Abstract

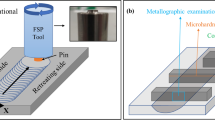

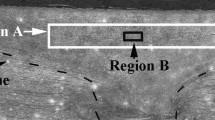

In the present study, friction stir processing (FSP) was carried out on as-cast Mg-Zn-Dy alloy to tailor grain size and texture which alter the mechanical properties and corrosion behaviour. The grain size of the as-cast alloy was reduced from 60 ± 2 µm to 3 ± 0.1 µm after FSP due to dynamic recrystallization. The effect of grain size, crystallographic orientation and fine precipitates on mechanical properties were investigated using field emission scanning electron microscope (FESEM) and electron back scattered diffraction (EBSD). The ultimate tensile strength, yield strength, % elongation and hardness of FSPed alloy improved by 55%, 60%, 53% and 46% when compared to as-cast alloy. The FSPed Mg-Zn-Dy alloy exhibited a 79% decrease in corrosion rate when compared to as-cast alloy which can be attributed to grain refinement, uniform distribution of secondary precipitates and strong basal texture. The surface of FSPed sample after immersion corrosion exhibited calcium phosphate rich minerals which help in apatite formation on the sample surface. Cytotoxicity studies using MTT assay revealed more than 80% cell viability for both as-cast and FSPed alloy illustrating non-toxic nature of both the samples. The results of this study indicate that FSPed Mg-Zn-Dy alloy is a potential material for biodegradable implants due to its high strength, corrosion resistance and biocompatibility.

Graphical Abstract

Similar content being viewed by others

References

Song M, Zeng R, Ding Y, Li RW, Easton M, Cole I, Birbilis N, Chen X (2019) Journal of materials science & technology recent advances in biodegradation controls over mg alloys for bone fracture management : a review. J Mater Sci Technol 35:535–544. https://doi.org/10.1016/j.jmst.2018.10.008

Zhang J, Shang Z, Jiang Y, Zhang K, Li X, Ma M, Li Y, Ma B (2020) Biodegradable metals for bone fracture repair in animal models : a systematic review. Regen Biomater 8(1):1–17. https://doi.org/10.1093/rb/rbaa047

Agarwal-harding KJ, Meara JG, Greenberg SLM, Hagander LE, Zurakowski D, Dyer GSM (2015) Estimating the Global Incidence of Femoral Fracture from Road Traffic Collisions. JBJS 31:1–10

Chen Y, Xu Z, Smith C, Sankar J (2014) Recent advances on the development of magnesium alloys for biodegradable implants. ACTA Biomater. https://doi.org/10.1016/j.actbio.2014.07.005

Han H, Loffredo S, Jun I, Edwards J, Kim Y, Seok H, Witte F, Mantovani D, Glyn-jones S (2019) Current status and outlook on the clinical translation of biodegradable metals. Mater Today 23:57–71. https://doi.org/10.1016/j.mattod.2018.05.018

Chen Q, Thouas GA (2015) Metallic implant biomaterials. Mater Sci Eng R 87:1–57. https://doi.org/10.1016/j.mser.2014.10.001

Zheng FWYF, Gu XN (2014) Biodegradable metals. Mater Sci Eng A 77:1–34

Chen J, Tan L, Yang K (2016) Recent advances on the development of biodegradable magnesium alloys: a review. Mater Technol 31:681–688. https://doi.org/10.1080/10667857.2016.1212587

Gu XN, Li SS, Li XM, Fan YB (2014) Magnesium based degradable biomaterials: a review, front. Mater Sci 8:200–218. https://doi.org/10.1007/s11706-014-0253-9

Prakasam M, Locs J, Salma-Ancane K, Loca D, Largeteau A, Berzina-Cimdina L (2017) Biodegradable materials and metallic implants—a review. J Funct Biomater 8:44. https://doi.org/10.3390/jfb8040044

