Abstract

Polyethylene oxide (PEO) incorporated with potassium permanganate (KMnO4) was prepared using the solution casting technique forming PEO/KMnO4 complex composite films. The physicochemical properties, doping mechanism, and electron transition bands of PEO/KMnO4 were investigated. Introducing KMnO4 PEO matrix led to a decrease in crystallinity degree and optical bandgap energy due to the creation of polarons and bipolarons that form new energy levels in the bandgap between the HOMO and LUMO; in addition, to form of a new transition band appears at about 380 nm is attributed to the \(n{-}{\pi }^{*}\) electronic transitions are generated due to the unsaturated center of the molecules. The existence of KMnO4 in the polymer matrix leads to the blocking of light in the 250–400 nm range. Consequently, PEO/KMnO4 complex composite films could be used as UV-light shielding filters. Furthermore, the electrical conductivity of the PEO/KMnO4 complex composite films increases as KMnO4 concentration is increased in the PEO matrix since the created new energy levels in the bandgap between the HOMO and LUMO can be populated with conduction electrons providing true ohmic conduction with the delocalization of the electron densities moving on the polymer chain.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The development of advanced complex composite films by tuning the bandgap energy, absorption properties, and electrical conductivity has attracted attention because of their application in advanced optoelectronic devices [1,2,3,4]. Polyethylene oxide (PEO) has attracted particular attention as a polymer electrolyte used as a host medium of fuel cells, lithium-ion batteries, and hybrid power sources with supercapacitors since the segmental motion of the PEO polymer chain supports the polymer electrolyte conductivity [5,6,7]. PEO has many essential properties such as semicrystalline nature, low absorbance value, low electrical conductivity, high chemical and electrochemical stability, and good ability to dissolve ionic salts and dissociate ions [8,9,10,11,12]. Moreover, the high solubility of PEO in water and organic solvent leads to efficient fabrication of PEO solid films [13, 14].

The hydroxyl (O–H) group in PEO is considered a hydrogen bonding source that leads to the formation of polymer complexes [15]. The electrical conductivity of PEO is enhanced by doping the PEO with suitable electron donors or acceptors [16]. Potassium permanganate (KMnO4) is an excellent oxidant inorganic molecule because it is safe, inexpensive, and water-soluble [17]. Optical and dielectric properties in addition to the ionic conductivity of polyvinyl alcohol, polyacrylonitrile, and poly(methylmethacrylate) doped with KMnO4 led to the decrease in bandgap energy and increase in ionic conductivity [18,19,20,21,22].

Based on the above presentation, incorporating KMnO4 with PEO is anticipated to create new energy levels in the bandgap between the HOMO and LUMO, decreasing optical energy gaps. The generation of polaron and bipolaron as a result of the introducing KMnO4 in PEO matrix leading the formation of new energy gap levels. Additionally, the electrical conductivity is expected to be enhanced significantly since the new energy levels can be populated with conduction electrons leading to Ohmic conduction that moves on the polymer chain. Hence, this study is geared towards investigating the crystal and chemical structural properties of the PEO/KMnO4 complex composite films. In addition, the optical and electrical properties of PEO/KMnO4 complex composite films are explored to understand the electrical conductivity and the electronic transition bands.

2 Experimental sections

2.1 Sample preparation

Polyethylene oxide (PEO, (–CH2CH2O–)n, 600,000 g/mol) and potassium permanganate (KMnO4, 158.034 g/mol) were purchased from Sigma-Aldrich. Firstly, a stock solution was prepared by dissolving 1.00 g of PEO powder in 100 mL methanol under continuous stirring at 60 °C for 5 h to obtain a homogeneous PEO solution. Four different amounts of KMnO4 (0, 2, 4, and 8 mg) were added to four allocated 20 mL of the prepared PEO solution under continuous stirring for 2 h until the solutions became red in color and pellucid forming PEO/KMnO4 in 0, 1, 2, and 4 wt%. PEO film and PEO/KMnO4 complex composite films were prepared using the casting technique at room temperature. The films were left to dry overnight under 1 atmospheric pressure of nitrogen in a temperature-controlled oven.

2.2 Sample characterizations

The crystal and chemical properties were studied using powder X-ray diffraction (Malvern Panalytical Ltd, Malvern, UK) and Fourier transform infrared radiation (FTIR Microscope HYPERION 3000 from Bruker), respectively. Thermal properties were studied using differential scanning calorimetry (DSC 204F1, Netzsch-Proteus). Optical and electrical properties were investigated using UV–Vis spectrophotometer (U-3900H) connected with a total internal reflectance sphere and 4-point probe (Microworld Inc.) provided with a high-resolution multimeter (Keithley 2450 Sourcemeter).

