Abstract

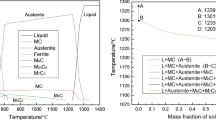

Precipitation behavior of carbide/carbonitride in high-strength low-carbon steel is significantly affected by the ferrite transformation modes, which may change from the negligible partitional local equilibrium mode to the partitional local equilibrium mode as holding temperature increases or holding time increases at a certain temperature for ferrite phase transformation. Herein, the isothermal precipitation behavior of V(C, N) under negligible partitional local equilibrium mode of ferrite transformation in V-, N-added low carbon steel has been investigated. Not only the complex precipitation coexisting phenomenon of random precipitation and fibrous precipitation but also that of random precipitation and interphase precipitation was observed and certificated by the selected area electron diffraction patterns. In addition to Baker–Nutting orientation relationship, the Kurdjumov–Sachs OR [111]α//[110]P, \(\left( {1\overline{1}0} \right){\upalpha }//\left( {1\overline{1}\overline{1}} \right)\) P between ferrite and interphase precipitation were found. Due to big variation in the movement velocity of austenite/ferrite interface, non-uniform distribution of precipitates occurred, resulting in hardness of ferrite grains changing from 185 to 215 HV.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

Guo J, Shang C, Yang S, Guo H, Wang X, He X (2009) Weather resistance of low carbon high performance bridge steel. Mater Des 30:129–134

Ghosh A, Das S, Chatterjee S, Rao PR (2006) Effect of cooling rate on structure and properties of an ultra-low carbon HSLA-100 grade steel. Mater Charact 56:59–65

Funakawa Y, Shiozaki T, Tomita K, Yamamoto T, Maeda E (2004) Development of high strength hot-rolled sheet steel consisting of ferrite and nanometer-sized carbides. ISIJ Int 44:1945–1951

Chen CY, Chen CC, Yang JR (2014) Microstructure characterization of nanometer carbides heterogeneous precipitation in Ti–Nb and Ti–Nb–Mo steel. Mater Charact 88:69–79

Tsai S, Su T, Yang J, Chen C, Wang Y, Huang C (2017) Effect of Cr and Al additions on the development of interphase-precipitated carbides strengthened dual-phase Ti-bearing steels. Mater Des 119:319–325

Tsai S, Tsai Y, Chen Y, Yang J, Chen C, Wang Y, Huang C (2018) Precipitation behavior in bimodal ferrite grains in a low carbon Ti–V–bearing steel. Scripta Mater 143:103–107

Kui LZ, Ågren J (1989) On the transition from local equilibrium to paraequilibrium during the growth of ferrite in Fe–Mn–C austenite. Acta Metall 37:3157–3163

Perevoshchikova N, Appolaire B, Teixeira J, Aeby-Gautier E, Denis S (2014) Investigation of the growth kinetics of γ→α in Fe–C–X alloys with a thick interface model. Comp Mater Sci 82:151–158

Yen H, Chen P, Huang C, Yang J (2011) Interphase precipitation of nanometer-sized carbides in a titanium–molybdenum-bearing low-carbon steel. Aata Mater 59:6264–6274

Dong H, Chen H, Zhang C, Yang Z (2018) An overview of interphase precipitation of nano-carbide in low alloy steels. Mater China 37:403–409

Honeycombe RWK, Mehl RF (1976) Transformation from austenite in alloy steels. Metal Trans A 7:915–936

Ricks RA, Howell PR (1983) The formation of discrete precipitate dispersions on mobile interphase boundaries in iron-base alloys[J]. Acta Metall 31(6):853–861

Ricks RA, Howell PR (1982) Bowing mechanism for interphase boundary migration in alloy steels[J]. Metal Sci 16(6):317–322

Okamoto R, Borgenstam A, Ågren J (2010) Interphase precipitation in niobium-microalloyed steels. Acta Mater 58:4783–4790

Li X, Wang Z (2015) Interphase precipitation behaviors of nanometer-sized carbides in a Nb–Ti-bearing low-carbon microalloyed steel. Acta Metall Sin 51(4):417–424

Chen MY, Gouné M, Verdier M, Bréchet Y, Yang JR (2014) Interphase precipitation in vanadium-alloyed steels: strengthening contribution and morphological variability with austenite to ferrite transformation. Acta Mater 64:78–92

Chen CY, Yen HW, Kao FH, Li WC, Huang CY, Yang JR, Wang SH (2009) Precipitation hardening of high-strength low-alloy steels by nanometer-sized carbides. Mater Sci Eng A 499:162–166

Bu FZ, Wang XM, Yang SW, Shang CJ, Misra RDK (2015) Contribution of interphase precipitation on yield strength in thermomechanically simulated Ti–Nb and Ti–Nb–Mo microalloyed steels. Mater Sci Eng A 620:22–29

