Abstract

The reduction in the production of conventional polymers based on crude oil by using bio-based plastics and by valorizing rubber wastes is an essential route to reverse the negative impact of the polymer industry on the environment. To contribute to this challenge, we prepared polylactic acid (PLA)/natural rubber (NR)/ground tyre rubber (GTR) blends via dynamic vulcanization. The PLA/NR/GTR blends with a rubber content and above 30 wt% show a continuous rubber phase (NR/GTR) where the GTR particles are encapsulated into the NR matrix as shown by dissolution experiment in dichloromethane and microscopy images on etched samples. PLA/NR/GTR blends with 30 wt% of rubber show a tensile modulus of 1.3 GPa, a tensile toughness of 8.3 MJ m−3 and an impact strength of 260 kJ m−2 higher than 1.1 GPa, 4.2 MJ m−3 and 160 kJ m−2, respectively, for the binary PLA/NR blend. The presence of reinforcing carbon black particles in the GTR as well as their partially vulcanized state of the GTR before dynamic vulcanization may result in a higher cross-linking level of the rubber phase in the ternary blends as compared to binary blends that likely contribute to concomitantly improve tensile modulus, toughness and impact tensile strength.

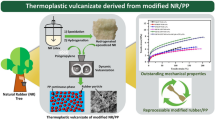

Graphical abstract

Similar content being viewed by others

References

European Commission (2018) A European strategy for plastics in a circular economy

Mekonnen T, Mussone P, Khalil H, Bressler D (2013) Progress in bio-based plastics and plasticizing modifications. J Mater Chem A 1(43):13379–13398. https://doi.org/10.1039/C3TA12555F

Spierling S et al (2018) Bio-based plastics–A review of environmental, social and economic impact assessments. J Clean Prod 185:476–491. https://doi.org/10.1016/j.jclepro.2018.03.014

Iwata T (2015) Biodegradable and bio-based polymers: future prospects of eco-friendly plastics. Angew Chem Int Ed 54(11):3210–3215. https://doi.org/10.1002/anie.201410770

Wool R, Sun XS (2011) Bio-based polymers and composites. Elsevier

Carrasco F, Pagès P, Gámez-Pérez J, Santana OO, Maspoch ML (2010) Processing of poly(lactic acid): characterization of chemical structure, thermal stability and mechanical properties. Polym Degrad Stab 95(2):116–125. https://doi.org/10.1016/j.polymdegradstab.2009.11.045

Cailloux J et al (2019) Melt-processing of cellulose nanofibril/polylactide bionanocomposites via a sustainable polyethylene glycol-based carrier system. Carbohydr Polym 224:115188. https://doi.org/10.1016/j.carbpol.2019.115188

Oguz O et al (2021) Poly(lactide)/cellulose nanocrystal nanocomposites by high-shear mixing. Polym Eng Sci 61(4):1028–1040. https://doi.org/10.1002/pen.25621

Oguz O, Candau N, Citak MK, Cetin FN, Avaz Seven S, Menceloglu YZ (2019) A sustainable approach to produce stiff, super-tough, and heat-resistant poly(lactic acid)-based green materials. ACS Sustain Chem Eng 7(8):7869–7877. https://doi.org/10.1021/acssuschemeng.9b00319

Harada M, Iida K, Okamoto K, Hayashi H, Hirano K (2008) Reactive compatibilization of biodegradable poly(lactic acid)/poly(ε-caprolactone) blends with reactive processing agents. Polym Eng Sci 48(7):1359–1368. https://doi.org/10.1002/pen.21088

Feng Y, Hu Y, Yin J, Zhao G, Jiang W (2013) High impact poly(lactic acid)/poly(ethylene octene) blends prepared by reactive blending. Polym Eng Sci 53(2):389–396. https://doi.org/10.1002/pen.23265

Nagarajan V, Mohanty AK, Misra M (2016) Perspective on polylactic acid (pla) based sustainable materials for durable applications: focus on toughness and heat resistance. ACS Sustain Chem Eng 4(6):2899–2916. https://doi.org/10.1021/acssuschemeng.6b00321

Wang R, Wang S, Zhang Y, Wan C, Ma P (2009) Toughening modification of PLLA/PBS blends via in situ compatibilization. Polym Eng Sci 49(1):26–33. https://doi.org/10.1002/pen.21210

