Abstract

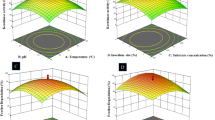

Streptomyces sp. 2M21 was evaluated for keratinase production in bioreactors using chicken feathers. Firstly, optimization of bioengineering parameters (agitation and aeration rates) using Response Surface Methodology was carried out in 2 L bioreactors. Optimized conditions identified by the modified quadratic model were verified as 150 rpm and 1 vvm experimentally corresponding to 351 U/ml of keratinase activity. Moreover, scaling up sequentially to 20 L bioreactors was implemented using constant impeller tip speed and constant mass transfer coefficient as key scale-up parameters. The keratinase activity in 5, 10 and 20 L bioreactors showed similar results with the one of shake flasks (412 U/ml) and 2 L bioreactors (351 U/ml)with respect to the keratinase activity values of 336, 385 and 344 U/ml, respectively. The results suggest keratinase production by evaluating chicken feathers in commercial level. Furthermore, this study has potential to contribute industrial scale production of keratinase by Streptomyces sp. 2M21 using the proposed bioreactor conditions.

Similar content being viewed by others

References

Acda MN (2010) Waste chicken feather as reinforcement in cement-bonded composites. Philipp J Sci 139:161–166

Dama ME (2020) Enzyme hydrolysis of chicken feathers and characterization of the metabolites, University of Nairobi.

Bhari R, Kaur M, Singh RS (2020) Nutritional enhancement of chicken feather waste by Bacillus aerius NSMk2. Indian J Microbiol 60:518–525

Suzuki Y, Tsujimoto Y, Matsui H, Watanabe K (2006) Decomposition of extremely hard-to-degrade animal proteins by thermophilic bacteria. J Biosci Bioeng 102:73–81

Zeisler-Diehl V, Al-Khutabi EAA, Kirfel G, Schreiber L, van Echten-Deckert G, Herzog V (2020) Detection of endogenous lipids in chicken feathers distinct from preen gland constituents. Protoplasma 257:1709–1724

Su C, Gong JS, Qin J, Li H, Li H, Xu ZH, Shi JS (2020) The tale of a versatile enzyme: molecular insights into keratinase for its industrial dissemination. Biotechnol Adv 45:107655

Jaouadi NZ, Rekik H, Badis A, Trabelsi S, Belhoul M, Yahiaoui AB, Aicha HB, Toumi A, Bejar S, Jaouadi B (2013) Biochemical and molecular characterization of a serine keratinase from Brevibacillus brevis US575 with promising keratin-biodegradation and hide-dehairing activities. PLoS ONE 8:e76722

Riffel A, Lucas F, Heeb P, Brandelli A (2003) Characterization of a new keratinolytic bacterium that completely degrades native feather keratin. Arch Microbiol 179:258–265

Brandelli A, Daroit DJ, Riffel A (2010) Biochemical features of microbial keratinases and their production and applications. Appl Microbiol Biotechnol 85:1735–1750

Moallaei H, Zaini F, Larcher G, Beucher B, Bouchara J-P (2006) Partial purification and characterization of a 37 kDa extracellular proteinase from Trichophyton vanbreuseghemii. Mycopathologia 161:369–375

Nnolim NE, Udenigwe CC, Okoh AI, Nwodo UU (2020) Microbial keratinase: next generation green catalyst and prospective applications. Front Microbiol 11:3280

Song N-B, Jo W-S, Song H-Y, Chung K-S, Won M, Song KB (2013) Effects of plasticizers and nano-clay content on the physical properties of chicken feather protein composite films. Food Hydrocolloids 31:340–345

Demir T, Hameş EE, Öncel SS, Vardar-Sukan F (2015) An optimization approach to scale up keratinase production by Streptomyces sp. 2M21 by utilizing chicken feather. Int Biodeterioration Biodegradation 103:134–140

Nielsen J, Villadsen J (2001) Bioreactors: description and modelling. Biotechnol Set 1:77–104

DelMar E, Largman C, Brodrick J, Geokas M (1979) A sensitive new substrate for chymotrypsin. Anal Biochem 99:316–320

Deniz I, Zihnioglu F, Öncel SS, Hames EE, Vardar-Sukan F (2019) Production, purification and characterization of a proteolytic enzyme from Streptomyces sp. 2M21. Biocatal Biotransformation 37:377–387

Shijin W, Xiang Y, Zhihang H, Zhang L, Jianmeng C (2009) Optimizing aerobic biodegradation of dichloromethane using response surface methodology. J Environ Sci 21:1276–1283

