Abstract

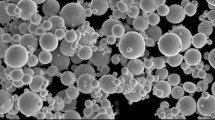

Lately, as electronic devices are continually becoming smaller, thinner, and multifunctional, there has been a growing demand for highly integrated packaging technologies. Accordingly, the application of flip-chip bonding technology has significantly increased to meet these demands. Therefore, the reliability evaluation of the micro-sized solder bumps used in flip-chip bonding and an understanding of the relevant mechanical properties has become essential. To evaluate the properties and reliability of Sn–2.3Ag (in wt%) flip-chip bump in various environments, this study compared the results of shear tests performed under three varying conditions, viz., shear heights (10, 15, 20, and 25 μm), shear rates (50, 100, 150, 200, 300, and 500 μm/s), and shear temperatures (25, 50, 100, 125, and 150 °C). A global bond tester was used for the shear tests and scanning electron microscopy was used to observe and analyze the fracture surfaces and joint cross sections subsequent to the tests. The experimental analysis showed that the shear test conditions had a significant impact on the shear strength and joint mechanical properties of the flip-chip bumps. The shear strength tends to decrease as the shear height and temperature increase, whereas it tends to increase in correspondence with increase in the shear rate. The correlations between the results of the mechanical characterization according to these test conditions were comparatively analyzed.

Similar content being viewed by others

Data availability

We have read and understood your journal’s policies and believe that neither the manuscript nor the study violates any of these.

References

J.W. Yoon, J.W. Kim, J.M. Koo, S.S. Ha, B.I. Noh, W.C. Moon, J.H. Moon, S.B. Jung, J. Weld. Join. 25(2), 6 (2007). https://doi.org/10.5781/KWJS.2007.25.2.006

J.H. Ahn, K.S. Kim, Y.C. Lee, Y.I. Kim, S.B. Jung, J. Microelectron. Packag. Soc. 17(3), 1 (2010)

J.M. Koo, J.W. Kim, J.W. Yoon, B.I. Noh, C.Y. Lee, J.H. Moon, C.D. Yoo, S.B. Jung, J. Weld. Join. 26(1), 31 (2008). https://doi.org/10.5781/KWJS.2008.26.1.031

J.D. Wu, P.J. Zheng, C.W. Lee, S.C. Hung, J.J. Lee, Microelectron. Reliab. 46(1), 41 (2006). https://doi.org/10.1016/j.microrel.2005.01.012

S.S. Ha, J.K. Jang, S.O. Ha, J.W. Yoon, H.J. Lee, J.H. Joo, Y.H. Kim, S.B. Jung, Microelectron. Eng. 87(3), 517 (2010). https://doi.org/10.1016/j.mee.2009.07.015

K.S. Choi, H. Lee, H.C. Bae, Y.S. Oem, Electron. Telecommun. Trends. 28(5), 100 (2013)

J.P. Jung, H.Y. Lee, J.H. Cheon, J. Weld. Join. 26(1), 24 (2008). https://doi.org/10.5781/KWJS.2008.26.1.024

G. Kim, K. Son, G.T. Park, Y.B. Park, Korean J Met. Mater. 55(11), 798 (2017). https://doi.org/10.3365/KJMM.2017.55.11.798

J.W. Kim, S.B. Jung, Int. J. Solids Struct. 43(7–8), 1928 (2006). https://doi.org/10.1016/j.ijsolstr.2005.07.014

J.W. Kim, J.K. Jang, S.O. Ha, S.S. Kim, D.G. Kim, S.B. Jung, Microelectron. Reliab. 48(11–12), 1882 (2008). https://doi.org/10.1016/j.microrel.2008.07.066

S.Y. Lee, B. Hwang, Korean. J. Mater. Res. 26(5), 281 (2016). https://doi.org/10.3740/MRSK.2016.26.5.281

J.W. Kim, D.G. Kim, S.B. Jung, Thin Solid Films 504(1–2), 405 (2006). https://doi.org/10.1016/j.tsf.2005.09.058

I. Shohji, S. Shimoyama, H. Ishikawa, M. Kojima, J. Jpn. Inst. Electron. Packag. 1(1), 9 (2008). https://doi.org/10.5104/jiepeng.1.9

I. Shohji, T. Yoshida, T. Takahashi, S. Hioki, Mater. Sci. Eng. A 366(1), 50 (2004). https://doi.org/10.1016/j.msea.2003.09.057

C.K. Hsiung, C.A. Chang, Z.H. Tzeng, C.S. Ho, F.L. Chien, 9th Electronics Packaging Technology Conference, (2007) 719. https://doi.org/10.1109/EPTC.2007.4469686

A. Mohammadi, R. Mahmudi, J. Electron. Mater. 47(2), 1721 (2018). https://doi.org/10.1007/s11664-017-5923-9

X. Huang, Z. Wang, Y. Yu, J. Mater. Res. Technol. 9(3), 5533 (2020). https://doi.org/10.1016/j.jmrt.2020.03.078

Acknowledgments

This work was supported by the National Research Foundation of Korea(NRF) grant funded by the Korea government(MSIT) (No. 2021R1A2C1009714) and Korea Institute for Advancement of Technology(KIAT) grant funded by the Korea Government (MOTIE)(P0008458, HRD Program for Industrial Innovation).

Funding

Funding was provided by National Research Foundation of Korea (Grant No.: 2021R1A2C1009714) and Korea Institute for Advancement of Technology (Grant No.: P0008458).

Author information

Authors and Affiliations

Contributions

All the authors contributed to the conception and design of the study. Material preparation, data collection, and analyses were performed by MHH, DHL, MSJ, and JWY. The first draft of the manuscript was written by MHH, and all the authors commented on the previous versions of the manuscript. All authors have read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Heo, MH., Lee, DH., Jeong, MS. et al. Effects of shear test temperatures and conditions on mechanical properties of Sn–Ag flip-chip solder bumps. J Mater Sci: Mater Electron 33, 10002–10012 (2022). https://doi.org/10.1007/s10854-022-07991-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-07991-7