Abstract

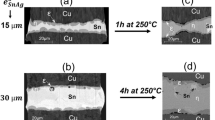

This paper reports the intermetallic growth and microvoid formation in the Cu–Sn layers, which were annealed at low temperatures (sub-200°C) for durations varying from 120 to 1440 min. A 10 µm thick tin was electrodeposited on copper samples. Both Cu6Sn5 and Cu3Sn IMCs were formed and had a non-uniform scalloped shaped profile but with different scallops sizes. Void growth was studied at three different locations, i.e., the Cu–Cu3Sn interface, within the Cu3Sn, and at the Cu3Sn–Cu6Sn5 interface. The void size in these locations increased with increasing annealing durations and temperatures due to the coalescence of nearby voids. The void fraction at the Cu–Cu3Sn and Cu3Sn–Cu6Sn5 interfaces was observed to decrease, whereas the void fraction within the Cu3Sn IMC increased with increasing annealing durations. The largest voids were seen at the Cu–Cu3Sn interface, while the highest void fraction was found within the Cu3Sn IMC. The overall void size and void fractions for all experimental conditions were always smaller than 3 µm2 and 1.44 µm−1, respectively. The obtained results can be used in the hermetic packaging of MEMS devices performed at sub-200 °C. Processing at these low temperatures result in reduced thermo-mechanical stress and also eliminate the molten tin squeezing-out from the bonding zone, which is a known issue in Cu–Sn solid–liquid inter-diffusion bonding performed at temperature > 232 °C.

Similar content being viewed by others

References

M.A. Schmidt, Proc. IEEE 86, 8 (1998)

M. Esashi, J. Micromech. Microeng. 18, 7 (2008)

R.R. Tummala, Fundamentals of Microsystems Packaging, 2nd edn. (McGraw-Hill Education, New York, 2001), pp. 580–610

S. Farrens, “Metal based wafer level packaging,” in Int. Wafer-Level Pack. Conf. (IWLPC), 2008, pp. 8–14

Y. I. Kim, K. H. Yang, and W. S. Ire, in Annual Inter. Rel. Phy. Sym., 2 (2004)

K.N. Tu, Acta Mater. 21, 4 (1973)

M. Onishi, H. Fujibuchi, Trans. Japan Inst. Met. 16, 9 (1975)

W. Tang, A. He, Q. Liu, D.G. Ivey, Trans. Nonferrous Met. Soc. China 20, 8 (2010)

H. Liu, K. Wang, K.E. Aasmundtveit, N. Hoivik, J. Electron. Mater. 41, 9 (2012)

T.T. Luu, A.N.I. Duan, K.E. Aasmundtveit, N. Hoivik, J. Electron. Mater. 42, 12 (2013)

B.S. Lee, S.K. Hyun, J.W. Yoon, J. Mater. Sci.: Mater. Electron. 28, 11 (2017)

T. Laurila, V. Vuorinen, J.K. Kivilahti, Mater. Sci. Eng. R Rep. 49, 1–60 (2005)

A. Munding, H. Hubner, A. Kaiser, S. Penka, P. Benkart, E. Kohn, Wafer Level 3-D ICs Process Technology (Springer, New York, 2008), p. 131

C. Yuhan, L. Le, J. Semicond. 30, 8 (2009)

B. Balakrisnan, C.C. Chum, M. Li, Z. Chen, T. Cahyadi, J. Electron. Mater. 32, 3 (2003)

H. Liu, G. Salomonsen, K. Wang, K.E. Aasmundtveit, N. Hoivik, IEEE Trans. Componen. Packag. Manuf. Technol. 1, 9 (2011)

S. Bader, W. Gust, H. Hieber, Acta Mater. Mater. 43, 1 (1995)

A. Duan, T. Luu, K. Wang, K. Aasmundtveit, N. Hoivik, J. Micromech. Microeng. 25(9), 097001 (2015)

C. Hang, Y. Tian, R. Zhang, J. Mater. Sci.: Mater. Electron. 24, 10 (2013)

H.K. Kannojia, S.K. Sharma, P. Dixit, J. Electron. Mater. 47, 12 (2018)

J.F. Li, P.A. Agyakwa, C.M. Johnson, Acta Mater. 59(3), 1198–1211 (2011)

N. Zhao, Y. Zhong, M.L. Huang, H.T. Ma, W. Dong, Sci. Rep. 5, 131491 (2015)

G. Ross, V. Vuorinen, M. Paulasto-Kröckel, J. Alloys Compd. 677, 127–138 (2016)

G. Ghosh, M. Asta, J. Mater. Res. 20, 11 (2005)

K. Nogita, C.M. Gourlay, S.D. Mcdonald, Y.Q. Wu, J. Read, Q.F. Gu, Scr. Mater. 65, 10 (2011)

K.N. Tu, R.D. Thompson, Acta Mater. 30, 5 (1982)

M.S. Park, S.L. Gibbons, R. Arroyave, J. Electron. Mater. 43, 7 (2014)

L. Yin, G. Electric, J. Mater. Res. 26, 3 (2016)

G. Ross, X. Tao, M. Broas, N. Mäntyoja, V. Vuorinen, A. Graff, F. Altmann, M. Petzold, M. Paulasto-kröckel, J. Electron. Mater. Lett. 13, 4 (2017)

K. Chen, D. Wang, H. Ling, A. Hu, M. Li, W. Zhang, L. Cao, J. Mater. Sci.: Mater. Electron. 29, 22 (2018)

Acknowledgements

The authors would like to acknowledge the financial support from Industrial Research and Consultancy Centre (IRCC), IIT Bombay, under the research Grant 15IRCCSG002.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kannojia, H.K., Dixit, P. Experimental investigations in the intermetallic and microvoid formation in sub-200 °C Cu–Sn bonding. J Mater Sci: Mater Electron 30, 16427–16438 (2019). https://doi.org/10.1007/s10854-019-02017-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-02017-1