, Scherer GW (1990) Sol-gel science, the physics and chemistry of Sol-gel processing. Academic Press, London

Pekala RW (1989) Organic aerogels from the polycondensation of resorcinol with formaldehyde. J Mater Sci 24(9):3221–3227. doi:10.1007/bf01139044

Fricke J, Pekala RW, Alviso CT, Kong FM, Hulsey SS (1992) Aerogels derived from multifunctional organic monomers. J Non Cryst Solids 145:90–98. doi:10.1016/S0022-3093(05)80436-3

Durairaj RB (2005) Resorcinol: chemistry, technology and application. Springer, Germany

ElKhatat AM, Al-Muhtaseb SA (2011) Advances in tailoring resorcinol-formaldehyde organic and carbon gels. Adv Mater 23(26):2887–2903. doi:10.1002/adma.201100283

Liu J, Qiao ShZ, Liu H, Chen J, Orpe A, Zhao D, Lu GQ (2011) Extension of the Stober method to the preparation of monodisperse resorcinol-formaldehyde resin polymer and carbon spheres. Angew Chem Int 50:5947–5951. doi:10.1002/anie.201102011

Pekala RW, Alviso CT, Lu X, Gross J, Fricke J (1995) New organic aerogels based upon a phenolic-furfural reaction. J Non Cryst Solids 188(1–2):34–40. doi:10.1016/0022-3093(95)00027-5

Biesmans G, Randall D, Francais E, Perrut M (1998) Polyurethane-based organic aerogels’ thermal performance. J Non Cryst Solids 225:36–40. doi:10.1016/S0022-3093(98)00103-3

Leventis N, Sotiriou-Leventis C, Mohite DP, Larimore ZJ, Mang JT, Churu G, Lu H (2011) Polyimide aerogels by ring-opening metathesis polymerization (ROMP). Chem Mater 23(8):2250–2261. doi:10.1021/cm200323e

Daniel C, Giudice S, Guerra G (2009) Syndiotatic polystyrene aerogels with β, γ, and ε crystalline phases. Chem Mater 21:1028–1034. doi:10.1021/cm802537g

Lee JK, Gould GL (2010) Polyolefin-based aerogel. US Patent No 7,691,911 B2

Gouerec P, Miousse D, Tran-van F, Dao LH (1999) Characterizaion of pyrolyzed polyacrylonitrile aerogel thin films used in double-layer supercapacitors. J New Mater Electrochem Syst 2:221–226

Schwan M, Ratke L (2013) Flexibilisation of resorcinol–formaldehyde aerogels. J Mater Chem A 1:13462. doi:10.1039/c3ta13172f

Schwan M, Naikade M, Raabe D, Ratke L (2015) From hard to rubber-like: mechanical properties of resorcinol–formaldehyde aerogels. J Mater Sci 50(16):5482–5493. doi:10.1007/s10853-015-9094-x

Hajizadeh A, Bahramian A, Sharif A (2014) Effect of rubber modification on the morphology and properties of novolac nanostructures. Adv Mater Res 829(1):41–45

Job N, Théry A, Pirard R, Marien J, Kocon L, Rouzaud J-N, Béguin F, Pirard J-P (2005) Carbon aerogels, cryogels and xerogels: influence of the drying method on the textural properties of porous carbon materials. Carbon 43(12):2481–2494. doi:10.1016/j.carbon.2005.04.031

Czakkel O, Marthie K, Geissler E, Laszlo K (2005) Influence of drying on the morphology of resorcinol–formaldehyde-based carbon gels. Micros Meso Mater 86:124–133. doi:10.1016/j.micromeso.2005.07.021

Saliger R, Bock V, Petricevic R, Tillotson T, Geis S, Fricke J (1997) Carbon aerogels from dilute catalysis of resorcinol with formaldehyde. J Non Cryst Solids 221:144–150. doi:10.1016/S0022-3093(97)00411-0

Reuß M, Ratke L (2008) Subcritical dried RF-aerogels catalysed by hydrochloric acid. J Sol Gel Sci Technol 47(1):74–80. doi:10.1007/s10971-008-1733-0

Wu D, Fu R, Zhang S, Dresselhaus MS, Dresselhaus G (2004) Preparation of low-density carbon aerogels by ambient pressure drying. Carbon 42(10):2033–2039. doi:10.1016/j.carbon.2004.04.003

Wu D, Fu R (2008) Requirements of organic gels for a successful ambient pressure drying preparation of carbon aerogels. J Porous Mater 15(1):29–34. doi:10.1007/s10934-006-9048-4

Naseri I, Kazemi A, Bahramian AR, Razzaghi Kashani M (2014) Preparation of organic and carbon xerogels using high-temperature–pressure sol–gel polymerization. Mater Des 61:35–40. doi:10.1016/j.matdes.2014.04.061

Lorjai P, Chaisuwan T, Wongkasemjit S (2009) Porous structure of polybenzoxazine-based organic aerogel prepared by sol–gel process and their carbon aerogels. J Sol Gel Sci Technol 52(1):56–64. doi:10.1007/s10971-009-1992-4

