Abstract

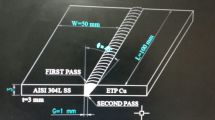

Hand-tungsten inert gas welding is employed using Inconel 82 as a filler metal to weld T92 ferritic steel and HR3C austenitic steel. The microstructures of the joints are analyzed via optical and transmission electron microscopy. The corrosion resistance of the joints is evaluated via electrochemical and immersion corrosion tests, whereas the corrosion products and passive films are analyzed using scanning electron microscopy and X-ray photoelectron spectroscopy. The results show that the weld metal region of the T92/HR3C dissimilar metal joint formed a dense passivation film containing Cr2O3 and NiO owing to the highest Cr and Ni contents, which effectively prevented the entry of chloride ions into the matrix, thus impeding corrosion and providing optimal corrosion resistance. Compared to the base material of T92, the heat-affected zone of T92 shows fine austenite grains and subgrain structures, as well as a relatively thick Cr2O3 passivation film, which improved the corrosion resistance.

Graphical Abstract

Similar content being viewed by others

Availability of data and material

All data included in this study are available upon request by contact with the corresponding author.

References

Zhao Y, Liu HL, Wei LL, Chen LQ (2022) An overview on the novel heat-resistant ferritic stainless steels. Tungsten. Doi: https://doi.org/10.1007/s42864-022-00171-4

Cao J, Gong Y, Zhu K, Yang ZG, Luo XM, Gu FM (2011) Microstructure and mechanical properties of dissimilar materials joints between T92 martensitic and S304H austenitic steels. Mater Des 32(5):2763–2770. https://doi.org/10.1016/j.matdes.2011.01.008

Kaneko K, Matsumura S, Sadakata A, Fujita K, Moon WJ, Ozaki S, Nishimura N, Tomokiyo Y (2004) Characterization of carbides at different boundaries of 9Cr-steel. Mater Sci Eng A 374(1–2):82–89. https://doi.org/10.1016/j.msea.2003.12.065

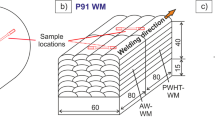

Wang QB, Xin RS, Wang ZC, Han ZW, Jiao XD, Kang J (2022) Microstructure and its effect on high temperature tensile properties of T92/HR3C dissimilar weld joints. J Manuf Process 82:792–799. https://doi.org/10.1016/j.jmapro.2022.08.046

Kang J, Wang QB, Wang ZC, Han WZ, Zuo Y, Zhang H, Jiao XD (2022) A review on high temperature rupture mechanisms of dissimilar metal welded joints for the USC thermal power units. J Mech Eng-En 58(24):58–83. https://doi.org/10.3901/JME.2022.24.058

Lee WS, Tzeng FT, Lin CF (2005) Mechanical properties of 304L stainless steel SMAW joints under dynamic impact loading. J Mater Sci 40:4839–4847. https://doi.org/10.1007/s10853-005-1920-0

Maurya AK, Chhibber R, Pandey C (2023) Studies on residual stresses and structural integrity of the dissimilar gas tungsten arc welded joint of sDSS 2507/Inconel 625 for marine application. J Mater Sci. https://doi.org/10.1007/s10853-023-08562-9

Zhou RY, Zhu LH, Liu YY, Lu ZR, Chen L, Ma X (2017) Microstructural evolution and the effect on hardness of Sanicro 25 welded joint base metal after creep at 973 K. J Mater Sci 52:6161–6172. https://doi.org/10.1007/s10853-017-0758-6

Hu YY, Chen JP, Wang B (2022) Global nonequilibrium energy criterion for predicting strength of 316L stainless steel under complex loadings: theoretical modeling and experimental validation. Sci China Phys Mech 65(4):244611. https://doi.org/10.1007/s11433-021-1850-0

Samal MK, Seidenfuss M, Roos E et al (2011) Investigation of failure behavior of ferritic–austenitic type of dissimilar steel welded joints. Eng Fail Anal 18(3):999–1008. https://doi.org/10.1016/j.engfailanal.2010.12.011

Kang J, Wang QB, Wang ZC, Han ZW, Xin RS, Jiao XD (2022) Fatigue fracture mechanism of T92/HR3C dissimilar metal weld joints at elevated temperature. Mater Charact 190:112081. https://doi.org/10.1016/j.matchar.2022.112081