Kirkland NT, Lespagnol J, Birbilis N, Staiger MP (2010) A survey of bio-corrosion rates of magnesium alloys. Corros Sci 52:287–291. https://doi.org/10.1016/j.corsci.2009.09.033

Samaniego A, Llorente I, Feliu S Jr (2013) Combined effect of composition and surface condition on corrosion behaviour of magnesium alloys AZ31 and AZ61. Corros Sci 68:66–71. https://doi.org/10.1016/j.corsci.2012.10.034

Liu D, Yang D, Li X, Hu S (2018) Mechanical properties, corrosion resistance and biocompatibilities of degradable Mg-RE alloys. Integr Med Res 8:1538–1549. https://doi.org/10.1016/j.jmrt.2018.08.003

Mardali M, Salimijazi HR, Karimzadeh F, Luthringer B, Blawert C, Labbaf S (2019) Applied Surface Science Comparative study on microstructure and corrosion behavior of nanostructured hydroxyapatite coatings deposited by high velocity oxygen fuel and flame spraying on AZ61 magnesium based substrates. Appl Surf Sci 465:614–624. https://doi.org/10.1016/j.apsusc.2018.09.127

Lima RS, Khor KA, Li H, Cheang P, Marple BR (2005) HVOF spraying of nanostructured hydroxyapatite for biomedical applications. Mater Sci Eng 396:181–187. https://doi.org/10.1016/j.msea.2005.01.037

Xie B, Zhao MC, Xu R, Zhao YC, Yin D, Gao C, Atrens A (2021) Biodegradation antibacterial performance and cytocompatibility of a novel ZK30-Cu-Mn biomedical alloy produced by selective laser melting. Int J Bioprint 7:78–89

Feyerabend F, Fischer J, Holtz J, Witte F, Willumeit R, Drücker H, Vogt C, Hort N (2010) Evaluation of short-term effects of rare earth and other elements used in magnesium alloys on primary cells and cell lines. Acta Biomater 6:1834–1842. https://doi.org/10.1016/j.actbio.2009.09.024

Zucchi F, Grassi V, Frignani A, Monticelli C, Trabanelli G (2006) Electrochemical behaviour of a magnesium alloy containing rare earth elements. J Appl Electrochem 36:195–204. https://doi.org/10.1007/s10800-005-9053-3

Ali M, Elsherif M, Salih AE, Ul-hamid A, Hussein MA, Park S, Yetisen AK, Butt H (2020) Surface modification and cytotoxicity of Mg-based bio-alloys : an overview of recent advances. J Alloys Compd 825:154140. https://doi.org/10.1016/j.jallcom.2020.154140

Ma A, Jiang J, Saito N, Shigematsu I, Yuan Y (2009) Improving both strength and ductility of a Mg alloy through a large number of ECAP passes. Mat Sci Eng 514:122–127. https://doi.org/10.1016/j.msea.2009.01.040

Liu M, Roven HJ, Liu X, Murashkin M, Valiev RZ, Unga T (2010) Grain refinement in nanostructured Al – Mg alloys subjected to high pressure torsion. J Mater Sci 45:4659–4664. https://doi.org/10.1007/s10853-010-4604-3

Zhang X, Yuan G, Niu J, Fu P, Ding W (2012) and cytotoxicity of as-extruded Mg – Nd – Zn – Zr alloy with different extrusion ratios. J Mech Behav Biomed Mater 9:153–162. https://doi.org/10.1016/j.jmbbm.2012.02.002

Valle JA, Ruano OA (2005) Accumulative roll bonding of a Mg-based AZ61 alloy. Mater Sci Eng 411:353–357. https://doi.org/10.1016/j.msea.2005.08.097

Kim K, Suh B, Bae H, Shim M (2010) Microstructure and texture evolution of Mg alloys during twin-roll casting and subsequent hot rolling. Scr Mater 63:716–720. https://doi.org/10.1016/j.scriptamat.2009.12.010

