Abstract

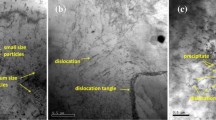

Precipitation behavior and elemental distribution of MC carbides in high carbon and vanadium high-speed steel were analyzed through the thermodynamic calculations and experimental measurements. The results illustrated that the primary MC carbide always nucleated from the fine inclusions or particles as the heterogeneous nuclei and was followed by the occurrence of eutectic reaction (L→γ + MC). 2D lumpy (primary) and stripe-like (eutectic) MC carbides were mainly formed inside the grains, the former was mainly in hexahedral shape with four-leaf grass-shaped surface and few in complex polyhedral shape with short branches, while the latter was mainly in clustered coral-like morphologies. High cooling rate can effectively refine the size and reduce the quantity of primary MC, it can also promote the uniform precipitation of fine eutectic MC. The primary MC precipitated preferentially contained more N, C, V, and less Cr, Mo, W with a better uniformity of elemental distribution when compared with that in eutectic MC. For the latter, its composition (mainly V) changed obviously which was mainly affected by the carbide’s quantity, distribution characteristic, and the actual solute concentration during the solidification process. Generally, the more quantity and much denser distribution of the eutectic MC branches, the less contents of C and V in the eutectic MC branches. Based on the 2D and 3D morphologies of MC carbides, the primary MC showed good symmetry and the eutectic MC showed an obvious directionality of its branch from grain interior to grain boundary. It provided an effective reference for further research on the growth mechanism of carbides.

Similar content being viewed by others

References

Y. Sano, T. Hattori and M. Haga, Characteristics of High Carbon High Speed Steel Rolls for Hot Strip Mill, ISIJ Int., 1992, 32(11), p 1194–1201

H.G. Fu, H.J. Zhao, Z.Z. Du, Z.J. Feng, Y.P. Lei, Y. Zhang, M.W. Li, Y.H. Jiang, R. Zhou and H.X. Guo, Heat Treatment of Centrifugally Cast High Carbon High Vanadium High Speed Steel Mill Roll, Ironmak. Steelmak., 2011, 38(5), p 338–345

C.K. Kim, P.I. Jong, S. Lee, Y.C. Kim, N.J. Kim and J.S. Yang, Effects of Alloying Alements on Microstructure, Hardness, and Fracture Toughness of Centrifugally Cast High-speed Steel Rolls, Metall. Mater. Trans. A, 2005, 36(1), p 87–97

C. Rodenburg and W.M. Rainforth, A Quantitative Analysis of the Influence of Carbides Size Distributions on Wear Behaviour of High-Speed Steel in Dry Rolling/Sliding Contact, Acta Mater., 2007, 55(7), p 2443–2454

L.J. Xu, W.L. Song, S.Q. Ma, Y.C. Zhou, K.M. Pan and S.Z. Wei, Effect of Slippage Rate on Frictional Wear Behaviors of High-Speed Steel with Dual-Scale Tungsten Carbides (M6C) Under High-Pressure Sliding-Rolling Condition, Tribol. Int., 2021, 154, p 106719

J.M. Artimez, j. García, J.M. Llano, M. Alvaré, and J. Belzunce, Characterization of MxCy Carbides Present in High Speed Steel (HSS) Rolls Manufactured by Centrifugal Casting Method. In: 17th Rolling Conference, 2008, Rosario, Argentina, pp. 484–493

L.J. Xu, S.Z. Wei, F.N. Xiao, H. Zhou, G.S. Zhang and J.W. Li, Effects of Carbides on Abrasive Wear Properties and Failure Behaviours of High Speed Steels with Different Alloy Element Content, Wear, 2017, 376–377, p 968–974

M. Pellizzari, D. Cescato and M.G. De Flora, Hot Friction and Wear Behaviour of High Speed Steel and High Chromium Iron for Rolls, Wear, 2009, 267, p 467–475

L.J. Xu, J.D. Xing, S.Z. Wei, Y.Z. Zhang and R. Long, Investigation on Wear Behaviors of High-Vanadium High-speed Steel Compared with High-Chromium Cast Iron Under Rolling Contact Condition, Mater. Sci. Eng. A, 2006, 434, p 63–70

Y. Miyasaka, K. Enami and T. Tanikawa, Effects of Vanadium Addition on Formation of Carbides of High Carbon High Speed Steel, J. Jpn. Foundry, 1997, 69(3), p 201–206

M. Pellizzari, Thermodynamic Modeling for the Alloy Design of High Speed Steels and High Chromium Cast irons, Mater. Technol., 2010, 44(3), p 121–127

Y.W. Yang, H.G. Fu, J. Ju, Y.P. Lei, L.L. Zhu and L. Jiang, Phase Diagram Calculation and Analyze on Cast High Vanadium Wear-Resistant Alloy, Metall. Res. Technol., 2017, 114(3), p 314

S.Z. Wei, J.H. Zhu and L.J. Xu, Mater, Research on Wear Resistance of High Speed Steel with High Vanadium Content, Sci. Eng. A, 2005, 404, p 138–145

L.J. Xu, S.Z. Wei, J.D. Xing and R. Long, Effects of Carbon Content and Sliding Ratio on Wear Behavior of High-Vanadium High-Speed Steel (HVHSS) under High-Stress Rolling–Sliding Contact, Tribol. Int., 2014, 70, p 34–41

