Abstract

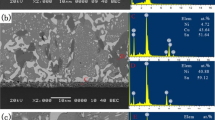

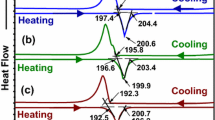

Aiming to solve the intrinsic brittleness of Sn–Bi solder alloy, the effects of In element on the microstructure evolution, mechanical and soldering properties were systematically investigated in Sn–57Bi–1Ag-based alloy. It was found that the addition of In could fragment the reticular Bi-rich phase and increase the content of β-Sn phase in the Sn–(57 − x)Bi–1Ag–xIn alloy, which significantly improved the fracture elongation of the In-containing solder alloy. The elongation of Sn–56.0Bi–1Ag–1.0In reached 68.51%, which was 2.3 times that of Sn–57Bi–1Ag (~ 29.68%). What’s more, the fracture mechanism of the alloy changes from brittle fracture to mixed ductile-brittle fracture with the addition of In element, implying a significant progress in solving the brittleness problem of Sn–Bi solder alloy. Meanwhile, compared to Sn–57Bi–1Ag, the lower melting point and solidification temperature of the In-containing solder alloys improved the solderability, which enhances the spreading rate of alloy and results in a maximum spreading rate of 72.00% for the Sn–56.0Bi–1Ag–1.0In. This work provides a valuable guidance for industrial production of solder alloys as it simultaneously improved both the solderability and the ductility of Sn–Bi-based alloys.

Similar content being viewed by others

Data availability

The data used to support the findings of this study are included within the article.

References

C.J. Lee, K.D. Min, H.J. Park, S.-B. Jung, Mechanical properties of Sn-58 wt% Bi solder containing Ag-decorated MWCNT with thermal aging tests. J. Alloys Compd. 820, 153077 (2020). https://doi.org/10.1016/j.jallcom.2019.153077

Y.-W. Yen, P.-H. Tsai, Y.-K. Fang, S.-C. Lo, Y.-P. Hsieh, C. Lee, Interfacial reactions on Pb-free solders with Au/Pd/Ni/Cu multilayer substrates. J. Alloys Compd. 503, 25–30 (2010). https://doi.org/10.1016/j.jallcom.2010.04.241

J.W. Yoon, S.W. Kim, S.B. Jung, Interfacial reaction and mechanical properties of eutectic Sn–0.7Cu/Ni BGA solder joints during isothermal long-term aging. J. Alloys Compd. 391, 82–89 (2005). https://doi.org/10.1016/j.jallcom.2004.09.001

M. Mueller, S. Schindler, K.-J. Wolter, S. Wiese, I. Panchenko, Determination of melting and solidification temperatures of Sn–Ag–Cu solder spheres by infrared thermography. Thermochim. Acta 714, 179245 (2022). https://doi.org/10.1016/j.tca.2022.179245

R.-D. Wang, Q. Hu, S.-M. Zhang, F.-W. Zhang, C.-T. Lu, Z.-G. Wang, Properties of (Fe–B)-doped Sn–1.0Ag–0.5Cu solders prepared by mechanical alloying. Rare Met. 38, 665–674 (2019). https://doi.org/10.1007/s12598-019-01248-9

L. Sun, M.H. Chen, L. Zhang, Microstructure evolution and grain orientation of IMC in Cu–Sn TLP bonding solder joints. J. Alloys Compd. 786, 677–687 (2019). https://doi.org/10.1016/j.jallcom.2019.01.384

F. Li, C. Pu, C. Li, J. Yang, Y. Jia, C. Geng, X. Zhang, Q. Bao, S. Guo, J. Yi, J. Zhang, Study on the effects of Ag addition on the mechanical properties and oxidation resistance of Sn–Zn lead-free solder alloy by high-throughput method. J. Mater. Sci.: Mater. Electron. (2023). https://doi.org/10.1007/s10854-022-09756-8

F. Wang, X. Wang, Z. Lv, C. Hang, H. Chen, M. Li, A novel antioxidant and low-temperature Sn–Zn solder paste based on Zn@Sn core–shell structure. Mater. Today Commun. 31, 103356 (2022). https://doi.org/10.1016/j.mtcomm.2022.103356

C. Geng, Y. Jia, X. Ma, Y. Jia, Y. Mu, G. Wang, C. Li, J. Peng, Q. Bao, Mechanical properties and oxidation resistance of Sn–Zn–xCu (2.3 ≤ x ≤ 20.2) solder alloys prepared by high-throughput strategy. Manuf. Lett. 27, 47–52 (2021). https://doi.org/10.1016/j.mfglet.2020.11.005

J.C. Liu, G. Zhang, Z.H. Wang, J.S. Ma, K. Suganuma, Thermal property, wettability and interfacial characterization of novel Sn–Zn–Bi–In alloys as low-temperature lead-free solders. Mater. Des. 84, 331–339 (2015). https://doi.org/10.1016/j.matdes.2015.06.148