Kasemo B (2002) Biological surface science. Surf Sci 500:656–677. https://doi.org/10.1016/S0039-6028(01)01809-X

Yang J, Cui F, Lee IS (2011) Surface Modifications of Magnesium Alloys for Biomedical applications. Ann Biomed Eng 39(7):1857–1871. https://doi.org/10.1007/s10439-011-0300-y

Zhang W, Zhao MC, Wang Z, Tan L, Qi Y, Yin DF, Yang K, Atrens A (2022) Enhanced initial biodegradation resistance of the biomedical Mg-Cu alloy by surface nanomodification. J Magnes Alloy. https://doi.org/10.1016/j.jma.2021.12.013

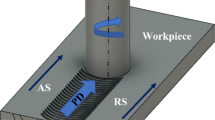

Mishra RS (2005) Friction stir welding and processing. Mater Sci Eng R 50:1–78. https://doi.org/10.1016/j.mser.2005.07.001

Wang W, Chen SY, Qiao K, Peng P, Han P, Wu B, Wang CX, Wang J, Wang YH, Wang KS (2022) Microstructure, mechanical properties, and corrosion behavior of Mg–Al–Ca alloy prepared by friction stir processing. Acta Metall Sin English Lett 35:703–713. https://doi.org/10.1007/s40195-021-01300-7

Badkoobeh F, Mostaan H, Rafiei M, Bakhsheshi-Rad HR, Berto F (2021) Friction stir welding/processing of mg-based alloys: A critical review on advancements and challenges. Materials (Basel) 14:15–17. https://doi.org/10.3390/ma14216726

Wang W, Han P, Peng P, Zhang T, Liu Q, Yuan SN, Huang LY, Yu HL, Qiao K, Wang KS (2020) Friction stir processing of magnesium alloys: a review. Acta Metall Sin (English Lett) 33:43–57. https://doi.org/10.1007/s40195-019-00971-7

Elyasi M, Razaghian A, Moharami A, Emamy M (2022) Effect of Zirconium micro-addition and multi-pass friction stir processing on microstructure and tensile properties of Mg–Zn–Si alloys. J Mater Res Technol 20:4269–4282. https://doi.org/10.1016/j.jmrt.2022.08.155

Xiao BL, Yang Q, Yang J, Wang WG, Xie GM, Ma ZY (2011) Enhanced mechanical properties of Mg – Gd – Y – Zr casting via friction stir processing. J Alloys Comp 509:2879–2884. https://doi.org/10.1016/j.jallcom.2010.11.147

Luo XC, Kang LM, Liu HL, Li ZJ, Liu YF, Zhang DT, Chen DL (2020) Materials science & engineering a enhancing mechanical properties of AZ61 magnesium alloy via friction stir processing : effect of processing parameters. Mater Sci Eng 797:139945. https://doi.org/10.1016/j.msea.2020.139945

Liu Q, Xian Ma Q, Qiang Chen G, Cao X, Zhang S, Luan Pan J, Zhang G, Yu Shi Q (2018) Enhanced corrosion resistance of AZ91 magnesium alloy through refinement and homogenization of surface microstructure by friction stir processing. Corros Sci 138:84–296. https://doi.org/10.1016/j.corsci.2018.04.028

Liu Q, Chen G, Zeng S, Zhang S, Long F (2021) The corrosion behavior of Mg-9Al-xRE magnesium alloys modified by friction stir processing. J Alloys Compd 851:156835. https://doi.org/10.1016/j.jallcom.2020.156835

Zeng Z, Zhou M, Esmaily M, Zhu Y, Choudhary S, Griffith JC, Ma J, Hora Y, Chen Y, Gullino A, Shi Q, Fujii H, Birbilis N (2022) Corrosion resistant and high-strength dual-phase Mg-Li-Al-Zn alloy by friction stir processing. Commun Mater 3:1–10. https://doi.org/10.1038/s43246-022-00245-3