Ma P, Hristova-Bogaerds DG, Goossens JGP, Spoelstra AB, Zhang Y, Lemstra PJ (2012) Toughening of poly(lactic acid) by ethylene-co-vinyl acetate copolymer with different vinyl acetate contents. Eur Polym J 48(1):146–154. https://doi.org/10.1016/j.eurpolymj.2011.10.015

Cailloux J et al (2018) Effect of the viscosity ratio on the PLA/PA10.10 bioblends morphology and mechanical properties. Express Polym Lett 12(6):569–582. https://doi.org/10.3144/expresspolymlett.2018.47

Phattarateera S, Pattamaprom C (2020) The effect of polylactic acid (PLA)/poly-d-lactide stereocomplex on the thermal and mechanical properties of various PLA/rubber blends. Polym Int 69(1):41–49. https://doi.org/10.1002/pi.5916

Zhang L, Hua J, Wang Z (2018) Dynamically vulcanized polylactide/nitrile butadiene rubber blends with continuous cross-linked rubber phase. J Polym Res 26(1):11. https://doi.org/10.1007/s10965-018-1669-1

Maroufkhani M, Katbab A, Bizhani H, Zhang J (2021) Toward morphology development and impact strength of Co-continuous supertough dynamically vulcanized rubber toughened PLA blends: effect of sulfur content. Polymer 217:123439. https://doi.org/10.1016/j.polymer.2021.123439

Chen Y, Yuan D, Xu C (2014) Dynamically vulcanized biobased polylactide/natural rubber blend material with continuous cross-linked rubber phase. ACS Appl Mater Interfaces 6(6):3811–3816. https://doi.org/10.1021/am5004766

Bitinis N, Verdejo R, Cassagnau P, Lopez-Manchado MA (2011) Structure and properties of polylactide/natural rubber blends. Mater Chem Phys 129(3):823–831. https://doi.org/10.1016/jmatchemphys.2011.05.016

Klinkajorn J, Tanrattanakul V (2020) The effect of epoxide content on compatibility of poly(lactic acid)/epoxidized natural rubber blends. J Appl Polym Sci 137(34):48996. https://doi.org/10.1002/app.48996

Boonmahitthisud A, Mongkolvai A, Chuayjuljit S (2021) Toughness improvement in bio-based poly(lactic acid)/epoxidized natural rubber blend reinforced with nanosized silica. J Polym Environ. https://doi.org/10.1007/s10924-021-02063-z

Inkinen S, Hakkarainen M, Albertsson A-C, Södergård A (2011) From lactic acid to poly(lactic acid) (PLA): characterization and analysis of PLA and its precursors. Biomacromol 12(3):523–532. https://doi.org/10.1021/bm101302t

Ikeda Y, Kato A, Kohjiya S, Nakajima Y (2017) Rubber science: A modern approach, Springer, Singapore, p 220 doi https://doi.org/10.1007/978-981-10-2938-7

Chen Y, Yuan D, Xu C (2014) Dynamically vulcanized biobased polylactide/natural rubber blend material with continuous cross-linked rubber phase. ACS Appl Mater Interfaces. https://doi.org/10.1021/am5004766

Yuan D, Chen K, Xu C, Chen Z, Chen Y (2014) Crosslinked bicontinuous biobased PLA/NR blends via dynamic vulcanization using different curing systems. Carbohydr Polym 113:438–445. https://doi.org/10.1016/j.carbpol.2014.07.044

Rabiei S, Shojaei A (2016) Vulcanization kinetics and reversion behavior of natural rubber/styrene-butadiene rubber blend filled with nanodiamond—the role of sulfur curing system. Eur Polym J 81:98–113. https://doi.org/10.1016/j.eurpolymj.2016.05.021

Leroy E, Souid A, Deterre R (2013) A continuous kinetic model of rubber vulcanization predicting induction and reversion. Polym Test 32(3):575–582. https://doi.org/10.1016/j.polymertesting.2013.01.003

Rios-Soberanis CR, Wakayama S, Sakai T, de Rodriguez-Laviada JLÁ, Pérez-Pacheco E (2013) Manufacture of Partially Biodegradable Composite Materials Based on PLA-Tires Powder: Process and Characterization. International Journal of Polymer Science 2013:1–8

Sakai T, Morikiyo T, Rios-Soberanis CR, Yoneyama S, Wakayama S (2013) Effect of crushing method of wasted tire on mechanical behavior on PLA Composites. In: Challenges in mechanics of time-dependent materials and processes in conventional and multifunctional materials. Springer, New York, pp 85–91. https://doi.org/10.1007/978-1-4614-4241-7_13