J.X. Hu, N. Su, X.M. Wang, F.C. Yin, X.M. Ouyang, Experimental investigation and thermodynamic calculation of the Co–Sn–Bi ternary system. CALPHAD 77, 102404 (2022). https://doi.org/10.1016/j.calphad.2022.102404

T. Yang, X. Zhao, Z. Xiong, W. Tan, Y. Wei, C. Tan, X. Yu, Y. Wang, Improvement of microstructure and tensile properties of Sn–Bi–Ag alloy by heterogeneous nucleation of β-Sn on Ag3Sn. Mater. Sci. Eng. A 785, 139372 (2020). https://doi.org/10.1016/j.msea.2020.139372

Y. Liu, K.N. Tu, Low melting point solders based on Sn, Bi, and in elements. Mater. Today Adv. 8, 100115 (2020). https://doi.org/10.1016/j.mtadv.2020.100115

F. Wang, H. Chen, Y. Huang, L. Liu, Z. Zhang, Recent progress on the development of Sn–Bi based low-temperature Pb-free solders. J. Mater. Sci. Mater. Electron. 30, 3222–3243 (2019). https://doi.org/10.1007/s10854-019-00701-w

Y. Hirata, C.-. Yang, S.-. Lin, H. Nishikawa, Improvements in mechanical properties of Sn–Bi alloys with addition of Zn and in. Mater. Sci. Eng. A 813, 141131 (2021). https://doi.org/10.1016/j.msea.2021.141131

S.T. Oh, J.H. Lee, Microstructural, wetting, and mechanical characteristics of Sn–57.6Bi–0.4Ag alloys doped with metal–organic compounds. Electron. Mater. Lett. 10, 473–478 (2014). https://doi.org/10.1007/s13391-014-8002-x

Y.Y. Shiue, T.H. Chuang, Effect of La addition on the interfacial intermetallics and bonding strengths of Sn–58Bi solder joints with Au/Ni/Cu pads. J. Alloys Compd. 491, 610–617 (2010). https://doi.org/10.1016/j.jallcom.2009.11.017

H.R. Kotadia, P.D. Howes, S.H. Mannan, A review: on the development of low melting temperature Pb-free solders. Microelectron. Reliab. 54, 1253–1273 (2014). https://doi.org/10.1016/j.microrel.2014.02.025

B.L. Silva, M.G.C. Xavier, A. Garcia, J.E. Spinelli, Cu and Ag additions affecting the solidification microstructure and tensile properties of Sn–Bi lead-free solder alloys. Mater. Sci. Eng. A 705, 325–334 (2017). https://doi.org/10.1016/j.msea.2017.08.059

C. Peng, J. Shen, W. Xie, J. Chen, C. Wu, X. Wang, Influence of minor Ag nano-particles additions on the microstructure of Sn30Bi0.5Cu solder reacted with a Cu substrate. J. Mater. Sci. Mater. Electron. 22, 797–806 (2010). https://doi.org/10.1007/s10854-010-0214-8

B.-S. Xu, L.-K. Zang, Z.-F. Yuan, Y. Wu, Z. Zhou, Dissolutive wetting process and interfacial characteristic of molten Sn–17Bi–0.5Cu alloy on copper substrate. Rare Met. 32, 537–543 (2013). https://doi.org/10.1007/s12598-013-0167-1

J.L. Paixão, L.F. Gomes, R.V. Reyes, A. Garcia, J.E. Spinelli, B.L. Silva, Microstructure characterization and tensile properties of directionally solidified Sn-52 wt% Bi-1 wt% sb and Sn-52 wt% Bi-2 wt% sb alloys. Mater. Charact. 166, 110445 (2020). https://doi.org/10.1016/j.matchar.2020.110445

J. Shen, Y.Y. Pu, H.G. Yin, Q. Tang, Effects of Cu, Zn on the wettability and shear mechanical properties of Sn–Bi-based lead-free solders. J. Electron. Mater. 44, 532–541 (2014). https://doi.org/10.1007/s11664-014-3460-3

X. Chen, F. Xue, J. Zhou, Y. Yao, Effect of in on microstructure, thermodynamic characteristic and mechanical properties of Sn–Bi based lead-free solder. J. Alloys Compd. 633, 377–383 (2015). https://doi.org/10.1016/j.jallcom.2015.01.219

Q. Li, N. Ma, Y. Lei, J. Lin, H. Fu, J. Gu, Characterization of low-melting-point Sn–Bi–In lead-free solders. J. Electron. Mater. 45, 5800–5810 (2016). https://doi.org/10.1007/s11664-016-4366-z

W. Zhu, W. Zhang, W. Zhou, P. Wu, Improved microstructure and mechanical properties for SnBi solder alloy by addition of Cr powders. J. Alloys Compd. 789, 805–813 (2019). https://doi.org/10.1016/j.jallcom.2019.03.027