Arora HS, Singh H, Dhindaw BK (2013) Corrosion behavior of a Mg alloy AE42 subjected to friction stir processing. Corrosion 9312:122–135

Argade GR, Kandasamy K, Panigrahi SK, Mishra RS (2012) Corrosion behavior of a friction stir processed rare-earth added magnesium alloy. Corros Sci 58:321–326. https://doi.org/10.1016/j.corsci.2012.01.007

Moharami A, Razaghian A (2020) Corrosion behaviour of friction stir processed Al–Mg2Si composites. Mater Sci Technol (United Kingdom) 36:1922–1929. https://doi.org/10.1080/02670836.2020.1852515

Long F, Liu Q, Chen G, Zhou M, Shi Q (2022) Improved corrosion resistance achieved in a friction stir processed Mg-5Zn-0.3Ca alloy with fragmented precipitates. Corros Sci 208:110675. https://doi.org/10.1016/j.corsci.2022.110675

Tapiero H, Tew KD (2003) Trace elements in human physiology and pathology : zinc and metallothioneins. Biomed Pharmacother 57:399–411. https://doi.org/10.1016/S0753-3322(03)00081-7

Bi G, Li Y, Zang S, Zhang J, Ma Y, Hao Y (2014) ScienceDirect Microstructure, mechanical and corrosion properties of Mg e 2Dy e x Zn ( x ¼ 0, 0.1, 0.5 and 1 at.%) alloys. J Magnes Alloy 2:64–71. https://doi.org/10.1016/j.jma.2014.03.002

Li H, Wen J, He J, Shi H, Liu Y (2020) Effects of Dy addition on the mechanical and degradation properties of Mg–2Zn–0.5Zr Alloy. Adv Eng Mater 22:1–11. https://doi.org/10.1002/adem.201901360

Kottuparambil RR, Bontha S, Rangarasaiah RM, Arya SB, Jana A, Das M, Balla VK, Amrithalingam S, Prabhu TR (2018) Effect of zinc and rare-earth element addition on mechanical, corrosion, and biological properties of magnesium. J Mater Res 33:3466–3478. https://doi.org/10.1557/jmr.2018.311

Gupta M, Meenashisundaram GK (2015) Insight into designing biocompatible magnesium alloys and composites processing mechanical and corrosion characteristics. Springer

I. Standard, (2009) International Standard, 2009

ASTM International (2004) ASTM G31: Standard Practice for Laboratory Immersion Corrosion Testing of Metals, Annu B ASTM Stand. i 5–7

Mathaudhu SN, Luo AA, Neelameggham NR, Nyberg EA, Sillekens WH (2014) An hydrogen evolution method for the estimation of the corrosion rate of magnesium alloys. Magnes Technol 9781118858:1–634. https://doi.org/10.1002/9781118859803

G Song, A Atrens (2016) An hydrogen evolution method for the estimation of the corrosion rate of magnesium alloys Guangling, Magnes Technol

Atrens A, Liu M, Zainal Abidin NI (2011) Corrosion mechanism applicable to biodegradable magnesium implants. Mater Sci Eng B Solid-State Mater Adv Technol 176:1609–1636. https://doi.org/10.1016/j.mseb.2010.12.017

Chai F, Zhang D, Li Y (2015) Microstructure evolution and mechanical properties of a submerged friction-stir-processed AZ91 magnesium alloy. J Mater Sci 50(8):3212–3225. https://doi.org/10.1007/s10853-015-8887-2

Nie JF (2012) Precipitation and hardening in magnesium alloys. Metall Mater Trans A Phys Metall Mater Sci 43:3891–3939. https://doi.org/10.1007/s11661-012-1217-2

Han J, Chen J, Peng L, Zheng F, Rong W, Wu Y, Ding W (2016) In fl uence of processing parameters on thermal fi eld in Mg – Nd – Zn – Zr alloy during friction stir processing. Mat Des 94:186–194. https://doi.org/10.1016/j.matdes.2016.01.044