Oliveira M, Santos E, Araújo A, Fechine GJM, Machado AV, Botelho G (2016) The role of shear and stabilizer on PLA degradation. Polym Test 51:109–116. https://doi.org/10.1016/j.polymertesting.2016.03.005

Yang J, Nie S, Zhu J (2016) A comparative study on different rubbery modifiers: Effect on morphologies, mechanical, and thermal properties of PLA blends. J Appl Polym Sci. https://doi.org/10.1002/app.43340

Yang J, Nie S-B, Ding G-X, Wang Z-F, Gao J-S, Zhu J-B (2015) Mechanical properties, morphologies and thermal decomposition kinetics of poly(lactic acid) toughened by waste rubber powder. Int Polym Process 30:467–475. https://doi.org/10.3139/217.3049

Candau N, Oguz O, León Albiter N, Förster G, Maspoch ML (2021) Poly (lactic acid)/ground tire rubber blends using peroxide vulcanization. Polymers. https://doi.org/10.3390/polym13091496

Al-Malaika S, Amir EJ (1989) Thermoplastic elastomers: part III—Ageing and mechanical properties of natural rubber-reclaimed rubber/polypropylene systems and their role as solid phase dispersants in polypropylene/polyethylene blends. Polym Degrad Stab 26(1):31–41. https://doi.org/10.1016/0141-3910(89)90026-8

Lima P, Oliveira J, Costa V (2014) Partial replacement of EPDM by GTR in thermoplastic elastomers based on PP/EPDM: effects on morphology and mechanical properties, J. Polym. Sci, Appl. https://doi.org/10.1002/app.40160

Lima PS, Oliveira JM, Costa VAF (2015) Partial replacement of EPR by GTR in highly flowable PP/EPR blends: effects on morphology and mechanical properties. J Appl Polym Sci. https://doi.org/10.1002/app.42011

Kumar CR, Fuhrmann I, Karger-Kocsis J (2002) LDPE-based thermoplastic elastomers containing ground tire rubber with and without dynamic curing. Polym Degrad Stab 76(1):137–144. https://doi.org/10.1016/S0141-3910(02)00007-1

Naskar AK, Bhowmick AK, De SK (2001) Thermoplastic elastomeric composition based on ground rubber tire. Polym Eng Sci 41(6):1087–1098. https://doi.org/10.1002/pen.10809

Grigoryeva OP, Fainleib AM, Tolstov AL, Starostenko OM, Lievana E, Karger-Kocsis J (2005) Thermoplastic elastomers based on recycled high-density polyethylene, ethylene–propylene–diene monomer rubber, and ground tire rubber. J Appl Polym Sci 95(3):659–671. https://doi.org/10.1002/app.21177

Wang L, Lang F, Li S, Du F, Wang Z (2014) Thermoplastic elastomers based on high-density polyethylene and waste ground rubber tire composites compatibilized by styrene–butadiene block copolymer. J Thermoplast Compos Mater 27(11):1479–1492. https://doi.org/10.1177/0892705712473628

Fazli A, Rodrigue D (2020) Waste rubber recycling: a review on the evolution and properties of thermoplastic elastomers. Materials. https://doi.org/10.3390/ma13030782

Candau N et al (2020) Effect of the strain rate on damage in filled EPDM during single and cyclic loadings. Polymers. https://doi.org/10.3390/polym12123021

Candau N, Oguz O, Peuvrel-Disdier E, Bouvard J-L, Pradille C, Billon N (2020) Strain and filler ratio transitions from chains network to filler network damage in EPDM during single and cyclic loadings. Polymer 197:122435. https://doi.org/10.1016/j.polymer.2020.122435

Candau N et al (2020) Heat source and voiding signatures of Mullins damage in filled EPDM. Polym Test 91:106838. https://doi.org/10.1016/j.polymertesting.2020.106838

Candau N, Oguz O, Federico CE, Stoclet G, Tahon J-F, Maspoch ML (2021) Strain induced crystallization in vulcanized natural rubber containing ground tire rubber particles with reinforcement and nucleation abilities. Polym Test 101:107313. https://doi.org/10.1016/j.polymertesting.2021.107313