3 Results and discussion

3.1 Fourier transform infrared spectroscopy (FTIR)

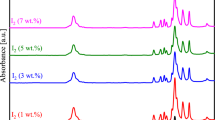

The vibrational bands of the PEO/KMnO4 complex composite films are studied using the FTIR technique after peeling off the films of the glass substrates because glass is known to shield the IR spectrum (Fig. 1). IR absorbance spectrum of pure PEO exhibits bands at 2880 cm−1 (C–H stretching), 1466 cm−1 (CH2 scissoring), 1340 cm−1 (CH2 wagging), 1276 and 1235 cm−1 (CH2 twisting), 955 and 840 cm−1 (CH2 rocking), and 527 cm−1 (C–H bending). Moreover, the triplet peak of the C–O–C stretching band at a maximum of 1088 cm−1 confirms the semicrystalline phase of PEO [23]. The slight shifting in the vibrational bands upon introducing KMnO4 into PEO confirms the formation of the charge transfer between the two materials through the formation of H-bonds between the PEO and KMnO4 [15, 21]. In addition, the change in the intensity, linewidth, and band position of the triplet peak of the C–O–C stretching band upon incorporation with KMnO4 confirms the induced change in the crystallinity degree (more details in Fig. 3b) [23].

3.2 X-ray diffraction (XRD)

The crystal structure parameters of PEO film and PEO/KMnO4 complex composite films with 1, 2, and 4 wt% of KMnO4 were investigated using XRD measurements by CuKα ray with \(\lambda =0.1540598\) nm (Fig. 2). The crystallinity degree of PEO film calculated according to the equations in Table 1 is found to be 28.65%, depending on the diffraction peaks at 19.08° and 23.19° associated with (120) and (112) crystallographic planes [24, 25]. The crystallinity degree was reduced to 21.45% as KMnO4 concentration was increased to 4 wt%, revealing the interaction between the KMnO4 and PEO polymer and the intermolecular interaction with PEO chains. The crystalline phase in the PEO is associated with the intermolecular interaction of the PEO chains through hydrogen bonds [15], which is in agreement with the studies of Abdullah et al. [15] and Ali [21]. The two studies were focused on the effect of KMnO4 on the PVA polymer electrolyte.

Multiple Gaussian peak fittings were performed for a plane peak (112) (Fig. 2b–e). XRD of pure PEO film peak at (112) plan was deconvoluted to three Gaussian peaks centered at 23.00°, 23.22°, and 23.45° with linewidths of 0.50°, 0.18°, and 0.32°, respectively, while the same peak was fairly deconvoluted only to double Gaussian peaks after adding KMnO4 to the PEO. For instance, the peak of PEO/KMnO4 (4 wt%) is composed of two Gaussian peaks centered at 22.98° and 23.43° with linewidths of 0.40° and 0.43°. This transformation in the (112) plane indicates the increase in the microstrain in the PEO crystal due to the oxidation in the polymer chains through the formation of layer by intermolecular interaction between the chains of PEO and KMnO4 via hydrogen bonding. Furthermore, the parameters of the crystal structure and the relevant equations are shown in Table 1 [26,27,28,29,30]. Scherrer and Wilson’s equations were used to calculate the average crystallite size and microstrain [31,32,33]. The crystallite size of the pure PEO film is 29 nm. It slightly decreases to 25 nm for the KMnO4 concentration of 4 wt% while the microstrain increases from \(0.73\times {10}^{-2}\) to \(1.40\times {10}^{-2}\) as KMnO4 concentration is increased from 0 to 4 wt%. The inversely proportional crystallite size to the microstrain means that the occupied volume in the polymer matrix is increased [34]. Moreover, oxidation of the PEO polymer film due to KMnO4 led to an increase in the dislocation density, total internal stress, and strain energy density. Consequently, the crystallization decreases, and the free spaces increase (Table 1) [35, 36].

3.3 Differential scanning calorimeter (DSC)

The obtained DSC profiles of PEO/KMnO4 complex composite films (Fig. 3a) represent the endothermic peaks according to the melting temperature (\({T}_{m}\)). The DSC curve shows that the melting temperature of the pure PEO is ~ 73 °C, which agrees with the literature [37, 38], and it was reduced due to the addition of KMnO4 and reached 60 °C in films containing 4 wt% of KMnO4. Likewise, the melting enthalpy (\(\Delta H_{m}\)) decreases from 85 J/g for pure PEO to 68 J/g for PEO/KMnO4 complex composite films containing 4 wt% of KMnO4. The crystallinity degree (\({X}_{\mathrm{cryst}}\)) can also be calculated as \({X}_{\mathrm{cryst}}=\Delta {H}_{c}/\Delta {H}_{p}\) [39], where \(\Delta {H}_{p}\) is the melting enthalpy of pure PEO of 100% crystallinity, which equals to 203 J/g, where \(\Delta {H}_{c}\) is the melting enthalpy of the film. The \({X}_{\mathrm{cryst}}\) of pure PEO film is found to be ~ 42%. Introducing KMnO4 into PEO films decreases the crystallinity degree to 34% for films containing 4 wt% of KMnO4 (Table 1, Fig. 3b). Typically, in polymers, decreasing the crystallinity degree enhances the electronic conductivity and charge transport by enhancing the segmental motion (Fig. 6) [14, 40].