Quagraine EK (2018) Chloride contamination of the water/steam cycle in power plants: part V. Evidence for chlorinated compound vapor ingress even after condenser re-tubing and tubesheet coating. PP Chem 20(1):4–22

Wang S, Ma Q, Li Y (2011) Characterization of microstructure, mechanical properties and corrosion resistance of dissimilar welded joint between 2205 duplex stainless steel and 16MnR. Mater Des 32(2):831–837. https://doi.org/10.1016/j.matdes.2010.07.012

Wang C, Yu Y, Yu J et al (2020) Microstructure evolution and corrosion behavior of dissimilar 304/430 stainless steel welded joints. J Manuf Process 50:183–191. https://doi.org/10.1016/j.jmapro.2019.12.015

Peethala AK, Naik B, Rambabu G (2023) Optimization of welding parameters and study on mechanical and pitting corrosion behavior of dissimilar stainless steel GTA welds. Chem Data Collect 43:100978. https://doi.org/10.1016/j.cdc.2022.100978

Vidyarthy RS, Kulkarni A, Dwivedi DK (2017) Study of microstructure and mechanical property relationships of A-TIG welded P91–316L dissimilar steel joint. Mater Sci Eng A 695:249–257. https://doi.org/10.1016/j.msea.2017.04.038

Mittal R, Sidhu BS (2018) Oxidation behaviour of T91/347H welds. J Mater Process Tech 261:266–279. https://doi.org/10.1016/j.jmatprotec.2018.05.020

Dak G, Sirohi S, Pandey C (2022) Study on microstructure and mechanical behavior relationship for laser-welded dissimilar joint of P92 martensitic and 304L austenitic steel. Int J Pres Ves Pip 196:104629. https://doi.org/10.1016/j.ijpvp.2022.104629

Xue JL, Guo W, Yang J, Xia MS, Zhao G, Tan CW, Wan ZD, Chi JX, Zhang HQ (2023) In-situ observation of microcrack initiation and damage nucleation modes on the HAZ of laser-welded DP1180 joint. J Mater Sci Tech 148:138–149. https://doi.org/10.1016/j.jmst.2023.01.001

Bignozzi MC, Calcinelli L, Carati M, Ceschini L, Chiavari C, Masi G, Morri A (2020) Effect of heat treatment conditions on retained austenite and corrosion resistance of the X190CrVMo20-4-1 stainless steel. Met Mater Int 26:1318–1328. https://doi.org/10.1007/s12540-019-00384-2

Esmailzadeh S, Aliofkhazraei M, Sarlak H (2018) Interpretation of cyclic potentiodynamic polarization test results for study of corrosion behavior of metals: a review. Prot Met Phys Chem 54:976–989. https://doi.org/10.1134/S207020511805026X

Lin X, Liu W, Wu F, Xu C, Dou J, Lu M (2015) Effect of O2 on corrosion of 3Cr steel in high temperature and high pressure CO2-O2 environment. Appl Surf Sci 329:104–115. https://doi.org/10.1016/j.apsusc.2014.12.109

Lu HJ, Xu WF, Wang H, Wang XZ (2023) Microstructure evolution and its effect on the corrosion of dissimilar aluminum alloys friction stir welding joint. Corros Sci 220:111249. https://doi.org/10.1016/j.corsci.2023.111249

Ojarand J, Priidel E, Min M (2022) Derivation of bioimpedance model data utilizing a compact analyzer and two capacitive electrodes: a forearm example. IEEE Trans Biomed Circ S 16(5):891–901. https://doi.org/10.1109/TBCAS.2022.3206666

Zuo Y, Pang R, Li W, Xiong JP, Tang YM (2008) The evaluation of coating performance by the variations of phase angles in middle and high frequency domains of EIS. Corros Sci 50(12):3322–3328. https://doi.org/10.1016/j.corsci.2008.08.049

Zhu G, Cui X, Zhang Y, Chen S, Dong M, Liu H, Shao Q, Ding T, Wu S, Guo Z (2019) Poly (vinyl butyral)/graphene oxide/poly (methylhydrosiloxane) nanocomposite coating for improved aluminum alloy anticorrosion. Polym 172:415–422. https://doi.org/10.1016/j.polymer.2019.03.056

Liu L, Li Y, Wang F (2010) Electrochemical corrosion behavior of nanocrystalline materials—a review. J Mater Sci Tech 26(1):1–14. https://doi.org/10.1016/S1005-0302(10)60001-1