Candau N, Vives E, Fernández AI, Maspoch ML (2021) Elastocaloric effect in vulcanized natural rubber and natural/wastes rubber blends. Polymer 236:124309. https://doi.org/10.1016/j.polymer.2021.124309

Kong Y, Hay JN (2003) The enthalpy of fusion and degree of crystallinity of polymers as measured by DSC. Eur Polym J 39(8):1721–1727. https://doi.org/10.1016/S0014-3057(03)00054-5

Schick C (2009) Differential scanning calorimetry (DSC) of semicrystalline polymers. Anal Bioanal Chem 395(6):1589. https://doi.org/10.1007/s00216-009-3169-y

Garlotta D (2001) A literature review of poly(lactic acid). J Polym Environ 9(2):63–84. https://doi.org/10.1023/A:1020200822435

Talbamrung T, Kasemsook C, Sangtean W, Wachirahuttapong S, Thongpin C (2016) Effect of peroxide and organoclay on thermal and mechanical properties of PLA in PLA/NBR melted blend. Energy Procedia 89:274–281. https://doi.org/10.1016/j.egypro.2016.05.035

Chenal JM, Chazeau L, Bomal Y, Gauthier C (2007) New insights into the cold crystallization of filled natural rubber. J Polym Sci Part B Polym Phys 45(8):955–962. https://doi.org/10.1002/polb.21105

Pongtanayut K, Thongpin C, Santawitee O (2013) The effect of rubber on morphology, thermal properties and mechanical properties of PLA/NR and PLA/ENR blends. Energy Procedia 34:888–897. https://doi.org/10.1016/j.egypro.2013.06.826

Najafi N, M. c. Heuzey,P. j. Carreau, (2013) Crystallization behavior and morphology of polylactide and PLA/clay nanocomposites in the presence of chain extenders. Polym Eng Sci 53(5):1053–1064. https://doi.org/10.1002/pen.23355

Yuan D, Xu C, Chen Z, Chen Y (2014) Crosslinked bicontinuous biobased polylactide/natural rubber materials: Super toughness, “net-like”-structure of NR phase and excellent interfacial adhesion. Polym Test. https://doi.org/10.1016/J.POLYMERTESTING.2014.07.004

Maspoch ML et al (2015) Ductile-brittle transition behaviour of PLA/o-MMT films during the physical aging process. Express Polym Lett 9(3):185–195. https://doi.org/10.3144/expresspolymlett.2015.20

Xu S, Tahon J-F, De-Waele I, Stoclet G, Gaucher V (2020) Brittle-to-ductile transition of PLA induced by macromolecular orientation. EXPRESS Polym Lett 14(11):1037–1047

Stoclet G, Lefebvre JM, Séguéla R, Vanmansart C (2014) In-situ SAXS study of the plastic deformation behavior of polylactide upon cold-drawing. Polymer 55(7):1817–1828. https://doi.org/10.1016/j.polymer.2014.02.010

Candau N et al (2014) Strain-induced crystallization of natural rubber and cross-link densities heterogeneities. Macromolecules 47(16):5815–5824. https://doi.org/10.1021/ma5006843

Flory PJ (1947) Thermodynamics of crystallization in high polymers I crystallization induced by stretching. J Chem Phys 15(6):397–408. https://doi.org/10.1063/1.1746537

Candau N, Chazeau L, Chenal J-M, Gauthier C, Munch E (2016) Complex dependence on the elastically active chains density of the strain induced crystallization of vulcanized natural rubbers, from low to high strain rate. Polymer 97:158–166. https://doi.org/10.1016/j.polymer.2016.05.020

Acknowledgements

The research leading to these results has received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie grant agreement No 712949 (TECNIOspring PLUS) and from the Agency for Business Competitiveness of the Government of Catalonia as well as the Spanish Ministerio de Ciencia e Innovación for the Project PID2019-1006518RB-I00.

Author information

Authors and Affiliations

Contributions

NC was responsible for conceptualization and writing the original draft; NC, NLA and HJ were involved in data curation and software; NC and MLM acquired the funding and carried out supervision; NC, HJ and MLM conducted the investigation; and NC, NLA, HJ and MLM took part in methodology, visualization and writing—reviewing and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Chris Cornelius.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Candau, N., León Albiter, N., Jeannot, H. et al. Dynamically vulcanized polylactic acid/natural rubber/waste rubber blends: effect of the rubber content. J Mater Sci 57, 17902–17919 (2022). https://doi.org/10.1007/s10853-022-07795-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07795-4