Abstract

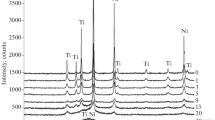

Mechanically induced reactive synthesis of TiN via magnetically controlled ball milling of titanium under nitrogen gas was investigated using X-ray diffraction, advanced electron microscopy and Raman spectroscopy. Ball milling of titanium powder with nitrogen gas was performed in Uni-Ball-Mill, with external temperature of the vial and initial pressures of the nitrogen gas monitored, while the milled samples were taken out periodically, both before and after detection of an exothermic ignition point. Before ignition, nitrogen-enriched Ti, small proportions of TiN and very minor amounts of Ti2N are formed, in addition to the heavily deformed Ti. Raman spectroscopy revealed the pre-ignition products to include off-stoichiometric nitrides (TiNx) and oxynitride skin (TiOxNy). The formation of the new TiN and Ti2N products before ignition was attributed to the diffusion of highly polarized active N atoms into the mechanically activated clean surfaces of Ti, followed by local reaction. This local reaction is likely promoted by numerous cycles of induced local temperature rise and rapid quenching, large surface area and accumulation of deformation defects. After the exothermic ignition, there was rapid nucleation of new TiN crystals, and simultaneous growth of the pre-existing TiN and the newly formed TiN crystals. This understanding explains the reaction pathways leading to the formation of small proportions of TiN and very minor amounts of Ti2N before ignition and the thin-plated TiN after ignition.

Similar content being viewed by others

References

Gotor FJ, Alcala MD, Real C, Criado JM (2002) Combustion synthesis of TiN induced by high-energy ball milling of Ti under nitrogen atmosphere. J Mater Res 17(7):1655–1663

Chin ZH, Perng TP (1997) In situ observation of combustion to form TiN during ball milling Ti in nitrogen. Appl Phys Lett 75(18):2380–2382

Chin ZH, Perng T (1997) Instant formation of TiN by reactive milling of Ti in nitrogen. Mater Sci Forum 235–238:73–78

Wexler Parker D, Palm V, Calka A (2004) Mechano-synthesis and compaction of titanium–titanium nitride composites. Mater Sci Eng, A 375:905–910

Bhaskar U, Bid S, Satpati B, Pradhan SK (2010) Mechanosynthesis of nanocrystalline titanium nitride and its microstructure characterization. J Alloys Compds 493(1):192–196

El-Eskandarany MS, Sumiyama K, Aoki K, Suzuki K (1992) Morphological and structural evolutions of nonequilibrium titanium-nitride alloy powders produced by reactive ball milling. J Mater Res 7(04):888–893

Calka A (1991) Formation of titanium and zirconium nitrides by mechanical alloying. Appl Phys Lett 59(13):1568–1569

Zhang H, Kisi EH, Myhra S (1996) A solid solution pumping mechanism for the nitrogenation of titanium during mechanical deformation in air. J Phys D Appl Phys 29(5):1367–1372

Zhang F, Kaczmarek WA, Lu L, Lai MO (2000) Formation of titanium nitrides via wet reaction ball milling. J Alloys Compds 307(1–2):249–253

Campbell S, Hofmann M, Calka A (2000) The synthesis of TiN by ball-milling—a neutron diffraction study. Phys B Cond Matter 276:899–900

Wexler D, Calka A, Mosbah AY (2000) Ti–TiN hardmetals prepared by in situ formation of TiN during reactive ball milling of Ti in ammonia. J alloys Compds 309(1):201–207

Sun JF, Wang MZ, Zhao YC, Li XP, Liang BY (2009) Synthesis of titanium nitride powders by reactive ball milling of titanium and urea. J Alloys Compds 482(1):L29–L31

Bolokang AS, Phasha MJ (2010) Formation of titanium nitride produced from nanocrystalline titanium powder under nitrogen atmosphere. Int J Refrac Metals Hard Mater 28(5):610–615

Liu G, Li J, and Chen K (2011) Combustion synthesis of ceramic powders with controlled grain morphologies. Intech open access publisher 49–74