3.4 UV–Vis spectroscopy

The transmittance spectra of pure PEO film have an abrupt rise in the transmittance values from 0 to 86% as the wavelength of the incident photon increases from 300 to 380 nm. The transmittance spectra exhibit no observable change in the 380–700 nm range, as shown in Fig. 4a. The PEO film exhibits a high transmittance in the visible region because there are no free electrons in the PEO matrix. Incorporation of PEO film with KMnO4 decreases the transmittance values in the visible range because the KMnO4 molecules contain free electrons that can absorb incident photons with lower energy and, consequently, transport them to higher energy [41]. In addition, the variation of transmittance as KMnO4 concentration is increased, which can be attributed to the formation of a new layer between PEO and KMnO4 mediated by intermolecular hydrogen bonding interactions. Moreover, shifting the absorption edge to the red region (low energy) indicates an increase in the salt concentrations that decrease the optical bandgap energy, as anticipated and confirmed by Fig. 4a. At KMnO4 concentration of 4 wt%, the value of the transmittance in the range (250–400 nm) approaches zero endorsing that PEO/KMnO4 complex composite films can be considered as a material for UV-light shielding as reported by Bafna et al. study [22]. The values of reflectance decrease upon introducing KMnO4 concentrations into the PEO matrix (Fig. 4b). In addition, the significant drop in the transmittance and reflectance spectra of PEO/KMnO4 complex composite films in the 300–550 nm range is attributed to a new transition band resulting from the existence of KMnO4 in the PEO matrix.

The extinction coefficient (\(k\)) spectra were calculated using \(k=\alpha \lambda /4\pi\), where \(\alpha\) is the absorption coefficient given by \(\alpha =\left(1/d\right)\mathrm{ln}\left(\left(1-R\right)/T\right)\) [42]. Obviously, the \(k\) spectra of pure PEO film exhibit an absorption band at 275 nm associated with the π–π* electronic transition that is expected for conjugated (\(\mathrm{C}{=}\mathrm{O}\)) group (Fig. 4c) [43]. Moreover, the extinction coefficient spectra for pure PEO film exhibit low values indicating that the PEO film permits the passage of the EM photons through the film without any decaying or damping. Introducing KMnO4 into the PEO matrix leads to many changes in the extinction coefficient spectra (Fig. 4c). For instance, the absorption band of \(\pi{-}{\pi }^{*}\) electronic transition shifted towards the red region, decreasing the optical bandgap energy. Furthermore, a new transition band that appears at about 380 nm is attributed to the \(n{-}{\pi }^{*}\) electronic transitions, which are generated due to the unsaturated center of the molecules and the existence of dopants in the polymer matrix [44]. Increasing KMnO4 concentrations in the PEO matrix leads to the \(n{-}{\pi }^{*}\) electronic transition band shift into the red region [45].

To get a deeper insight into the electronic polarization of KMnO4 ions in the PEO films, the refractive index (\(n\)) spectra are calculated as \(n=\left(1+R/1-R\right)+\sqrt{\left(4R/{\left(1-R\right)}^{2}\right)-{k}^{2}}\) [42]. The \(n\) spectra of the pure PEO film can be divided into two distinct regions (Fig. 4d). The anomalous behavior (\(250\le \lambda <350\) nm) related to many photon–matter interactions such as photon absorption due to the \(\pi{-}{\pi }^{*}\) electronic transition, photon dispersion, and the resonance effect result from the resonance of the incident photon frequency and the plasma frequency [46]. The normal behavior (\(350\le \lambda <700\) nm) represents the normal decrease of the refractive index from 2.14 to 1.80 as the wavelength of the incident photon is increased from 350 to 700 nm. Also, the significant drop in the refractive index spectra in the range from 300 nm until 550 nm is attributed to \(n{-}{\pi }^{*}\) electronic transitions due to the unsaturated center of the molecules in addition to the existence of dopants in the polymer matrix [44].

