Abstract

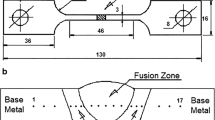

Heat input for gas tungsten arc welding process was varied at three different levels to fabricate three AISI 304L stainless steel welds to examine the influence of variable arc energy input on their sensitization and pitting performance. Welds were subjected to post-weld thermal aging treatments comprising of low-temperature sensitization of 500 °C for 1, 5, and 11 days and classical sensitization of 650 °C for 1, 12, and 24 h. Different morphologies of ferrite present in the fusion zone and the degree of the coarsening of grains in the heat-affected zone (HAZ) of the weldments under different aging conditions influenced their tendencies for carbide formation, which consequentially affected their sensitization and pitting corrosion behavior significantly. Lower heat input welds having lathy morphology of δ-ferrite in the fusion zone along with less coarsened HAZ exhibited a lesser degree of carbide precipitation. They hence showed a lower degree of sensitization (DOS), which accounted for higher pitting potential (Epitt). However higher heat input welds having vermicular morphology of δ-ferrite in the fusion zone and relatively higher grain coarsened HAZ promoted a higher degree of carbide precipitation, and thus accounted for the higher value of DOS and lower pitting potential (Epitt).

Similar content being viewed by others

References

A.J. Sedric, Corrosion of Stainless Steels, 2nd ed. Wiley, New York, 1996.

M. Finsgar and I. Milosev, Corrosion Behavior of Stainless Steels in Aqueous Solutions of Methanesulfonic Acid, Corros. Sci., 2010, 52, p 2430–2438.

W. Kuang, E.H. Han, X. Wu and J. Rao, Microstructural Characteristics of the Oxide Scale Formed on 304 Stainless Steel in Oxygenated High Temperature Water, Corros. Sci., 2010, 52, p 3654–3660.

S.M. Bruemmer and L.A. Charlot, Development of Grain Boundary Chromium Depletion in Type 304 and 316 Stainless Steels, Scr. Metall. Mater., 1986, 20, p 1019–1024.

W.E. White, Observations of the Influence of Microstructure on Corrosion of Welded Conventional and Stainless Steels, Mater. Charact., 1992, 28, p 349–358.

M.J. Povich, Low Temperature Sensitization of Type 304 Stainless Steel, Corrosion, 1978, 34, p 60–65.

S.M. Bruemmer, L.A. Charlot, A. Bagchi and D.G. Atteridge, Influence of Grain Boundary Carbides and Phosphorus Segregation on the Low Temperature Intergranular Embrittlement of Type 316 Stainless Steel, Scripta. Metall. Mater., 1989, 23, p 1549–1554.

E. Folkhard, Welding Metallurgy of Stainless Steels, Springer, Vienna, 1988.

U.K. Mudali, R.K. Dayal, J.B. Gnanamoorthy and P. Rodriguez, Influence of Thermal Aging on the Intergranular Corrosion Resistance of Types 304 LN and 316 LN Stainless Steels, Metall. Mater. Trans. A, 1996, 27A, p 2881–2887.

R. Beneke and R.F. Sandenbergh, The Influence of Nitrogen and Molybdenum on the Sensitization Properties of Low-Carbon Austenitic Stainless Steels, Corros. Sci., 1989, 29, p 543–555.

A. Pardo, M.C. Merino, A.E. Coy, F. Viejo, R. Arrabal and E. Matykina, Pitting Corrosion Behaviour of Austenitic Stainless Steels-Combining Effects of Mn and Mo Additions, Corros. Sci., 2008, 50, p 1796–1806.

H.Y. Ha and H.S. Kwon, Effects of Cr2N on the Pitting Corrosion of High Nitrogen Stainless Steels, Elertrochim. Acta, 2007, 52, p 2175–2180.

H.-B. Li, Z.-H. Jiang, Y. Yang, Y. Cao and Z.-R. Zhang, Pitting Corrosion and Crevice Corrosion Behaviors of High Nitrogen Stainless Steels, Int. J. Min. Met. Mater., 2009, 16(5), p 517–524.

R. Singh, S.G. Chowdhury, B.R. Kumar, S.K. Das, P.K. De and I. Chattoraj, The Importance of Grain Size Relative to Grain Boundary Character on the Sensitization of Metastable Austenitic Stainless Steel, Scr. Mater., 2007, 57, p 185–188.

A.D. Schino and J.M. Kenny, Effect of Grain Size on the Corrosion Resistance of a High Nitrogen-Low Nickel Austenitic Stainless Steel, J. Mater. Sci. Lett., 2002, 21, p 1969–1971.