Ibrahim MAM, El Abd, Rehim SS, Hamza MM (2009) Corrosion behavior of some austenitic stainless steels in chloride environments. Mater Chem Phys 115(1):80–85. https://doi.org/10.1016/j.matchemphys.2008.11.016

Mittal R, Sidhu BS (2015) Oil-Ash corrosion resistance of dissimilar T22/T91 welded joint of super heater tubes. J Mater Eng Perform 24:670–682. https://doi.org/10.1007/s11665-014-1338-4

Fu J, Li N, Zhou Q, Guo P (2015) Impacts of applied stresses on high temperature corrosion behavior of HR3C in molten salt. Oxid Met 83:317–333. https://doi.org/10.1007/s11085-014-9522-3

Liu C, Gao Y, Chong K, Guo F, Wu D, Zou Y (2023) Effect of Nb content on the microstructure and corrosion resistance of FeCoCrNiNbx high-entropy alloys in chloride ion environment. J Alloys Compd 935:168013. https://doi.org/10.1016/j.jallcom.2022.168013

Wu P, Zhu X, Xu L, Peng W, Zhao G (2020) Effect of stray current coupled with chloride concentration and temperature on the corrosion resistance of a steel passivation film. Electrochem Commun 118:106793. https://doi.org/10.1016/j.elecom.2020.106793

Mahesh BV, Raman RKS, Koch CC (2012) Bimodal grain size distribution: an effective approach for improving the mechanical and corrosion properties of Fe–Cr–Ni alloys. J Mater Sci 47:7735–7743. https://doi.org/10.1007/s10853-012-6686-6

Liu M, Cheng X, Li X, Pan Y, Li J (2016) Effect of Cr on the passive film formation mechanism of steel rebar in saturated calcium hydroxide solution. Appl Surf Sci 389:1182–1191. https://doi.org/10.1016/j.apsusc.2016.08.074

Gui Y, Zheng ZJ, Gao Y (2016) The bi-layer structure and the higher compactness of a passive film on nanocrystalline 304 stainless steel. Thin Solid Films 599:64–71. https://doi.org/10.1016/j.tsf.2015.12.039

Machet A, Galtayries A, Zanna S, Klein L, Naurice V, Jolivet P, Foucault M, Combrade P, Scott P, Marcus P (2004) XPS and STM study of the growth and structure of passive films in high temperature water on a nickel-base alloy. Electrochim Acta 49(22–23):3957–3964. https://doi.org/10.1016/j.electacta.2004.04.032

Lucio-Garcia MA, Gonzalez-Rodriguez JG, Casales M, Martinez L, Chacon-Nava JG, Neri-Flores MA, Martinez-Villafane A (2009) Effect of heat treatment on H2S corrosion of a micro-alloyed C-Mn steel. Corros Sci 51(10):2380–2386. https://doi.org/10.1016/j.corsci.2009.06.022

Kumar S, Shahi AS, Sharma V, Malhotra D (2021) Effect of welding heat input and post-weld thermal aging on the sensitization and pitting corrosion behavior of AISI 304L stainless steel butt welds. J Mater Eng Perform 30:1619–1640. https://doi.org/10.1007/s11665-021-05454-4

Min S, Liu H, Wang J, Hou J (2021) Early oxidation behavior of Ni-based Alloy 690 in simulated pressurized water reactor environment with varying surface conditions. Corros Commun 4:68–81. https://doi.org/10.1016/j.corcom.2021.10.004

Sun H, Wu X, Han EH (2009) Effects of temperature on the protective property, structure and composition of the oxide film on Alloy 625. Corros Sci 51(11):2565–2572. https://doi.org/10.1016/j.corsci.2009.06.04

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 52175286), the Project of Construction and Support for high-level Innovative Teams of Beijing Municipal Institutions (BPHR20220110), and Undergraduate Research Training Program (2023J00005, 2023J00058). The authors sincerely appreciate the above financial support.

Author information

Authors and Affiliations

Contributions

MS: Conceptualization, Formal analysis, Writing—Original Draft, Visualization. HW: Investigation, Validation. QW: Resources, Experiment. JY: Resources, Experiment. JK: Writing—Review & Editing, Supervision, Project administration, Funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Not required.

Additional information

Handling Editor: Naiqin Zhao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Si, M., Wang, H., Wang, Q. et al. Effect of microstructure on initial corrosion behavior of T92/HR3C dissimilar metal welded joint. J Mater Sci 58, 17648–17663 (2023). https://doi.org/10.1007/s10853-023-09139-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-09139-2