Tauc plot was used to determine the optical bandgap energy of the PEO/KMnO4 complex composite films by plotting \({\left(\alpha hv\right)}^{2}\) versus \(hv\), according to the Tauc equation \({\left(\alpha hv\right)}^{2}=\beta (hv-{E}_{\mathrm{g}})\) [47, 48]. In addition, the substates between the HOMO and LUMO resulting from the disorder in the PEO/KMnO4 complex composite films are studied using the Urbach energy (\({E}_{\mathrm{U}}\)) by the equation \(\mathrm{\alpha }= {\mathrm{\alpha }}_{0} \mathrm{exp}(hv/{E}_{\mathrm{U}})\) [49]. Increasing KMnO4 into the PEO matrix decreases the value of \({E}_{\mathrm{g}}\) and increases the \({E}_{\mathrm{U}}\) value in excellent agreement with Ahmad et al. study [50] (Fig. 4e). This could be interpreted in terms of the generation of new energy levels between the HOMO and LOMO due to the disorder in the complex composite films. This leads to an increase in localized state density in the mobility bandgap of the PEO matrix according to the Mott and Davis model. The model considers that the new energy levels exponentially decay into the bandgap [51, 52]. The XRD, DSC results (Fig. 3b), and the Urbach energy strongly support the disorder formation in the complex composite films. The sharp decrease in the optical bandgap energy upon increasing the KMnO4 concentrations alters the PEO behavior from dielectric to semiconductive. The resulting band structure including the \({E}_{\mathrm{HOMO}}\), \({E}_{\mathrm{LUMO}}\), optical bandgap energy, and the substates are investigated using the ionization energy and the electron affinity energy as previously formulated [53, 54]. The schematic diagram of band structure of PEO/KMnO4 complex composite films show the decrease in the \({E}_{\mathrm{LUMO}}\), as well as the increase in \({E}_{\mathrm{HOMO}}\) confirming the decrease of the \({E}_{\mathrm{g}}\) as KMnO4 concentration is increased (Fig. 4f).

The Cauchy equation describes the dependence of the refractive index of PEO/KMnO4 complex composite films on the incident photon wavelength as, \(n=A+B/{\lambda }^{2}\) (Fig. 5a), where A and B are constants called the Cauchy parameters [55]. The difference between the experimental refractive index and the Cauchy refractive index is attributed to many reasons, such as photon dispersion, electron transition bands, and the resonance phenomena between the incident photon frequency and the free electron frequency [56]. Figure 5b shows the refractive index loss, representing the difference between the experimental and Cauchy refractive indices. Obviously, the refractive index loss spectra are mainly similar to the extinction coefficient spectra, which represent the \(\pi{-}{\pi }^{*}\) and the \(n{-}{\pi }^{*}\) electronic transitions [44].

Figure 5c–e shows the multiple Gaussian peaks fit for the refractive index loss spectra of PEO/KMnO4 complex composite films. The peak 1 at 280 nm represents the \(\pi{-}{\pi }^{*}\) electronic transition that was anticipated for the conjugated (\(\mathrm{C}{=}\mathrm{O}\)) group [43], while the peak 2 at 320 nm represents the resonance phenomena, where the incident photon frequency becomes equal to plasma frequency and consequently leads to electrons coupling and absorbing the incident photon by the free electrons. Peak 3 of PEO/KMnO4 (1 wt%) at 390 nm represents the \(n{-}{\pi }^{*}\) electronic transitions due to the unsaturated center of the molecules and the existence of dopants in the polymer matrix [44], while for KMnO4 at concentrations of 2 and 4 wt%, the \(n{-}{\pi }^{*}\) electronic transitions are split into two frequency bands. This may be attributed to the increase of the disorder in the PEO structure and consequently leads to the formation of new electron transition bands.

3.5 Electrical conductivity

Electrical conductivity in complex composite materials depends on many parameters such as dopant type, dopant concentration, and crystallinity degree of the complex composite material [20]. Figure 6a illustrates the electrical conductivity values of the PEO/KMnO4 complex composite films as a function of KMnO4 concentrations. The average electrical conductivity of the PEO/KMnO4 complex composite films increases from \(1.98\) to \(3.06\) μS/cm as KMnO4 concentration is increased up to 4 wt%. This result agrees with the findings of Veena and Lobo study [20]. Increasing the electrical conductivity values upon increasing the KMnO4 concentration can be attributed to the segmental motion of PEO bonded with K+ cations in the PEO amorphous phase. Therefore, the vehicle transportation mechanism of the cations (K+) dominates the electrical conductivity of PEO/KMnO4 complex composite films. In contrast, the Grotthuss mechanism contribution, based on cation hoping, is limited [57]. In addition, the increase in the values of conductivity upon increasing KMnO4 concentration can also be attributed to bridging the gap between the localized states (for more detail, see Fig. 4e, f) [58].