Hajizadeh A, Bahramian AR, Sharif A (2014) Investigation of the effect of sol concentration on the microstructure and morphology of Novolac hyperporous. J Non Cryst Solids 402:53–57. doi:10.1016/j.jnoncrysol.2014.05.019

Fischer U, Saliger R, Bock V, Petricevic R, Fricke J (1997) Carbon aerogels as electrode material in supercapacitors. J Porous Mater 4(4):281–285. doi:10.1023/a:1009629423578

Hu Y, Chung Y, Mackenzie JD (1993) Gelation kinetics of an organically modified silicate. J Mater Sci 28(24):6549–6554. doi:10.1007/BF00356392

Hu Y, Mackenzie JD (1992) Rubber-like elasticity of organically modified silicates. J Mater Sci 27(16):4415–4420. doi:10.1007/BF00541574

Mackenzie JD, Chung YJ, Hu CY (1992) Section 6. Processing methods: rubbery ormosils and their applications. J Non Cryst Solids 147&148:271–279. doi:10.1016/S0022-3093(05)80629-5

Kramer SJ, Rubio-Alonso F, Mackenzie JD (1996) Organically modified silicate aerogels, “Aeromosils”. MRS Online Proc Libr 435:295–300. doi:10.1557/PROC-435-295

Mackenzie JD, Bescher E (1998) Structures, properties and potential applications of ormosils. J Sol Gel Sci Technol 13(1–3):371–377. doi:10.1023/A:1008600723220

Mackenzie JD (1994) Structures and properties of ormosils. J Sol Gel Sci Technol 2(1–3):81–86. doi:10.1007/BF00486217

Hajizadeh A, Bahramian A, Seifi A, Naseri I (2015) Effect of initial sol concentration on the microstructure and morphology of carbon aerogels. J Sol Gel Sci Technol 73(1):220–226. doi:10.1007/s10971-014-3520-4

Job N, Pirard R, Pirard J-P, Alié C (2006) Non-intrusive mercury porosimetry: pyrolysis of resorcinol-formaldehyde xerogels. Part Part Syst Charact 23(1):72–81. doi:10.1002/ppsc.200601011

Egger CC, Fresne CD, Raman VI, Schädler V, Frechen T, Roth SV, Müller-Buschbaum P (2008) Characterization of highly porous polymeric materials with pore diameters larger than 100 nm by mercury porosimetry and X-ray scattering methods. Langmuir 24(11):5877–5887. doi:10.1021/la800197p

Pirard R, Rigacci A, Maréchal JC, Quenard D, Chevalier B, Achard P, Pirard JP (2003) Characterization of hyperporous polyurethane-based gels by non-intrusive mercury porosimetry. Polymer 44(17):4881–4887. doi:10.1016/S0032-3861(03)00481-6

Alié C, Pirard R, Pirard J-P (2001) Mercury porosimetry applied to porous silica materials: successive buckling and intrusion mechanisms. Colloids Surf A 187–188:367–374. doi:10.1016/S0927-7757(01)00651-3

Miller RA (2009) Method for measuring thermal conductivity of small samples having very low thermal conductivity. NASA Glenn research center, NASA/TM-2009-215460

Gommes CJ, Roberts AP (2008) Structure development of resorcinol-formaldehyde gels: microphase separation or colloid aggregation. Phys Rev E 77 (4):041409-1–13.doi:10.1103/PhysRevE.77.041409

Alié C, Pirard R, Lecloux AJ, Pirard J-P (1999) Preparation of low-density xerogels through additives to TEOS-based alcogels. J Non Cryst Solids 246(3):216–228. doi:10.1016/S0022-3093(99)00088-5

Pirard R, Alié C, Pirard J-P (2002) Characterization of porous texture of hyperporous materials by mercury porosimetry using densification equation. Powder Technol 128(2–3):242–247. doi:10.1016/S0032-5910(02)00185-7

Gibson LJ, Ashby MF (1997) Cellular solids, structure and properties. Cambridge University Press, Cambridge

Ma H-S, Prévost J-H, Jullien R, Scherer GW (2001) Computer simulation of mechanical structure–property relationship of aerogels. J Non Cryst Solids 285(1–3):216–221. doi:10.1016/S0022-3093(01)00456-2

Fischer F, Rigacci A, Pirard R, Berthon-Fabry S, Achard P (2006) Cellulose-based aerogels. Polymer 47(22):7636–7645. doi:10.1016/j.polymer.2006.09.004

Lu X, Caps R, Fricke J, Alviso CT, Pekala RW (1995) Correlation between structure and thermal conductivity of organic aerogels. J Non Cryst Solids 188(3):226–234. doi:10.1016/0022-3093(95)00191-3

Acknowledgments

The authors are grateful to Ministry of Science, Research and Technology of Iran for the financial support for the present work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Shahzamani, M., Bagheri, R., Bahramian, A.R. et al. Preparation and characterization of hybrid aerogels from novolac and hydroxyl-terminated polybutadiene. J Mater Sci 51, 7861–7873 (2016). https://doi.org/10.1007/s10853-016-0042-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0042-1