Maiorano AE, da Silva ES, Perna RF, Ottoni CA, Piccoli RAM, Fernandez RC, Maresma BG, de Andrade Rodrigues MF (2020) Effect of agitation speed and aeration rate on fructosyltransferase production of Aspergillus oryzae IPT-301 in stirred tank bioreactor. Biotechnol Lett 42:2619–2629

Singh R, Sooch BS, Puri M (2007) Optimization of medium and process parameters for the production of inulinase from a newly isolated Kluyveromyces marxianus YS-1. Biores Technol 98:2518–2525

Xia X, Lin S, Xia X-X, Cong F-S, Zhong J-J (2014) Significance of agitation-induced shear stress on mycelium morphology and lavendamycin production by engineered Streptomyces flocculus. Appl Microbiol Biotechnol 98:4399–4407

Rosa J, Neto AB, Hokka C, Badino A (2005) Influence of dissolved oxygen and shear conditions on clavulanic acid production by Streptomyces clavuligerus. Bioprocess Biosyst Eng 27:99–104

Song X, Zhang Y, Xue J, Li C, Wang Z, Wang Y (2018) Enhancing nemadectin production by Streptomyces cyaneogriseus ssp. noncyanogenus through quantitative evaluation and optimization of dissolved oxygen and shear force. Bioresour Technol 255:180–188

Zhou Y, Han L-R, He H-W, Sang B, Yu D-L, Feng J-T, Zhang X (2018) Effects of agitation, aeration and temperature on production of a novel glycoprotein GP-1 by Streptomyces kanasenisi ZX01 and scale-up based on volumetric oxygen transfer coefficient. Molecules 23:125

Wang Z-J, Wang H-Y, Li Y-L, Chu J, Huang M-Z, Zhuang Y-P, Zhang S-L (2010) Improved vitamin B12 production by step-wise reduction of oxygen uptake rate under dissolved oxygen limiting level during fermentation process. Biores Technol 101:2845–2852

Bhattacharyya MS, Singh A, Banerjee UC (2008) Production of carbonyl reductase by Geotrichum candidum in a laboratory scale bioreactor. Biores Technol 99:8765–8770

Jang HD, Chang KS (2005) Thermostable cellulases from Streptomyces sp.: scale-up production in a 50-l fermenter. Biotechnol Lett 27:239–242

Liang J, Xu Z, Liu T, Lin J, Cen P (2008) Effects of cultivation conditions on the production of natamycin with Streptomyces gilvosporeus LK-196. Enzyme Microb Technol 42:145–150

Singh RS, Yadav M (2013) Enhanced production of recombinant aspartase of Aeromonas media NFB-5 in a stirred tank reactor. Biores Technol 145:217–223

Hussin ASM, Greiner R (2012) Optimization of cultivation conditions for the production of phytate-degrading enzymes by Enterobacter sakazakii ASUIA279 isolated from Malaysian maize root. J Biotechnol Biodiversity 3:1–10

Gupta R, Ramnani P (2006) Microbial keratinases and their prospective applications: an overview. Appl Microbiol Biotechnol 70:21–33

Crater JS, Lievense JC (2018) Scale-up of industrial microbial processes. FEMS Microbiol Lett 365:fny138

Fang Z, Sha C, Peng Z, Zhang J, Du G (2019) Protein engineering to enhance keratinolytic protease activity and excretion in Escherichia coli and its scale-up fermentation for high extracellular yield. Enzyme Microb Technol 121:37–44

Kalaikumari SS, Vennila T, Monika V, Chandraraj K, Gunasekaran P, Rajendhran J (2019) Bioutilization of poultry feather for keratinase production and its application in leather industry. J Clean Prod 208:44–53

Peng Z, Mao X, Zhang J, Du G, Chen J (2019) Effective biodegradation of chicken feather waste by co-cultivation of keratinase producing strains. Microb Cell Fact 18:1–11

Wang J, Shih J (1999) Fermentation production of keratinase from Bacillus licheniformis PWD-1 and a recombinant B. subtilis FDB-29. J Ind Microbiol Biotechnol 22:608–616

Laxman RS, Sonawane AP, More SV, Rao BS, Rele MV, Jogdand VV, Deshpande VV, Rao MB (2005) Optimization and scale up of production of alkaline protease from Conidiobolus coronatus. Process Biochem 40:3152–3158