L. Yang, W. Zhou, Y. Ma, X. Li, Y. Liang, W. Cui, P. Wu, Effects of Ni addition on mechanical properties of Sn58Bi solder alloy during solid-state aging. Mater. Sci. Eng. A 667, 368–375 (2016). https://doi.org/10.1016/j.msea.2016.05.015

Y. Li, K. Luo, A.B.Y. Lim, Z. Chen, F. Wu, Y.C. Chan, Improving the mechanical performance of Sn57.6Bi0.4Ag solder joints on Au/Ni/Cu pads during aging and electromigration through the addition of tungsten (W) nanoparticle reinforcement. Mater. Sci. Eng. A 669, 291–303 (2016). https://doi.org/10.1016/j.msea.2016.05.092

Y.-C. Huang, S.-W. Chen, Effects of Co alloying and size on solidification and interfacial reactions in Sn-57 wt.%Bi–(Co)/Cu couples. J. Electron. Mater. 40, 62–70 (2010). https://doi.org/10.1007/s11664-010-1386-y

J. Shen, C. Wu, S. Li, Effects of rare earth additions on the microstructural evolution and microhardness of Sn30Bi0.5Cu and Sn35Bi1Ag solder alloys. J. Mater. Sci. Mater. Electron. 23, 156–163 (2011). https://doi.org/10.1007/s10854-011-0566-8

R.M. Shalaby, Effect of silver and indium addition on mechanical properties and indentation creep behavior of rapidly solidified Bi–Sn based lead-free solder alloys. Mater. Sci. Eng. A 560, 86–95 (2013). https://doi.org/10.1016/j.msea.2012.09.038

F.Q. Hu, Q.K. Zhang, J.J. Jiang, Z.L. Song, Influences of Ag addition to Sn–58Bi solder on SnBi/Cu interfacial reaction. Mater. Lett. 214, 142–145 (2018). https://doi.org/10.1016/j.matlet.2017.11.127

B.-G. Park, W.-R. Myung, C.-J. Lee, S.-B. Jung, Mechanical, electrical, and thermal reliability of Sn–58 wt%Bi solder joints with Ag-decorated MWCNT for LED package component during aging treatment. Compos. B Eng. (2020). https://doi.org/10.1016/j.compositesb.2019.107617

R.K. SHIUE, L.W. TSAY, C.L.L. LIN, J.L. OU, A study of Sn–Bi–Ag–(In) lead-free solders. J. Mater. Sci. 38, 1269–1279 (2003). https://doi.org/10.1023/A:1022822127193

N. Jiang, L. Zhang, L.L. Gao, X.G. Song, H. Peng, Recent advances on SnBi low-temperature solder for electronic interconnections. J. Mater. Sci. Mater. Electron. 32, 22731–22759 (2021). https://doi.org/10.1007/s10854-021-06820-7

Y.Y. Chiang, R. Cheng, A.T. Wu, Effects on undercooling and interfacial reactions with Cu substrates of adding Bi and in to Sn–3Ag solder. J. Electron. Mater. 39, 2397–2402 (2010). https://doi.org/10.1007/s11664-010-1347-5

Z.H. Zhou, Y.C. Liu, M.J. Dong, Z.M. Gao, H.J. Li, Microstructure and interface evolution of Sn–2.5Bi–1.4In–1Zn–0.3Ag/Cu joint during isothermal aging. J. Mater. Sci. Mater. Electron. 24, 4122–4128 (2013). https://doi.org/10.1007/s10854-013-1370-4

R.T.J.I. Kivilahti, International symposium on advanced packaging materials (1998), p. 170–174

S.K. SEO, M.G. CHO, H.M. LEE, W.K. CHOI, Comparison of Sn2.8Ag20In and Sn10Bi10In solders for intermediate-step soldering. J. Electron. Mater. 35, 1975–1981 (2006). https://doi.org/10.1007/s11664-006-0302-y

Funding

The authors would like to thank the financial supports of the Science and Technology Major Project of Yunnan Province (Grant No. 2019ZE001-3, 202202AB080001), the National Natural Science Foundation of China (Grant No. 52061021), and the Young and middle–aged academic and technical leaders reserve talent project of Yunnan Province (Grant No. 202005AC160039).

Author information

Authors and Affiliations

Contributions

KX: Data curation, Writing—original draft. CL: Writing—review & editing. PG: Methodology. JQ: Resources. SG: Conceptualization. LZ: Investigation. JZ: Supervision. QH: Visualization. JP: Validation. JY: Project administration.

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

This article does not contain any studies involving humans and animals performed by any of the authors.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xiao, K.X., Li, C.J., Gao, P. et al. Significantly enhanced ductility of Sn–57Bi–1Ag alloy induced by microstructure modulation from in addition. J Mater Sci: Mater Electron 34, 1551 (2023). https://doi.org/10.1007/s10854-023-10946-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-10946-1