Kaneko K et al (2010) Fabrication and characterization of TiN nanocomposite powders fabricated by DC arc-plasma method. J Alloys Compds 492(1):685–690

Eslamloo-Grami M, Munir ZA (1990) Effect of nitrogen pressure and diluent content on the combustion synthesis of titanium nitride. J Am Ceram Soc 73(8):2222–2227

Mosbah A, Calka A, Wexler D (2006) Rapid synthesis of titanium nitride powder by electrical discharge assisted mechanical milling. J Alloys Compds 424(1):279–282

Takacs L (2002) Self-sustaining reactions induced by ball milling. Prog Mater Sci 47(4):355–414

Ding Z et al (2005) Formation of titanium nitride by mechanical milling and isothermal annealing of titanium and boron nitride. J Alloys Compds 391(1):77–81

Kudaka K, Iizumi K, Sasaki T (1999) Mechanochemical syntheses of titanium carbide, diboride and nitride. J Ceram Soc Jpn 107(11):1019–1024

Suryanarayana C (2001) Mechanical alloying and milling. Prog Mater Sci 46(1):1–184

Schaffer GB, McCormick PG (1989) Combustion synthesis by mechanical alloying. Scripta Metall 23(6):835–838

Schaffer GB, McCormick PG (1991) Anomalous combustion effects during mechanical alloying. Metall Trans A 22(12):3019–3024

Delogu F (2013) Activation of self-sustaining high-temperature reactions by mechanical processing of Ti–C powder mixtures. Scripta Mater 69(3):223–226

Deidda C, Delogu F, Maglia F, Anselmi-Tamburini U, Cocco G (2004) Mechanical processing and self-sustaining high-temperature synthesis of TiC powders. Mater Sci Eng, A 375–377(1–2):800–803

Delogu F, Takacs L (2014) Mechanochemistry of Ti–C powder mixtures. Acta Mater 80:435–444

Yang H, McCormick PG (1993) Synthesis of titanium oxynitride by mechanical milling. J Mater Sci 28(20):5663–5667. doi:10.1007/BF00367844

Calka A, Williams JS (1992) Synthesis of nitrides by mechanical alloying. Mater Sci Forum 88–90:787–794

Rochana P, Lee K, Wilcox J (2014) Nitrogen adsorption, dissociation, and subsurface diffusion on the Vanadium (110) surface: a DFT study for the nitrogen-selective catalytic membrane application. J Phys Chem C 118(8):4238–4249

Hu X, Tu R, Wei J, Pan C, Guo J, Xiao W (2014) Nitrogen atom diffusion into TiO2 anatase bulk via surfaces. Comp Mater Sci 82:107–113

Oghenevweta JE, David W, Calka A (2016) Early stages of phase formation before the ignition peak during mechanically induced self-propagating reactions (MSRs) of titanium and graphite. Scripta Mater 122:93–97

Oghenevweta JE, Wexler D, Calka A (2017) Sequence of phase evolution during mechanically induced self-propagating reaction synthesis of TiB and TiB2 via magnetically controlled ball milling of titanium and boron powders. J Alloys Compds 701:380–391

Ghosh B, Pradhan SK (2010) Microstructure characterization of nanocrystalline TiC synthesized by mechanical alloying. Mater Chem Phys 120(2):537–545

Lutterotti L (2008) Quantitative rietveld analysis in batch mode with Maud. http://www.ing.unitn.it/~maud

Mitchell DRG, Van den Berg JA (2016) Development of an ellipse fitting method with which to analyse selected area electron diffraction patterns. Ultramicroscopy 160:140–145

Mitchell DRG (2008) DiffTools: electron diffraction software tools for DigitalMicrograph™. Micro Res Tech 71(8):588–593

Fecht HJ (1995) Nanostructure formation by mechanical attrition. Nanostruc Mater 6(1–4):33–42

Spengler W, Kaiser R (1976) First and second order Raman scattering in transition metal compounds. Solid State Commun 18(7):881–884