a The average electrical conductivity of PEO/KMnO4 complex composite films as a function of KMnO4 concentrations, b electrical conductivity of the PEO/KMnO4 complex composite films as a function of KMnO4 [wt%], c electrical conductivity of PEO/KMnO4 complex composite films as a function of 1000/T [K−1], d activation energy deduced from conductivity fitted to Arrhenius law in the temperatures range of 298–328 K, and the conductivity mapping (1 cm × 1 cm) of PEO/KMnO4 at KMnO4 concentrations of e 0 wt%, f 1 wt%, g 2 wt%, and h 4 wt%

Moreover, increasing temperature leads to an increase in the electrical conductivity (Fig. 6b) due to the increase of the cation thermal activation, which leads to the cation jump to the next coordinating site [59] and thus increases the energy of segmental vibrations leading to more segment motion against the hydrostatic pressure [60]. Therefore, the conductivity of the polymer depends on the mobility of ions, and the increase in temperature leads to an increase in free volume around the PEO chains, consequently, increasing the mobility of the ions and free electrons [59, 61]. Moreover, increasing electrical conductivity upon increasing the temperature can also be attributed to the increase in the dominance of the amorphous phase in the PEO/KMnO4 complex composite films [62]. The electrical conductivity (\(\sigma\)) as a function (1000/T(K)) (Fig. 6c) follows Arrhenius-like behavior (\(\sigma ={\sigma }_{0}\mathrm{exp}(-{E}_{a}/{K}_{\mathrm{B}}T))\), where \({\sigma }_{0}\) is the preexponential factor, T is the temperature [K], \({K}_{\mathrm{B}}\) is the Boltzmann constant, and \({E}_{\mathrm{a}}\) is the activation energy [57]. Calculated activation energy by fitting \(\sigma\) to Arrhenius equation showing continuous increasing as KMnO4 concentration increases indicating the enhancement of the electrical conductivity (Fig. 6d).

The conductivity mapping (1 cm × 1 cm) of PEO film (Fig. 6e) shows a slight variation in the conductivity across the film that can be attributed to many parameters such as the quality of the growth process and the quality of the transfer process. Introducing KMnO4 into the PEO matrix increases the variation in the conductivity values across the films due to the distribution of the KMnO4 in the PEO/KMnO4 complex composite films (Fig. 6f–h).

4 Conclusions

The FTIR spectra of PEO/KMnO4 complex composite films confirm the charge transfer between the KMnO4 and PEO. In addition, the change in the intensity, linewidth, and band position of the triplet peak of the C–O–C stretching band confirms that the crystallinity degree is changed. According to XRD measurements, PEO polymer film has semicrystalline nature with a crystallinity degree of 28.65%. The increase in KMnO4 content in the PEO matrix decreases the crystallinity degree to 21.45%. DSC results confirm the decrease in the crystallinity degree of PEO/KMnO4 complex composite films. DSC curve shows that the melting temperature of the pure PEO dropped from 73 to 60 °C by the addition of 4 wt% of KMnO4 to PEO. Furthermore, introducing KMnO4 in the PEO matrix decreases the optical bandgap energy owing to the formation of new energy levels between HOMO and LOMO, leading to light blocking in the spectral range from 250 to 400 nm. Consequently, PEO/KMnO4 complex composite films are potential candidates for UV-light shielding filter applications. The average electrical conductivity of the PEO/KMnO4 complex composite films increases from \(1.98\) to \(3.06\) μS/cm as KMnO4 concentration is increased up to 4 wt%.

Data availability

Not applicable.

References

D.W. Mosley et al., High performance encapsulants for ultra high-brightness LEDs, in Light-Emitting Diodes: Research, Manufacturing, and Applications XII, vol. 6910 (International Society for Optics and Photonics, 2008), p. 691017

T. Nakamura, H. Fujii, N. Juni, N. Tsutsumi, Enhanced coupling of light from organic electroluminescent device using diffusive particle dispersed high refractive index resin substrate. Opt. Rev. 13(2), 104–110 (2006)

R.D. Allen, G.M. Wallraff, D.C. Hofer, R.R. Kunz, Photoresists for 193-nm lithography. IBM J. Res. Dev. 41(1.2), 95–104 (1997)

J. Regolini, D. Benoit, P. Morin, Passivation issues in active pixel CMOS image sensors. Microelectron. Reliab. 47(4–5), 739–742 (2007)

A. Karmakar, A. Ghosh, Dielectric permittivity and electric modulus of polyethylene oxide (PEO)–LiClO4 composite electrolytes. Curr. Appl. Phys. 12(2), 539–543 (2012)

Z. Xue, D. He, X. Xie, Poly(ethylene oxide)-based electrolytes for lithium-ion batteries. J. Mater. Chem. A 3(38), 19218–19253 (2015)