Y.W. Yang, H.G. Fu, Y.P. Lei, K.M. Wang, L.L. Zhu and L. Jiang, Phase Diagram Calculation and Analyze on Cast High-Boron High-Speed Steel, J. Mater. Eng. Perform., 2016, 25(2), p 409–420

M.T. Mao, H.J. Guo, F. Wang and X.L. Sun, Effect of Cooling Rate on the Solidification Microstructure and Characteristics of Primary Carbides in H13 Steel, ISIJ Int., 2019, 59(5), p 848–857

W.C. Jiao, H.B. Li, H. Feng, Z.H. Jiang, J. Dai, H.C. Zhu, S.C. Zhang, M.S. Chu and W. Wu, Effect of High Nitrogen Addition on Microstructure and Mechanical Properties of As-cast M42 High Speed Steel, ISIJ Int., 2020, 60(3), p 564–572

U. Klančnik, B. Košec, P. Mrvar and J. Medved, Non-equilibrium Solidification and Microsegregation in Centrifugally Cast High Speed Steel for Rolls, J. Min. Metall. Sect. B-Metall., 2018, 54(1), p 59–66

H. Miyahara, S.V. Bravo, K. Yamamoto and K. Ogi, Solute Concentration and Carbides Formation for Steel Milling rolls, ISIJ Int., 2009, 49(7), p 1075–1079

S.K. Choudhary and A. Ghosh, Mathematical Model for Prediction of Composition of Inclusions Formed during Solidification of Liquid Steel, ISIJ Int., 2009, 49(12), p 1819–1827

J. Golczewski and H.F. Fischmeister, Calculation of Phase Equilibria for AISI M2 High-Speed Steel, Steel Res., 1992, 63(8), p 354–360

G.Q. Shi, P.D. Ding and S.Z. Zhou, Effect of Vanadium on Cast Carbide in High Speed Steels, Mater. Sci. Technol., 1992, 8(5), p 449–454

P.D. Ding, G.Q. Shi and S.Z. Zhou, As-Cast Carbides in High-Speed Steels, Metal. Trans. A, 1993, 24(6), p 1265–1272

Y.J. Kang, J.C. Oh, H.C. Lee and S. Lee, Effects of Carbon and Chromium Additions on the Wear Resistance and Surface Roughness of Cast High-Speed Steel Rolls, Metall. Mater. Trans. A, 2001, 32(10), p 2515–2525

J. Zhang, J. Li, C.B. Shi and J. Huang, Growth and Agglomeration Behaviors of Eutectic M7C3 Carbide in Electroslag Remelted Martensitic Stainless Steel, J. Mater. Res. Technol., 2021, 11, p 1490–1505

P. Maugis and M. Gouné, Kinetics of Vanadium Carbonitride Precipitation in Steel: A Computer Model, Acta Mater., 2005, 53, p 3359–3367

K. Narita, Physical Chemistry of the Groups Iva (Ti, Zr), Va(V, Nb, Ta) and the Rare Earth Elements in Steel, Trans. ISIJ, 1975, 15(3), p 145–152

Y.F. Zhou, Y.L. Yang, J. Yang, F.F. Hao, D. Li, X.J. Ren and Q.X. Yang, Effect of Ti Additive on (Cr, Fe)7C3 Carbide in Arc Surfacing Layer and Its Refined Mechanism, Appl. Surf. Sci., 2012, 258, p 6653–6659

D. Turnbull and B. Vonnegut, Nucleation Catalysis, Ind. Eng. Chem., 1952, 44(6), p 1292–1298

O.V. Andreev, N.N. Parshukov, A.V. Kertman and T.M. Kislovskaya, Phase Equilibria in the CaS-Y2S3 System, Russ. J. Inorg. Chem., 1996, 41(2), p 284–288

R. Basso, S. Carbonin and A.D. Giusta, Cation and Vacancy Distribution in a Synthetic Defect Spine, Z. Kristallogr., 1991, 194(1–2), p 111–119

B.L. Bramfitt, The Effect of Carbide and Nitride Additions on the Heterogeneous Nucleation Behavior of Liquid Iron, Metal. Trans., 1970, 1(7), p 1987–1995

N. Hirashita and J.E. Greene, Electronic Properties of Epitaxial TiN/VN (001) Superlattices, J. Appl. Phys., 1991, 70(9), p 4963–4968

M. Godec, B.Š Batič, D. Mandrino, A. Nagode, V. Leskovšek, S.D. Škapin and M. Jenko, Characterization of the Carbides and the Martensite Phase in Powder-Metallurgy High Speed Steel, Mater. Charact., 2010, 61, p 452–458

J.B. Wang, X.L. Xing, Y.F. Zhou, S.C. Liu, X.W. Qi and Q.X. Yang, Formation Mechanism of Ultrafine M7C3 Carbide in a Hypereutectic Fe-25Cr-4C-05Ti-05Nb-02N-2LaAlO3 Hardfacing Alloy Layer, J. Mater. Res. Technol., 2020, 9, p 7711–7720

Acknowledgment

The authors are very grateful to the financial support of National Natural Science Foundation of China (52004188). We also would like to thank the Analytical & Testing Center of Wuhan University of Science and Technology for the help on EPMA analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cao, Y., Zhao, Z., Ma, C. et al. Precipitation Behavior and Elemental Distribution of MC Carbides in High Carbon and Vanadium High-Speed Steel. J. of Materi Eng and Perform 31, 4444–4458 (2022). https://doi.org/10.1007/s11665-021-06553-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06553-y