Stanford N (2010) Micro-alloying Mg with Y, Ce, Gd and La for texture modification-a comparative study. Mater Sci Eng A 527:2669–2677. https://doi.org/10.1016/j.msea.2009.12.036

Hilgert J, Herzberg K, Huber N (2012) Temperature and texture development during high speed friction stir processing of magnesium AZ31. Adv Eng Mater 14(9):762–771. https://doi.org/10.1002/adem.201200112

Kumar N, Dendge N, Banerjee R, Mishra RS (2014) Effect of microstructure on the uniaxial tensile deformation behavior of Mg-4Y-3RE alloy. Mater Sci Eng A 590:116–131. https://doi.org/10.1016/j.msea.2013.10.009

Sekban DM, Saray O, Aktarer SM, Purcek G, Ma ZY (2015) Microstructure, mechanical properties and formability of friction stir processed interstitial-free steel. Mater Sci Eng A 642:57–64. https://doi.org/10.1016/j.msea.2015.06.068

Jin Y, Wang K, Wang W, Peng P, Zhou S, Huang L (2019) Materials characterization microstructure and mechanical properties of AE42 rare earth-containing magnesium alloy prepared by friction stir processing. Mater Charact 150:52–61. https://doi.org/10.1016/j.matchar.2019.02.008

Xin R, Zheng X, Liu Z, Liu D, Qiu R, Li Z, Liu Q (2016) Microstructure and texture evolution of an Mg e Gd e Y e Nd e Zr alloy during friction stir processing. J Alloys Compd 659:51–59. https://doi.org/10.1016/j.jallcom.2015.11.034

Li J, He Z, Fu P, Wu Y, Peng L, Ding W (2016) Heat treatment and mechanical properties of a high-strength cast Mg-Gd-Zn alloy. Mater Sci Eng A 651:745–752. https://doi.org/10.1016/j.msea.2015.11.021

Freeney TA, Mishra RS (2010) Effect of friction stir processing on microstructure and mechanical properties of a cast-magnesium – rare earth alloy. Metall Mater Trans 41:73–84. https://doi.org/10.1007/s11661-009-0080-2

Huang Y, Wang Y, Meng X, Wan L, Cao J, Zhou L (2017) Dynamic recrystallization and mechanical properties of friction stir processed Mg-Zn-Y-Zr alloys. J Mater Process Tech 249:331–338. https://doi.org/10.1016/j.jmatprotec.2017.06.021

Bhargava G, Yuan W, Webb SS, Mishra RS (2010) Influence of texture on mechanical behavior of friction-stir-processed magnesium alloy. Metall Mater Trans A Phys Metall Mater Sci 41:13–17

Yu Z, Choo H, Feng Z, Vogel SC (2010) Influence of thermo-mechanical parameters on texture and tensile behavior of friction stir processed Mg alloy. Scr Mater 63:1112–1115. https://doi.org/10.1016/j.scriptamat.2010.08.016

Xin R, Li BO, Liao A, Zhou Z, Liu Q (2012) Correlation between texture variation and transverse tensile behavior of friction-stir-processed AZ31 Mg alloy. Metall Mater Trans 43(7):2500–2508. https://doi.org/10.1007/s11661-012-1080-1

Sharahi HJ, Pouranvari M, Movahedi M (2020) Materials science & engineering a strengthening and ductilization mechanisms of friction stir processed cast Mg – Al – Zn alloy. Mater Sci Eng 781:139249

Han J, Chen J, Peng L, Tan S, Wu Y, Zheng F, Yi H (2017) Materials & Design Microstructure, texture and mechanical properties of friction stir processed Mg-14Gd alloys. Mater Des 130:90–102. https://doi.org/10.1016/j.matdes.2017.05.046

Wang H, Zhang DT, Cao GH, Qiu C (2022) Improving room-temperature ductility of a Mg–Zn–Ca alloy through friction stir processing. J Mater Res Technol 17:1176–1186. https://doi.org/10.1016/j.jmrt.2022.01.082