Y. Abu-Lebdeh, I. Davidson, Nanotechnology for Lithium-Ion Batteries (Springer Science & Business Media, Boston, 2012)

D. Bresser, S. Lyonnard, C. Iojoiu, L. Picard, S. Passerini, Decoupling segmental relaxation and ionic conductivity for lithium-ion polymer electrolytes. Mol. Syst. Des. Eng. (2019). https://doi.org/10.1039/C9ME00038K

J. Mindemark, M.J. Lacey, T. Bowden, D. Brandell, Beyond PEO—alternative host materials for Li+-conducting solid polymer electrolytes. Prog. Polym. Sci. 81, 114–143 (2018)

D. Lin et al., A silica-aerogel-reinforced composite polymer electrolyte with high ionic conductivity and high modulus. Adv. Mater. 30(32), 1802661 (2018)

I. Aldalur, M. Martinez-Ibañez, M. Piszcz, L.M. Rodriguez-Martinez, H. Zhang, M. Armand, Lowering the operational temperature of all-solid-state lithium polymer cell with highly conductive and interfacially robust solid polymer electrolytes. J. Power Sources 383, 144–149 (2018)

M.-A. AL-Akhras, S.E. Alzoubi, A.A. Ahmad, R. Ababneh, A. Telfah, Studies of composite films of polyethylene oxide doped with potassium hexachloroplatinate. J. Appl. Polym. Sci. 138, e49757 (2020)

U. Siemann, Solvent cast technology—a versatile tool for thin film production, in Scattering Methods and the Properties of Polymer Materials. (Springer, Berlin, 2005), pp. 1–14

H. Schönherr, C.W. Frank, Ultrathin films of poly(ethylene oxides) on oxidized silicon. 1. Spectroscopic characterization of film structure and crystallization kinetics. Macromolecules 36(4), 1188–1198 (2003)

O.G. Abdullah, S.B. Aziz, M.A. Rasheed, Structural and optical characterization of PVA:KMnO4 based solid polymer electrolyte. Results Phys. 6, 1103–1108 (2016)

J.-L. Brédas, B. Thémans, J. Fripiat, J.-M. André, R. Chance, Highly conducting polyparaphenylene, polypyrrole, and polythiophene chains: an ab initio study of the geometry and electronic-structure modifications upon doping. Phys. Rev. B 29(12), 6761 (1984)

L. Ma, Y. Cui, R. Cai, X. Liu, C. Zhang, D. Xiao, Optimization and evaluation of alkaline potassium permanganate pretreatment of corncob. Bioresour. Technol. 180, 1–6 (2015)

G. Veena, B. Lobo, Experimental investigations on potassium permanganate doped polyvinyl alcohol-polyvinyl pyrrolidone blend. AIP Conf. Proc. 1942(1), 140033 (2018)

S.H. Mortazavi, S. Pilehvar, M. Ghoranneviss, M. Hosseinnejad, L. Dejam, Plasma and KMnO4 oxidation of polyacrylonitrile nanofiber. Mol. Cryst. Liq. Cryst. 592(1), 115–122 (2014)

G. Veena, B. Lobo, AC and DC electrical transport properties of potassium permanganate doped PVA-PVP solid polymer electrolyte. Mater. Res. Express 6(3), 035315 (2018)

H.E. Ali, A novel optical limiter and UV–visible filters made of poly(vinyl alcohol)/KMnO4 polymeric films on glass-based substrate. J. Mater. Sci.: Mater. Electron. 30(7), 7043–7053 (2019)

M. Bafna, A.K. Gupta, R.K. Khanna, Y.K. Vijay, Development of potassium permanganate (KMnO4) doped poly methyl methacrylate (PMMA) composite using layered structure for electromagnetic shielding purpose. Mater. Today 30, 11–16 (2020)

S. Noor, A. Ahmad, I. Talib, M.Y. Rahman, Morphology, chemical interaction, and conductivity of a PEO-ENR50 based on solid polymer electrolyte. Ionics 16(2), 161–170 (2010)

A.R. Polu, H.-W. Rhee, The effects of LiTDI salt and POSS-PEG (n = 4) hybrid nanoparticles on crystallinity and ionic conductivity of PEO based solid polymer electrolytes. Sci. Adv. Mater. 8(5), 931–940 (2016)

A. Azli, N. Manan, M. Kadir, Conductivity and dielectric studies of lithium trifluoromethanesulfonate doped polyethylene oxide-graphene oxide blend based electrolytes. Adv. Mater. Sci. Eng. (2015). https://doi.org/10.1155/2015/145735

A. Alsaad, A. Ahmad, I. Qattan, Q.M. Al-Bataineh, Z. Albataineh, Structural, optoelectrical, linear, and nonlinear optical characterizations of dip-synthesized undoped ZnO and group III elements (B, Al, Ga, and In)-doped ZnO thin films. Curr. Comput. Aided Drug Des. 10(4), 252 (2020)