Y.J. Oh and J.H. Hong, Nitrogen Effect on Precipitation and Sensitization in Cold-Worked Type 316 L (N) Stainless Steels, J. Nucl. Mater., 2000, 278, p 242–250.

R. Singh, Influence of Cold Rolling on Sensitization and Intergranular Stress Corrosion Cracking of AISI 304 Aged at 500°C, J. Mater. Process. Tech., 2008, 206, p 286–293.

S. Mannepalli, R.K. Gupta, A.V. Kumar, N. Parvathavarthini and U.K. Mudali, Influence of Prior Deformation on Sensitization Kinetics of Nitrogen Alloyed 316L Stainless Steels, J. Mater. Eng. Perform., 2015, 24, p 1848–1855.

L. Peguet, B. Malki and B. Baroux, Influence of Cold Working on the Pitting Corrosion Resistance of Stainless Steels, Corros. Sci., 2007, 49, p 1933–1948.

Y. Fu, X. Wu, E.-H. Han, W. Ke, K. Yang and Z. Jiang, Effects of Cold Work and Sensitization Treatment on the Corrosion Resistance of High Nitrogen Stainless Steel in Chloride Solutions, Elertrochim. Acta, 2009, 54, p 1618–1629.

J. Moon, H.-Y. Ha and T.-H. Lee, Corrosion Behavior of High Heat Input Welded Heat-Affected Zone of Ni-Free High-Nitrogen Fe-18Cr-10Mn-N Austenitic Stainless Steels, Mater. Charact., 2013, 82, p 113–119.

J. Moon, H.-Y. Ha, T.-H. Lee and C. Lee, Different Aspects of Pitting Corrosion in the Weld Heat-Affected Zone of High-Nitrogen Fe-18Cr-10Mn-N Steel, Mater. Chem. Phys., 2013, 142, p 556–563.

Y. Cui and C.D. Lunding, Evaluation of Initial Corrosion Location in E316 Austenitic Stainless Steel Weld Metals, Mater. Lett., 2005, 59, p 1542–1546.

Y. Cui and C.D. Lunding, Austenite-Preferential Corrosion Attack in 316 Austenitic Stainless Steel Weld Metals, Mater. Des., 2007, 28, p 324–328.

M. Dadfar, M.H. Fathi, F. Karimzadeh, M.R. Dadfar and A. Saatchi, Effect of TIG Welding on Corrosion Behaviour of 316L Stainless Steel, Mater. Lett., 2007, 61, p 2343–2346.

C.-M. Lin, H.-L. Tsai, C.-D. Cheng and C. Yang, Effect of Repeated Weld-Repairs on Microstructure, Texture, Impact Properties and Corrosion Properties of AISI 304L Stainless Steel, Eng. Fail. Anal., 2012, 21, p 9–20.

T.A. Mozhi, M.C. Juhas and B.E. Wilde, Modeling Low Temperature Sensitization of Austenitic Stainless Steels, Scr. Metall. Mater., 1987, 21, p 1547–1552.

V. Moura, Y.A. Kina, S.S.M. Tavares, M.M.S.G. Faria and F.B. Mainier, Investigation of Cracks and Sensitization in an AISI304L Stainless Steel Exposed to 500–600°C, Eng. Fail. Anal., 2009, 16, p 545–551.

G. Suresh, T. Nandakumar and A. Viswanath, Effect of Low-Temperature Sensitization on the Corrosion Behavior of AISI 304L SS Weld Metal in Simulated Groundwater, J. Mater. Eng. Perform., 2018, 27, p 2484–2491.

ASTM International E407-07: Standard Practice for Microetching Metals and Alloys.

N. Lopez, M. Cid, M. Puiggali, I. Azkarate and A. Pelayo, Application of Double Loop Electrochemical Potentiodynamic Reactivation Test to Austenitic and Duplex Stainless Steels, Mater. Sci. Eng. A, 1997, 229, p 123–128.

V. Cihal and R. Stefec, On the Development of the Electrochemical Potentiokinetic Method, Elertrochim. Acta, 2001, 46, p 3867–3877.

M. Momeni, M.H. Moayed and A. Davoodi, Tuning DOS Measuring Parameters Based on Double-Loop EPR in H2SO4 Containing KSCN by Taguchi Method, Corros. Sci., 2010, 52, p 2653–2660.

P.D. Tiedra, O. Martin and M. Lopez, Combined Effect of Resistance Spot Welding and Post-Welding Sensitization on the Degree of Sensitization of AISI 304 Stainless Steel, Corros. Sci., 2011, 53, p 2670–2675.

V. Kain, K. Chandra, K.N. Adhe and P.K. De, Effect of Cold Work on Low-Temperature Sensitization Behaviour of Austenitic Stainless Steels, J. Nucl. Mater., 2004, 334, p 115–132.