Zambare VP, Nilegaonkar S, Kanekar PP (2014) Scale up production of protease using Pseudomonas aeruginosa MCM B-327 and its detergent compatibility. J Biochem Technol 5:698–707

Saran S, Isar J, Saxena RK (2007) Statistical optimization of conditions for protease production from Bacillus sp. and its scale-up in a bioreactor. Appl Biochem Biotechnol 141:229–239

Saurabh S, Jasmine I, Pritesh G, Kumar SR (2007) Enhanced productivity of serine alkaline protease by Bacillus sp. using soybean as substrate. Malays J Microbiol 3:1–6

Asif M, Hussain A, Ali MA, Rasool M (2012) Scale up studies for the production of protease enzyme using Bacillus subtilis adopting response surface methodology. Afri J Microbiol Res 6:2120–2128

Abdella A, Segato F, Wilkins MR (2020) Optimization of process parameters and fermentation strategy for xylanase production in a stirred tank reactor using a mutant Aspergillus nidulans strain. Biotechnol Rep 26:e00457

Bettin F, Rosa LOD, Montanari Q, Zaccaria S, Dillon AJP, Silveira MMD (2020) Influence of oxygen supply on growth and laccases production by Pleurotus sajor-caju PS-2001 in submerged process. Braz Arch Biol Technol 63:e20190015

Prasad R, Abraham TK, Nair AJ (2014) Scale up of production in a bioreactor of a halotolerant protease from moderately halophilic Bacillus sp. isolated from soil. Braz Arch Biol Technol 57:448–455

Hiruta O, Futamura T, Takebe H, Satoh A, Kamisaka Y, Yokochi T, Nakahara T, Suzuki O (1996) Optimization and scale-up of γ-linolenic acid production by Mortierella ramanniana MM 15–1, a high γ-linolenic acid producing mutant. J Ferment Bioeng 82:366–370

Hardy N, Augier F, Nienow AW, Béal C, Chaabane FB (2017) Scale-up agitation criteria for Trichoderma reesei fermentation. Chem Eng Sci 172:158–168

Stephenie W, Kabeir B, Shuhaimi M, Rosfarizan M, Yazid A (2007) Influence of pH and impeller tip speed on the cultivation ofBifidobacterium pseudocatenulatum G4 in a milk-based medium. Biotechnol Bioprocess Eng 12:475–483

Koganti V, Carroll F, Ferraina R, Falk R, Waghmare Y, Berry M, Liu Y, Norris K, Leasure R, Gaudio J (2010) Application of modeling to scale-up dissolution in pharmaceutical manufacturing. AAPS PharmSciTech 11:1541–1548

Marques MP, Cabral JM, Fernandes P (2010) Bioprocess scale-up: quest for the parameters to be used as criterion to move from microreactors to lab-scale. J Chem Technol Biotechnol 85:1184–1198

Bandaiphet C, Prasertsan P (2006) Effect of aeration and agitation rates and scale-up on oxygen transfer coefficient, kLa in exopolysaccharide production from Enterobacter cloacae WD7. Carbohyd Polym 66:216–228

Islam R, Tisi D, Levy M, Lye G (2008) Scale-up of Escherichia coli growth and recombinant protein expression conditions from microwell to laboratory and pilot scale based on matched kLa. Biotechnol Bioeng 99:1128–1139

F Siebler (2020) Scale-up of gas fermentations: modelling tools for risk minimization.

MB Murphy (1987) Growth and production of amylotic enzymes by aspergillus spp, Dublin City University.

Gamboa-Suasnavart RA, Marín-Palacio LD, Martínez-Sotelo JA, Espitia C, Servín-González L, Valdez-Cruz NA, Trujillo-Roldán MA (2013) Scale-up from shake flasks to bioreactor, based on power input and Streptomyces lividans morphology, for the production of recombinant APA (45/47 kDa protein) from Mycobacterium tuberculosis. World J Microbiol Biotechnol 29:1421–1429

Acknowledgements

This study was a part of Ege University Research Fund (Grant Number 11.MUH.005) and the authors wish to present their appreciations to the Scientific and Technological Research Council of Turkey (TUBITAK) for the financial support under the Grant Number of MAG-112M250.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Deniz, I., Demir, T., Oncel, S.S. et al. Effect of Agitation and Aeration on Keratinase Production in Bioreactors Using Bioprocess Engineering Aspects. Protein J 40, 388–395 (2021). https://doi.org/10.1007/s10930-021-09978-5

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10930-021-09978-5