Kumar N, Choudhuri D, Banerjee R, Mishra RS (2015) Strength and ductility optimization of Mg-Y-Nd-Zr alloy by microstructural design. Int J Plast 68:77–97. https://doi.org/10.1016/j.ijplas.2014.11.003

Zhang W, Tan L, Ni D, Chen J, Zhao Y, Liu L, Shuai C, Yang K, Atrens A, Zhao M (2018) Effect of grain refinement and crystallographic texture produced by friction stir processing on the biodegradation behavior of a Mg-Nd-Zn alloy. J Mater Sci Technol. https://doi.org/10.1016/j.jmst.2018.11.025

Li XW, Zheng FY, Wu YJ, Peng LM, Zhang Y, Lin DL, Ding WJ (2013) Modification of long period stacking ordered phase and improvement of mechanical properties of Mg–Gd–Zn–Zr alloy by friction stir processing. Mater Lett 113:206–209. https://doi.org/10.1016/j.matlet.2013.09.054

Zheng FY, Wu YJ, Peng LM, Li XW, Fu PH, Ding WJ (2013) Microstructures and mechanical properties of friction stir processed Mg e 2. 0Nd e 0. 3Zn e 1. 0Zr magnesium alloy. J Magnes Alloys 1:122–127. https://doi.org/10.1016/j.jma.2013.06.001

Chen Y, Hung F, Lin Y, Lin C (2020) Biodegradation ZK50 magnesium alloy compression screws : Mechanical properties, biodegradable characteristics and implant test. J Orthop Sci. https://doi.org/10.1016/j.jos.2020.01.018

Zhang W, Tan L, Ni D, Chen J, Zhao YC, Liu L, Shuai C, Yang K, Atrens A, Zhao MC (2019) Effect of grain refinement and crystallographic texture produced by friction stir processing on the biodegradation behavior of a Mg-Nd-Zn alloy. J Mater Sci Technol 35:777–783. https://doi.org/10.1016/j.jmst.2018.11.025

Hansen N (2004) Hall-petch relation and boundary strengthening. Scr Mater 51:801–806. https://doi.org/10.1016/j.scriptamat.2004.06.002

Xin Y, Hu T, Chu PK (2010) Influence of Test Solutions on In Vitro Studies of Biomedical Magnesium Alloys. J Electrochem Soc 157(7):238–243. https://doi.org/10.1149/1.3421651

Xie B, Zhao MC, Tao JX, Zhao YC, Yin D, Gao C, Shuai C, Atrens A (2021) Comparison of the biodegradation of ZK30 subjected to solid solution treating and selective laser melting. J Mater Res Technol 10:722–729. https://doi.org/10.1016/j.jmrt.2020.12.041

Marco I, Marco I, Myrissa A, Martinelli E, Feyerabend F, Weinberg AM (2017) In vivo and in vitro degradation comparison of pure MG Mg-10Gd and Mg-2Ag : a short term study. Eur Cells Mater. https://doi.org/10.22203/eCM.v033a07

Witte F, Kaese V, Haferkamp H, Switzer E, Meyer-Lindenberg A, Wirth CJ, Windhagen H (2005) In vivo corrosion of four magnesium alloys and the associated bone response. Biomaterials 26:3557–3563. https://doi.org/10.1016/j.biomaterials.2004.09.049

Gao Z, Song M, Liu R, Shen Y, Ward L, Cole I, Chen X, Liu X (2019) Materials science & engineering c improving in vitro and in vivo antibacterial functionality of Mg alloys through micro-alloying with Sr and Ga. Mater Sci Eng C 104:109926. https://doi.org/10.1016/j.msec.2019.109926

Sanchez AHM, Luthringer BJC, Feyerabend F, Willumeit R (2015) Mg and Mg alloys: how comparable are in vitro and in vivo corrosion rates? A review. Acta Biomater 13:16–31. https://doi.org/10.1016/j.actbio.2014.11.048