ASTM International G5-13: Standard Reference Test Method for Making Potentiodynamic Anodic Polarization Measurements.

X. Wu, Y. Fu, J. Huang, E. Han, W. Ke, K. Yang and Z. Jiang, Investigation of Pitting Corrosion of Nickel-Free and Manganese-Alloyed High Nitrogen Stainless Steels, J. Mater. Eng. Perform., 2009, 18(3), p 287–298.

M. Hazra, K.S. Rao and G.M. Reddy, Friction Welding of a Nickel Free High Nitrogen Steel: Influence of Forge Force on Microstructure, Mechanical Properties and Pitting Corrosion Resistance, J. Mater. Res. Tech., 2014, 3(1), p 90–100.

D. Malhotra and A.S. Shahi, Metallurgical, Fatigue and Pitting Corrosion Behavior of AISI 316 Joints Welded with Nb-Based Stabilized Steel Filler, Metall. Mater. Trans. A, 2020, 51, p 1647–1664.

U.K. Mudali and R.K. Dayal, Pitting Corrosion Resistance of as Welded and Thermally Aged Nitrogen Containing Type 316 Stainless Steel Weld Metal, Mater. Sci. Tech., 2000, 16, p 393–398.

U.K. Mudali, R.K. Dayal, J.B. Gnanamoorthy and P. Rodriguez, Relationship Between Pitting and Intergranular Corrosion of Nitrogen-Bearing Austenitic Stainless Steels, ISIJ Int., 1996, 36(7), p 799–806.

C. Gracia, M.P. de Tiedra, Y. Blanco, O. Martin and F. Martin, Intergranular Corrosion of Welded Joints of Austenitic Stainless Steels Studied by Using an Electrochemical Minicell, Corros. Sci., 2008, 50, p 2390–2397.

A. Yae Kina, V.M. Souza, S.S.M. Tavares, J.M. Pardal and J.A. Souza, Microstructure and Intergranular Corrosion Resistance Evaluation of AISI 304 Steel for High Temperature Service, Mater. Charact., 2008, 59, p 651–655.

A.D. Schino and J.M. Kenny, Effects of the Grain Size on the Corrosion Behaviour of Refined AISI 304 Stainless Steel, J. Mater. Sci. Lett., 2002, 21, p 1631–1634.

J.M. Aquino, C.A. Della Rovere and S.E. Kuri, Intergranular Corrosion Susceptibility in Supermartenistic Stainless Steel Weldments, Corros. Sci., 2009, 51, p 2316–2323.

J.H. Potgieter, P.A. Olubambi, L. Cornish, C.N. Machio and E.M. Sherif, Influence of Nickel Additions on the Corrosion Behavior of Low Nitrogen 22% Cr Series Duplex Stainless Steels, Corros. Sci., 2008, 50(9), p 2572–2579.

J. Moon, H. Ha, S. Park, J. Loo, J. Jang, C. Lee, H. Han and H. Hong, Effect of Mo and Cr Additions on the Microstructure, Mechanical Properties and Pitting Corrosion Resistance of Austenitic Fe-30Mn-10.5Al-1.1C Lightweight Steels, J. Alloys Compd., 2019, 775, p 1136–1146.

Y. Zhang, H. Luo, Q. Zhong, H. Yu and J. Lv, Characterization of Passive Films Formed on As-Received and Sensitized AISI 304 Stainless Steel, Chin. J. Mech. Eng., 2019, 32–27, p 1–12.

C.M. Abreu, M.J. Cristobal, R. Losada, X.R. Novoa, G. Pena and M.C. Perez, The Effect of Ni in the Electrochemical Properties of Oxide Layers Grown on Stainless Steels, Electrochim. Acta, 2006, 51(15), p 2991–3000.

S. Marcelin, N. Pebera and S. Regnier, Electrochemical Characterisation of Martensitic Stainless Steel in an Neutral Chloride Solution, Electrochim. Acta, 2013, 87, p 32–40.

Acknowledgments

The infrastructural support, especially metallography and corrosion testing facilities, extended by the Welding Metallurgy Laboratory, Mechanical Engineering Department, S.L.I.E.T., Longowal, Sangrur (Deemed to be University), Punjab, India, is gratefully acknowledged. A special thanks to Amrindra Pal for providing the support to finalize the art work in the figures.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, S., Shahi, A.S., Sharma, V. et al. Effect of Welding Heat Input and Post-weld Thermal Aging on the Sensitization and Pitting Corrosion Behavior of AISI 304L Stainless Steel Butt Welds. J. of Materi Eng and Perform 30, 1619–1640 (2021). https://doi.org/10.1007/s11665-021-05454-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05454-4