Yuan CC, Fan CS, Chon CC, Ren YJ (2015) Control of precipitation morphology in the novel HSLA steel. Mater Sci Eng A 634:123–133

Murakami T, Hatano H, Miyamoto G, Furuhara T (2012) Effects of ferrite growth rate on interphase boundary precipitation in V microalloyed steels. ISIJ Int 52:616–625

Clark S, Janik V, Lan Y, Sridhar S (2017) Interphase precipitation—an interfacial segregation model. ISIJ Int 57:524–532

Enomoto M, Ibaraki UJ (1999) Influence of solute drag on the growth of proeutectoid ferrite in Fe–C–Mn alloy. Acta Mater 47:3533–3540

Chen H, Zwaag SVD (2014) A general mixed-mode model for the austenite-to-ferrite transformation kinetics in Fe–C–M alloys. Acta Mater 72:1–12

Aaronson HI, Furuhara T, Hall MG, Hirth JP, Nie JF, Purdy GR, Reynolds WT (2006) On the mechanism of formation of diffusional plate-shaped transformation products. Acta Mater 54:1227–1232

Yuan CC, Chon CC, Ren YJ (2015) Dualism of precipitation morphology in high strength low alloy steel. Mater Sci Eng A 626:74–79

Miyamoto G, Hori R, Poorganji B, Furuhara T (2013) Crystallographic analysis of proeutectoid ferrite/austenite interface and interphase precipitation of vanadium carbide in medium-carbon steel. Metall Mater Trans A 44:3436–3443

Kamikawa N, Abe Y, Miyamoto G, Funakawa Y, Furuhara T (2014) Tensile behavior of Ti, Mo-added low carbon steels with interphase precipitation. ISIJ Int 54:212–221

Gong P, Liu XG, Rijkenberg A, Rainforth WM (2018) The effect of molybdenum on interphase precipitation and microstructures in microalloyed steels containing titanium and vanadium. Acta Mater 161:374–387

Jang JH, Heo Y, Lee C, Bhadeshia HKDH, Suh D (2014) Interphase precipitation in Ti–Nb and Ti–Nb–Mo bearing steel. Mater Sci Technol 29:309–313

Dhal A, Panigrahi SK, Shunmugam MS (2015) Precipitation phenomena, thermal stability and grain growth kinetics in an ultra-fine grained Al 2014 alloy after annealing treatment. J Alloy Compd 649:229–238

Chen C, Chen C, Yang J (2015) Synergistic effect of austenitizing temperature and hot plastic deformation strain on the precipitation behavior in novel HSLA steel. Mater Sci Eng A 639:145–154

Yong QL (2006) Secondary phase in steels. Metallurgical Industry Press, Beijing

Lee W, Hong S, Park C, Park S (2002) Carbide precipitation and high-temperature strength of hot-rolled high-strength, low-alloy steels containing Nb and Mo. Metall Mater Trans A 33:1689–1698

Baker TN (2009) Processes, microstructure and properties of vanadium microalloyed steels. Mater Sci Technol 25(9):1083–1107

Chen M, Yen H, Yang J (2013) The transition from interphase-precipitated carbides to fibrous carbides in a vanadium-containing medium-carbon steel. Scripta Mater 68:829–832

Chen J, Lv M, Tang S, Liu Z, Wang G (2014) Influence of cooling paths on microstructural characteristics and precipitation behaviors in a low carbon V–Ti microalloyed steel. Mater Sci Eng A 594:389–393

Miyata K, Kushida T, Omura T, Komizo Y (2003) Coarsening kinetics of multicomponent MC-type carbides in high-strength low-alloy steels. Metall Mater Trans A 34:1565–1573

Bramfitt BL (1970) The effect of carbide and nitride additions on the heterogeneous nucleation behavior of liquid iron. Metall Mater Trans B 1:1987–1995

Dunlop GL, Carlsson C, Frimodig G (1978) Precipitation of VC in ferrite and pearlite during direct transformation of a medium carbon microalloyed steel. Metall Trans A 9:261–266

Acknowledgements

This work is financially supported by National Key R&D Program of China from the Ministry of Science and Technology of China under Grant No. 2017YFB0305300 and the Opening Foundation of Anhui Province Key Laboratory of Metallurgical Engineering & Resources Recycling under Grant No. SKF19-02.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: P. Nash.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, Y., Zhang, X.F., Li, Y.M. et al. Complex isothermal precipitation behavior of V(C, N) in V-, N-added low carbon steel. J Mater Sci 56, 2638–2649 (2021). https://doi.org/10.1007/s10853-020-05385-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05385-w