Abstract

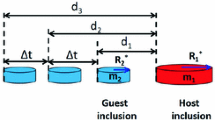

Particle aggregation is a widespread phenomenon spontaneously occurring in nature, and it is also widely explored in industry, for instance, metallurgical engineering and colloid chemical engineering. In this work, deformation behavior of Al2O3 aggregates in liquid steel is investigated as a case study. Using high-temperature confocal laser scanning microscopy, the morphologies of Al2O3 chain aggregates during their deformation are observed in situ at liquid steel/Ar interface. Thereafter, the change of morphology of aggregates over time is quantitatively investigated, and the results show that circularity of aggregates increases during deformation. This fact indicates that the morphology of aggregates tends towards spherical with time. The bending forces between the particles in an aggregate during the deformation are calculated based on the experimental data obtained from in situ observations. The force exerted to cause bending is predicted by the capillary force model established for attractive capillary force of inclusions. It is found that the bending force is slightly lower than the capillary force, and this indicates that the capillary force plays a significant role in the bending of aggregates during deformation. Moreover, the difference between the two forces is due to a resistance force existed from inflection part of the aggregate during deformation. The residence is quantitatively evaluated, and there is a clear tendency showing that the resistance force increases with decreasing distance between two particles during bending. In addition, initial sintering between contacted particles after bending is reported, and the radius of neck formed between sintered particles is evaluated. Finally, the effects of inclusion size and steel flow velocity in actual steelmaking process on the radius of neck and shear stress exerted on the sintered neck during deformation are discussed.

Similar content being viewed by others

References

Elimelech M, Gregory J, Jia X (1998) Particle deposition and aggregation: measurement, modelling and simulation. Butterworth-Heinemann, Oxford

Russel WB, Saville DA, Schowalter WR (1989) Colloidal dispersions. Cambridge University Press, Cambridge

Kim AY, Hauch KD, Berg JC, Martin JE, Anderson RA (2003) Linear chains and chain-like fractals from electrostatic hetero-aggregation. J Colloid Interface Sci 260(1):149–159

Pratsinis SE, Kim KS (1989) Particle coagulation, diffusion and thermophoresis in laminar tube flows. J Aerosol Sci 20(1):101–111

Dickinson E, Eriksson L (1991) Particle flocculation by adsorbing polymers. Adv Coll Interface Sci 34:1–29

Gibbs RJ, Konwar L (1986) Coagulation and settling of Amazon River suspended sediment. Cont Shelf Res 6(1–2):127–149

Edzwald JK (1993) Coagulation in drinking water treatment: particles, organics and coagulants. Water Sci Technol 27(11):21–35

Antunes E, Garcia FAP, Ferreira P, Rasteiro MG (2008) Flocculation of PCC filler in papermaking: influence of the particle characteristics. Chem Eng Res Des 86(10):1155–1160

Fagan CC, Castillo M, Payne FA, O’Donnell CP, Leedy M, O’Callaghan DJ (2007) Novel online sensor technology for continuous monitoring of milk coagulation and whey separation in cheese making. J Agric Food Chem 55(22):8836–8844

Friedlander SK (1977) Smoke, dust and haze: fundamentals of aerosol behavior, 2nd edn. Wiley-Inter science, New York

Schmidt Ott A (1988) In situ measurement of the fractal dimensionality of ultrafine aerosol particles. Appl Phys Lett 52(12):954–956

Weber AP, Friedlander SK (1997) In situ determination of the activation energy for restructuring of nanometer aerosol agglomerates. J Aerosol Sci 28(2):179–192

Yin H, Shibata H, Emi T, Suzuki M (1997) “In-situ” observation of collision, agglomeration and cluster formation of alumina inclusion particles on steel melts. ISIJ Int 37(10):936–945

Mu W, Dogan N, Coley KS (2017) Agglomeration of non-metallic inclusions at steel/Ar interface: in situ observation experiments and model validation. Metall Mater Trans B 48:2379–2388. https://doi.org/10.1007/s11663-017-1027-4

Malmberg KJ, Shibata H, Kitamura SY, Jönsson PG, Nabeshima S, Kishimoto Y (2010) Observed behavior of various oxide inclusions in front of a solidifying low-carbon steel shell. J Mater Sci 45(8):2157–2164. https://doi.org/10.1007/s10853-009-3982-x

Janis J, Nakajima K, Karasev A, Shibata H, Jönsson PG (2010) An experimental study on the influence of particles on grain boundary migration. J Mater Sci 45(8):2233–2238. https://doi.org/10.1007/s10853-009-3908-7

