Abstract

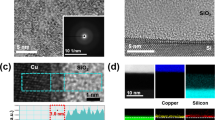

Cu dual-damascene interconnects with an amorphous Ru–Mo–C (labeled as RuMoC) seedless barrier layer were successfully fabricated and its feasibility for advanced Cu dual-damascene interconnects were investigated. The results show that the RuMoC II films obtained with sputtering rates (Ru:MoC) of 100:50 demonstrated the best performance, exhibiting an amorphous structure, low residual oxygen content, low resistivity at temperatures up to 500 °C. A Cu plug of good quality was successfully electroplated on the RuMoC II barrier layer with 4-nm-thick without seed layer in a damascene structure. The ultra-thin RuMoC II barrier effectively blocked the diffusion of Cu and O atom after being annealed up to 500 °C. The damascene structure showed much lower leakage current and via resistance compared to the damascene structures with traditional Ta barrier, suggesting that RuMoC II film has sufficient barrier properties. Moreover, the via resistance of the damascene structures with RuMoC II barrier were quite low and met the requirement of different technology nodes for the future semiconductor industry, indicating great prospects for advanced seedless Cu metallization applications.

Similar content being viewed by others

References

B. Hoefflinger, in Chips 2020: A Guide to the Future of Nanoelectronics, ed. by B. Hoefflinger (Springer, Berlin, 2011), pp. 161–174

L.Y. Yang, D.H. Zhang, C.Y. Li, P.D. Foo, Thin Solid Films 462–463, 176 (2004)

K. Holloway, P.M. Fryer, C. Cabral, J.M.E. Harper, P.J. Bailey, K.H. Kelleher, J. Appl. Phys. 71, 5433 (1992)

M. Traving, I. Zienert, E. Zschech, G. Schindler, W. Steinhögl, M. Engelhardt, Appl. Surf. Sci. 252, 11 (2005)

H. Wojcik, C. Krien, U. Merkel, J.W. Bartha, M. Knaut, M. Geidel, B. Adolphi, V. Neumann, C. Wenzel, M. Bendlin, K. Richter, D. Makarov, Microelectron. Eng. 112, 103 (2013)

L.C. Leu, D.P. Norton, L. McElwee-White, T.J. Anderson, Appl. Phys. Lett. 92, 1 (2008)

T.N. Arunagiri, Y. Zhang, O. Chyan, M. El-Bouanani, M.J. Kim, K.H. Chen, C.T. Wu, L.C. Chen, Appl. Phys. Lett. 86, 1 (2005)

L.B. Henderson, J.G. Ekerdt, Thin Solid Films 517, 1645 (2009)

K.C. Hsu, D.C. Perng, J.Bin Yeh, Y.C. Wang, Appl. Surf. Sci. 258, 7225 (2012)

K.C. Hsu, D.C. Perng, Y.C. Wang, J. Alloys Compd. 516, 102 (2012)

H. Wojcik, R. Kaltofen, U. Merkel, C. Krien, S. Strehle, J. Gluch, M. Knaut, C. Wenzel, A. Preusse, J.W. Bartha, M. Geidel, B. Adolphi, V. Neumann, R. Liske, F. Munnik, Microelectron. Eng. 92, 71 (2012)

M. Damayanti, T. Sritharan, S.G. Mhaisalkar, Z.H. Gan, Appl. Phys. Lett. 88, 1 (2006)

U. Jansson, E. Lewin, Thin Solid Films 536, 1 (2013)

J. Zou, B. Liu, G. Jiao, Y. Lu, Y. Dong, Q. Li, J. Appl. Phys. 120, 95305 (2016)

G. Steinlesberger, M. Engelhardt, G. Schindler, J. Kretz, W. Steinhögl, E. Bertagnolli, Solid State Electron. 47, 1237 (2003)

S. Kacim, L. Binst, F. Reniers, F. Bouillon, Thin Solid Films 287, 25 (1996)

W. Steinhögl, G. Schindler, G. Steinlesberger, M. Traving, M. Engelhardt, J. Appl. Phys. 97, 23706 (2005)

J. Zou, B. Liu, G. Jiao, Y. Lu, Y. Dong, Q. Li, J. Appl. Phys. 120, (2016)

G. Jiao, B. Liu, Q. Li, Appl. Phys. A 120, 579 (2015)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 11605116), the Shenzhen Industry Development Fund Project (Project Nos. JCYJ20150925163313898, JCYJ20160608153308846 and JCYJ20160510154531467) and Youth Innovation Promotion Association, CAS, No. 20160320.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zou, J., Li, Q., Lin, L. et al. Fabrication of an ultra-thin low resistance and high stability Ru–Mo–C seedless barrier for advanced Cu dual-damascene interconnects. J Mater Sci: Mater Electron 29, 10346–10352 (2018). https://doi.org/10.1007/s10854-018-9091-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-9091-3