Gu XN, Xie XH, Li N, Zheng YF, Qin L (2012) In vitro and in vivo studies on a Mg-Sr binary alloy system developed as a new kind of biodegradable metal. Acta Biomater 8:2360–2374. https://doi.org/10.1016/j.actbio.2012.02.018

Xiao C, Wang L, Ren Y, Sun S, Zhang E, Yan C, Liu Q, Sun X, Shou F, Duan J, Wang H, Qin G (2018) Journal of Materials Science & Technology Indirectly extruded biodegradable Zn-0. 05wt % Mg alloy with improved strength and ductility: in vitro and in vivo studies. J Mater Sci Technol 34:1618–1627. https://doi.org/10.1016/j.jmst.2018.01.006

Op’t Hoog C, Birbilis N, Zhang MX, Estrin Y (2008) Surface grain size effects on the corrosion of magnesium. Key Eng Mater 384:229–240. https://doi.org/10.4028/0-87849-372-7.229

Op’t Hoog C, Birbilis N, Estrin Y (2008) Corrosion of pure Mg as a function of grain size and processing route. Adv Eng Mater 10:579–582. https://doi.org/10.1002/adem.200800046

Ralston KD, Birbilis N (2010) Effect of grain size on corrosion: a review. Corrosion 66:1–13

Rokkala U, Bontha S, Ramesh MR, Krishna V, Srinivasan A, Kailas SV (2021) Tailoring surface characteristics of bioabsorbable Mg-Zn-Dy alloy using friction stir processing for improved wettability and degradation behavior. J Mater Res Technol 12:1530–1542. https://doi.org/10.1016/j.jmrt.2021.03.057

Qu Z, Liu L, Deng Y, Tao R, Liu W, Zheng Z, Zhao MC (2022) Relationship between biodegradation rate and grain size itself excluding other structural factors caused by alloying additions and deformation processing for pure Mg. Materials (Basel). 15(5):5295. https://doi.org/10.3390/ma15155295

Birbilis N, Ralston KD, Virtanen S, Fraser HL, Davies CHJ (2010) Grain character influences on corrosion of ECAPed pure magnesium. Corros Eng Sci Technol 45:224–230. https://doi.org/10.1179/147842209X12559428167805

Song G (2012) The effect of texture on the corrosion behavior of AZ31 Mg alloy. Jom 64(6):671–679. https://doi.org/10.1007/s11837-012-0341-1

Wang B, Xu D, Dong J, Ke W (2016) Effect of texture on biodegradable behavior of an As-Extruded Mg–3%Al–1%Zn Alloy in phosphate buffer saline medium. J Mater Sci Technol 32:646–652. https://doi.org/10.1016/j.jmst.2016.02.002

Zhen Z, Liu X, Huang T, Xi T, Zheng Y (2014) Hemolysis and cytotoxicity mecha- nisms of biodegradable magnesium and its alloys. Mater Sci Eng C. https://doi.org/10.1016/j.msec.2014.08.038

Wang J, Witte F, Xi T, Zheng Y, Yang K, Yang Y, Zhao D (2015) Acta biomaterialia recommendation for modifying current cytotoxicity testing standards for biodegradable magnesium-based materials. Acta Biomater 21:237–249. https://doi.org/10.1016/j.actbio.2015.04.011

Acknowledgements

The authors like to thank the Department of Metallurgical and Materials Engineering and Central Research Facility at National Institute of Technology Karnataka for providing access to the various characterization and testing facilities.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rokkala, U., Bontha, S., Ramesh, M.R. et al. Influence of friction stir processing on microstructure, mechanical properties and corrosion behaviour of Mg-Zn-Dy alloy. J Mater Sci 58, 2893–2914 (2023). https://doi.org/10.1007/s10853-023-08208-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08208-w