Abstract

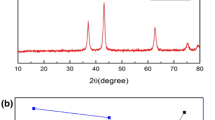

Synthesis of nanoparticles with unique properties has attracted a lot of interest of scientists and researchers these days. A key aspect of being able to manipulate the properties of the nanomaterials is the nanoscale architecture and engineering by various processing techniques. A synthetic strategy was developed to control the preparation of nickel nanoparticles Ni-NPs produced using an arc discharge technique with an ultrasonic nebulizer. The sample was characterized for its structural and magnetic properties using X-ray diffraction, ultraviolet–visible (UV–Vis) spectrophotometer, zeta potential, high resolution transmission electron microscope, scanning electron microscope, vibrating sample magnetometer. The resulted sample unveiled small, spherical and homogeneous Ni nanoparticles with an average size 15 nm lower than the critical size which indicates a superparamagnetic behavior. The zeta potential measurements shows + 49.01 ± 3.2 mV which confirms the synthesis of stable Ni nanoparticles. A UV–Vis spectrum of the nanosized Ni sample shows a sharp absorption peak between 362 and 380 nm. The magnetic properties shows no hysteresis and zero results for coercivity force and remanence that indicates superparamagnetic behavior of the Ni nanoparticles.

Similar content being viewed by others

References

N. T. K. Thanh (ed.) Magnetic Nanoparticles: From Fabrication to Clinical Applications (CRC Press, Boca Raton, 2012).

R. Serrano García, S. Shelley, and Y. K. Gun’ko (2018). Appl. Sci. 8, (2), 172.

T. Hyeon (2003). Chem. Commun. 8, 927–934.

B. Xia, I. W. Lenggoro, and K. Okuyama (2001). J. Mater. Sci. 36, (7), 1701–1705.

A. D. Omrani, M. A. Bousnina, L. S. Smiri, M. Taibi, P. Leone, F. Schoenstein, and N. Jouini (2010). Mater. Chem. Phys. 123, (2–3), 821–828.

N. R. Nik Roselina and A. Azizan (2012). Procedia Eng. 41, 1620–1626.

R. Rudolf, B. Friedrich, S. Stopic, I. Anzel, S. Tomic, and M. Colic (2012). J. Biomater. Appl. 26, (5), 595–612.

M. Hemalatha, N. Suriyanarayanan, and S. Prabahar (2014). Opt. Int. J. Light Electron Opt. 125, (8), 1962–1966.

M. R. Vaezi, M. Barzgar Vishlaghi, M. Farzalipour Tabriz, and O. Mohammad Moradi (2015). J. Alloys Compd. 635, 118–123.

M. D. Stopić (2015). Vojnotehnički glasnik 63, (4), 215–223.

N. R. Haghighi and R. Poursalehi (2015). Procedia Mater. Sci. 11, 347–351.

A. M. El-Khatib, M. S. Badawi, G. D. Roston, A. M. Khalil, R. M. Moussa, and M. M. Mohamed (2018). J. Nano Res. 52, 88–101.

J. Singh, T. Patel, N. Kaurav, and G. S. Okram (2016). AIP Conf. Proc. 1731, (1), 050036.

A. M. El-Khatib, M. S. Badawi, Z. F. Ghatass, M. M. Mohamed, and M. Elkhatib (2018). J. Clust. Sci. https://doi.org/10.1007/s10876-018-1430-2.

J. H. Bang and K. S. Suslick (2010). Adv. Mater. 22, (10), 1039–1059.

E. Hontañón, J. M. Palomares, M. Stein, X. Guo, R. Engeln, H. Nirschl, and F. E. Kruis (2013). J. Nanopart. Res. 15, (9), 1957.

P. Ahuja, S. K. Ujjain, R. K. Sharma, and G. Singh (2014). RSC Adv. 4, (100), 57192–57199.

R. Sharma, D. P. Bisen, U. Shukla, and B. G. Sharma (2012). Recent Res. Sci. Technol. 4, (8), 77–79.

B. Ingham (2015). Crystallogr. Rev. 21, (4), 229–303.

M. M. Mohamed, Z. F. Ghatass, E. A. Shalaby, M. M. Kotb, and M. El-Raey (2000). Fresenius’ J. Anal. Chem. 368, (8), 809–815.

J. Kang, Y. Kim, H. Kim, X. Hu, N. Saito, J.-H. Choi, and M.-H. Lee (2016). Sci. Rep. https://doi.org/10.1038/srep38652.

H. T. Rahal, R. Awad, A. M. Abdel-Gaber, and D. Bakeer (2017). J. Nanomater. https://doi.org/10.1155/2017/7460323.

M. Kaszuba, J. Corbett, F. M. Watson, and A. Jones (2010). Philos. Trans. A. Math. Phys. Eng. Sci. 368, (1927), 4439–4451.

J. D. Clogston and A. K. Patri (2011). Methods Mol. Biol. 697, 63–70.

C. J. Pandian, R. Palanivel, and S. Dhananasekaran (2015). Chin. J. Chem. Eng. 23, (8), 1307–1315.

G. Cheng, D. Romero, G. T. Fraser, and A. R. Hight Walker (2005). Langmuir 21, (26), 12055–12059.

Y.-Y. Xu, L. Wang, T. Wu, and R.-M. Wang (2017). Rare Met. https://doi.org/10.1007/s12598-017-0938-1.

M. R. Sanaee, S. Chaitoglou, N. Aguiló-Aguayo, and E. Bertran (2016). Appl. Sci. 7, (1), 26.

N. Cordente, M. Respaud, F. Senocq, M.-J. Casanove, C. Amiens, and B. Chaudret (2001). Nano Lett. 1, (10), 565–568.

X. He, W. Zhong, C.-T. Au, and Y. Du (2013). Nanoscale Res. Lett. 8, (1), 446.

M. Khairy (2013). Int. J. Mater. Chem. 3, (5), 106–111.

A. Chiolerio and P. Allia Magnetic nanostructures and spintronics. in B. Bhushan (ed.), Encyclopedia of Nanotechnology (Springer, Dordrecht, 2012), pp. 1248–1256.

D. L. Leslie-Pelecky and R. D. Rieke (1996). Chem. Mater. 8, (8), 1770–1783.

D. A. Dimitrov and G. M. Wysin (1996). Phys. Rev. B 54, (13), 9237.

Acknowledgements

The authors wish to thank the physics department, Faculty of Science, Alexandria University for providing instrumental and laboratory facilities to carry out this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest regarding the publication of this paper.

Rights and permissions

About this article

Cite this article

El-Khatib, A.M., Badawi, M.S., Roston, G.D. et al. Structural and Magnetic Properties of Nickel Nanoparticles Prepared by Arc Discharge Method Using an Ultrasonic Nebulizer. J Clust Sci 29, 1321–1327 (2018). https://doi.org/10.1007/s10876-018-1451-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10876-018-1451-x