Abstract

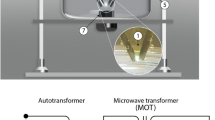

Arc discharge technique was modified by using non-traditional rotational electrode and AC applied voltage. Two different systems were designed and locally fabricated to improve the properties of prepared yields. The rotational speed of the target, shape of the electrode and type of dielectric medium have a great effect on the yield, shape, size, stability and mass production. Ethanol as a dielectric medium was used in this study and compared with published works. The yields were characterized by Particle Size Analyzer, high-resolution electron microscope (HRTEM), inductively coupled plasma optical emission spectrometry (ICP-OES), X-ray diffraction (XRD), the ultraviolet–visible spectrophotometer (UV–Vis) and Zeta potential. All characterizations show that spherical silver nanoparticles are successfully produced for both systems. The results showed that the size of the nanoparticles prepared by cylindrical rotating electrode system is (23.45 ± 0.16) compared with those produced by disk rotating electrode system with size (26.83 ± 0.44). According to the obtained data the shape of the used cathodes was greatly affected the mass production rate of the nanoparticles, it was found that the rate in case of the cylindrical cathode was (46 ± 0.6 mg/min) compared with those prepared in case of disk cathode (34 ± 0.9 mg/min) and both rotational electrodes yielded more than simple arc discharge (23 ± 0.8 mg/min).

Similar content being viewed by others

References

F. Nasirpouri (2017). Springer Ser. Surface Sci. 62, https://doi.org/10.1007/978-3-319-44920-3_1.

J. E. Morris (ed.), Nanopackaging: Nanotechnologies and Electronics Packaging (© Springer Science + Business Media, LLC, 2008). https://doi.org/10.1007/978-0-387-47326-0_6.

K. H. Tseng, M. Y. Chung, and J. L. Chiu (2018). J. Clust. Sci. 29, 215. https://doi.org/10.1007/s10876-017-1325-7.

A. M. El-Khatib, M. M. Mohamed, M. S. Badawi, A. S. Doma, A. S. Mohamed, and A. A. Thabet (2018). Int. J. Adv. Res. https://doi.org/10.21474/ijar01/6819.

Y. Y. Tsai, J. S. Su, and C. Y. Su (2008). Int. J. Mach. Tools Manuf. 48, 1653–1657. https://doi.org/10.1016/j.ijmachtools.2008.07.005.

N. Arora and N. N. Sharma (2014). Diamond Related Mater. 50, 135–150. https://doi.org/10.1016/j.diamond.2014.10.001.

A. J. Fetterman, Y. Raitses, and M. Keidar (2008). Carbon N. Y. 46, 1322–1326. https://doi.org/10.1016/j.carbon.2008.05.018.

T. Zhao, Y. Liu, and J. Zhu (2005). Carbon N. Y. 43, 2907–2912. https://doi.org/10.1016/j.carbon.2005.06.005.

M. I. Mohammad, A. A. Moosa, J. H. Potgieter, and M. K. Ismael (2013). ISRN Nanomater. https://doi.org/10.1155/2013/785160.

L. Zhen-Hua,W. Miao,W. Xin-Qing, Z. Hai-Bin, L. Huan-Ming, Y. Ando (2002). Chin. Phys. Lett. 19, 91–93. http://cpl.iphy.ac.cn/Y2002/V19/I1/091.

N. R. Haghighi and R. Poursalehi (2015). Procedia, Mater. Sci. 11, 347–351. https://doi.org/10.1016/j.mspro.2015.11.119.

K. H. Tseng, Y. C. Chen, and J. J. Shyue (2011). J. Nanopart Res. 13, 1865. https://doi.org/10.1007/s11051-010-9937-y.

T. Charinpanitkul, W. Tanthapanichakoon, and N. Sano (2009). Curr. Appl. Phys. 9, 629. https://doi.org/10.1016/j.cap.2008.05.018.

Y. Su, Y. Zhang, H. Wei, B. Qian, Z. Yang, and Y. Zhang (2012). Phys. E Low-dimensional Syst. Nanostruct. 44, 1548. https://doi.org/10.1016/j.physe.2012.03.025.

A. M. El-Khatib, Z. F. Ghatass, M. S. Badawi, M. El-Khatib, M. M. Mohamed (2018). Int. J. Sci. Eng. Res. 9.

B. D. Hall, D. Zanchet, and D. Ugarte (2000). J. Appl. Crystallogr. 33, 1335–1341. https://doi.org/10.1107/s0021889800010888.

X. Pan, I. Medina-Ramirez, R. Mernaugh, and J. Liu (2010). Coll. Surf. B: Biointerfaces 77, 82. https://doi.org/10.1016/j.colsurfb.2010.01.010.

S. Bhattacharjee (2016). J. Controll. Release 235, 337–351. https://doi.org/10.1016/j.jconrel.2016.06.017.

D. Paramelle, A. Sadovoy, S. Gorelik, P. Free, J. Hobley, and D. G. Fernig (2014). https://doi.org/10.1039/c4an00978a.

S. Ratan, D. Gautam, and Ramendhu (2010). J. Exp. Nanosci. https://doi.org/10.1080/17458080903583915.

J. D. J. Ingle and S. R. Crouch Spectrochemical Analysis (Prentice Hall, New Jersey, 1988).

Y. Ando, X. Zhao, K. Hirahara, K. Suenaga, S. Bandow, and S. Iijima (2001). Diamond Relat. Mater. 10, 1185–1189. https://doi.org/10.1016/S0925-9635(00)00513-6.

X. Cai, H. Cong, and C. Liu (2012). Carbon N. Y. 50, 2726–2730. https://doi.org/10.1016/j.carbon.2012.02.031.

G. Raniszewski, L. Szymanski, Z. Kolacinski (2012) Carbon nanotubes synthesis by electric arc plasma with external magnetic field, 4th International Conference Nanocon, pp. 131–137.

H. Zhang, G. Zou, and L. Liu (2017). J. Mater. Sci. 52, 3375. https://doi.org/10.1007/s10853-016-0626-9.

M. Miranzadeh and M. Kassaee (2014). Chem. Eng. J. 257, 105–111. https://doi.org/10.1016/j.cej.2014.06.088.

H. Zhang, G. Zou, L. Liu, Y. Li, H. Tong, Z. Sun, and Y. N. Zhou (2016). Appl. Phys. A 122, 896. https://doi.org/10.1007/s00339-016-0424-x.

D.-C. Tien, L.-C. Chen, N. Van Thai, and S. Ashraf (2010). J. Nanomater. https://doi.org/10.1155/2010/634757.

K.-H. Tseng, C.-J. Chou, T.-C. Liu, D.-C. Tien, T.-C. Wu, and L. Stobinski (2018). Adv. Sci. Eng. Mater. https://doi.org/10.1155/2018/3240959.

B. C. Sih and Michael (2006). J. Phys. Chem. B. https://doi.org/10.1021/jp065213a.

Acknowledgements

The authors wish to thank Physics Department, Faculty of Science, Alexandria University for providing instrumental and laboratory facilities to carry out this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest regarding the publication of this paper.

Rights and permissions

About this article

Cite this article

El-Khatib, A.M., Badawi, M.S., Ghatass, Z.F. et al. Synthesize of Silver Nanoparticles by Arc Discharge Method Using Two Different Rotational Electrode Shapes. J Clust Sci 29, 1169–1175 (2018). https://doi.org/10.1007/s10876-018-1430-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10876-018-1430-2