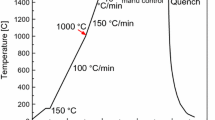

Zhang D, Shintaku Y, Suzuki S, Komizo YI (2012) Effect of cooling rate on phase transformation in the low-carbon boron-treated steel. J Mater Sci 47(14):5524–5528. https://doi.org/10.1007/s10853-012-6444-9

Wan XL, Wei R, Cheng L, Enomoto M, Adachi Y (2013) Lengthening kinetics of ferrite plates in high-strength low-carbon low alloy steel. J Mater Sci 48(12):4345–4355. https://doi.org/10.1007/s10853-013-7250-8

Mu W, Jönsson PG, Nakajima K (2016) Prediction of intragranular ferrite nucleation from TiO, TiN, and VN inclusions. J Mater Sci 51(4):2168–2180. https://doi.org/10.1007/s10853-015-9527-6

Sasai K, Mizukami Y (2001) Mechanism of alumina adhesion to continuous caster nozzle with reoxidation of molten steel. ISIJ Int 41(11):1331–1339

Sasai K (2014) Direct measurement of agglomeration force exerted between alumina particles in molten steel. ISIJ Int 54(12):2780–2789

Mizoguchi T, Ueshima Y, Sugiyama M, Mizukami K (2013) Influence of unstable non-equilibrium liquid iron oxide on clustering of alumina particles in steel. ISIJ Int 53(4):639–647

Wikström J, Nakajima K, Shibata H, Tilliander A, Jönsson P (2008) In situ studies of agglomeration between Al2O3-CaO inclusions at metal/gas, metal/slag interfaces and in slag. Ironmak Steelmak 35(8):589–599

Forrest SR, Witten TA Jr (1979) Long-range correlations in smoke-particle aggregates. J Phys A Math Gen 12(5):L109

Doo WC, Kim DY, Kang SC, Yi KW (2007) Measurement of the 2-dimensional fractal dimensions of alumina clusters formed in an ultra-low carbon steel melt during RH process. ISIJ Int 47(7):1070–1072

Mu W, Dogan N, Coley KS (2017) Agglomeration of non-metallic inclusions at the steel/Ar interface: model application. Metall Mater Trans B 48:2092–2103. https://doi.org/10.1007/s11663-017-0998-5

Kimura S, Nakajima K, Mizoguchi S (2001) Behavior of alumina-magnesia complex inclusions and magnesia inclusions on the surface of molten low-carbon steels. Metall Mater Trans 32:79–85

Nakajima K, Mizoguchi S (2001) Capillary interaction between inclusion particles on the 16Cr stainless steel melt surface. Metall Mater Trans 32:629–641

Coble RL (1958) Initial sintering of alumina and hematite. J Am Ceram Soc 41(2):55–62

Ooi H, Sekine M, Kasai G (1973) On the mechanisms of alumina cluster formation in molten iron. Tetsu-to-Hagané 59(8):1078–1088

Xuan C, Karasev AV, Jönsson PG, Nakajima K (2017) Attraction force estimations of Al2O3 particle agglomerations in the melt. Steel Res Int 88(2):262–270

Nogi K, Ogino K (1983) Role of interfacial phenomena in deoxidation process of molten iron. Can Metall Q 22(1):19–28

Braun TB, Elliott JF, Flemings MC (1979) The clustering of alumina inclusions. Metall Mater Trans B 10(2):171–184

Noro A, Kaneko M, Murata I, Yoshinari M (2013) Influence of surface topography and surface physicochemistry on wettability of zirconia (tetragonal zirconia polycrystal). J Biomed Mater Res B Appl Biomater 101(2):355–363

Mandelbrot Benoit B (1983) The fractal geometry of nature. Macmillan, London. ISBN 978-0-7167-1186-5

Tsukaguchi Y, Hayashi H, Kurimoto H, Yokoya S, Marukawa K, Tanaka T (2010) Development of swirling-flow submerged entry nozzles for slab casting. ISIJ Int 50(5):721–729

Acknowledgements

The Natural Sciences and Engineering Research Council of Canada (NSERC), Canada Foundation for Innovation John Evans Leaders Fund (CFI JELF, Project No. 32826), and McMaster Steel Research Centre (SRC) members are acknowledged for funding this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mu, W., Dogan, N. & Coley, K.S. In situ observation of deformation behavior of chain aggregate inclusions: a case study for Al2O3 at a liquid steel/argon interface. J Mater Sci 53, 13203–13215 (2018). https://doi.org/10.1007/s10853-018-2557-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2557-0