Stoehr M, Shin CS, Petrov I, Greene JE (2011) Raman scattering from TiNx (0.67 ≤ x ≤ 1.00) single crystals grown on MgO (001). J Appl Phys 110(8):083503

Ding ZH, Yao B, Qiu LX, Lv TQ (2006) Raman scattering investigation of nanocrystalline δ-TiNx synthesized by solid-state reaction. J Alloys Compds 421(1):247–251

Dreiling I, Raisch C, Glaser J, Stiens D, Chassé T (2011) Characterization and oxidation behavior of MTCVD Ti–B–N coatings. Surf Coatings Technol 206(2–3):479–486

Constable CP, Yarwood J, Münz WD (1999) Raman microscopic studies of PVD hard coatings. Surf Coatings Technol 116–119:155–159

Spengler W, Kaiser R, Christensen AN, Müller-Vogt G (1978) Raman scattering, superconductivity, and phonon density of states of stoichiometric and nonstoichiometric TiN. Phys Rev B 17(3):1095

Song P, Zhang X, Sun M, Cui X, Lin Y (2012) Graphene oxide modified TiO2 nanotube arrays: enhanced visible light photoelectrochemical properties. Nanoscale 4(5):1800–1804

Takacs L (1996) Combustive mechanochemical reactions with titanium, zirconium and hafnium. Mater Sci Forum 225–227:553–558

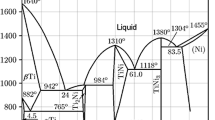

Wriedt H, Murray J (1987) The n–ti (nitrogen–titanium) system. Bull Alloy Phase Diagr 8(4):378–388

Moffatt WG (1976) Binary phase diagrams handbook. General Electric, Schenectady

Murray JL, Liao PK, Spear KE (1986) The B–Ti (Boron–Titanium) system. Bull Alloy Phase Diagr 7(6):550–555

Weichert R, Schönert K (1974) On the temperature rise at the tip of a fast running crack. J Mech Phys Solids 22(2):127–133

Schönert K, Weichert R (1969) The heat effect of the fracture in iron and its dependence on the velocity of propagation. Chem Eng Technol 41:295–300

Weichert R, Schönert K (1978) Heat generation at the tip of a moving crack. J Mech Phys Solids 26(3):151–161

Tonejc A, Tonejc AM, Dužević D (1991) Estimation of peak temperature reached by particles trapped among colliding balls in the ball-milling process using excessive oxidation of antimony. Scripta Metall et Mater 25(5):1111–1113

Tonejc A, Stubicar M, Tonejc AM, Kosanović K, Subotić B, Smit I (1994) Transformation of γ-AIOOH (boehmite) and AI(OH)3 (gibbsite) to α-Al2O3 (corundum) induced by high energy ball milling. J Mater Sci Lett 13(7):519–520

Bab M, Mendoza-Zelis L, Damonte L (2001) Nanocrystalline HfN produced by mechanical milling: kinetic Aspects. Acta Mater 49(20):4205–4213

Shih HD, Jona F, Jepsen DW, Marcus PM (1976) Low-energy-electron-diffraction determination of the atomic Arrangement in a Monatomic Underlayer of Nitrogen on Ti (0001). Phys Rev Lett 36(14):798

Acknowledgements

We thank the Australian Research Council (ARC) Linkage, Infrastructure, Equipment and Facilities (LIEF) Grant Numbers LE120100104, LE0237478 and LE0882613 located at Electron Microscopy Centre (EMC) and Australian National Nanofabrication Facility (ANNF) materials node located at Intelligent Polymer Research Institute (IPRI), University of Wollongong, Australia, for all the equipment uses.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Oghenevweta, J.E., Wexler, D. & Calka, A. Understanding reaction sequences and mechanisms during synthesis of nanocrystalline Ti2N and TiN via magnetically controlled ball milling of Ti in nitrogen. J Mater Sci 53, 3064–3077 (2018). https://doi.org/10.1007/s10853-017-1734-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1734-x