Q.M. Al-Bataineh, A. Alsaad, A. Ahmad, A. Al-Sawalmih, Structural, electronic and optical characterization of ZnO thin film-seeded platforms for ZnO nanostructures: sol–gel method versus ab initio calculations. J. Electron. Mater. 48(8), 5028–5038 (2019)

A.M. Alsaad et al., Optical, structural, and crystal defects characterizations of dip synthesized (Fe–Ni) Co-doped ZnO thin films. Materials 13(7), 1737 (2020)

Q.M. Al-Bataineh et al., Synthesis, crystallography, microstructure, crystal defects, optical and optoelectronic properties of ZnO:CeO2 mixed oxide thin films. Photonics 7(4), 112 (2020)

A. Alsaad et al., Measurement and ab initio investigation of structural, electronic, optical, and mechanical properties of sputtered aluminum nitride thin films. Front. Phys. 8, 115 (2020)

K. Ramakanth, Basics of X-Ray Diffraction and Its Application (I.K. International Publishing House, New Delhi, 2007)

J.-M. Zhang, Y. Zhang, K.-W. Xu, V. Ji, General compliance transformation relation and applications for anisotropic hexagonal metals. Solid State Commun. 139(3), 87–91 (2006)

J. Valasek, Piezo-electric and allied phenomena in Rochelle salt. Phys. Rev. 17(4), 475 (1921)

S. Horiuchi et al., Above-room-temperature ferroelectricity in a single-component molecular crystal. Nature 463(7282), 789 (2010)

A.A. Akl, A. Hassanien, Microstructure and crystal imperfections of nanosized CdSxSe1−x thermally evaporated thin films. Superlattices Microstruct. 85, 67–81 (2015)

G. Williamson, R. Smallman, III. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray Debye–Scherrer spectrum. Philos. Mag. 1(1), 34–46 (1956)

A.R. Polu, D.K. Kim, H.-W. Rhee, Poly (ethylene oxide)-lithium difluoro (oxalato) borate new solid polymer electrolytes: ion–polymer interaction, structural, thermal, and ionic conductivity studies. Ionics 21(10), 2771–2780 (2015)

I. Noor, S. Majid, A. Arof, Poly(vinyl alcohol)–LiBOB complexes for lithium–air cells. Electrochim. Acta 102, 149–160 (2013)

J. Gurusiddappa, W. Madhuri, R.P. Suvarna, K.P. Dasan, Studies on the morphology and conductivity of PEO/LiClO4. Mater. Today 3(6), 1451–1459 (2016)

B.K. Money, J. Swenson, Dynamics of poly(ethylene oxide) around its melting temperature. Macromolecules 46(17), 6949–6954 (2013)

A.K. Gupta, M. Bafna, Y. Vijay, Study of optical properties of potassium permanganate (KMnO4 KMnO4) doped poly(methylmethacrylate)(PMMA) composite films. Bull. Mater. Sci. 41(6), 1–7 (2018)

A. Ahmad, A. Alsaad, Q. Al-Bataineh, M. Al-Naafa, Optical and structural investigations of dip-synthesized boron-doped ZnO-seeded platforms for ZnO nanostructures. Appl. Phys. A 124(6), 458 (2018)

S.B. Aziz et al., Characteristics of PEO incorporated with CaTiO3 nanoparticles: structural and optical properties. Polymers 13(20), 3484 (2021)

V. Manjunatha, K. Subramanya, H. Devendrappa, Structural optical and electrical conductivity properties of Li2SO4 doped polymer electrolytes. Compos. Interfaces 21(2), 121–131 (2014)

F.F. Bruno, R. Nagarajan, J. Kumar, L.A. Samuelson, Novel enzymatic polyethylene oxide-polyphenol system for ionic conductivity. J. Macromol. Sci. A 39(10), 1061–1068 (2002)

A.A. Ahmad, M.H. Khazaleh, A.M. Alsaad, Q.M. Al-Bataineh, A.D. Telfah, Characterization of As-prepared PVA-PEO/ZnO-Al2O3-NPs hybrid nanocomposite thin films. Polym. Bull. (2021). https://doi.org/10.1007/s00289-021-03969-3

A.A. Ahmad, Q.M. Al-Bataineh, I.A. Aljarrah, A.D. Telfah, Electrochemical degradation of methyl red in zinc hydroxide and zinc oxide thin films, physical and chemical activation. Mater. Chem. Phys. 280, 125793 (2022)

A.A. Ahmad, A.A. Bani-Salameh, Q.M. Al-Bataineh, I. Jum’h, A.D. Telfah, Optical, structural and morphological properties of synthesized PANI-CSA-PEO-based GaN nanocomposite films for optoelectronic applications. Polym. Bull. (2022). https://doi.org/10.1007/s00289-021-04033-w

P. Norouzzadeh, K. Mabhouti, M. Golzan, R. Naderali, Investigation of structural, morphological and optical characteristics of Mn substituted Al-doped ZnO NPs: a Urbach energy and Kramers-Kronig study. Optik 204, 164227 (2020)

A.A. Ahmad, I.A. Aljarrah, M.D. Telfah, A.M. Alsaad, A. Telfah, Optical, chemical, electrical, and morphological properties of PEO–Nb-doped KMnO4 thin films. J. Mater. Sci.: Mater. Electron. (2022). https://doi.org/10.1007/s10854-022-08044-9

R. Bhajantri, V. Ravindrachary, A. Harisha, C. Ranganathaiah, G. Kumaraswamy, Effect of barium chloride doping on PVA microstructure: positron annihilation study. Appl. Phys. A 87(4), 797–805 (2007)

N. Tomozeiu, Silicon oxide (SiOx, 0 < x < 2): a challenging material for optoelectronics, in Optoelectronics-Materials and Techniques (2011), pp. 55–100

A. Hassanien, A.A. Akl, Effect of Se addition on optical and electrical properties of chalcogenide CdSSe thin films. Superlattices Microstruct. 89, 153–169 (2016)

Q.M. Al-Bataineh, A.A. Ahmad, A. Alsaad, A.D. Telfah, Optical characterizations of PMMA/metal oxide nanoparticles thin films: bandgap engineering using a novel derived model. Heliyon 7(1), e05952 (2021)

A. Benchaabane, Z.B. Hamed, M. Sanhoury, F. Kouki, A. Zeinert, H. Bouchriha, Influence of nanocrystal concentration on the performance of hybrid P3HT:TBPO-capped CdSe nanocrystal solar cells. Appl. Phys. A 122(2), 60 (2016)

Q.M. Al-Bataineh, A. Alsaad, A. Ahmad, A. Telfah, A novel optical model of the experimental transmission spectra of nanocomposite PVC-PS hybrid thin films doped with silica nanoparticles. Heliyon 6(6), e04177 (2020)

A. Telfah et al., Dielectric relaxation, XPS and structural studies of polyethylene oxide/iodine complex composite films. Polym. Bull. (2021). https://doi.org/10.1007/s00289-021-03593-1

M. Morsi, S.A. El-Khodary, A. Rajeh, Enhancement of the optical, thermal and electrical properties of PEO/PAM:Li polymer electrolyte films doped with Ag nanoparticles. Physica B 539, 88–96 (2018)

M.A. AL-Akhras, S.E. Alzoubi, A.A. Ahmad, R. Ababneh, A. Telfah, Studies of composite films of polyethylene oxide doped with potassium hexachloroplatinate. J. Appl. Polym. Sci. 138(5), 49757 (2021)

P. Pillai, P. Khurana, A. Tripathi, Dielectric studies of poly(methyl methacrylate)/polystyrene double layer system. J. Mater. Sci. Lett. 5(6), 629–632 (1986)

A. Mohamad et al., Ionic conductivity studies of poly(vinyl alcohol) alkaline solid polymer electrolyte and its use in nickel–zinc cells. Solid State Ion. 156(1–2), 171–177 (2003)

Z. Gadjourova, Y.G. Andreev, D.P. Tunstall, P.G. Bruce, Ionic conductivity in crystalline polymer electrolytes. Nature 412(6846), 520–523 (2001)

Acknowledgements

The authors would like to acknowledge Jordan University of Science and Technology, The deanship of research, for their support in Project Number 016/2021. Our thanks also to Prof. Mohammad-Ali H. Al-Akhras for helping our members to use biomedical laboratories. The scientific support by the Ministerium für Innovation, Wissenschaft und Forschung des Landes Nordrhein-Westfalen, the Senatsverwaltung für Wirtschaft, Technologie und Forschung des Landes Berlin, and the Bundesministerium für Bildung und Forschung is gratefully acknowledged.

Funding

Open Access funding enabled and organized by Projekt DEAL. The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

QMA-B: conceptualization, methodology, and writing—review & editing. IAA: preparation and data acquisition. AAA: data acquisition and writing—original draft. AAA: data acquisition and writing—review & editing. AT: conceptualization, supervision, and writing—review & editing.

Corresponding author

Ethics declarations

Conflict interest

The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported in this paper.

Consent to participate

All authors participate in this work.

Consent to publish

All authors agree to publish this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Al-Bataineh, Q.M., Aljarrah, I.A., Ahmad, A.A. et al. Investigation of the doping mechanism and electron transition bands of PEO/KMnO4 complex composite films. J Mater Sci: Mater Electron 33, 14051–14062 (2022). https://doi.org/10.1007/s10854-022-08336-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08336-0